പ്രെസിഷൻ ഡൈ കാസ്റ്റിംഗിന്റെ അടിസ്ഥാനങ്ങൾ

ഓട്ടോമോട്ടീവ് ഡൈ കാസ്റ്റിംഗിന്റെ പ്രാഥമിക തത്വങ്ങൾ

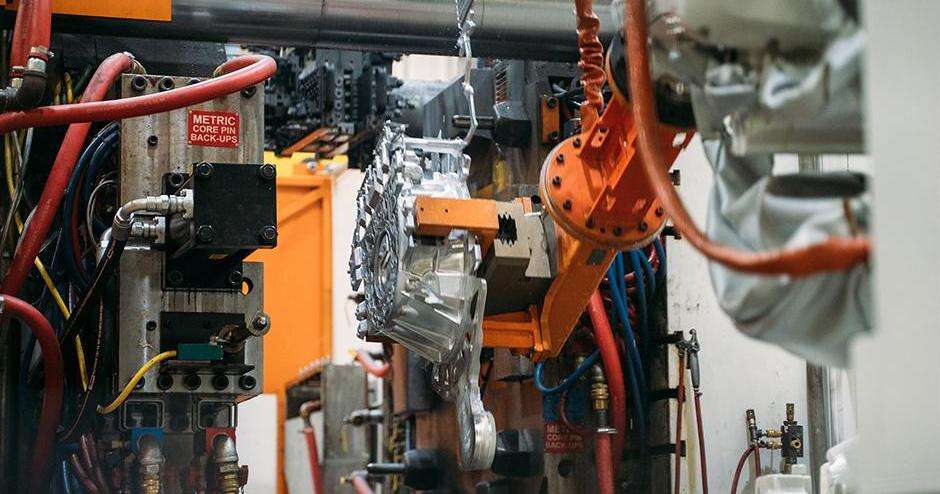

കാർ നിർമ്മാണത്തിൽ കാര്യങ്ങൾ ശരിയായി ചെയ്യുന്നത് വളരെ പ്രാധാന്യമർഹിക്കുന്നു, ഗുണനിലവാരമുള്ള ഭാഗങ്ങൾ നിർമ്മിക്കാൻ സാധിക്കുന്ന പ്രധാനപ്പെട്ട ഒരു പ്രക്രിയയാണ് ഡൈ കാസ്റ്റിംഗ്. സാധാരണ നടക്കുന്നത് ഇതാണ്: ഉയർന്ന മർദ്ദത്തിൽ ഉരുകിയ ലോഹത്തെ സ്റ്റീൽ മോൾഡുകളിലേക്ക് പ്രയോഗിക്കുന്നു, ഇത് നിർമ്മാതാക്കൾക്ക് കൃത്യമായ അളവുകളിൽ വിശദമായ ആകൃതികൾ ഉണ്ടാക്കാൻ അനുവദിക്കുന്നു. എഞ്ചിൻ ബ്ലോക്കുകൾ മുതൽ ട്രാൻസ്മിഷൻ ഹൗസിംഗുകൾ വരെയുള്ള സങ്കീർണ്ണമായ ഭാഗങ്ങൾ ആവശ്യമായതിനാൽ തന്നെ ഈ സാങ്കേതികത കൃത്യമായി നിർമ്മാണം നടത്തുന്നു. ഡൈ കാസ്റ്റിംഗിനെ വ്യത്യസ്തമാക്കുന്നത് പഴയ രീതികളേക്കാൾ ഭാഗങ്ങൾ ഉണ്ടാക്കുന്നതിൽ ഉള്ള വേഗതയാണ്. യൂണിറ്റിന് കൂടുതൽ സമയമെടുക്കുന്ന പാരമ്പര്യ രീതികളേക്കാൾ ആധുനിക ഉൽപ്പാദന ഷെഡ്യൂളിനൊപ്പം നിൽക്കാൻ ഡൈ കാസ്റ്റിംഗിന് സാധിക്കും, ഗുണനിലവാരത്തിന് കോട്ടം വരുത്താതെ തന്നെ. അതിനാലാണ് ആദ്യകാല നിക്ഷേപ ചെലവുകൾ കാരണം പോലും ധാരാളം ഫാക്ടറികൾ ഇത് വർഷങ്കൊറ്റം ഉപയോഗിക്കുന്നത്, കാർ ലോകമെമ്പാടുമുള്ള അസംബ്ലി ലൈനുകളിൽ നിന്ന് പുറത്തുവരുമ്പോൾ അവയ്ക്ക് എല്ലായ്പ്പോഴും കൃത്യമായ അളവുകളിൽ വിശ്വസനീയമായ ഘടകങ്ങൾ ആവശ്യമായി വരുന്നത്.

