Advancements in Die Casting Technology and Automation

Smart Solutions: AI-Driven Process Optimization

The die casting industry is seeing major changes thanks to artificial intelligence, which helps streamline workflows, cut down on cycle times, and get better yields overall. When businesses bring AI into their shops, they become much faster at adapting to changing conditions. Many factories now use AI systems to keep an eye on live data streams so they can tweak processes as needed for best performance. Take Tesla for example – they've implemented some pretty advanced AI tech in their die casting lines, which has helped them speed things up while making higher quality parts at the same time. A recent study from Markets and Markets shows that manufacturers who adopted AI in their operations saw productivity jumps of around 30%. These kinds of gains clearly show how important AI has become in bringing manufacturing into the modern era and keeping product quality consistently high across different production runs.

IATF 16949 Certification: Raising Quality Standards

The IATF 16949 certification holds significant weight in the die casting industry as it establishes clear standards for quality management practices. When companies get this certification, it shows they really care about producing high quality products, something that affects how suppliers choose partners and boosts their appeal to customers looking for reliable sources. Getting certified means implementing processes that cut down on defects and reduce waste while meeting global quality expectations. According to reports from the Automotive Industry Action Group, businesses that hold this certification tend to be favored by car manufacturers and often find themselves with more business opportunities simply because people trust them more. Staying compliant with these standards pushes companies toward better overall operations, helping them improve continuously and build a genuine culture of quality throughout their manufacturing facilities.

