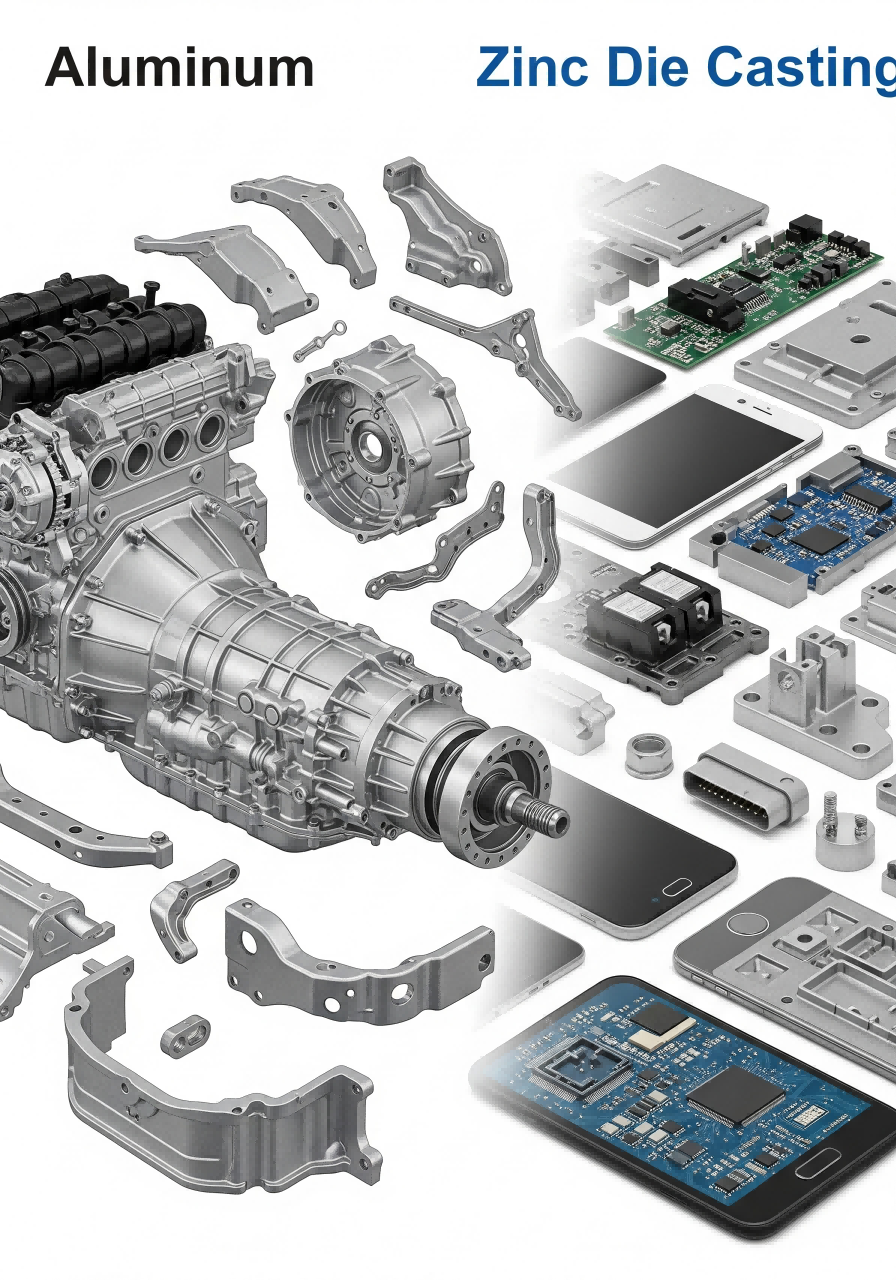

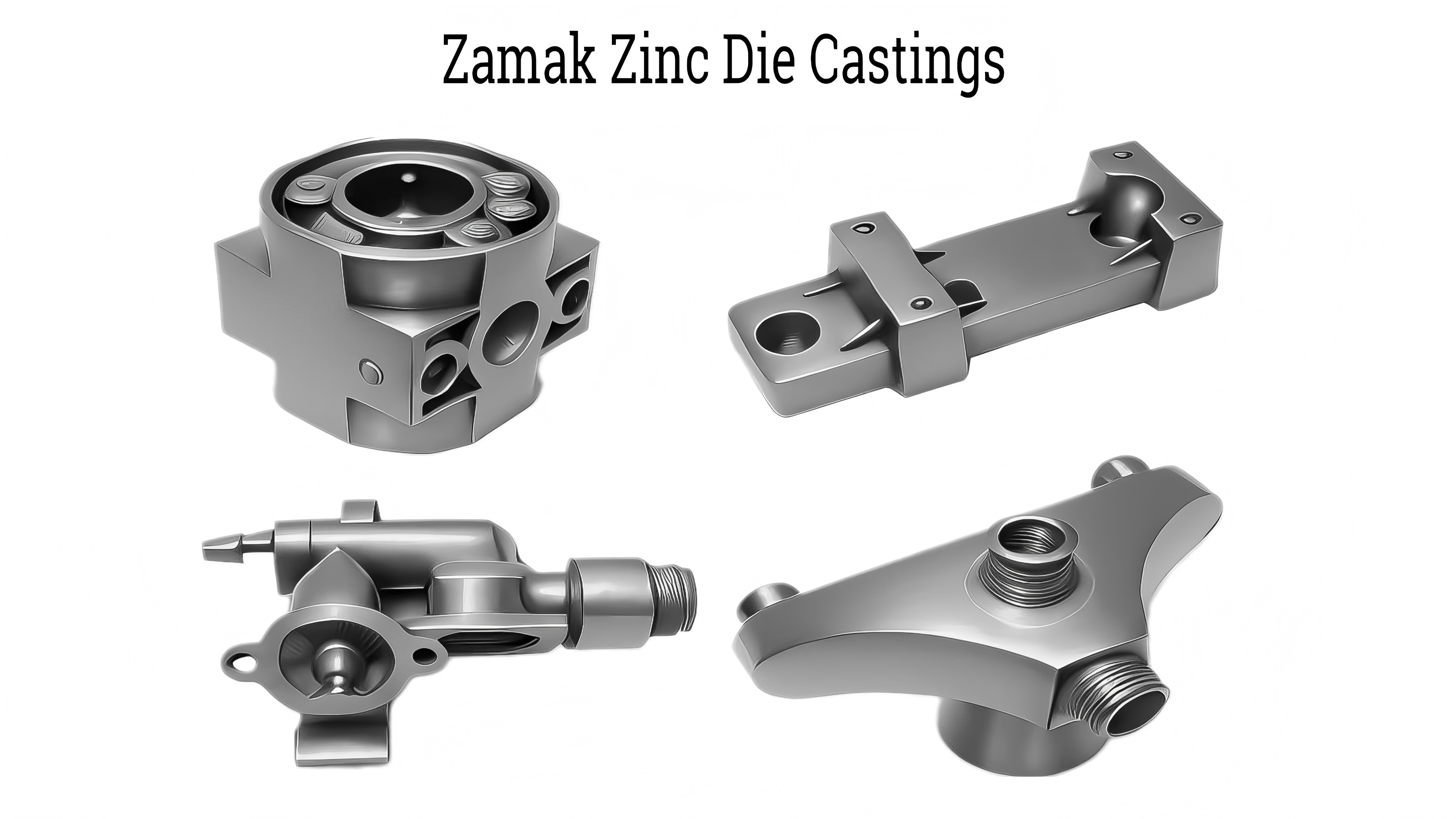

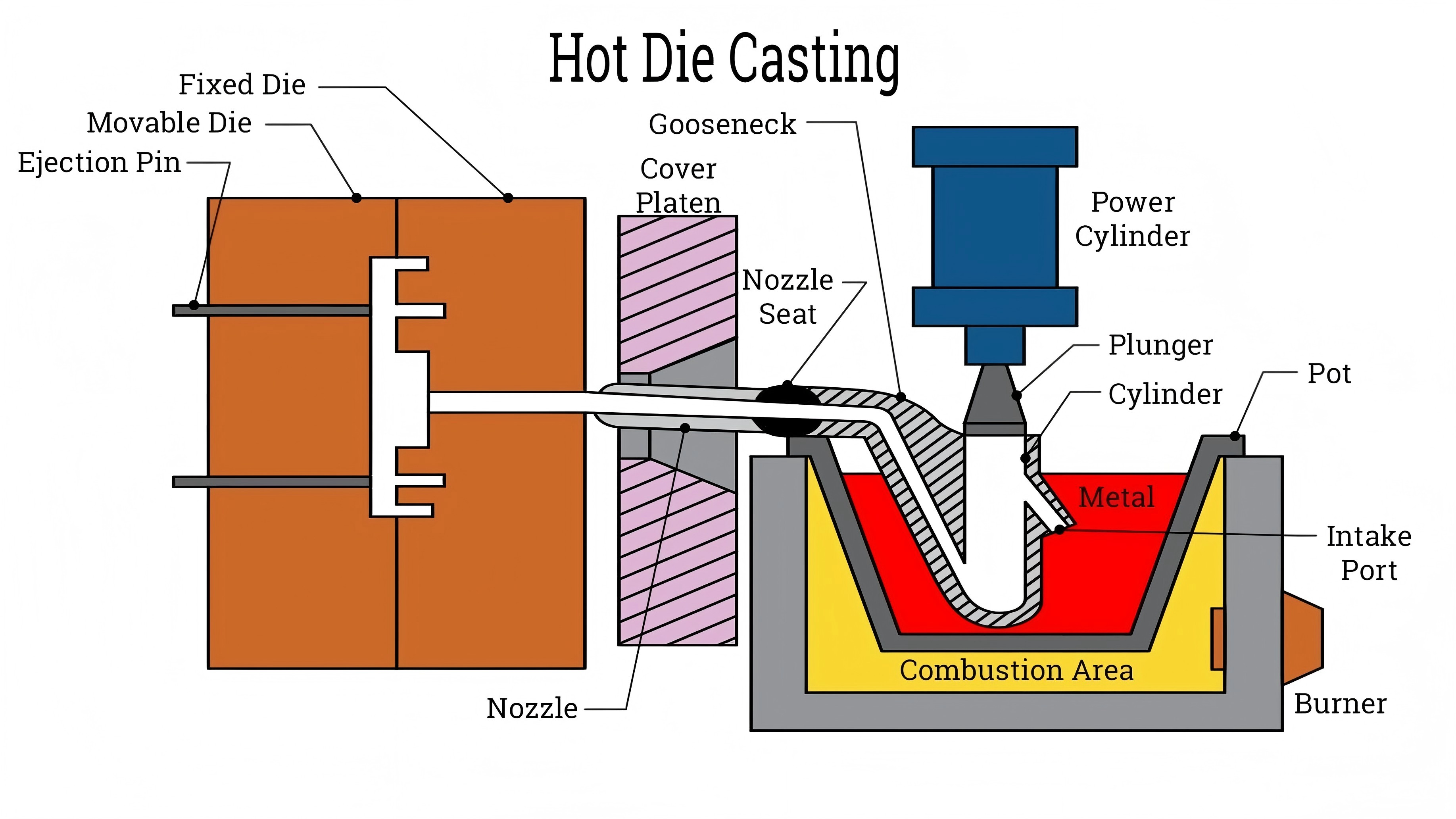

Sino Die Casting jau no 2008. gada ir bijusi cinkota lējuma nozares priekšgalā. Mūsu atrašanās vieta Šenzhenā, Ķīnā, nodrošina piekļuvi kvalificētam darba spēkam un attīstītai ražošanas infrastruktūrai. Cinkota lējuma procesi ir daudzpusīgs ražošanas paņēmiens, ko mēs izmantojam dažādu veidu detaļu izgatavošanai. Jaunās enerģētikas nozarē mēs ražojam cinkota lējuma komponentus fotovoltaisko invertoru, vēja dzinēju daļām un citai enerģētikas iekārtai. Šīm detaļām jābūt ļoti precīzām un uzticamām, un mūsu cinkota lējuma process to nodrošina. Mēs