തണുത്ത കാമറ എതിർ ചൂടുള്ള കാമറ സാങ്കേതികവിദ്യകൾ

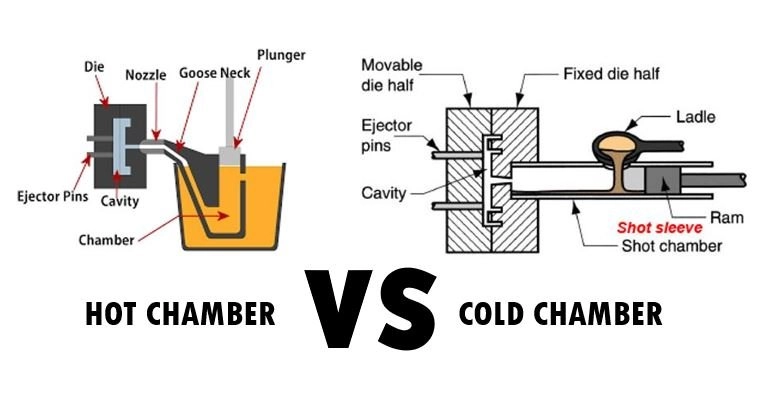

രണ്ട് പ്രധാന ഡൈ കാസ്റ്റിംഗ് രീതികൾ ഉണ്ട്- കോൾഡ് ചേമ്പർ, ഹോട്ട് ചേമ്പർ രീതികൾ. ഇവയ്ക്ക് രണ്ടിനും അതിന്റേതായ ശക്തിയും പരിമിതികളും ഉണ്ട്. കോൾഡ് ചേമ്പർ കാസ്റ്റിംഗിൽ, മെറ്റൽ ആദ്യം പ്രത്യേകം ഉരുക്കുകയും തുടർന്ന് മോൾഡിലേക്ക് ഒഴിക്കുകയും ചെയ്യുന്നു. അലൂമിനിയം അലോയ്കൾ പോലുള്ള ഉയർന്ന താപനിലയിൽ ഉരുകുന്ന വസ്തുക്കൾക്ക് ഇത് ഏറ്റവും അനുയോജ്യമാണ്. ഹോട്ട് ചേമ്പർ കാസ്റ്റിംഗ് ഒരു വ്യത്യസ്തമായ സമീപനമാണ് സ്വീകരിക്കുന്നത്. മോൾഡിന് അടുത്തുള്ള ബന്ധിപ്പിച്ച ചേമ്പറിൽ മെറ്റൽ ഉരുകി നിൽക്കുന്നു, ഇത് കുറഞ്ഞ താപനിലയിൽ ഉരുകുന്ന സിങ്ക് പോലുള്ളവയ്ക്ക് അനുയോജ്യമാണ്. കോൾഡ് ചേമ്ബർ കാസ്റ്റിംഗ് മികച്ച ഘടനാപരമായ ശക്തിയുള്ള ഭാഗങ്ങൾ ഉണ്ടാക്കുന്നു, എങ്കിലും ഹോട്ട് ചേമ്പർ പ്രക്രിയകളേക്കാൾ സൈക്കിൾ ചെയ്യാൻ കൂടുതൽ സമയമെടുക്കും. ഹോട്ട് ചേമ്പർ മെഷീനുകൾ വളരെ വേഗത്തിൽ ഉൽപ്പന്നങ്ങൾ നിർമ്മിക്കുന്നു, എങ്കിലും ബഹുസങ്കീർണ്ണമായ ആകൃതികളോ വലിയ ഭാഗങ്ങളോ കൈകാര്യം ചെയ്യാൻ കഴിയില്ല, ഇടപരിമിതി കൊണ്ട്. ഈ രണ്ട് ഓപ്ഷനുകൾ തമ്മിൽ തിരഞ്ഞെടുക്കുമ്പോൾ, നിർമ്മാതാക്കൾ മെറ്റീരിയലിന്റെ ഗുണങ്ങൾ, ഭാഗത്തിന്റെ വലുപ്പം, ഉൽപ്പാദന വേഗത എന്നിവ പരസ്പരം താരതമ്യം ചെയ്യേണ്ടതുണ്ട്. ഈ ബാലൻസ് ശരിയായി കണ്ടെത്തുന്നത് പ്രത്യേക ആവശ്യങ്ങൾക്കായി ശരിയായ പ്രക്രിയ തിരഞ്ഞെടുക്കുകയും ചെലവും കാര്യക്ഷമതയും കണക്കിലെടുക്കുകയും ചെയ്യുന്നു.

