Automotive Innovations Driving Die Casting Demand in 2025

EV Battery Housings and Motor Casings

Electric vehicles are becoming increasingly popular, and this trend is driving significant demand for die cast components, especially when it comes to manufacturing battery enclosures and motor housing units. The die casting process creates parts that are both light weight and strong enough to withstand rigorous conditions, which helps improve how well these vehicles perform overall. Looking ahead, market analysts predict substantial growth in the EV sector, with forecasts suggesting over 22% compound annual growth from 2021 through 2028. For manufacturers trying to meet the demanding specs required by modern EV designs, aluminum remains the go to material for die cast parts because they handle heat better and maintain structural strength under stress. Advanced techniques in aluminum die casting help reduce vehicle weight while still meeting all those strict automotive regulations around fuel efficiency and safety standards that keep getting tighter every year.

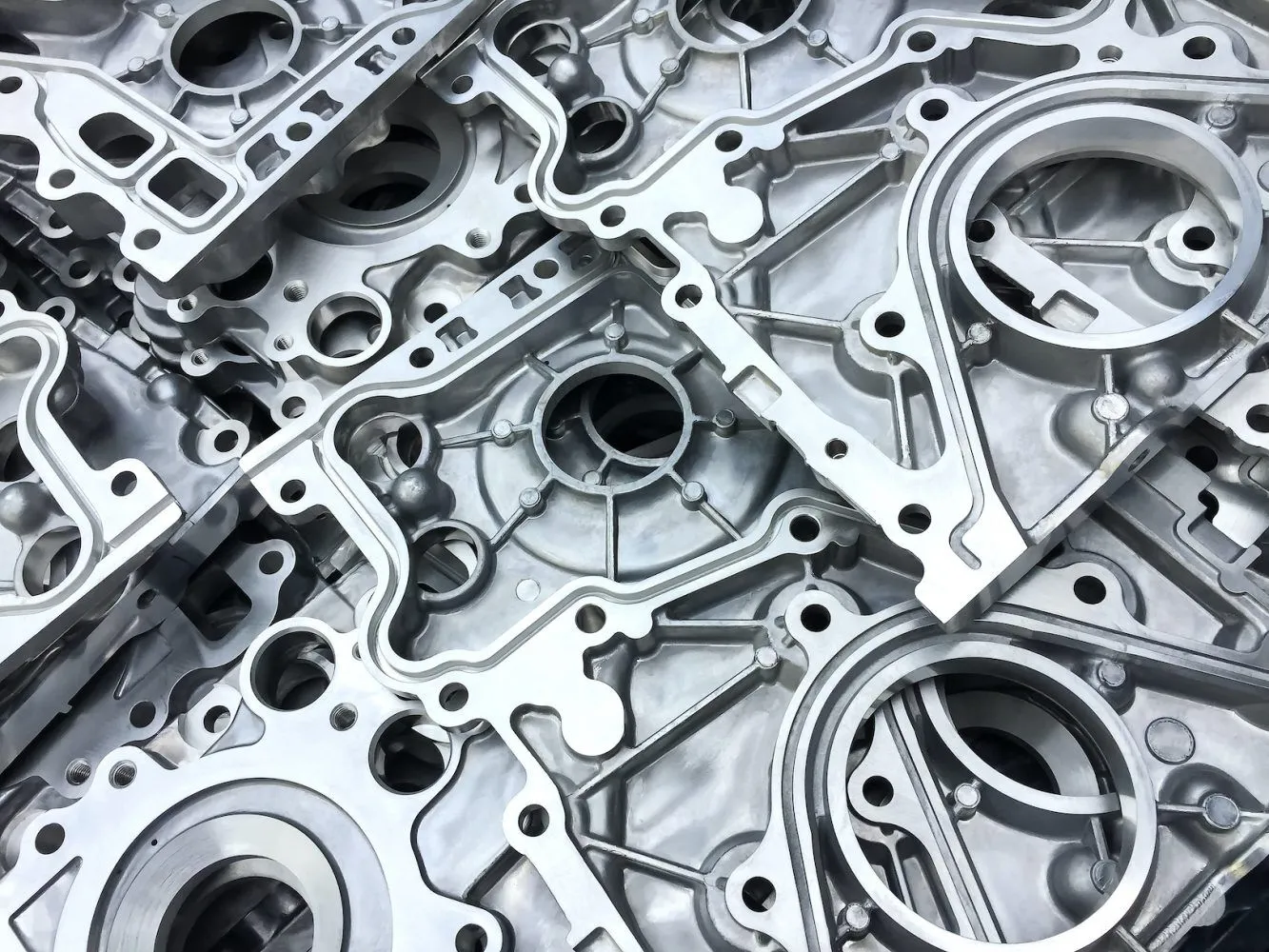

Lightweight Structural Components

Car makers have been pushing harder toward lighter materials lately because they want better gas mileage and lower emissions. Aluminum die casting stands out as a great option for making parts that are both tough and light weight. The process works really well for cars since it meets all those strict safety requirements while still helping save fuel. Big car companies are pouring money into new die casting tech to hit these tough standards. Some estimates suggest fuel savings could be around 6 to 8 percent when using these methods properly. So die casting isn't just about building cars anymore it plays a key part in making vehicles greener without sacrificing how they perform on the road today.

