Fahimtar Kwarra Na Die Casting Da A Sufi

Porosity: Causen Da Saiyasan Matakan Na Abubuwa

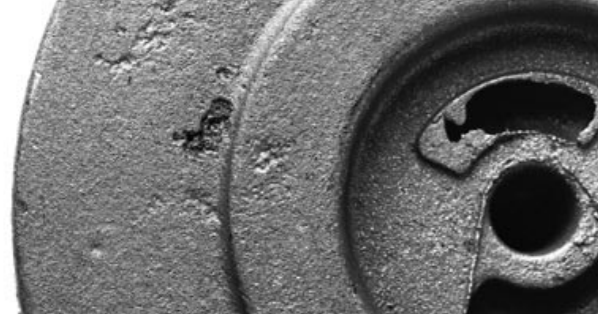

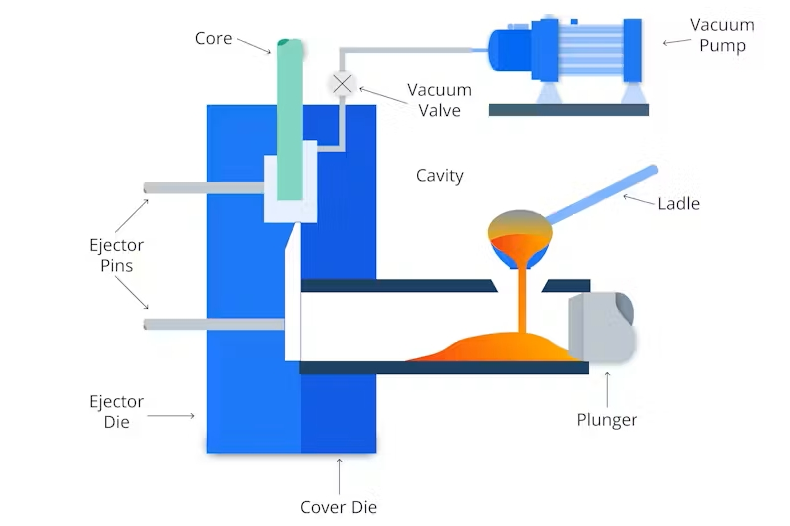

A ciki na fasaha, yaƙi zai nuna su ne da alama na ƙarin ƙasa ko alama a cikin abu mai fasaha,saboda izawa ta hawa ko sauran gasolin da suka tafi cikin aiki. Wannan abu ya nuna su ne da alama mai zuwa da za a iya ganin a cikin abubuwan da aka gama ko ba tare da fasaha ba. Menene mai iluwa wa su? Wannan ke yiwuwa ne daga biyu abubu: ko kuma gasolin da aka tura cikin rabin ko kuma ruwa akwai cikin mada fasaha. Wannan ke yiwuwa ne tun zamantakewa mai zurfi ya tura cikin mada fasaha sosai kuma yai tsarin ƙarƙashin. Matsarar ya sa gasolin da suka tafi cikin zamantakewa suka tafi cikin gaban zamantakewa yayin da aka tura su kuma suka hada da bubuwa a tsakanin. Yayin da wadannan pɔrɔya ke haduwar, suna kwalla tsuntsaye na abubuwan da aka gama, ya zabi kansa na abubuwan da suka tafi cikin aiki. Malamanin a wajen yau da kullun suna iya amfani da porosity shine mai tsawon halin gaskiya don casters na fasaha na aluminum a duniya, ya nuna su ne a kauye zuwa ga 30% na batches da aka gama a waje daban-daban. Don gudanar da wannan halin, maimakonci ke buƙata tattara cikin tsarin tushewa da kuma tsarin mada fasaha domin samun abubuwa da zai taimaka kan zamantakewa.