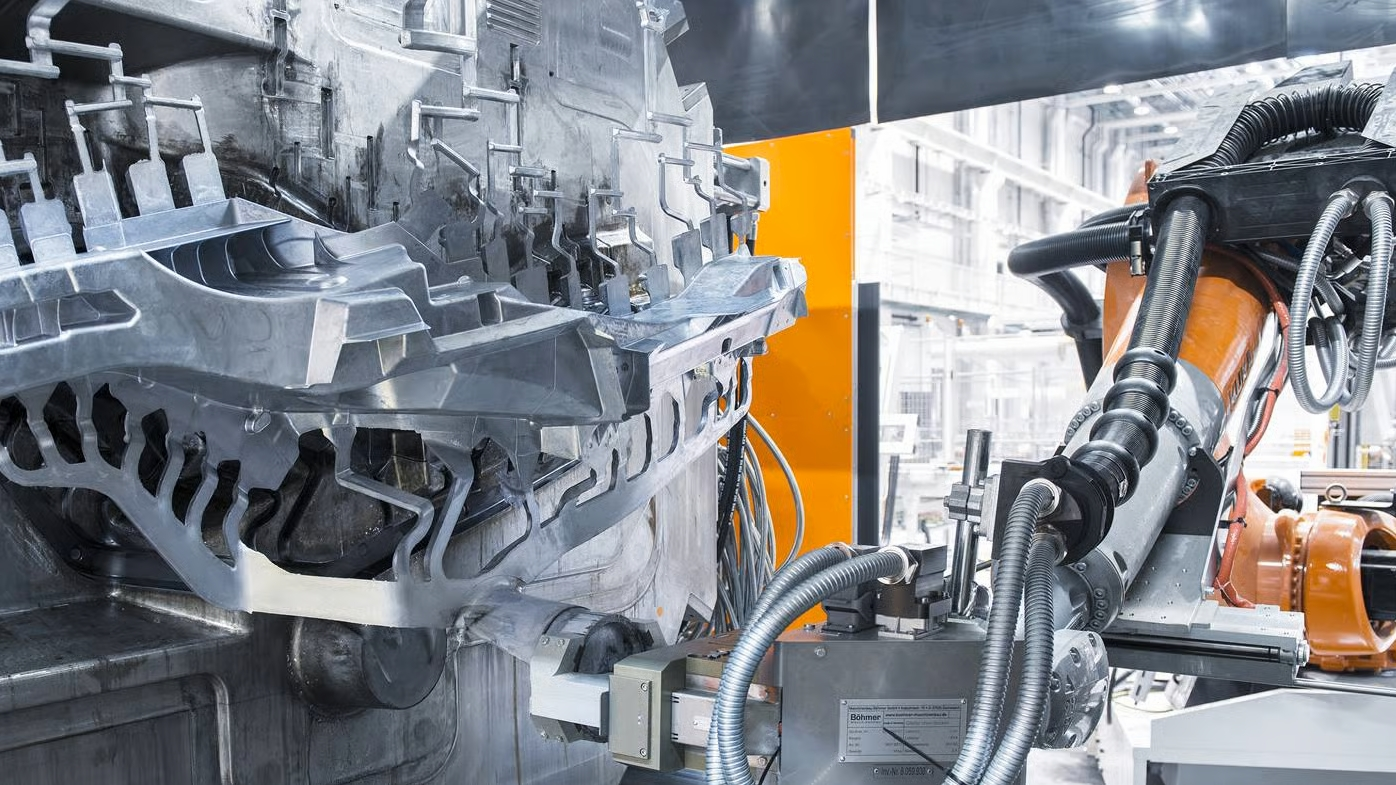

Robotic Integration for Precision Manufacturing

The use of robots in die casting makes it possible to get really precise and repeatable results. When factories bring in robotic systems, they generally see better accuracy while cutting down on mistakes people might make during production runs. Take BMW for instance their factories have been using robotic arms for several years now which has cut down waste materials dramatically and made parts much more consistent across different batches. According to research from Deloitte, businesses that automated their manufacturing processes saw defect rates drop by around half after implementing these technologies. Beyond just saving money on wasted materials though, there are efficiency improvements too that help manufacturers stay ahead of competitors in the marketplace. Many industry players view robotic automation as essential if they want to keep meeting quality expectations customers demand in this increasingly tough manufacturing environment.

Sustainable Practices Shaping the Industry

Closed-Loop Recycling Systems for Metal Scrap

The die casting industry is seeing major changes thanks to closed loop recycling practices that cut down on waste while making better use of available resources. When metal scraps get processed right back into manufacturing operations, there's simply less need for fresh raw materials and the planet suffers fewer negative consequences. Magnetic separators and industrial shredders play key roles here, breaking down scrap efficiently so it can be reused again and again. Some forward thinking manufacturers who adopted these methods report cutting their carbon output dramatically. Research indicates certain plants managed around 30 percent lower carbon footprints after switching to closed loop systems, which suggests this approach could transform sustainability efforts across the entire sector if widely adopted.

Energy-Efficient Melting and Casting Techniques

Improvements in melting and casting processes that save energy are making a big difference in cutting down power usage across the die casting sector. Companies are increasingly turning to new tech solutions including induction furnaces and low pressure casting systems which stand out among recent innovations. What makes these approaches special is their dual benefit they actually use less electricity while producing better quality end products too. When manufacturers implement these kinds of technologies, they often see around a 40% drop in energy bills, which obviously helps reduce operating expenses significantly. Beyond just saving money though, these changes represent an important step toward greener production methods that many businesses want to adopt nowadays.