മെറ്റീരിയൽ സയൻസ്: അലുമിനിയം അലോയ്കൾ, സിങ്ക് ഉപയോഗങ്ങൾ

ആൽയൂമിനിയം ലോഹസങ്കരങ്ങളും സിങ്കും രണ്ടും ഓട്ടോമോട്ടീവ് ഭാഗങ്ങൾ നിർമ്മിക്കുമ്പോൾ പ്രധാന പങ്കുവഹിക്കുന്നു. ഭാരം കുറവായിരിക്കുമ്പോഴും ശക്തി നിലനിർത്തുന്നതിനാൽ ആൽയൂമിനിയം വ്യത്യസ്തമാണ്, ഇത് ഘടനാപരമായ സമഗ്രതയ്ക്ക് ബലി കൊടുക്കാതെ തന്നെ ഇന്ധനം ലാഭിക്കാൻ വാഹനങ്ങളെ സഹായിക്കുന്നു. കൂടാതെ, ആൽയൂമിനിയം പെട്ടെന്ന് മാറ്റില്ലാത്തതും വിഘടിക്കാതെ നന്നായി വളയുന്നതുമാണ്, അതിനാൽ തന്നെ എഞ്ചിൻ ബ്ലോക്കുകൾ, ട്രാൻസ്മിഷൻ ഹൗസിംഗുകൾ തുടങ്ങിയ ഭാഗങ്ങൾക്ക് ഇത് ഏറ്റവും അനുയോജ്യമാണ്, അവിടെ വിശ്വാസ്യത ഏറ്റവും പ്രധാനമാണ്. സിങ്കും വ്യത്യസ്തമായ കാര്യങ്ങൾ കൊണ്ടുവരുന്നു. കാസ്റ്റിംഗ് നടക്കുമ്പോൾ ഇത് വളരെ നന്നായി ഒഴുകുന്നു, കൂടാതെ മാറ്റില്ലാത്തതിനാൽ ഇലക്ട്രിക്കൽ കണക്ടറുകൾ, മൗണ്ടിംഗ് ബ്രാക്കറ്റുകൾ തുടങ്ങിയ വിശദമായ ഭാഗങ്ങൾ നിർമ്മിക്കാൻ അനുയോജ്യമാണ്, അവിടെ കൃത്യത പ്രധാനമാണ്. ഈ രണ്ട് ലോഹങ്ങളുടെയും വൈവിധ്യം കാരണം ഓട്ടോ നിർമ്മാതാക്കൾക്ക് കഠിനമായ റോഡ് സാഹചര്യങ്ങളിൽ പോലും നിലനിൽക്കുന്ന നിരവധി ഭാഗങ്ങൾ നിർമ്മിക്കാൻ കഴിയും. ഗുണനിലവാരമുള്ള ഉൽപ്പന്നങ്ങൾ നൽകുമ്പോൾ ചെലവ് കുറക്കാൻ ആഗ്രഹിക്കുന്ന നിർമ്മാതാക്കൾക്ക് ഈ മെറ്റീരിയലുകൾ എങ്ങനെ പെരുമാറുന്നു എന്ന് മനസ്സിലാക്കുന്നത് വ്യവസായത്തിൽ കഠിനതയും കാര്യക്ഷമതയും തമ്മിലുള്ള മികച്ച ബിന്ദുവിൽ എത്തിച്ചേരാൻ സഹായിക്കും.

ഓട്ടോമോട്ടീവ് ലൈറ്റ് വെയ്റ്റിംഗ് ഗുണങ്ങള്

ഭാരം കുറയ്ക്കുന്നതിലൂടെ ഇന്ധനക്ഷമത

കുറഞ്ഞ ഭാരമുള്ള വാഹനങ്ങൾ കുറഞ്ഞ പെട്രോൾ ഉപയോഗിക്കുന്നു, അതിനാൽ ഇന്ന് ഡ്രൈവർമാർക്കും കാർ കമ്പനികൾക്കും താൽപ്പര്യമുള്ള മികച്ച ഇന്ധന ക്ഷമത നേടാൻ ഭാരം കുറയ്ക്കുന്നത് ഗുണകരമാണ്. NHTSA-യുടെ ഗവേഷണം കാണിക്കുന്നത് ഒരു കാറിന്റെ ആകെ ഭാരത്തിന്റെ 10 ശതമാനം കുറച്ചാൽ പെട്രോളിന്റെ മൈലേജ് 6 മുതൽ 8 ശതമാനം വരെ വർദ്ധിപ്പിക്കാമെന്നാണ്. ഇത്തരം ഭാഗങ്ങൾ കുറഞ്ഞ ഭാരത്തിൽ എന്നാൽ ശക്തിയോടെ നിർമ്മിക്കാൻ ഡൈ കാസ്റ്റിംഗ് വളരെ പ്രധാനമാണ്. നിയന്ത്രകർ നിശ്ചയിച്ചിട്ടുള്ള കർശനമായ ഉദ്വമന പരിധികൾക്കുള്ളിൽ തന്നെ നിൽക്കാൻ വാഹന നിർമ്മാതാക്കൾ ഈ സാങ്കേതികതയെ വളരെയധികം ആശ്രയിക്കുന്നു. Ford-ന്റെ F-150 പിക്കപ്പ് ട്രക്കിനെ ഉദാഹരണമായി എടുക്കുക, അവർ ഡൈ കാസ്റ്റിംഗ് പ്രക്രിയയിലൂടെ നിർമ്മിച്ച അലുമിനിയം ബോഡി പാനലുകളിലേക്ക് മാറി. ഈ മാറ്റം ട്രക്കിന്റെ ആകെ ഭാരത്തിൽ നിന്ന് ഏകദേശം 700 പൗണ്ട് കുറച്ചു, അതിനാൽ ഡ്രൈവർമാർക്ക് പമ്പിൽ മികച്ച മൈലേജ് ലഭിക്കുന്നു. ഇന്ധന ചെലവ് ലാഭിക്കുന്നതിനപ്പുറം, ഈ കുറഞ്ഞ ഭാരമുള്ള വസ്തുക്കൾ ലോകമെമ്പാടുമുള്ള വാഹന വ്യവസായത്തിന്റെ കാർബൺ ഫുട്ട്പ്രിന്റ് കുറയ്ക്കാൻ സഹായിക്കുന്നു.

