Understanding Common Die Casting Defects

Porosity: Causes and Impact on Part Integrity

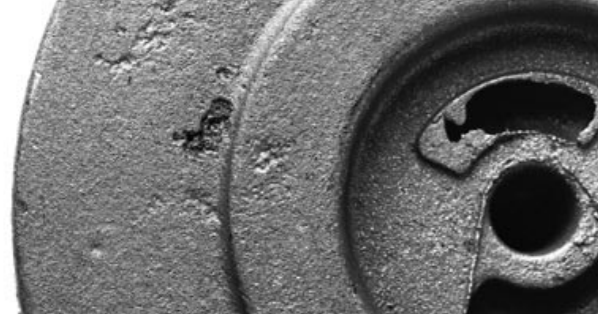

In die casting, porosity shows up as tiny voids or holes inside the casting material, usually because of trapped air or other gases getting stuck during the process. These defects appear as odd-looking gaps that can be seen on finished parts whether they've been machined or not. What causes this? Mainly two things happen: either gas gets caught in the mix or there's moisture hanging around in the mold itself. This typically occurs when hot metal rushes into the die too fast and creates all sorts of turbulence. The movement搅乱 everything, letting those pesky gases settle in before the metal hardens, forming bubbles along the way. When these pores form, they really weaken the structural strength of whatever was cast, increasing the chances of parts breaking down later on. Industry reports suggest porosity remains the biggest headache for aluminum die casters worldwide, showing up in roughly 30% of batches produced across different regions. To tackle this problem head-on, manufacturers need to focus on better ventilation systems and smarter mold designs if they want their products to hold up over time.

Cold Shuts and Misruns: Flow-Related Challenges

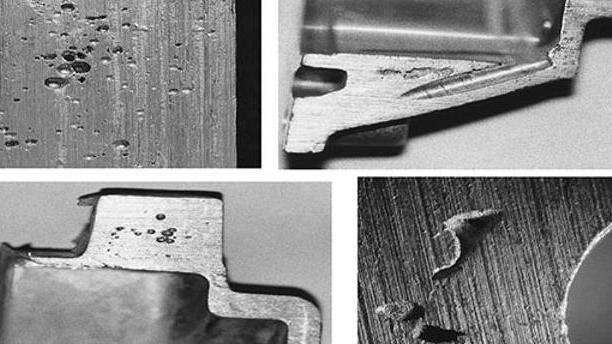

Cold shuts and misruns are pretty much standard issues in die casting operations where the metal doesn't properly fill the mold. When we talk about cold shuts, they show up as visible lines where separate metal flows didn't merge properly during casting. This usually happens when either the metal is too cool or there isn't enough pressure pushing it into the mold. Misruns happen differently though. These occur when molten metal simply fails to reach all areas of the die cavity. Often this points to problems with how the die was designed or maybe just not enough metal getting through. Either way, both defects really mess with the strength of what comes out of the machine, making parts prone to breakage long before they should. Looking at actual production floor examples, companies that tweak their melt temps, redesign dies for better flow, and adjust injection speed settings see dramatic reductions in these defects. Some manufacturers report cutting rejection rates by over 40% after implementing these changes across their casting lines.

Surface Imperfections: Roughness and Flash Formation

Imperfections on surfaces remain a big problem in die casting work, especially when it comes to rough spots and those annoying flash formations. Rough surfaces usually happen because molds aren't kept up properly or cooling times vary too much, which leaves behind all sorts of texture problems. When molten metal leaks out around the edges of the mold cavity, that's what creates flash those thin layers that nobody wants. These flaws do more than just look bad they actually affect how well parts function in real applications. According to various industry stats, fixing these surface issues costs companies quite a bit of money, so most manufacturers have started putting serious money into quality control systems. Keeping molds clean and watching cooling rates closely remains key for reducing defects, something every shop knows if they want to produce die cast components that truly stand up to quality expectations.