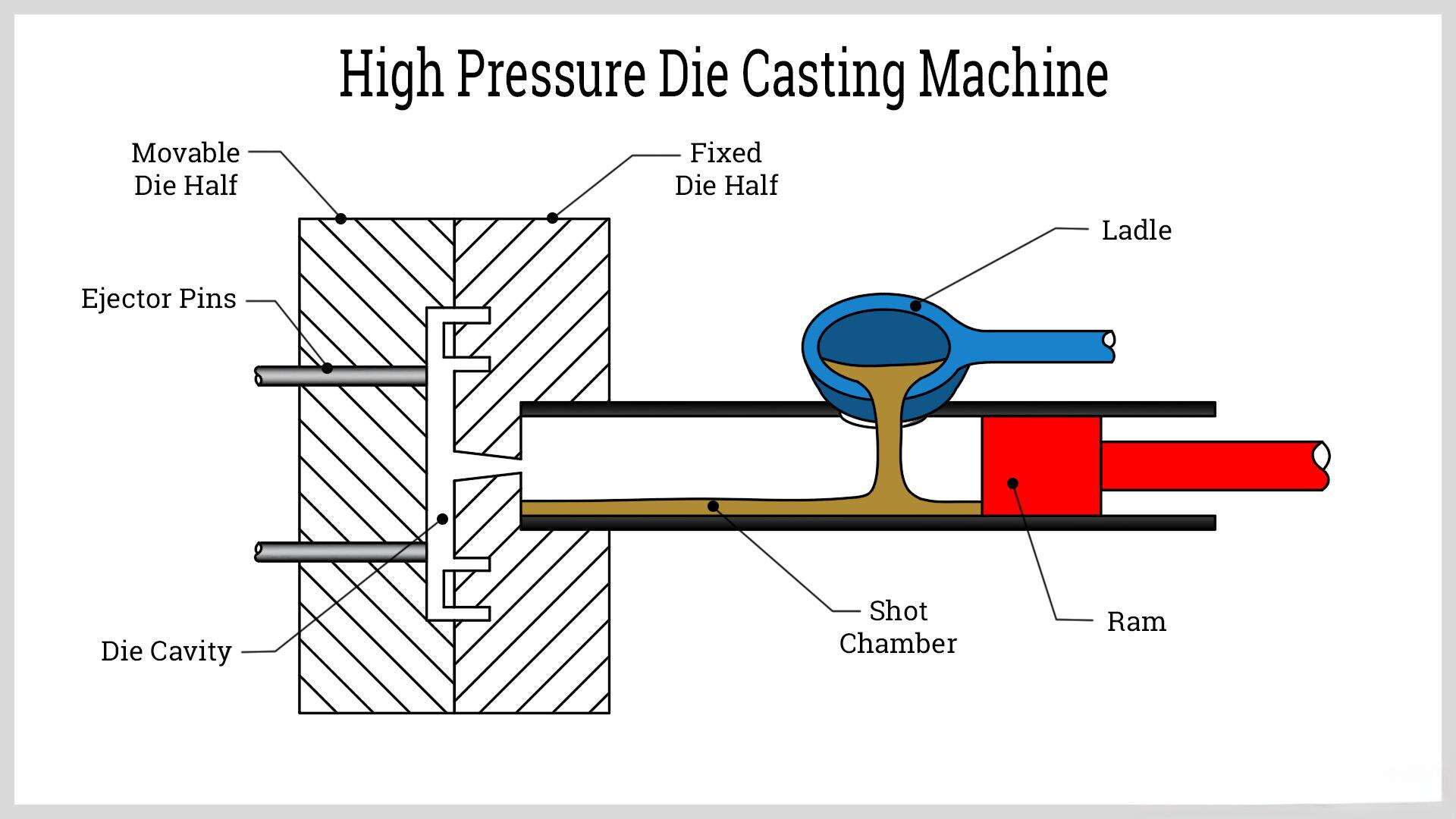

High-Pressure Die Casting for Transmission Systems

The automotive industry relies heavily on high pressure die casting when making transmission parts that need both accuracy and strength to last through years of use. What makes this method so valuable is its ability to produce intricate shapes that just aren't possible with other techniques, which directly impacts how well cars perform today. Manufacturers report around a 40% improvement in production speed when they switch to high pressure die casting methods, cutting down costs while maintaining quality standards. We're seeing growing interest across North America specifically, where automakers want better fuel efficiency without sacrificing power output from transmissions. For plant managers looking at long term investments, high pressure die casting isn't just another option anymore it's becoming essential for keeping pace with evolving vehicle specifications and customer expectations.