പാതള ഘടകങ്ങളിലെ ഘടനാപരമായ ഖരത

സ്ഥിരതയുള്ള ഘടകങ്ങൾ നിർമ്മിക്കുന്നതിൽ ഡൈ കാസ്റ്റിംഗ് പ്രധാന പങ്കുവഹിക്കുന്നു, ഇത് കാർ സുരക്ഷാ മാനദണ്ഡങ്ങൾക്ക് വളരെ പ്രാധാന്യമുള്ളതാണ്. ഭാഗങ്ങൾ വളരെ ചെറുതായിത്തീരുമ്പോഴും പ്രക്രിയ കൃത്യതയും കാഠിന്യവും ഉറപ്പാക്കുന്നു, കാമറകൾ പായ്ക്ക് ചെയ്യുന്നതിനോ എഞ്ചിനെ പിന്തുണയ്ക്കുന്നതിനോ പോലുള്ള സുരക്ഷാ ഭാഗങ്ങൾക്ക് ഇത് ആവശ്യമാണ്. എന്നാൽ ചെറിയ ഭിത്തികൾ ഉപയോഗിച്ച് പ്രവർത്തിക്കുന്നതിൽ പ്രശ്നങ്ങളും ഉണ്ട്. മോൾഡുകളിലൂടെ ലോഹം ചലിക്കുന്നത് നിയന്ത്രിക്കുകയും ഭാഗങ്ങൾ വക്രമാകാതെ ശരിയായ ശീതകരണം ഉറപ്പാക്കുകയും പോലുള്ള കാര്യങ്ങളിൽ എഞ്ചിനീയർമാർ ബുദ്ധിമുട്ടുന്നു. ടെസ്ല പോലുള്ള കമ്പനികൾ കൃത്യമായ കമ്പ്യൂട്ടർ മാതൃകകൾ ഉപയോഗിച്ച് ഈ പ്രശ്നം പരിഹരിച്ചിട്ടുണ്ട്. ലോഹം ഒഴിക്കുന്നതിന് മുമ്പ് തന്നെ ഇവ സിമുലേഷൻ ഉപയോഗിച്ച് എന്തെങ്കിലും തെറ്റായിപ്പോകുമോ എന്ന് കണ്ടെത്താൻ സഹായിക്കുന്നു, ഇത് അവരുടെ ചെറിയ ഭിത്തി കാസ്റ്റിംഗുകൾ എല്ലാ സുരക്ഷാ പരിശോധനകളും നേടാനും ഉത്പാദന റൺസിനായി മതിയായ കാലം നിലനിൽക്കാനും സഹായിക്കുന്നു.

ഇലക്ട്രിക് വാഹന ഘടക പരമാവധി പ്രയോജനം

ഇലക്ട്രിക് വാഹനങ്ങൾ നിർമ്മാതാക്കൾ അവരുടെ ഘടക വസ്തുക്കളിൽ നിന്ന് ആവശ്യപ്പെടുന്നതിനെ മാറ്റുന്നു, കൂടാതെ ഡൈ കാസ്റ്റിംഗ് ഈ പുതിയ വെല്ലുവിളികൾക്ക് നേരിടാൻ തയ്യാറാകുന്നു. ബാറ്ററി പെട്ടികൾ, മോട്ടോർ കേസിംഗുകൾ പോലുള്ള ഭാഗങ്ങൾക്ക് ഡൈ കാസ്റ്റിംഗ് സാങ്കേതികവിദ്യ വളരെ നന്നായി പ്രവർത്തിക്കുന്നു, കാരണം അവ ലഘുവും കരുത്തുറ്റതുമായ ഭാഗങ്ങൾ നിർമ്മിക്കാൻ കഴിയും. ഉദാഹരണത്തിന് അലൂമിനിയം ഡൈ കാസ്റ്റിംഗ് എടുക്കുക, അത് വാഹനത്തിന്റെ ഭാരം കുറയ്ക്കുന്നു, ഒരു ചാർജ്ജിൽ ഒരു EV എത്ര ദൂരം സഞ്ചരിക്കുമെന്നതിൽ വലിയ വ്യത്യാസം ഉണ്ടാക്കുന്നു. ഈ നേട്ടം ഉപയോഗിച്ച് കമ്പനികൾ ഇതിനകം തുടങ്ങിയിട്ടുണ്ട്. ഡൈ കാസ്റ്റിംഗ് പ്രക്രിയകൾ വഴി ലഘുവായ വസ്തുക്കൾ അവരുടെ ഡിസൈനുകളിൽ ഉൾപ്പെടുത്തിയ Lucid Motors നോക്കുക. ഇത് അവർക്ക് സുരക്ഷാ മാനദണ്ഡങ്ങൾ ഉപേക്ഷിക്കാതെ മികച്ച പ്രകടനമുള്ള കാറുകൾ നിർമ്മിക്കാൻ സഹായിച്ചു, ഇന്നത്തെ മത്സരാധിഷ്ഠിത EV വിപണിയിൽ ആവശ്യമാണ്.