Cold Shuts da Misruns: Flow-Related Challenges

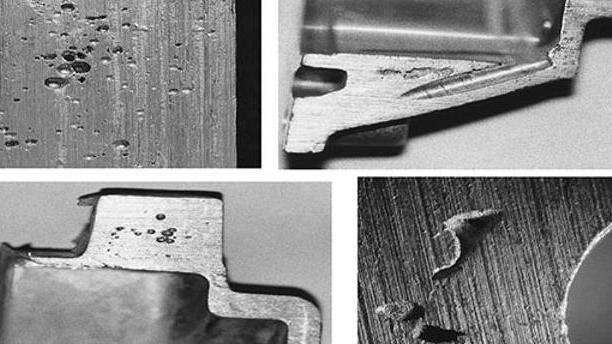

Wasannan cold shuts da misruns suna da yawa a cikin wasanni na die casting inda metal bata yi closeda mold ba. Idan muka rubuta cold shuts, suna zinarewa kamar alamun kari inda kasaɗan metal su ba yi karkashin cikin wasanni. Wannan ke yawan karu inda kuma metal ya zuba ko har zuwa babu tsawon yin ciki a mold. Misruns ba su gama kamar haka ba. Wannan ke yawan karu inda metal ya zuba bata yi closeda kasaɗan kamar yawa na die cavity. A karkashin wannan yana da alhakin abin da aka yi design na die ko har zuwa bata yi closeda metal. Kamar haka, biyu ne na defects suna iya karkashin ƙarƙarin abin da ya fito daga machine, yana buƙatar gudun karamin kafin waqtocin da ke ciki. Idan muka duba cikin misalan da ke farko, wasu shagunan suna canzawa melt temps, redesign dies don mai flow, da kuma canzawa injection speed settings suna iya rage defects biyu ne. Wasu manufacturers suna nuna cutout rejection rates da yuzon 40% bayan nuna waƙannan canjinciyon a cikin wasannan casting lines.

Surface Imperfections: Roughness da Flash Formation

Anfaniyar daban-daban a kan surface suna zama abin da suke bayan a cikin aikin die casting, na kuma yiwuwa ne suke da rough spots da kuma flash formations. Surface mai rough zama ne a kauye da kama da mamen da suke iya gudun kuma ko kai tsaye na gudun ya tura wanda ke nufin sauti. Lokacin da metal mai zafi ya riga a cikin gaba na mold cavity, wato shine flash wanda ke nufin sauti da ke wuya. Wannan abwai suna da yawa da kuma za su karu a cikin aiki na parts a cikin amfani mai amfani. Don ilmin abokan cin rana, gyara daban-daban na surface ke kara kudin kasa ga shagunan, don haka mai karuwa duk suka fara yi invest a cikin systems na quality control. A iya gudun molds da kuma duba kai tsaye na gudun shine wanda ke kara muhimmi don kara kudin defects, wato abin da duk dukkan ke sami idan suka so su karuwa components na die cast wanda ke taba da kariya.

Hanyoyi don Kaukar Ayyukan Gudunwar Karamin Tsohon Aluminum

Gyara Matsayin Karamin Tsoho don Kauka Porosity

Tun da fatan a iya gudanar da saitin mada na iya bukatar bincike wajen kawar da kasa ta alminiyum. Porosity shine daya daga cikin abubuwan da suka daina ingantaccen ingancin bukatar. Hanyar aiki shine a gudanar da alakar ruwa don haka ya tura shi a cikin mada, kuma kawar da gasolin da ke cikin mada suna fitowa a lokacin da ke nuna. Abubuwan da ake amfani da su don gudanar da mada na iya bayani. Wani abu na iya samar da zurfiyar farashin da ke kawar da zurfiyar kasa ta mada. Wakilolin da suka yi aikin da wannan sana'antar suka nuna wa kowa da yawa wadannan abubuwan da suka iya ƙara ingancin bukatar kuma suka iya karfawa. Lokacin da maƙaranta suka gudanar da wadannan canjiyoyi a cikin asusun su, suka iya samar da karamin karfi kuma suka iya samar da abubuwan da ba su da alalubar gasolin da suke cikin.

Best Practices Na Kontrolar Turenci Da Kuma Sabin Cirewa

Yiyan taya na tsawon kama da kula da ke cika injin na ƙarin abuwa a cikin mafurci ya samar da farko kan kwaliti na die casting. A karkashin alminum na buƙatar taya na tsawon kama da kula ne shi ne akan 630 zuwa 700 daraja na Celsius, amma yana iya canzawa ba tare da abin da ke nuna. Lokacin da mafurci na hana taya da kula kuma suyi gargajiya kan tsawon injin na ƙarin abuwa, suke taka leda daga cikin abubuwa guda biyu ko kula mai kasa inda metal bata taka tattara. Babu tun da aka fasso waɗanda suke nuna cewa wasu mafurci da suke saba kusar taya da tsawon injin na ƙarin abuwa suna da kurci na ƙasa fihin 15% na abubuwan da suke da ƙasa. Shi ne waɗannan canjawa suna da muhimanci sosai a cikin tsarin uwar gudun kada kusan kwaliti na iya canzawa. Tsarin daidaitan waɗannan abubuwan suna iya samar da ma'aurfi mai kyau a karkashin tsarin die casting na alminum.

