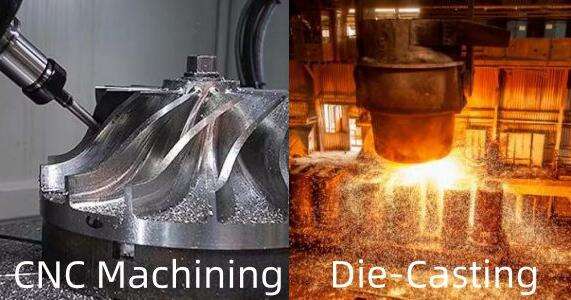

Understanding Die Casting and CNC Machining Processes

Fundamentals of Die Casting: Mold-Based Production

Die casting remains one of the most important ways manufacturers create parts by pushing molten metal into molds using high pressure. Two main approaches exist in this field: hot chamber and cold chamber techniques. With hot chamber casting, there's basically a built-in furnace keeping the metal melted all the time, making it work best for those metals that don't need super high temps to melt. Cold chamber works differently though. Here workers actually pour the metal into a separate container before injecting it into the mold cavity, which makes sense when dealing with metals that require much hotter conditions. Most commonly we see aluminum and zinc being cast this way because they're light weight and won't rust easily. Automotive companies love this method for creating things like engine blocks and gears. But it's also showing up everywhere else too, from smartphones to kitchen gadgets, thanks largely to how thin and smooth finished products can get with proper casting techniques.

CNC Machining Explained: Computer-Controlled Precision

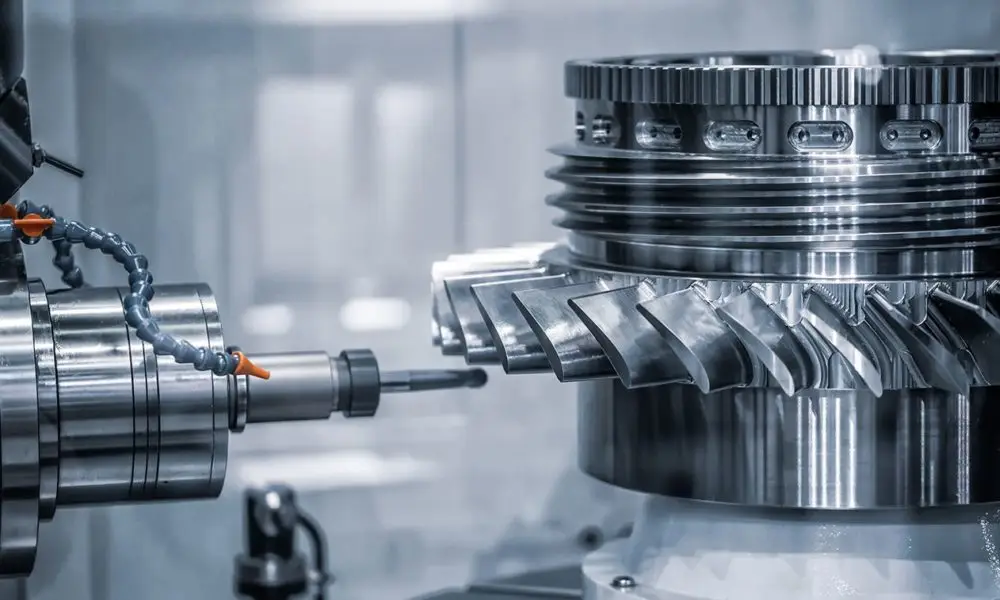

CNC machining stands out as an essential method in subtractive manufacturing where computer controlled tools chip away at solid blocks until they get the right shape. Different types exist including mills and lathes, each one good at different things from basic material removal all the way to fine details work across materials like metal, plastic or composite stuff. What really makes CNC machining special though is how accurate it gets. Parts made this way meet those super tight tolerances required for complicated designs used in places like aircraft manufacturing or medical device production. The programming aspect matters a lot too because these programs tell the machine exactly where to cut and move around. That's why parts come out so consistently precise every single time, even when there might be tiny differences between batches.