varam izgatavot detaļas ar sarežģītām ģeometrijām un ciešām tolerancēm, kas ir būtiskas jaunās enerģētikas sistēmu efektīvai darbībai. Mūsu cinkota lējuma mašīnas ir no 88 tonnām līdz 1350 tonnām, kas ļauj apstrādāt projektus dažādos apjomos. Vai nu jums nepieciešams neliels prototipa detaļu sērijas ražojums vai lielapjoma masveida ražošana, mums ir iespējas, lai apmierinātu jūsu vajadzības. Mēs piedāvājam arī CNC apstrādes pakalpojumus, lai papildu apstrādātu cinkota lējuma detaļas. Tas ir īpaši noderīgi detaļām, kurām ir nepieciešamas precīzas dimensijas vai konkrēts virsmas apdare. Mūsu inženieru komanda cieši sadarbojas ar jums visā cinkota lējuma procesa gaitā. No sākotnējā dizaina stadijas līdz pabeigtajam produktam, mēs nodrošinām, ka tiek izpildīti jūsu nosacījumi. Mēs varam piedāvāt dizaina optimizācijas ieteikumus, lai uzlabotu jūsu cinkota lējuma detaļu ražošanas iespējas un izmaksu efektivitāti. Ar mūsu pārbaudes pārvaldības sistēmu, katra cinkota lējuma detaļa tiek pakļauta stingrām pārbaudēm. Mēs izmantojam koordinātu mērīšanas ierīces, attēlu mērīšanas ierīces un citu testēšanas aprīkojumu, lai pārbaudītu detaļu izmērus un funkcionalitāti. Izvēloties Sino Die Casting savām cinkota lējuma vajadzībām, jūs iegūstat partneri, kas apvieno tehnoloģisko ekspertīzi ar lielisku klientservisa nodrošināšanu.