Strategies to Minimize Aluminum Die Casting Defects

Optimizing Mold Design for Reduced Porosity

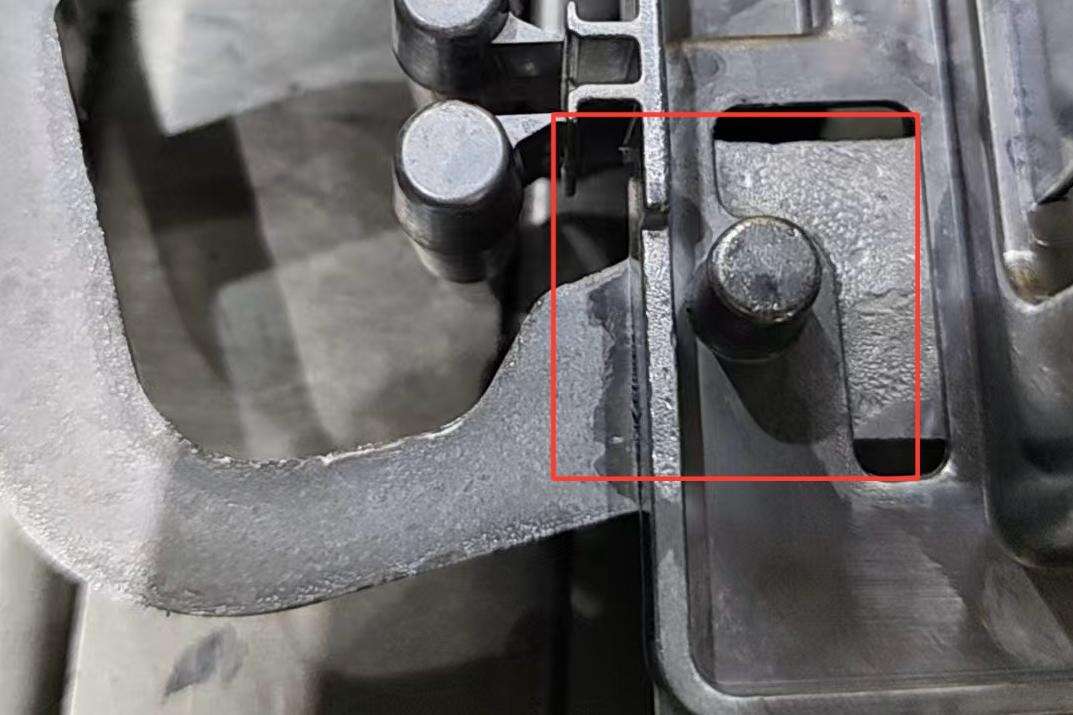

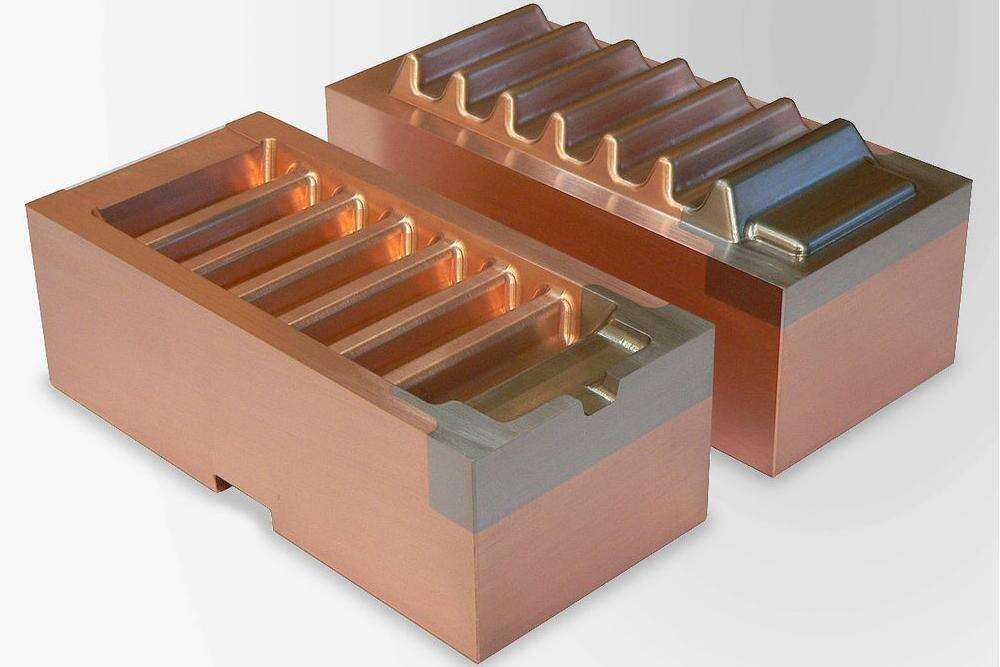

Getting the mold design right makes all the difference when it comes to reducing porosity issues in aluminum die casting parts. Porosity remains one of those pesky defects that really messes with component integrity over time. Good practice involves working on those flow channels so molten metal moves smoothly through the system, plus making sure there's proper venting throughout to let trapped gases escape during the process. What kind of material goes into making those molds matters too. Some materials conduct heat better than others, which helps control how fast things cool down and solidify inside the mold cavity. Most people who've been around this industry for years will tell anyone willing to listen about these design tweaks because they genuinely make parts last longer and perform better overall. When manufacturers actually implement these changes in their production lines, they tend to see fewer rejects and much cleaner end products without those annoying little bubbles hidden inside.

Temperature Control and Injection Speed Best Practices

Getting the temperature right and controlling how fast material gets injected into molds makes all the difference when it comes to die casting quality. Most aluminum work needs temperatures somewhere between 630 and 700 degrees Celsius, though exact numbers can vary depending on what's being cast. When manufacturers keep temperatures stable and tweak injection speeds properly, they avoid problems like incomplete fills or cold spots where metal doesn't bond correctly. Some research showed that shops keeping close tabs on both temperature and injection speed saw around 15 percent fewer defects overall. That kind of improvement matters a lot in production environments where consistency counts. Proper management of these variables leads to better results across the board for aluminum die casting operations.