നിലവാരവും സർട്ടിഫിക്കേഷൻ മാനദണ്ഡങ്ങളും

IATF 16949 സർട്ടിഫിക്കേഷൻ ആവശ്യകതകൾ

ഐഎടിഎഫ് 16949 വാഹന നിർമ്മാണ മേഖലയിൽ പ്രത്യേകിച്ച് മെറ്റൽ കാസ്റ്റിംഗ് പ്രവർത്തനങ്ങൾക്ക് ഗുണനിലവാര നിയന്ത്രണത്തിന്റെ ഒരു സുവർണ്ണ മാനമായി മാറിയിട്ടുണ്ട്. ഈ സർട്ടിഫിക്കേഷൻ അത്രമേൽ മൂല്യമുള്ളതാക്കുന്നത് നിർമ്മാതാക്കൾ കർശനമായ മാർഗ്ഗനിർദ്ദേശങ്ങൾ പാലിക്കാൻ നിർബന്ധിതരാകുന്നതിലൂടെ കൃത്യമായി നല്ല ഭാഗങ്ങൾ ലഭിക്കുന്നതിനാണ്. പ്രക്രിയ തന്നെ നിരവധി പ്രധാനപ്പെട്ട മേഖലകളെ ഉൾക്കൊള്ളുന്നു. ആദ്യം മാനേജ്മെന്റ് ഉത്തരവാദിത്തം എന്നതാണ്, അവിടെ ഉന്നത ഉദ്യോഗസ്ഥർ ഗുണനിലവാരത്തെക്കുറിച്ച് സംസാരിക്കുന്നതിന് പകരം അതിനോട് യഥാർത്ഥ ബന്ധമുണ്ടെന്ന് തെളിയിക്കേണ്ടതുണ്ട്. തുടർന്ന് ഉപകരണങ്ങളും ജീവനക്കാരും ഉൾപ്പെടെയുള്ള എല്ലാ വിഭവങ്ങളും ശരിയായി ഉപയോഗിക്കപ്പെടുന്നുവെന്ന് ഉറപ്പാക്കുന്ന റിസോഴ്സ് മാനേജ്മെന്റിലേക്ക് ഞങ്ങൾ കടക്കുന്നു. അവസാനമായി, ഉപഭോക്തൃ സവിശേഷതകളെ അവ്യക്തമായി നിർവ്വചിച്ചതിനെ ഉദ്ദേശിച്ച് പ്രൊഡക്റ്റ് റിയലൈസേഷൻ അവയെ യഥാർത്ഥ ഉൽപ്പന്നങ്ങളായി മാറ്റുന്നു, അവ ഉദ്ദേശിച്ചതുപോലെ പ്രവർത്തിക്കുന്നു. മത്സരാധിഷ്ഠിതമായ വിപണിയിൽ മുന്നിൽ നിൽക്കാൻ ആഗ്രഹിക്കുന്ന വിതരണക്കാർക്ക് സർട്ടിഫൈ ചെയ്യുന്നത് ഇനി കുറഞ്ഞ നിലവാരം മാത്രം പാലിക്കുന്നതിനല്ല. ഗുണനിലവാരത്തോട് കമ്പനികൾ ഗൗരവമുള്ളവയാണെന്ന് തെളിയിക്കാനും ഇതേ നിക്ഷേപം നടത്താത്ത മത്സരക്കാരെ അപേക്ഷിച്ച് മുൻതൂക്കം നേടാനും ഇത് ഏതാണ്ട് ആവശ്യമാണ്.