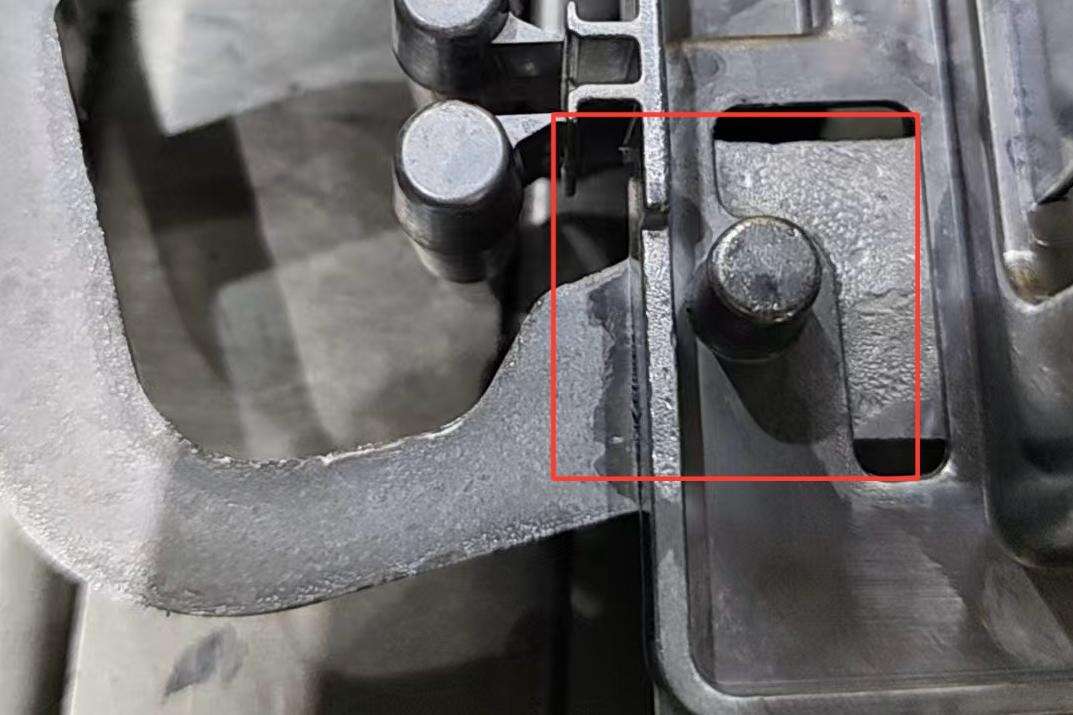

Aikin sigogin venting a gas escape efficiency

A cikin ƙwararwar ganyawa, sistin fayil yaɗu da ke mucaccin gishin ƙwararwar ta hanyar fitowa daga cikin ƙwararwar. Idan ba a yi haka ba, zamu sami alaƙa da alaƙa da suka fuskyara a cikin zaɓi mu. Idan sarrafai na iya rarraba sistin fayilin mai kyau, suna da iya karɓar aiki dukkan da samar da abubuwa mai kwaliti saboda an fitowa dukkanin gishin da ke mucaccin. Wasu litattafai suna nuna cewa ana ba da alaƙa da gishin yana da ƙarin ƙarin 30% idan fayilin suna yi aiki maimakon, wanda ya ban muhimmiyar. Yana da muhimmiyar a matsayin sa sistin fayilin wajen yi aiki don samar da abubuwa mai aljanna. Abubuwan za su fito mai sau, za su zutsu da kyau kuma za su yi aiki mai kyau idan mai amfani ya gani cewa sistin fayilin ta yi aiki a cikin wasanni da daban-daban.

