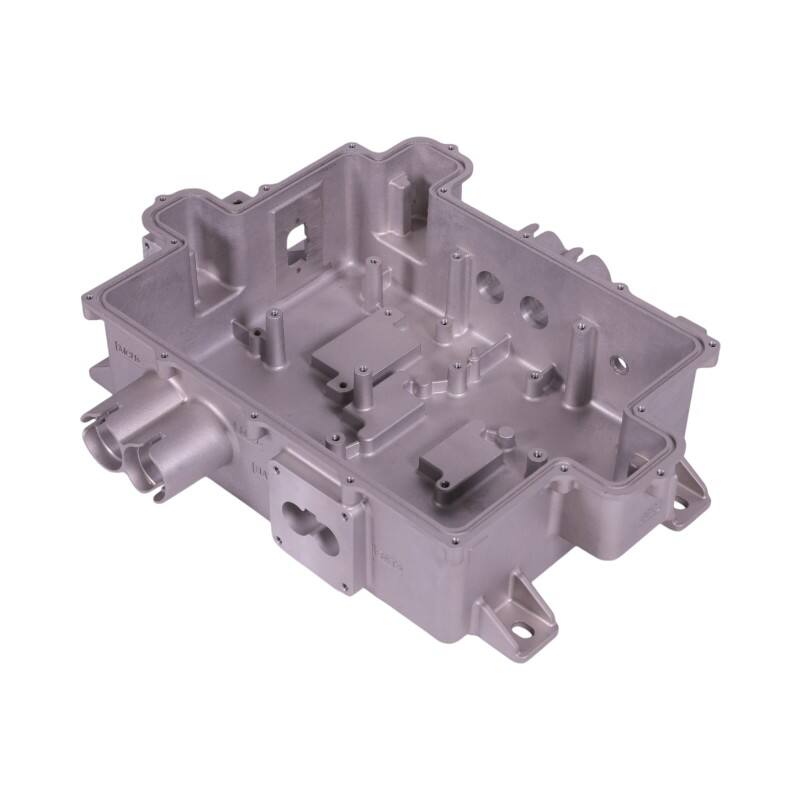

High-voltage Power Distribution Unit Box | Shot Blasting | Passivation | Aluminium Alloy Die Castings | New Energy Vehicles (NEVs) | Electric Vehicles (EVs) | Automotive Industry

- Overview

- Recommended Products

Products Description

| Place of Origin | China |

| Brand Name | Sino Die Casting Manufacturing |

| Product name | Automotive Power Distribution Unit |

| Material | ADC12 Aluminium Alloy |

| Application | Automotive Industry, New Energy Vehicles (NEVs), Electric Vehicles (EVs) |

| Method | Die casting |

| Size | Customers' drawings |

| tolerance | ± 0.05mm |

| Drawing Format | step, stp, x_t, dwg, pdf |

| Surface Treatment | Shot blasting |

| Color | Based on customer requirement |

| Certification | ISO 9001:2015 & IATF 16949:2016 & RoHS & REACH |

| Packing | Carton |

Other Attributes

| Mold Material | SKD61, H13, 8407, 8418 |

| Cavity | Single or multiple |

| Mold Life Time | 50K-80K times |

| Product Material | 1) Aluminium Alloy: ADC10, ADC12, A360, A380, A356, A383, A413 |

| 2) Zinc Alloy: ZAMAK 3, ZAMAK 5, ZAMAK 8 | |

| 3) Magnesium Alloy: AZ91D, MA60B | |

| Surface Treatment | 1) Polishing, lacquer coating, sandblasting, passivation, powder coating, shot blasting, anodising, e-coating |

| 2) Polish combined with zinc plating, chrome plating, pearl chrome plating, nickel plating, or copper plating | |

| Size | 1) According to customers' drawings |

| 2) According to customers' samples | |

| Drawing Format | step, stp, x_t, dwg, pdf |

| Certificates | ISO 9001:2015 & ISO 14001:2015 & IATF 16949:2016 |

Packaging and delivery

| Packaging Details | Packaging Details: |

| 1. With plastic bag,with pearl-cotton package. | |

| 2. To be packed in cartons. | |

| 3. Use glues tape to seal cartons. | |

| 4. Deliver by sea or air. | |

| Or according to customers' requirements. | |

| Each carton is less than 15 kg. | |

| Port | Shenzhen |

| MOQ | 2000 PCS |

| Payment Term | T/T, L/C |

Competitive Advantage

Factory Customization: Our product is designed to meet specific customer requirements, offering a tailored solution for unique applications. We work closely with clients to ensure that the final product meets their exact specifications.

High-Quality Materials: The product is crafted from high-quality aluminum alloy, providing excellent durability and heat dissipation properties, making it ideal for applications such as led lamp components.

ISO 9001:2015 Certification: Our manufacturing process adheres to the strict standards of the ISO 9001:2015 certification, guaranteeing a high level of quality and reliability in our products.

Custom Packaging: We offer customized packaging options, including carton packaging, to ensure safe and secure delivery of the product to our clients worldwide.

Competitive Pricing: We offer competitive pricing, with a minimum order quantity of 1000 pieces, making our product an attractive option for businesses looking to source high-quality aluminum die-casting parts while minimizing costs.

FAQ

Q1. Are you a factory or a trading company?

We have our own factory. Our factory is located at Longwan Road 77, Longtian Community, Longtian Street, Pingshan District, Shenzhen, Guangdong Province, China, postal code 518122.

Welcome to visit our factory.

Q2. What production services do you offer?

Mold design and manufacturing, die casting, CNC machining, assembly, and surface treatment.

Q3. What is the lead time?

Mold: 3–5 weeks

Mass production: 3–4 weeks

Q4. How about your quality assurance?

♦ We are certified to ISO 9001:2015 and IATF 16949.

♦ After sample approval, we will prepare operation instructions for production.

♦ We conduct 100% product inspection before shipment.

Q5. How long does it take to get a quotation?

We will provide a quotation within 2 days after receiving detailed information (your 2D/3D drawings or samples).

Q6. What factors are included in your quotation?

Drawings or samples, materials, surface treatment, and quantity.

Q7. What are your payment terms?

Mold: 50% deposit in advance, balance due after sample approval.

Goods: 50% deposit in advance, balance via T/T before shipment.