Material Options and Efficiency Differences

What kind of material gets used makes all the difference in manufacturing, especially when looking at die casting versus CNC machining. For die casting, manufacturers mostly go with non-ferrous stuff like aluminum, zinc, and magnesium because these metals flow really well during the process. They're great for making intricate parts that need to be consistent across thousands of units. CNC machining works differently though. It can handle pretty much anything from metals to plastics and even some composite materials. This versatility means shops can tackle a wider variety of projects without switching equipment. When it comes to getting things done fast, die casting wins hands down for big orders. The machines crank out parts quickly with little waste, so production stays steady. But if a company needs to make adjustments mid-project or work on smaller batches, CNC machining offers that flexibility. Many fabrication shops actually keep both options available depending on what their customers need most at any given time.

Statistics show die casting's rapid production speed, with cycles often lasting only seconds to minutes, is ideal for mass production, whereas CNC machining might be slower due to its subtractive nature, which inherently involves more time-consuming processes.

Production Volume and Cost Analysis

Looking at how much stuff gets made versus what it actually costs, there's a big difference between die casting and CNC machining. Die casting really shines when companies need to produce tons of parts because each individual item ends up cheaper once all those tooling costs get spread out across thousands of units. That's why car manufacturers and makers of gadgets love this method so much they can count on every single part being exactly the same. On the flip side, CNC machining tends to set people back more money per piece since it cuts away material rather than pouring molten metal into molds. While setting up a CNC machine doesn't cost nearly as much initially compared to creating dies, all that wasted material adds up fast. So most folks stick with CNC when they just want to test something out or make a few dozen prototypes before going full scale.

Industry reports back the notion that die casting maintains financially feasible production over extended periods, whereas CNC machining's adaptability suits lower-volume needs better. The cost per unit analysis reveals that for high volumes, die casting remains the more economically viable option, while CNC machining offers flexibility for smaller runs.

Precision, Tolerance, and Complexity Capabilities

When comparing die casting versus CNC machining, one of the biggest differences lies in how precisely each method can manufacture parts. CNC machining stands out because it creates components with really tight tolerances, often getting down to around plus or minus 0.0005 inches. That makes it perfect for complicated parts that need exact measurements, like the tiny gears used in airplanes or medical equipment where even small errors matter a lot. Die casting isn't quite as precise though, usually falling somewhere between plus or minus 0.002 and 0.005 inches. For many projects this level works fine, but sometimes manufacturers have to do extra work after casting to get everything looking right and meeting all the size specifications they need.

Computer Numerical Control (CNC) machines are really good at making complex parts because they can cut materials with pinpoint accuracy controlled by computers. Die casting works better for simpler parts where exact measurements aren't so critical. According to recent studies published in the Journal of Manufacturing Processes, there's clear evidence showing that CNC machining beats out other methods when dealing with complicated shapes inside parts and maintaining very tight tolerances during production runs. This makes sense practically too since many industries need components with internal features that just cant be achieved through traditional casting techniques alone.

Lead Time and Flexibility Adaptations

When looking at how fast things get done and how adaptable each process is, there's some interesting stuff about die casting versus CNC machining. CNC machining generally cuts down on waiting time, which makes it great for making prototypes or getting products out quickly when designs need changing. No need to mess around with physical setups when adjustments are needed. On the flip side, die casting works well for big batches but takes longer because creating those tools and molds just takes time. The whole process from start to finish can drag on months sometimes, especially if there are any last minute changes required in the tooling.

CNC machining offers real flexibility that lets designers make changes throughout a project's lifecycle. This stands in stark contrast to die casting, which requires completely new molds whenever there's even a minor design tweak. And let's face it, creating those molds takes both money and time. Manufacturing reports consistently point to this advantage of CNC machining, especially when fast turnaround times matter most. For instance, automotive companies often switch to CNC when developing prototypes because they can adjust parts on the fly without waiting weeks for mold revisions. The ability to adapt quickly makes all the difference in competitive markets where getting products right matters more than ever.

Applications and Industry Standards

Ideal Projects for Aluminum and Zinc Die Casting Parts

When it comes to manufacturing parts that need to be light yet tough against wear and tear, aluminum and zinc die casting really shine. The electronics world loves aluminum because it conducts heat so well, which is why we see it all over in heat sinks for computers and other gadgets. Meanwhile, zinc has become something of a workhorse material in car manufacturing thanks to how strong it is while still being easy to shape into intricate designs. Take a look at modern vehicles and their countless tiny connectors or the protective cases around sensitive electronics components – these are often made from zinc. What makes both metals stand out isn't just their performance characteristics but also how they hold up when produced in large quantities without breaking the bank. Manufacturers have found that switching to these materials can save money long term while maintaining product quality standards.