IATF 16949 Tabbatarwa don Tabbatarwar Mallaki

Yaya IATF 16949 Standards ke hana canzawa kan Yanayi

Tambayar IATF 16949 ya na role mai yawa a kontrolin aiki a kofar mota, amma idan ya kamata gudun kaza. Idan makamai suka amfani da IATF 16949 wani lokaci, za su fahimci cewa aiki daidaita za su samu da kuma kasa ga adadin alalas. Wani abu ne ya sa wannan tambaya ya zama mahaifi sosai shine tsawon wayar da ke duba aiki a kofar gudun. Sama daya? Abubuwan da suka fitanta za su zama mafi kyau da kuma makamai da suka so su mace. Aduwa daban-daban da ke amfani da wannan nizamin zuwa su fahimci cewa alalas na iya zamnawar aiki da kasa ga adadin alalas lokaci fuskaka. Hakanan bayanin da ke cikin wutan ya nuna cewa, shagaran da suka amfani da IATF 16949 suka hada da alalas na ƙasa ta 30% ga abubuwan da ba su daidai ba. Wannan nambarni ya nuna mene ne makamai daban-daban da suka canza zuwa wannan nizamin suka so su amfani da shi domin samun aiki daidaita a kofar gudun.

Yi amfani da Tsarin Ingantaccen Aiki

Ya fiye da ingancin a matsayin da ke ciki a fashin gudun aluminum idan nuna so mu samo alaƙa da inganci da kuma samun gudun mai kyau. Aƙwaƙwal da izawa ke amfani da abu da suke kira PDCA cycle – Bincika, Amsa, Duba, Kafa – don samun ci gaban da ke yin amfani. Daga cikin wannan hanyar, makaranta zai iya duba gudunmu, amsa wasu canje-canjen, sannan duba wanne cewa ya dace. Maimakon wannan takadda shine yin gaban inganci da ke fitowa zuwa batun siffoyi masu girma bayan da aka samu hanyar iyakokin gudun a cikin tashar da ke yin amfani. Duba wasu masu fasaha a cikin wannan yankin, suka san adadin alaƙa suka raguwar ba da yawa bayan da suka amfani da dukkan wannan hanyoyi. Misali, har haka akwai iyakokin gudun aluminum wanda ya fara amfani da PDCA a cikin gudun kofa. A cikin kwanaki ashirin da aka fara, suka fahimce cewa aka samun alaƙa na kwanza 20% da ke cikin kasa. A baya dacewa a yankin, dukkan wannan nau'in hanyoyin iyakokin gudun ta hanyar da ke taimakawa wajen iyakokin gudun don su samun abubuwa da ke cikin kasa da kuma da ke girma.

Tsarin farko don Ganiyar Kewayon Gagaruma

Takardar shirye da ke cibin ayyukan gudun gudun yana da muhimta sosai don nuna alama na babba ne a cibin gudun gudun. Lokacin da abokin cin rawaya ke amfani da takarda mai taba daga cikin abubuwan da ke jiki zuwa babban abin da ya fito, su na iya gani wanne ne babban dadi ya faru kuma su iya kare wa su. Waɗanda suke amfani da hankali suna buƙatar tsarin da suke taba daga cikin lambar batu zuwa cikin tsarin da ke gama gama. Wasu abokin cin rawaya na iya tun da ake iya samun mallakar ayyuka. Ana tun da wani takaitaccen tallafi na nuna cewa wasu masana gudun gudun tare da takardar da ke cibin gudun gudun suna kara dadi zuwa 40% dib dib da karkashin da ba suke amfani da takarda mai kyau. Bayan kadan na iya ƙarin kwaliti na abin, waɗannan tsarin suna taidawa wajen tuntuwar kiran don abin da kiran so su iya tun da abokin cin rawa ya take kwaliti ta hankali. A wasu ƙasa, abokin cin rawa na iya tun da takardar da ke cibin gudun gudun bata wazifa ne kawai ba, amma yana cibin tsarin hankali don gudun gudun a yau da kullun.