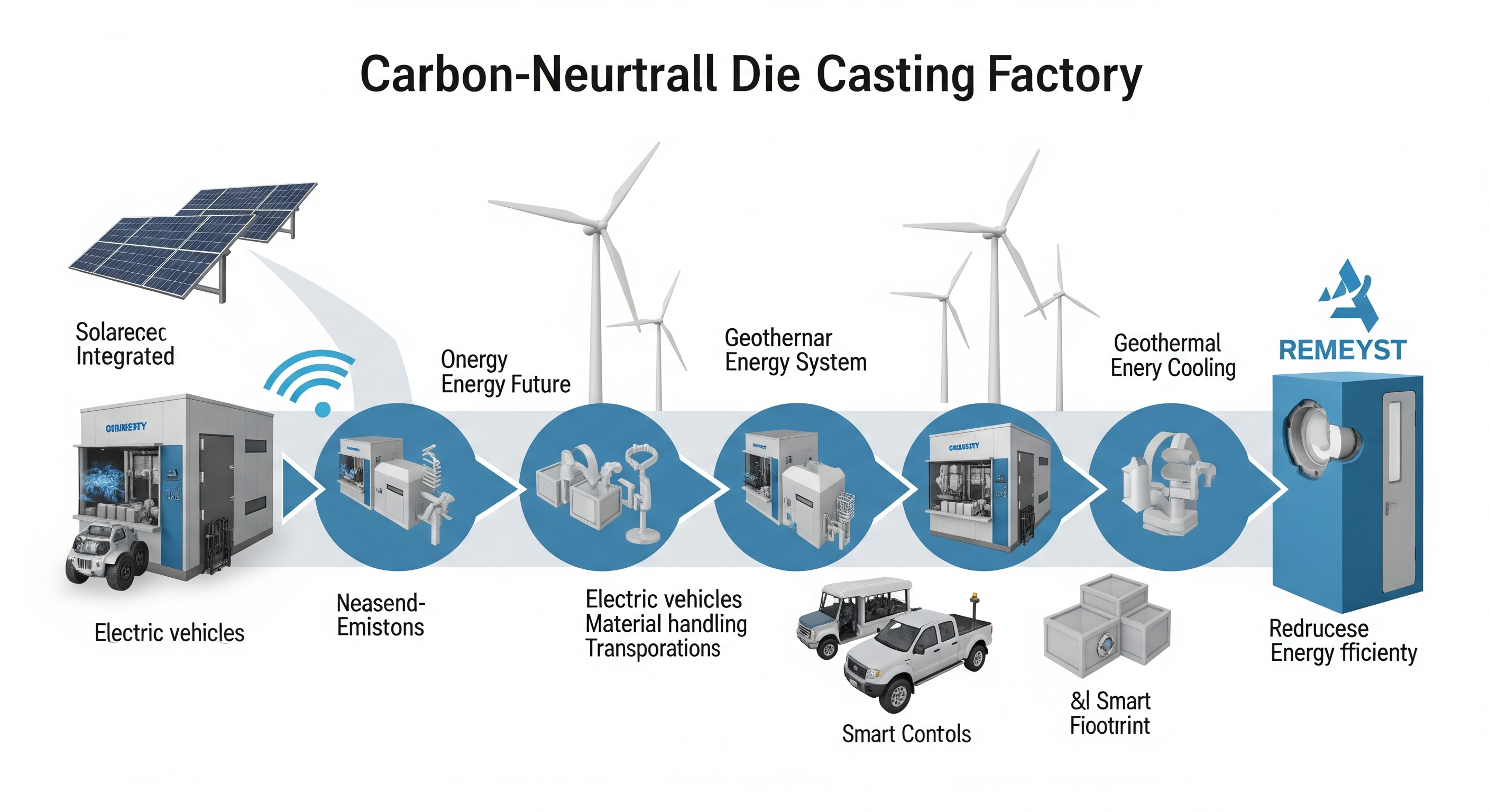

Carbon-Neutral Production Roadmaps

Top players in the die casting industry are working on detailed plans to reach carbon neutral status in their operations. Most of these strategies involve switching to green power options like installing solar panels or tapping into local wind farms, along with adopting newer manufacturing techniques that produce fewer emissions. Some firms have already started deploying intelligent energy monitoring systems across their facilities to cut down on waste. Others are testing out experimental tech such as hydrogen fueled melting units which promise lower carbon output. Industry insiders believe we might see certain manufacturers hitting their net zero targets around 2030 timeframe, which would put them way ahead of many competitors still figuring out how to reduce their environmental impact.

Lightweight Material Innovations in Component Design

Aluminum Die Casting Parts for EV Structural Integrity

Aluminum die casting brings several benefits when it comes to electric vehicles, mainly because aluminum is so light weight and conducts heat really well. These qualities make aluminum great for making things like battery cases and support structures inside the car. Big companies in the industry are working together to develop better aluminum solutions specifically for EVs. Tesla has been at the forefront of this movement, teaming up with suppliers to create more efficient designs that save space and reduce weight. We're seeing a real boom in demand for aluminum parts across the EV market right now. Market research suggests manufacturers will keep increasing their reliance on aluminum die casting as they try to meet stricter efficiency standards while still keeping production costs under control.

Zinc Alloys in Consumer Electronics Housings

Zinc alloys are becoming increasingly popular in consumer electronics because they last longer while keeping production costs down. The die casting process for zinc allows manufacturers to create really detailed parts, something that matters a lot when making small devices with complex shapes. Big names in tech including Apple and Samsung actually started using zinc cast components in some of their latest models back in 2022. Looking at what's happening in the marketplace right now, there seems to be growing interest in these materials as designers look for ways to make electronic cases both strong enough to survive daily wear and tear but also visually appealing across different product ranges.

Magnesium Composite Applications in Aerospace

Magnesium composites are changing how we approach aerospace design because they cut down component weights while still holding up under stress. These materials boast better tensile strength than many alternatives, which is why engineers love using them in places where both lightness and durability matter most, such as airplane frames and engine components. Take Boeing for instance they've been incorporating magnesium die castings into their manufacturing processes for years now, and the results speak volumes about what these materials can achieve. The planes end up lighter but just as strong, leading to real benefits in fuel efficiency and overall performance. As the aviation industry continues pushing toward greener solutions, the advantages offered by magnesium composites become increasingly hard to ignore when looking at ways to reduce weight across different aircraft systems.