When CNC Machining Excels: Complex Low-Volume Components

When companies need precise custom parts for small production runs, CNC machining becomes essential. Look at the aerospace sector or medical device manufacturers who rely on this technology to make complicated parts where even minor flaws could lead to major problems down the line. What sets CNC apart is how it handles those intricate details with remarkable accuracy, which is why so many designers turn to it during the prototype stage. They get to test their ideas without breaking the bank compared to traditional methods like die casting that just don't make sense economically for limited quantities. For businesses working on specialized products, CNC offers both flexibility and reliability when other options fall short.

IATF 16949 Certification Considerations

Getting IATF 16949 certification matters a lot when it comes to making sure quality management works properly across the automotive supply chain. To meet this standard, manufacturers need to stick closely to established best practices in their day to day operations. For companies involved in die casting or CNC machining, having well documented procedures and constantly looking for ways to improve becomes essential before they can even think about getting certified. When businesses comply with these requirements, products tend to be better quality overall. Customers start trusting them more too, which helps secure contracts in the tough automotive market where getting things right every time makes all the difference between success and failure for most suppliers.

Choosing Between Die Casting and CNC Machining

Key Decision Factors: Volume, Budget, and Requirements

Picking between die casting and CNC machining requires looking at a few important things to find what works best for any given manufacturing job. Production volume matters a lot here. Die casting tends to save money when making thousands of parts at once, but gets expensive for small quantities. On the flip side, CNC machining handles those smaller orders much better, especially when each piece needs something unique. Money is another big factor. The upfront tooling costs for die casting can really add up, though this drops the cost per unit once production ramps up. CNC doesn't require these special tools, so it stays affordable even for limited runs. Material options, part complexity, and how flexible the design needs to be also come into play. Take projects needing tight tolerances or regular design tweaks? CNC machining often makes more sense in these situations.

Companies looking at their options often find decision matrices really helpful for getting clear on exactly what they need. While I cant show an actual example here, most people look at things like how much each item costs, how much waste gets created during production, how long it takes to get stuff made, and whether designs can be changed easily later on. When businesses take all these aspects into account, they end up making better decisions that actually match what they want to accomplish. Real world examples help too. Looking at what other companies did when facing similar problems gives some good ideas about how to handle things without breaking the bank or slowing down operations too much.

Real-World Scenarios: From PV Inverter Housings to Prototypes

Looking at what happens on factory floors shows how tough it can be for companies deciding between die casting and CNC machining techniques. Take PV inverter housing production as an example. The choice of materials matters a lot here. Many manufacturers go with CNC machining when they need something really precise or want to test out multiple design variations quickly. With this approach, businesses get to try different configurations without shelling out big bucks for brand new dies every time. On the flip side, die casting works wonders when there's a need for consistent quality across thousands of identical parts. This is why we see it so much in industries that churn out standard components by the truckload.

Looking at all these different options teaches us something important about manufacturing decisions. First off, companies need to figure out what matters most for their particular situation. Is design flexibility top priority? Or maybe they care more about how many units they can produce or keeping costs down? Once they know where their focus lies, picking the right manufacturing approach becomes much easier. When it comes time to actually make parts, manufacturers must pay close attention to what exactly they need. Take PV inverters for instance. Some might worry about prices while others look at material properties. Should they go with zinc die casting or aluminum? That depends on factors like required strength levels or resistance to corrosion over time. From what we've seen across various industries, taking the time to analyze past experiences really pays off. Companies that learn from previous mistakes tend to find better ways to balance all those competing demands between different manufacturing methods.

Table of Contents

- Understanding Die Casting and CNC Machining Processes

- Material Options and Efficiency Differences

- Production Volume and Cost Analysis

- Precision, Tolerance, and Complexity Capabilities

- Lead Time and Flexibility Adaptations

- Applications and Industry Standards

- Choosing Between Die Casting and CNC Machining