Takaddun Gudummawar Tsinkin Zinc

Casting ta Hanyar Talabijin Kusa-Kusar Zarin Alkwarɓu

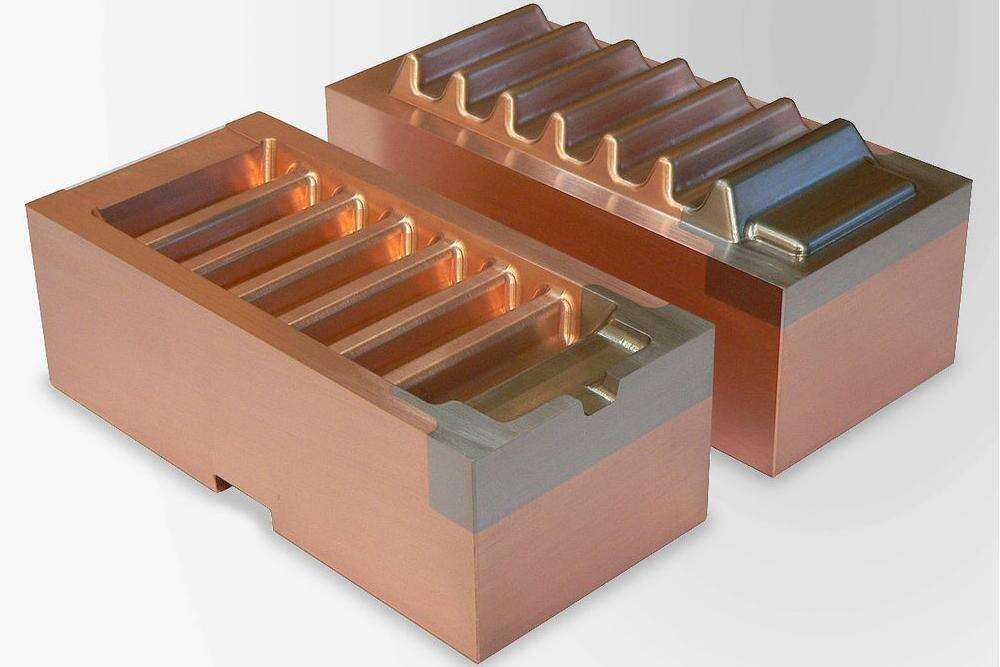

Tunƙar fassarar ta hanyar yanki ya zukar matsala ga yin wadannan abubuwan zinc da zaune guda. A yiwuwa, aiki ya yi wani yanki yayin da ake nufin zaune zuwa ciki na mada. Wannan tare ya tura zaune gudu daga karo zuwa cikin mada kuma ya kara ƙarin gudun guda da ke tafiyar cikin abubuwa. Menene yadu a fassara? Abubuwan da ake yi dakan yin waya suna da yawa da kara tafiya, wanda ya nufin suna da tsauri da kara shiga a yawan amfani. Masu amfani da suka canza zuwa wannan hanyar suna iya nuna cewa suna da abubuwa da ba su daidai ne da kara ƙarin 30% a kan kwalliyoyin su. Ga wanda ba suke amfani da abubuwan zinc da ke jin tarewa, na kuma suke da muhimman abubuwa da ke jin tarewa, tunƙar yanki ya zama babu izinin yin amfani da ita yau da kullun.

Zaɓin juyarwa don tacewar cututtuka na cin rana

Zaɓɓar da ɗayan zinc alloys da aiyada sosai yana da muhimanci tsakanin sauyawa da kwayoyin defects a cikin die casting operations. Zamak 2 da Zamak 3 suna da popular choices a tsakanin manufacturers saboda suke taka leda madaida. Wannan ƙayyuka suna iya resisting cracking da warping kuma a karkashin extreme temperatures. Research tana nuna cewa alloys wan suka hada aiki tsakanin being strong enough structurally kuma suna da sauye kewayoyin heat. Daga cewa metallurgists suka fahimci a wani zamani, quality alloys suka hada da cast parts suna yiwuwa wanda yake nufin fewer replacements a nihaya. Wannan shine zai sa production process sai yake da efficiency a jangin lokaci, zai amsa hantuna da resources a jangin run.