Role of Venting Systems in Gas Escape Efficiency

The venting system is really important during die casting because it lets gases get out of the mold cavity. Without this, we end up with those annoying pores forming in our parts. When engineers design good venting systems, they actually make the whole operation run smoother and produce better quality parts since all that trapped air gets pushed out properly. Some research indicates around 30% fewer issues related to gas when the vents work right, which makes sense if you think about it. Getting these systems set up correctly matters a lot for aluminum die castings specifically. Parts come out cleaner, last longer, and function better overall when manufacturers pay attention to how their venting works across different production runs.

IATF 16949 Certification for Quality Assurance

How IATF 16949 Standards Prevent Process Variability

The IATF 16949 standard plays a major role in quality control across the automotive industry, especially when it comes to die casting operations. When manufacturers put IATF 16949 into practice, they generally see better consistency in their production runs while cutting down on defects. What makes this standard so valuable is its comprehensive approach to quality checks throughout the manufacturing chain. The result? Products that meet specifications more reliably and customers who come back for more. Many businesses following these guidelines notice fewer issues with process variations and lower defect counts over time. Some real world data backs this up too – companies that implement IATF 16949 often experience around 30% fewer problems with non-conforming parts. These numbers highlight why so many automotive suppliers are making the switch to this framework for maintaining consistent quality standards across their operations.