കൃത്യതയുള്ള നിയന്ത്രണങ്ങളിലൂടെ പ്രക്രിയാ കൃത്യത

പ്രൊസസ്സുകളുടെ കൃത്യമായ നിയന്ത്രണം ഡൈ കാസ്റ്റിംഗിന്റെ കാര്യത്തിൽ പ്രത്യേകിച്ചും നിലനിർത്തുന്നത് സ്ഥിരതയും വിശ്വാസ്യതയും ഉറപ്പാക്കാൻ വളരെ പ്രധാനമാണ്, കാരണം എല്ലാവരും ആഗ്രഹിക്കുന്ന ഉയർന്ന നിലവാരമുള്ള ആട്ടോമോട്ടീവ് ഘടകങ്ങൾ നിർമ്മിക്കുന്നതിന്റെ കാര്യമാണ് പറയുന്നത്. ഇന്നത്തെ നിർമ്മാതാക്കൾ ഉൽപ്പാദന പ്രക്രിയകൾക്കിടെ താപനിലയും മർദ്ദവും പോലുള്ള കാര്യങ്ങളിൽ നിരീക്ഷണം നടത്താൻ പലതരം അളവുകൾ ഉപയോഗിക്കുന്നു, കൂടാതെ ചില സാങ്കേതിക വിദ്യകളും ഉപയോഗിക്കുന്നു. ഉദാഹരണത്തിന് ഡിജിറ്റൽ സെൻസറുകൾ ഇപ്പോൾ എല്ലായിടത്തും ഉണ്ട്, തുടർച്ചയായി വിവരങ്ങൾ പിന്തിരിപ്പിക്കുന്നു, കൂടാതെ യഥാർത്ഥ സമയ വിശകലനം പ്രശ്നങ്ങൾ വലിയ പ്രശ്നങ്ങളായി മാറുന്നതിന് മുമ്പായി അവ കണ്ടെത്താൻ സഹായിക്കുന്നു. കൂടാതെ കണക്കുകൾ തെറ്റായിരിക്കില്ല, കൂടുതൽ നിയന്ത്രണ സംവിധാനങ്ങൾ നടപ്പിലാക്കിയ ശേഷം പല കമ്പനികളും തകരാറുകളിൽ വൻ കുറവ് റിപ്പോർട്ട് ചെയ്യുന്നു. കൂടാതെ പറയാതെ വയ്ക്കാൻ പറ്റില്ല, കുറഞ്ഞ തകരാറുള്ള ഭാഗങ്ങൾ എന്നത് ആകെയുള്ള ഉപഭോക്താക്കൾക്ക് സന്തോഷം തന്നെയാണ്. അതുകൊണ്ട് പറയുകയാണെങ്കിൽ, നിർമ്മാതാക്കൾക്ക് ഇന്നത്തെ വിപണിയിൽ മത്സരക്ഷമരായി നിൽക്കാൻ ഗുണനിലവാരം എന്നത് ഏറ്റവും പ്രധാനമായതിനാൽ അത്തരം നിയന്ത്രണങ്ങൾ ശരിയായി നടപ്പിലാക്കുന്നത് ഒരു ആവശ്യകതയായി മാറിയിരിക്കുന്നു.