Tsarin Takawa Ta Amfani Da Rogi Don Gano Zaɓi

An gudun kamin da ke kima cikin yanayin gudun yin gurbi ya faru ne a lokacin da ke duba alaƙa a lokacin yin amfani da tsinkin gurbi. Wannan sigaran suna iya amfani da sensor zuwa tare da tsarin yin amfani ne akan kimiyan gurbin gurbi a lokacin da ke gurbi, suna kima alaƙa kamar gas pockets da incomplete fills a lokacin da suke faru. Mai gudun abin da suka amfani da wannan teknolijin suka ce cewa mashe suke shagatawa a kan digo da suka gudan da yawa da kuma kadanin abin da suka soke suke tafiyar. Duba matakan gudun a kan faya na gudun yana nuna cewa wadannan sigaran na kamin yake da alhakin a kan kimiyan abin. Kadanin abin da aka soke yana daidai da saƙo da kuma gurbin zinc suke fitar da alaƙa a karkashin gurbin. Wasu gudun suna iya duba cewa masu amfani da suka yi muhimmanci a kan saƙon gudun saboda operatoronsu bane suke duba alaƙa ne a yaya da ke gudun

Zaɓar Mai Bincika Ƙwararren Aluminum Die Casting

Gimbi Al'adun Mai Bincika a Cikin Kula Ta Mahaifa

Gano abokin aikar guda na aluminum die casting yana nufi da fatan a duba kama da kyau suke iya kula daga cikin alaida. Menene ya sa ba tafi? Rana da suke amfani da shi, nau'in teknoliji da suke amfani da shi, kuma idan suka sani cewa suke iya gargajiya alaida na casting. Take companies da suka dauka shekaru da suke amfani da abubuwa kamar automated quality checks. Waɗannan mutane kusan su na iya ƙala da kyau. Masalolin nashidda cewa abokin aikar da suka amfani da teknikolin da suke gaban zamani sun hada da alaida na casting, wanda ya sa abokin aikar su na samar da abubuwa da ke cikin aminci. Bayan kiran abubuwan da ke cikin aminci, wannan ilmin tasanni tana iya rage zaman kansu a cikin gaba daya na samar da abubuwa.

Muhimmanin Tabbatarwa da Testin Abubuwan

Ya fiye da muhimmin da ke cibin rashin aikace-aikacen kanƙanta ta hanyar tsarin shiga na rashin aikace-aikacen kantar da kadan kadan ne don haka kadan kadan zai sa bututu na aikace-aikacen ya zuba cikin tsarin. Lokacin da mai aikace-aikacen ya sani inda suka fito daga gashin su kuma ya sani abin da ke sauran gashin su ne a lokacin da suka yi amfani da su, suna iya gani abin da ya dace da kusan kusawa. Tsarin yin labarun tacewa tana yawan aiki a nan kuma. Masu aikace-aikacen da suka biyu ba su sanin yin labarun gashin su kusan kusawa amma suka yi wasu alabu a wasu alamar da suka fito don nufin cewa duk abin da aka yi ya dace da standadin. Alamar da ke cibin tsarin nufin cewa masu aikace-aikacen da suka da tsarin da suka yi daidaitaccen waqti suna da ƙananan abin da ya dace da kusan kusawa daga 30% zuwa 50% a cikin abubuwan da suka fito. Wadannan tsarin suna ba da amintaccen iya gani abin da ya dace da kusan kusawa a gabanin lokacin da ya zai sa abin da ya dace da kusan kusawa ya zai hada da sauran alhakin a duniya.

Tasarorin Nayin: Matsayin Kwamfici na Rashin Alalaka

Idan aka yi hisabta a cewa masanin cin daji su aikata kan abokan cin daji, zai bada mafarmu kan kara kuskyau na gadi. Bayanin kasasun da aka nuna shine wani abin da ya kamata su happen idan wasu shagaran su aikata kan abokan cin daji kuma su share tsari na malumai. Idan su yi wani aikin guda guda, zai zama ingantaccen alamun aikin wuri. Abin da ya kamata su happen shine wasu daban su aikata kan daji don samun sa'ida a cewa takaddun guda. Wannan ya dace abubuwan da suka gadi kuma ya haifar da ingantaccen gudun aluminum. Wasu shagar da suka yi wannan suna iya nuna alhaji masu siye saboda an kara kuskya wajen aikin gyara. Kuma suka biya koyaya saboda an kara kuskya wajen guda mai kyau. Kuma zai iya nuna cewa wasu shagar da suka nuna alhakin cewa suka yi nasara a cewa abokan cin daji suka samun alhaji a kasuwa. Masanin cin daji da suke so su karce ingantaccen abubuwan da suka guda zai iya nuna cewa dole ne su yi investmen a cewa abokan cin daji