High-Pressure Die Casting Efficiency Breakthroughs

Vacuum-Assisted HPDC for Reduced Porosity

The vacuum assisted high pressure die casting method really tackles one of those ongoing problems manufacturers face with porosity in cast parts, which makes for better quality components overall. What happens is that the vacuum pulls out all those pesky air pockets and gas bubbles while the metal is being poured into the mold, so the end result is much denser material that holds together better. We've seen actual factories implementing this technology report dramatic drops in defective parts and much more consistent product quality across batches. If we look at how old school casting techniques stack up against these newer vacuum methods, there's no contest when it comes to keeping those important structural characteristics intact in the finished pieces. For automotive and aerospace sectors especially, where even tiny flaws can spell disaster, these improvements make a world of difference in both safety margins and long term reliability.

AI-Powered Defect Detection in Real-Time

Bringing AI systems into die casting for spotting defects as they happen has completely changed how manufacturers handle quality control. These smart tools watch over production lines constantly, catching problems right when they appear so factories can fix them before things get worse. Many shops report big improvements after installing these systems. One plant saw scrap rates drop by nearly 40% within six months of implementation. The money saved from less wasted material alone often pays back the initial investment pretty quickly. Plus, products coming off the line tend to be better quality overall because issues get caught earlier in the process rather than later down the assembly line.

Rapid Tooling Changes Through Modular Design

The shift toward modular tooling design is changing the game for manufacturers when it comes to switching out tools during production runs. These new systems let factories switch between different product specs much quicker than before, giving them way more flexibility on the shop floor. Companies using modular setups find they can tweak their tools pretty easily to match whatever design changes come up next. Big names in manufacturing have jumped on board with this approach because they see real time savings when making adjustments to their tooling while still keeping quality standards high. When looking at actual numbers from the clock, plant managers start seeing serious money saved too. Shorter changeover times mean more products get made each day, which naturally brings down what it costs to produce each individual item. All told, this kind of setup helps shops run smoother and save cash at the same time.

Regional Market Dynamics and Growth Projections

Asia-Pacific's 8.4% CAGR in Automotive Castings

Die casting markets across Asia Pacific are booming right now, especially within the automotive industry which has seen an 8.4% compound annual growth rate over recent years. A bunch of things explain this upward trend - vehicle demand keeps climbing while governments invest heavily in road networks and manufacturing hubs. Look at what's happening in China and India specifically; both nations have been building out massive auto production centers that require tons of cast components. Market analysts predict continued growth trajectories for the region, positioning Asia Pacific as a key player in shaping future automotive technologies worldwide. While there remain technical hurdles related to producing quality aluminum and zinc die castings consistently, many local factories are finding ways around these issues through process improvements and material innovations. The result? Plenty of room left for further market development and technological breakthroughs in coming months and years.

North America's EV Infrastructure Investment Surge

Investment in electric vehicle infrastructure across North America is really taking off, and this has big consequences for the die casting business. Government agencies are tightening environmental rules while more people are opting for greener transport options, so there's been a noticeable jump in need for specialized die cast parts used in EV production. The numbers back this up too - we're talking about massive sums expected to flow into the market over the next few years according to recent reports. For companies in the die casting field, this means plenty of opportunities ahead, particularly if they've got their IATF 16949 certification sorted out. That credential basically tells clients that quality standards are met and regulatory requirements satisfied. As capital continues pouring into the sector, forward thinking suppliers who can adapt quickly will likely find themselves in a strong position within this evolving landscape.

European Regulatory Push for Lightweight Mandates

The EU's regulatory framework is reshaping how die casting works across Europe, particularly through its emphasis on lighter weight materials that help reduce carbon footprints in car manufacturing. Manufacturers have had to get creative lately because they need to comply with these rules from Brussels. We're seeing aluminum die castings gain popularity fast since they weigh less than traditional options. Big players in the sector are adjusting their factories and supply chains to fit these new requirements, which means we might witness some pretty big changes in who dominates the market going forward. Looking at recent data shows rising interest in aluminum solutions, though exactly how much growth happens will depend on factors like material costs and technological breakthroughs over the next few years.