Precision Die Casting Fundamentals

Core Principles of Automotive Die Casting

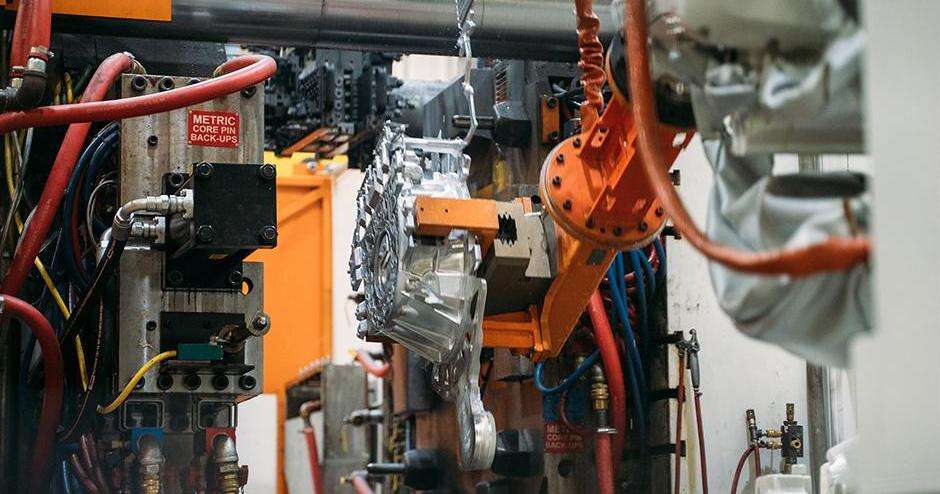

Getting things right matters a lot in car manufacturing, and die casting stands out as one of those key processes that makes quality parts possible. Basically, what happens is molten metal gets forced into steel molds at high pressure, which lets manufacturers create detailed shapes with exact measurements. The automotive world needs all sorts of complicated parts from engine blocks to transmission housings, and this technique delivers them consistently. What really sets die casting apart though is how fast it can churn out parts compared to older methods. While traditional approaches might take longer per unit, die casting keeps pace with modern production schedules without sacrificing quality. That's why so many factories stick with it year after year despite the initial investment costs, because when cars roll off assembly lines across the globe, they need reliable components made to tight tolerances every single time.

Cold Chamber vs. Hot Chamber Techniques

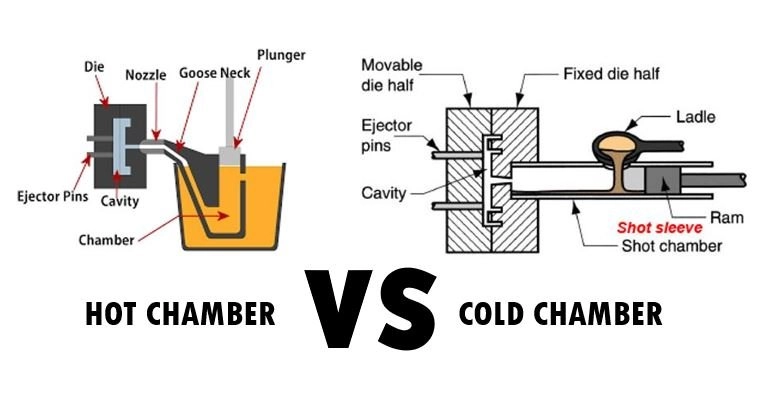

There are basically two main approaches to die casting out there cold chamber and hot chamber methods, each with its own strengths and limitations. With cold chamber casting, the metal gets melted separately first, then poured into the mold. This works best when dealing with materials that need really high temperatures to melt, like aluminum alloys. Hot chamber casting takes a different approach entirely. The metal stays molten in a connected chamber right next to the mold, which makes sense for stuff like zinc that melts at lower temps. Cold chamber casting does produce parts with better structural strength overall, though it takes longer between cycles than hot chamber processes. Hot chamber machines crank out products much faster, but they can't handle complex shapes or larger pieces because of space constraints. When picking between these options, manufacturers have to weigh factors like material properties, part size, and production speed against each other. Getting this balance right means selecting the right process for specific applications while keeping costs and efficiency in mind.