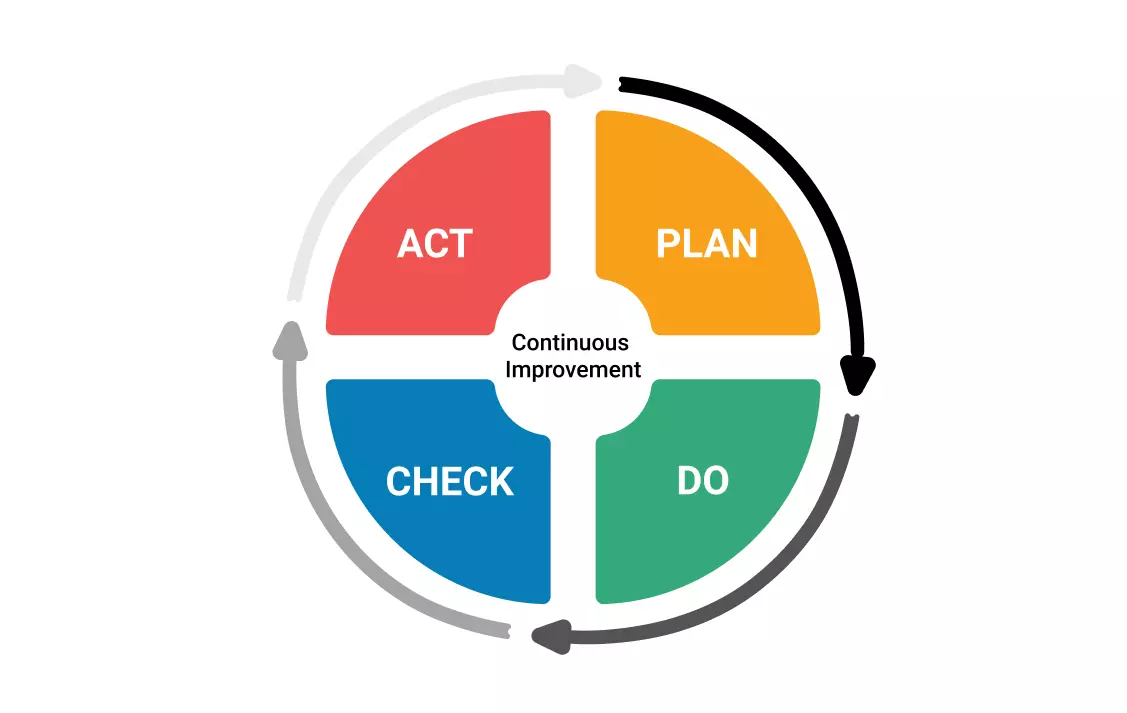

Implementing Continuous Improvement Frameworks

Getting better all the time matters a lot in die casting if we want fewer flaws and smoother operations. Many shops rely on something called the PDCA cycle – Plan, Do, Check, Act – to make real progress. With this approach, factories can look at their processes, try out changes, then see what actually works. The beauty of this method lies in catching problems before they become big headaches while building an environment where everyone keeps looking for ways to do things better. Take a look at some top companies in the field, and they've seen defect rates drop dramatically after adopting these methods. For instance, there was this aluminum die casting company that started using PDCA across their production lines. Within just twelve months, they noticed around twenty percent fewer quality issues with their products. Beyond staying competitive in the market, these kinds of continuous improvement strategies help businesses stick around longer because they produce parts with much greater accuracy and consistency.

Documentation Protocols for Defect Traceability

Good documentation is essential for tracking where problems come from in die casting work. When manufacturers keep detailed records covering everything from raw material sources all the way through to finished products, they can actually figure out why defects happen and stop them from coming back again. The smart ones have developed solid systems that track things like batch numbers and exact process settings throughout production runs. Companies that do this right see real results too. One recent analysis showed that factories with strict documentation rules cut down on defects by around 40% versus places with sloppy record keeping. Beyond just improving product quality, these practices help build client confidence because customers want to know their supplier takes quality seriously. Most experienced manufacturers will tell anyone who asks that proper documentation isn't just paperwork it's part of running a competitive operation in today's market.