തകരാറുകൾ തടയുകയും നിലവാരം സ്ഥിരീകരിക്കുകയും ചെയ്യുക

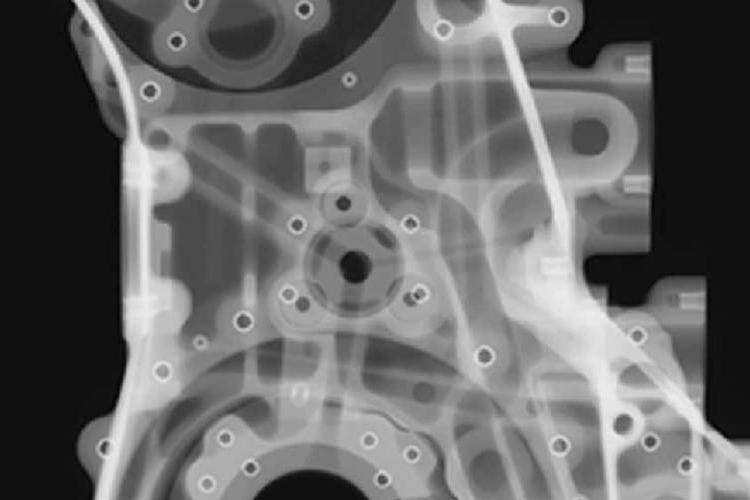

ഡൈ കാസ്റ്റിംഗിൽ, പൊറോസിറ്റി, മിസ് അലൈൻഡ് ചെയ്ത ഭാഗങ്ങൾ അല്ലെങ്കിൽ കട്ടിയുള്ള ഉപരിതലങ്ങൾ തുടങ്ങിയ പ്രശ്നങ്ങൾ പലപ്പോഴും നിർമ്മാണത്തിനിടെ പ്രത്യക്ഷപ്പെടുന്നു. അനുഭാവപൂർവ്വം, ഈ പ്രശ്നങ്ങൾ സംഭവിക്കാതെ തടയാനുള്ള മാർഗ്ഗങ്ങൾ ഉണ്ട്. ഇപ്പോൾ പല ഫാക്ടറികളും ഉൽപ്പന്നത്തിന് കേടുപാടുകൾ ഉണ്ടാക്കാതെ തന്നെ നടത്താവുന്ന ഗുണനിലവാര പരിശോധനകളെ ആശ്രയിക്കുന്നു, അതിനെ നോൺ-ഡിസ്ട്രക്ടീവ് ടെസ്റ്റിംഗ് അല്ലെങ്കിൽ ചുരുക്കത്തിൽ NDT എന്ന് വിളിക്കുന്നു. ഈ പരിശോധനകൾ നിർമ്മാതാക്കൾക്ക് പാരമ്പര്യ രീതികളിൽ നിന്നും വളരെ മുമ്പേ സാധ്യതയുള്ള കുറ്റങ്ങൾ കണ്ടെത്താൻ അനുവദിക്കുന്നു. യഥാർത്ഥ ലോക ഉദാഹരണങ്ങൾ പരിശോധിച്ചാൽ ഇത് കൂടുതൽ വ്യക്തമാകും. ഒരു പ്ലാന്റ് X-റേകൾ ഉം ശബ്ദതരംഗ പരിശോധനയും ക്രമപ്രകാരം ഉപയോഗിച്ചതോടെ വലിയ മെച്ചപ്പാട് കാണിച്ചു. ഉൽപ്പന്നങ്ങൾ ഉപഭോക്താക്കളിലേക്ക് എത്തുന്നതിന് മുമ്പേ തന്നെ ഗുണനിലവാര മാനദണ്ഡങ്ങൾ ഉറപ്പാക്കുന്നതിൽ വ്യവസായം തന്നെ തലം ഉയർത്തിയിട്ടുണ്ട്. ആർക്കും തെറ്റുകൾ ഉള്ള ഭാഗങ്ങൾ അന്തിമ ഉൽപ്പന്നങ്ങളിൽ എത്തിച്ചേരാൻ ആഗ്രഹിക്കില്ല എന്നതിനാൽ കമ്പനികൾ ഈ പരിശോധനകളിൽ സമയവും പണവും നിക്ഷേപിക്കുന്നു.

സ്ട്രാറ്റജിക് നടപ്പാക്കൽ അവബോധങ്ങൾ

അലൂമിനിയം ഡൈ കാസ്റ്റിംഗ് വിതരണക്കാരെ തിരഞ്ഞെടുക്കൽ

നിലവാരമുള്ള ഭാഗങ്ങൾ കാര്യക്ഷമമായി നേടുന്നതിന് നല്ല അലുമിനിയം ഡൈ കാസ്റ്റിംഗ് വിതരണക്കാരെ കണ്ടെത്തുന്നതിന് വലിയ പ്രാധാന്യമുണ്ട്. ഗുണനിലവാര നിയന്ത്രണത്തെക്കുറിച്ച് യഥാർത്ഥത്തിൽ ബന്ധപ്പെട്ടിരിക്കുന്ന കമ്പനികളെയും ഇന്നത്തെ നിർമ്മാണ മാനദണ്ഡങ്ങൾക്ക് ആവശ്യമായ സാങ്കേതിക അപ്ഗ്രേഡുകൾ ഉള്ളവയെയും തിരഞ്ഞെടുക്കുക. സർട്ടിഫിക്കേഷനുകളും പ്രാധാന്യമർഹിക്കുന്നു. പ്രത്യേകിച്ച് IATF 16949 സർട്ടിഫിക്കേഷൻ അവർ ഗുണനിലവാരത്തെ ഗൗരവമായി എടുക്കുന്നു എന്നും കർശനമായ പ്രക്രിയകൾ പിന്തുടരുന്നു എന്നും കാണിക്കുന്നു. സാധ്യതയുള്ള പങ്കാളികളെക്കുറിച്ച് പരിശോധിക്കുമ്പോൾ, അവരുടെ ദൈനംദിന ഗുണനിലവാര പരിശോധനകൾ എങ്ങനെയാണ് കൈകാര്യം ചെയ്യുന്നത് എന്നത് പര്യാലോചിക്കുകയും അവർക്ക് മുമ്പ് ഇതുപോലുള്ള പ്രവർത്തനങ്ങളിൽ പരിചയമുണ്ടോ എന്നും ആവശ്യം മാറുമ്പോൾ ഉൽപാദനം വിപുലീകരിക്കാൻ അവർ എങ്ങനെ കൈകാര്യം ചെയ്യുന്നു എന്നതും മറക്കരുത്. ഈ വിശദാംശങ്ങൾ ആദ്യം തന്നെ ലഭ്യമാക്കുന്നത് പിന്നീടുള്ള പ്രശ്നങ്ങൾ ഒഴിവാക്കുകയും നിങ്ങളുടെ ബിസിനസ്സിനൊപ്പം സമയാനുസൃതമായി വളരാൻ കഴിയുന്ന ഒരു വിതരണക്കാരനെ കണ്ടെത്താൻ സഹായിക്കുകയും ചെയ്യും.