Aerospace Applications of Advanced Die Casting Technologies

Turbine Components Using Aluminum Die Casting Process

Aerospace companies are turning to aluminum die casting more and more for making turbine parts because it offers excellent strength while being relatively light weight. This matters a lot when talking about how well turbines actually perform. Research shows aircraft with lighter turbines burn way less fuel during flights, which cuts down on running expenses over time. Recent improvements in aluminum die casting technology mean manufacturers can now produce parts with much greater accuracy, something needed to pass all those tough safety checks in aviation. Looking at the numbers, there seems to be rising interest in better die casting methods within the aerospace sector. Some analysts predict around 5 or 6 percent growth each year as companies switch to stronger but lighter aluminum components that help make their turbines work better overall.

Heat-Resistant Zinc Alloy Parts for Engine Systems

Zinc die cast components play a vital role in aerospace engineering thanks to their impressive ability to handle high temperatures, which is why they show up so often in jet engine assemblies. The strength of zinc alloys allows manufacturers to produce parts capable of surviving both intense heat and pressure conditions that would damage other materials. As aircraft manufacturers push harder for fuel savings across the board, many are turning back to zinc die casting methods as a way to cut part weights by around 10 to 15 percent without sacrificing durability. These improvements directly translate into better fuel economy during flights. Recent advancements in how we work with zinc continue to meet the growing needs of aerospace engineers who need reliable solutions for managing heat while maintaining peak engine performance standards.

Die Casting in Next-Gen Consumer Electronics

5G Network Equipment Enclosures

As 5G continues its expansion across industries, there's growing need for enclosures that combine durability with light weight and reasonable costs, which makes die casting stand out among manufacturing options. Aluminum die casting particularly shines here since it can produce intricate, precision parts that actually boost network performance while keeping heat issues under control. Industry reports point to around a third rise in demand for all things 5G related over recent years, which naturally increases reliance on die casting techniques. When applied to consumer gadgets, these casting methods enable design breakthroughs we simply couldn't achieve before, opening doors to new product features that will shape what comes next in tech development.

-

Benefits of Die Casting in 5G Enclosures

- Durability and lightweight construction

- Enhanced thermal management

- Increased demand for complex designs

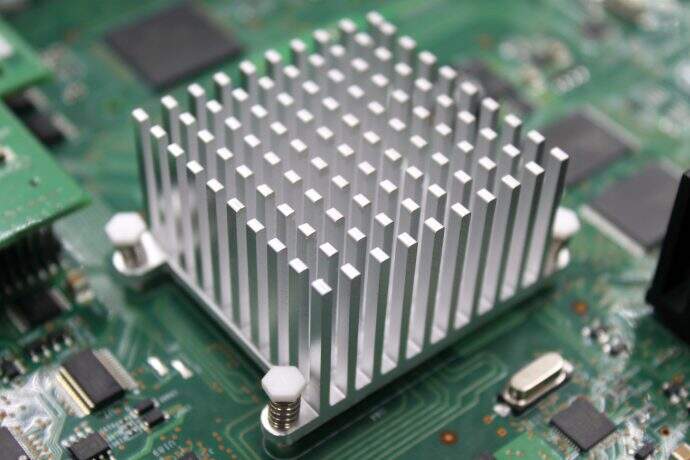

Thermal Management Solutions for IoT Devices

With all these IoT gadgets popping up everywhere, good thermal management has become really important for keeping them running well and lasting longer. That's where die casting comes into play big time. Companies rely on this process to make heat sinks and various parts needed to keep things cool inside those small electronic packages. When devices stay at the right temperature, they tend to last much longer, which makes sense why so many consumer products now include die cast components. Looking ahead, the IoT market seems headed towards something like a trillion dollars by mid decade or so. To keep up with what everyone wants, the folks in die casting will need to come up with some fresh ideas and better ways of doing things.

-

Role of Die Casting in Thermal Management

- Creation of heat sinks and essential components

- Enhancement of device lifespan and performance

- Preparation for growing IoT market demands

By implementing advanced die casting techniques, manufacturers can ensure that consumer electronics keep pace with technological advancements, meeting the ever-increasing consumer demands for high-efficiency devices. This approach not only supports better device performance but also offers opportunities for innovation in design and functionality.