Advanced Techniques for Zinc Die Casting Parts

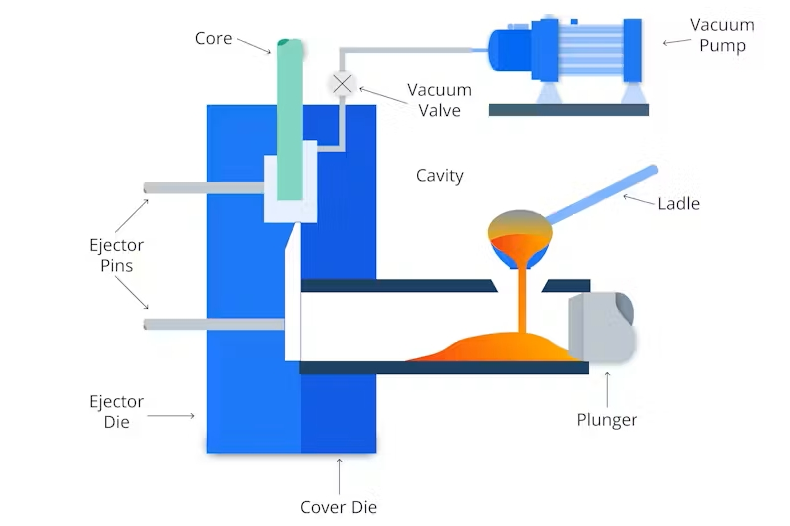

Vacuum-Assisted Casting for Thin-Wall Components

Vacuum assisted casting stands out as a game changer for making those tricky thin wall zinc components. Basically, the process creates a vacuum while pouring molten metal into molds. This helps the metal spread evenly throughout the mold cavity and cuts down on pesky air bubbles getting trapped inside. What does this mean practically? Parts made this way tend to have fewer holes and cracks, which means they're stronger and last longer in real world applications. Manufacturers who switched to this approach report around 30% fewer rejects on their production lines. For anyone working with zinc die castings, especially in industries where part reliability matters most, vacuum casting has become almost essential these days.

Alloy Selection to Mitigate Thermal Fatigue

The selection of appropriate zinc alloys is really important when it comes to reducing thermal fatigue and avoiding defects in die casting operations. Zamak 2 and Zamak 3 remain popular choices among manufacturers because they handle heat pretty well. These materials tend to resist cracking and warping even under extreme temperatures. Research indicates that such alloys strike a good balance between being strong enough structurally while still conducting heat effectively. From what metallurgists observe in practice, quality alloys make cast parts last longer, which means fewer replacements needed down the line. This ultimately makes the whole production process more efficient over time, saving both money and resources in the long run.

Automated Monitoring Systems for Defect Detection

Automated monitoring has changed the game when it comes to spotting defects during die casting operations. These systems combine sensors with artificial intelligence to keep an eye on the whole casting process nonstop, catching issues such as gas pockets and incomplete fills right when they happen. Manufacturers who've adopted this technology tell us their machines spend less time offline for repairs and their product rejection rates drop dramatically. Looking at actual shop floor results shows these monitoring setups really work wonders for quality control. Less scrap means better bottom line numbers too, while zinc castings come out consistently reliable across batches. Some plants even notice improvements in worker safety since operators aren't constantly checking for flaws manually anymore.

Selecting a Reliable Aluminum Die Casting Supplier

Evaluating Supplier Expertise in Defect Prevention

Finding the right aluminum die casting supplier means looking closely at how good they are at preventing defects. What really matters? Experience level, what kind of tech they work with, and whether they know their stuff when it comes to fixing those pesky casting issues. Take companies that have been around for years and invest in things like automated quality checks. These folks generally produce better quality parts. Studies show that suppliers who stick with cutting edge methods cut down on casting problems quite a bit, which means customers get more reliable end products. Beyond just making sure the parts hold up, this kind of know-how actually speeds things up across the whole manufacturing line too.

Importance of Material Traceability and Testing

Keeping track of materials throughout the die casting supply chain matters a lot because it means every step in production gets documented properly. When manufacturers know where their raw materials came from and what happened to them during processing, they can spot quality problems much faster. Good testing procedures play a big role here too. The best suppliers don't just check materials once or twice but run multiple tests at different stages to make sure everything meets standards. Industry reports consistently show that companies with solid traceability systems see anywhere from 30% to 50% fewer defects in their finished products. These systems give plant managers real power to catch issues early on before they turn into bigger headaches down the line.

Case Studies: Successful Defect Reduction Partnerships

Looking at how manufacturers work together with their suppliers gives some real clues about cutting down on defects. The case studies show something interesting actually happens when companies team up with suppliers and share information back and forth. When they do this kind of collaboration, product quality tends to get much better. What usually happens is both sides sit down together to figure out ways to improve those casting processes. This leads to fewer flaws in the final products and better performing aluminum castings overall. Companies that have done this report happier customers because there's less need for fixing things later on. Plus, they save money since there's not so much wasted material from bad casts. And let's face it, businesses that maintain good working relationships with their suppliers tend to stand out more in the marketplace. Manufacturers looking to boost the reliability of their cast components would do well to invest time building those supplier connections.