Material Science: Aluminum Alloys and Zinc Applications

In die casting processes, aluminum alloys and zinc both have important roles to play when it comes to making automotive parts. Aluminum stands out because it's light yet strong, which helps cars save fuel without sacrificing structural integrity. Plus, aluminum doesn't rust easily and bends well without breaking, so it works great for things like engine blocks and transmission housings where reliability matters most. Zinc brings something different to the table too. It flows really well during casting and resists corrosion, making it ideal for creating detailed parts like electrical connectors and mounting brackets with tight tolerances. The versatility of these two metals means auto makers can build all sorts of durable components that perform well even under tough road conditions. For manufacturers looking to cut costs while still delivering quality products, understanding how these materials behave makes all the difference in hitting those sweet spots between toughness and efficiency requirements across the industry.

Automotive Lightweighting Advantages

Fuel Efficiency Through Weight Reduction

Lighter vehicles burn less gas, so cutting down on weight makes sense if we want better fuel economy, something both drivers and car companies care deeply about these days. Research from NHTSA shows that trimming 10 percent off a car's total weight can actually boost gas mileage by around 6 to 8 percent. That's where die casting comes into play for making parts that weigh less without sacrificing strength. Automakers rely heavily on this technique to stay within strict emission limits set by regulators. Take Ford's F-150 pickup truck as a case in point they switched to aluminum body panels made through die casting processes. This change knocked about 700 pounds off the truck's overall weight, which means drivers get better miles per gallon at the pump. Beyond saving money on fuel costs, these lighter materials help reduce carbon footprints across the automotive industry worldwide.

Structural Integrity in Thin-Wall Components

Die casting plays a vital role in manufacturing thin wall components that still hold up under stress, which matters a lot for car safety standards. Even when parts get really thin, the process manages to deliver both accuracy and toughness needed for critical safety parts such as those housing cameras or supporting engines. Working with thin walls isn't without its headaches though. Engineers struggle with things like controlling how hot metal moves through molds and getting the cooling right so parts don't warp. Companies like Tesla have cracked this problem by running detailed computer models ahead of time. These simulations let them see what might go wrong before pouring real metal, helping ensure their thin wall castings pass all the safety tests while lasting long enough to make it through production runs.

Electric Vehicle Component Optimization

Electric vehicles are changing what manufacturers need from their component materials, and die casting is stepping up to meet these new challenges. Parts such as battery boxes and motor casings really work well with die casting techniques because they can produce parts that are both light and tough. Take aluminum die castings for instance they cut down on vehicle weight, something that makes a big difference in how far an EV can go on a single charge. Companies have started leveraging this advantage too. Look at Lucid Motors, who incorporated lighter materials into their designs through die casting processes. This helped them build better performing cars without compromising safety standards required in today's competitive EV market.

Quality and Certification Standards

IATF 16949 Certification Requirements

IATF 16949 has become something of a gold standard for quality control across the auto manufacturing sector, particularly when it comes to metal casting operations. What makes this certification so valuable is that it forces manufacturers to adhere to strict guidelines that result in consistently good parts. The process itself covers several critical areas. First, there's management responsibility where top brass actually has to show they care about quality instead of just talking about it. Then we get into resource management, making sure everything from machinery to personnel gets used properly. And finally, product realization takes those vague customer specs and turns them into real products that work as intended. For suppliers looking to stand out in a crowded marketplace, getting certified isn't just about meeting minimum standards anymore. It's practically required if companies want to prove they take quality seriously while gaining an edge over competitors who haven't made the same investment.

Process Consistency Through Precision Controls

Getting precise control over processes is really important for keeping things consistent and reliable when it comes to die casting, especially since we're talking about making those high quality automotive components everyone wants. Manufacturers these days use all sorts of measurement methods along with some pretty advanced tech to keep tabs on stuff like temperatures and pressures during production runs. Take digital sensors for instance they're everywhere now, constantly feeding back information while real time analytics help spot issues before they become big problems. The numbers don't lie either companies report seeing major drops in defects after implementing better control systems. And let's face it, fewer defective parts means happier customers overall. So yeah, getting those controls right isn't just nice to have anymore it's basically essential if manufacturers want to stay competitive in today's market where quality matters more than ever.