Medical Device Manufacturing Breakthroughs

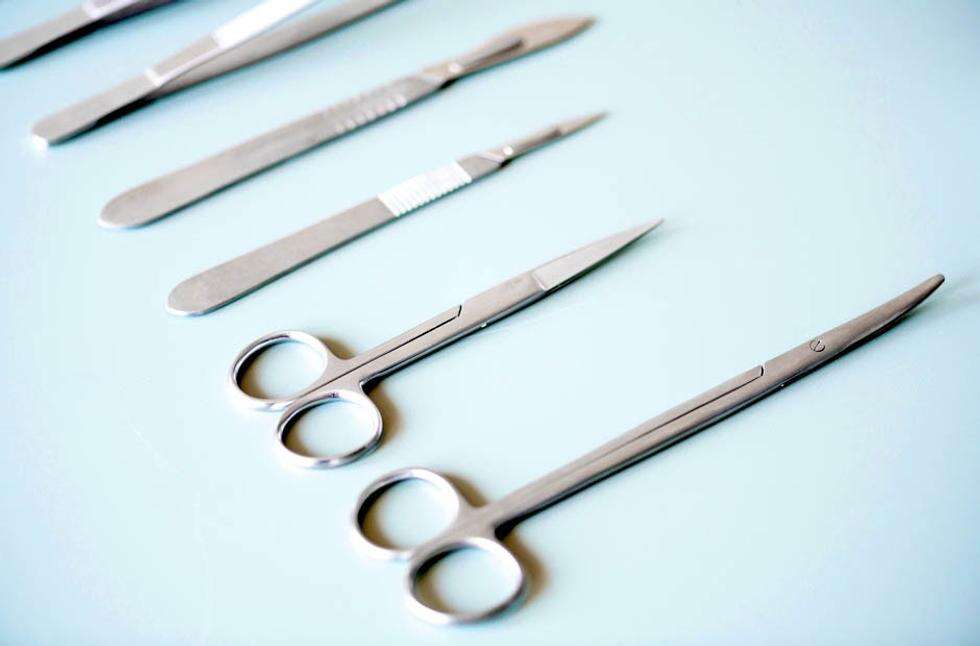

Sterile Surgical Instrument Production

Die casting is really important when it comes to making those high quality sterile surgical tools that hospitals rely on every day. This method helps manufacturers meet all those tough medical standards and regulations they have to follow. What makes die casting so good is how precise it is, meaning there's less work needed after production, which actually helps keep things sterile for longer. Looking at the bigger picture, we're talking about a medical devices market that's growing fast - estimates suggest it might hit around $600 billion by 2024. With such growth, techniques like die casting are becoming even more sought after. Beyond just being light weight, these casted instruments perform better during surgeries too, which ultimately leads to better results for patients. That's why so many doctors and surgeons depend on them across various procedures in modern medicine.

Implantable Device Casting with Biocompatible Alloys

Biocompatible alloys used in die casting for medical implants provide patients with safer options that work reliably over time. Medical device regulations demand these sophisticated manufacturing techniques to meet strict safety requirements set by agencies like FDA. Doctors and researchers keep stressing how crucial biocompatibility really is when it comes to things inside the body for years at a time, think coronary stents or hip replacements. That makes die casting not just important but absolutely essential in this field. Looking ahead, the market for these kinds of devices seems poised for real growth, which means plenty of room for innovation in the die casting sector as manufacturers look to apply their expertise across different areas of healthcare technology.

Sustainable Die Casting Practices and Certifications

IATF 16949 Certification for Automotive Quality Standards

Getting IATF 16949 certification matters a lot when it comes to keeping quality standards up in automotive die casting shops. The standard basically sets out what good practice looks like across the industry. For manufacturers, this isn't just paperwork - it actually makes their day-to-day operations run smoother while improving how efficiently they produce parts. Consistency becomes much easier to maintain too, which means fewer defects and happier customers down the line. Companies that have gone through the certification process tend to stand out from competitors because clients know they can rely on consistent quality. Plus, getting into new markets becomes less of a headache since many buyers now expect suppliers to meet these standards. With governments around the world cracking down on quality requirements, we're seeing an increasing number of automotive parts makers jump on board with IATF 16949 as part of their long term strategy for staying relevant in the market.

Closed-Loop Recycling in Aluminum Die Casting Process

Using closed loop recycling for aluminum die casting is basically a green approach that gets the most out of materials by working with scrap metal instead of starting from scratch. The process cuts down on what companies spend to make products while also generating far less waste than traditional methods. Environmentally speaking, it makes a real difference too since it slashes energy needs by around 95% according to some recent numbers we've seen. With so many sectors talking about going green these days, manufacturers who switch to these kinds of recycling systems are not just following trends but actually making smart business decisions that save money and protect our planet at the same time.