ടൂളിംഗ് ആൻഡ് പ്രൊഡക്ഷൻ സ്കെയിലബിലിറ്റി

നിലവിലെ ആവശ്യങ്ങളും ഭാവിയിൽ ഉണ്ടാകാവുന്നതുമായ ആവശ്യങ്ങൾ പരിഗണിക്കുമ്പോൾ ഡൈ കാസ്റ്റിംഗ് ടൂളിംഗ് സ്കെയിൽ ചെയ്യാനുള്ള കഴിവ് വളരെ പ്രധാനമാണ്. നിർമ്മാതാക്കൾക്ക് എളുപ്പത്തിൽ ക്രമീകരിക്കാൻ കഴിയുന്ന ടൂൾ ഡിസൈനുകൾ ഉൽപ്പാദന നിലവാരം ഉയർത്തുമ്പോൾ സഹായകമാകുന്നു. ഉദാഹരണത്തിന് ഹൈ പ്രഷർ ഡൈ കാസ്റ്റിംഗ് പറ്റുന്നത് ഫാക്ടറികൾ വളരുന്ന ആവശ്യകതകൾക്കനുസരിച്ച് പ്രവർത്തനങ്ങൾ വേഗത്തിൽ ക്രമീകരിക്കാൻ അനുവദിക്കുന്നു, കൂടാതെ ഉൽപ്പന്നത്തിന്റെ നിലവാരം നിലനിർത്തുന്നു. ഇത്തരത്തിൽ ഓട്ടോമോട്ടീവ് നിർമ്മാണം മനസ്സിലാക്കാം, കാരണം കാർ കമ്പനികൾ പലപ്പോഴും ചില സീസണുകളിലോ പുതിയ മോഡലുകൾ പ്രഖ്യാപിക്കുമ്പോഴോ ഓർഡറുകളുടെ എണ്ണത്തിൽ പെട്ടെന്നുള്ള വർദ്ധനവ് കാണാറുണ്ട്. കൂടാതെ പറയട്ടെ, സ്വയംപ്രവർത്തകമായ സവിശേഷതകൾ ഉള്ള ആധുനിക യന്ത്രങ്ങൾ വിവിധ ഉൽപ്പാദന പ്രവർത്തനങ്ങൾ തമ്മിൽ വേഗത്തിൽ മാറാൻ സഹായിക്കുന്നു. ഇത്തരം മെച്ചപ്പെടുത്തലുകൾ കൊണ്ട് നിർമ്മാതാക്കൾ അവരുടെ ഉപകരണങ്ങൾ ആദ്യം നിർമ്മിച്ച അളവിലുള്ളതിനേക്കാൾ കൂടുതൽ വോളിയം കൈകാര്യം ചെയ്യുന്നതിൽ പുരയിടാതെ നോക്കുന്നു.

ആയുസ്സിന്റെ ചെലവ് കാര്യക്ഷമത വിശകലനം

ഡൈ കാസ്റ്റിംഗ് പ്രോജക്ടുകൾ ആസൂത്രണം ചെയ്യുമ്പോൾ ലൈഫ് സൈക്കിൾ ചെലവുകൾ പരിഗണിക്കുന്നത് കമ്പനികൾക്ക് ഭാവിയിൽ എന്തൊക്കെ ചെലവുകൾ വരാം എന്നതിനെക്കുറിച്ച് വ്യക്തമായ ധാരണ നൽകുന്നു. ഇത്തരം വിശകലനം പണച്ചെലവുമായി ബന്ധപ്പെട്ട് എല്ലാ ഘടകങ്ങളെയും ഉൾക്കൊള്ളുന്നു, ആദ്യ സജ്ജീകരണം മുതൽ യഥാർത്ഥ ഉത്പാദന പ്രവർത്തനങ്ങൾ, നാളുകൾ കഴിയുമ്പോഴുള്ള പരിപാലനം, അവസാനം റീസൈക്കിൾ ചെയ്യുന്നതു വരെയുള്ള പ്രക്രിയകൾ എന്നിവ ഉൾപ്പെടുന്നു. പദ്ധതി ആസൂത്രണത്തിൽ ലൈഫ് സൈക്കിൾ ചെലവ് വിശകലനം ഉൾപ്പെടുത്തുന്നത് നിർമ്മാതാക്കൾക്ക് വലിയ മാറ്റങ്ങൾ വരുത്താൻ സഹായിക്കുന്നു. ഉദാഹരണത്തിന് സസ്റ്റെയിനബിൾ മാനുഫാക്ചറിംഗ്, അതിൽ കമ്പനികൾ പിന്നീട് പുനരുപയോഗിക്കാവുന്ന മെറ്റീരിയലുകൾ ഉപയോഗിക്കാൻ തുടങ്ങുന്നു. ഇത്തരം സമീപനങ്ങൾ പണം ലാഭിക്കുന്നതോടൊപ്പം പരിസ്ഥിതിക്കും നല്ലതാണ്. ഇത്തരം രീതികൾ സ്വീകരിച്ചതിന് ശേഷം നിരവധി ബിസിനസ്സുകൾ അവരുടെ പ്രവർത്തനങ്ങൾ മാറ്റിയതായി കണ്ടെത്തിയിട്ടുണ്ട്. അവർ പദ്ധതിയുടെ മുഴുവൻ ജീവിതകാലത്തുടനീളം പണം ചെലവഴിക്കുന്നതിനെക്കുറിച്ചും പ്രവർത്തനങ്ങൾ കാര്യക്ഷമമായി നടത്തുന്നതിനെക്കുറിച്ചും അവർ കൂടുതൽ ബുദ്ധിപരമായ തീരുമാനങ്ങൾ എടുക്കുന്നു.