Defect Prevention and Quality Validation

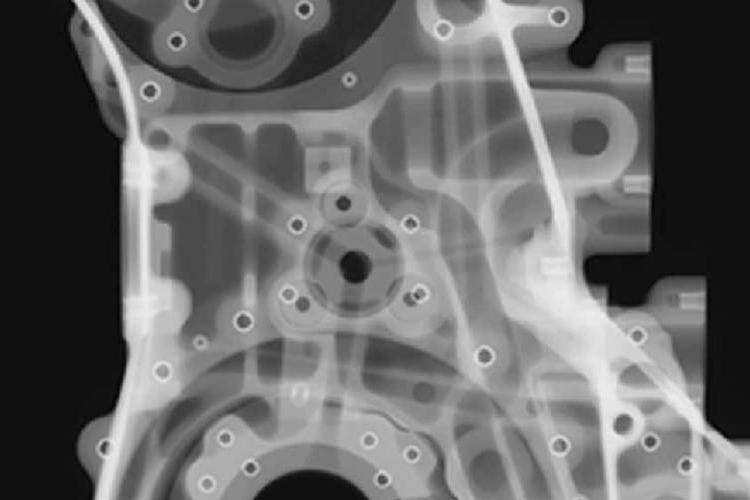

In die casting, problems like porosity, misaligned parts, or rough surfaces often show up during manufacturing. Fortunately, there are ways to stop these issues from happening in the first place. Many factories now rely on quality checks that don't damage the actual product, like what's called Non-Destructive Testing or NDT for short. These tests let manufacturers spot possible flaws much earlier than traditional methods would allow. Looking at real world examples makes this clearer. One plant saw a big improvement after they started using X-rays and sound wave testing regularly. The industry has really stepped up its game when it comes to making sure products meet quality standards before they even reach customers. Companies invest time and money into these inspections because nobody wants defective parts ending up in finished goods.

Strategic Implementation Insights

Selecting Aluminum Die Casting Suppliers

Finding good aluminum die casting suppliers makes all the difference when it comes to getting quality parts out efficiently. Look for companies that actually care about quality control and have the tech upgrades needed for today's manufacturing standards. Certifications matter too. The IATF 16949 one specifically shows they take quality seriously and follow strict processes. When checking out possible partners, don't forget to dig into how they handle quality checks day to day. Ask if they've worked on anything similar before and how they handle scaling up production when demand changes. Getting these details upfront saves headaches later and helps find a supplier that works well now and can grow with your business over time.

Tooling and Production Scalability

The ability to scale die casting tooling matters a lot when thinking about current requirements plus what might come down the road. Tool designs that let manufacturers tweak things easily really help when they need to boost output levels. Take high pressure die casting for example it lets factories adjust operations fast enough to keep up with growing demand while still keeping product quality intact. Automotive manufacturing comes to mind here since car companies often see sudden spikes in orders during certain seasons or model launches. And there's something else worth mentioning too modern machines with automation features make switching between different production runs much quicker. These kinds of improvements mean manufacturers don't get stuck trying to handle bigger volumes than their equipment was originally built for.

Lifecycle Cost Efficiency Analysis

Looking at lifecycle costs when planning die casting projects really helps companies see what they might spend down the road. This kind of analysis covers everything that affects money spent, starting with setting things up, going through actual production runs, dealing with maintenance issues as time goes on, and eventually handling recycling at the end of it all. Many manufacturers find that bringing lifecycle cost analysis into their planning makes a big difference. Take sustainable manufacturing for instance where companies start using materials that can be recycled again later on. These approaches save cash while being better for the environment too. We've actually seen several businesses transform how they operate after adopting these methods. They end up making smarter choices about spending money and running operations efficiently throughout the whole life of whatever casting project they're working on.