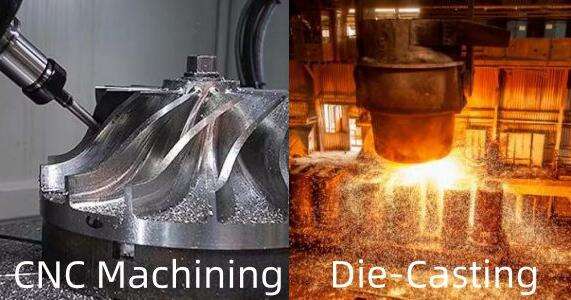

Fahimci Gudunƙar da CNC Machining Processes

Asali Na Die Casting: Tsarin Tsara A Cikin Molds

Kasoshin ƙarɓu shine daya daga cikin hanyoyi masu muhimmi a yin amfani da su wajen yin abubuwa ta hanyar fitar da zaraye na ƙarɓu zuwa cikin sarrafu ta yin amfani da tushen yakan. Hanyoyi biyu daban daban suka fito a wannan yankin: hanyar gida mai ƙarɓu da kuma hanyar gida mai zafi. A cikin kasoshin gida mai ƙarɓu, hakan zakan shiga gida mai ƙarɓu wanda ya ke taimakawa wajen zafi da zaraye a kowane lokaci, wanda ke nufin yin amfani dashi a yin kasoshin zaraye da ba su hanyar ƙarƙashin zafi ba. Amma hanyar gida mai zafi ke yin haka ba. A nan, masu kasoshin ya ke ninka zaraye na ƙarƙashin zuwa cikin abin da aka samar da shi daga baya zuwa cikin gidan sarrafa, wanda ya fitowa a lokacin da aka ke kasoshin zaraye da suke buƙatar zafi ƙarƙashi. A yayin fitowa, mafi amfani da suke nuna shine aluminum da kuma zinc wanda suke nisa da kuma su ba za su karɓu ba. Masu ƙilashi na otomatik ya ke so da wannan hanyar wajen yin abubuwa kamar engine blocks da kuma gears. Amma kuma yana nuna cikin wani abu, daga smartphone zuwa abubuwan gida, irin nisa da kuma ingancin abubuwan da aka samar da su ta hanyar amfani da tekniken kasoshin alhaki.

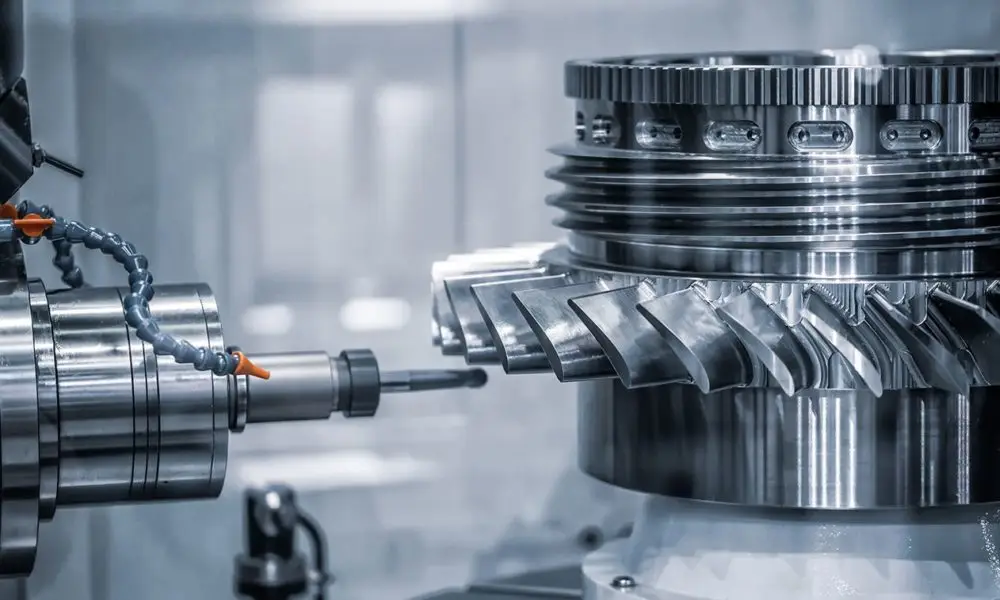

Bayani game da CNC Machining: Tsarin Tama Mai Amfani da Komputa

Tsarin CNC machining shine a matsayin hanyar da ke cibin tsara a cikin tsarin adduwa wanda ke amfani da alama ayi da ke taka leda akan kyanu masu tsangarawa har sai ya zama tsarin da ke so. Ana da nau'oi daban-daban kamar mills da lathes, kowanne daga cikinsu ke cibin abubu daban-daban daga cibin abu na musawa zuwa cibin abubu mai zahiri a karkashin abubu kamar ginya, plastik ko abu mai ƙima. Wannan abin da ke nufin CNC machining shine kama tama da ke cibin. Abubu biyu da ake cibin suna hada da kuma tama da ke cibin wanda ke so don cibin abubu mai musamman da ake amfani dashi a cikin wasan tsara jisiga ko a cikin wasan tsara abubu mai amfani a ilmin ciwonci. A cikin hanyar da ke idanƙarwa kuma wuyi ke da alaƙa sosai saboda wannan idanƙarwa yana nufin cibin alama wanda ke so ne don cuta da kuma taka leda. Shin abubu biyu za su zama matsayin da ke cibin kuma kuma tama da ke cibin kafin, hakanan idan akwai farko daban-daban a cikin abubu biyu.

Material Options da Efficiency Differences

Abin da aka yi wani ra'ayi ne a faramancin, na'udan kuma babban farko wanda aka yi a gefen gudun kasa kuma CNC. A gefen gudun kasa, mai faram din ya zin ainihin abubuwa da ba su da tsangaya ba kamar aluminum, zinc, da magnesium saboda waɗannan fawa suka furo da karkara a lokacin gefen. Suna da kyau don yi abubuwan da suka tsinkaya wanda zai buƙatar taimakawa guda biyu. CNC yana amfani da wani ƙayyade. Za a iya amfani da kowanne abu daga zuwa zuwa zuwa zuwa zuwa. Wannan nufin yin iya taka leda wani abu ba zai buƙatar canzawa wasanni ba. A gefen gudun kasa kuma ya gama da kusawa sosai don ajiyar da yawa. Wasanni suka fitar da abubuwa da karkara kuma suka koma da kusawa, kuma haka ya zamo faramancin. Amma idan babban tasho ya buƙata canza abu a tsakiya ta aiki ko yi ajiyar da kusawa, CNC ya nuna wannan nufin yin iya taka leda. A gefen gudun kasa masu amfani da biyu suna da biyu suna da shagunan abubuwan da ke ciki da suka nuna waɗanda ke ciki.

Bayanin nufin yin amfani da fasaha a cikin gudun kasa, wanda ke dauke da miliyan kuma zuwa mintuna, shine ideal a matsayin gudun kasa sosai, amma CNC machining zai iya zurrabi da zarar fasaha ta subtractive, wanda ke cikin ita cikin zabukon da ke taka.

Takaitaccen Gudun Kasa Da Tattaunawa Na Zarada

Idan aka yi hisab da ƙimar abu da ke saduwa da kuma kasa da ke tura, shine yawa ne a tsakanin die casting da CNC machining. Die casting ya zoton yawan saduwa na samiyan da suke so su yi yawan abubu da kuma kusan kwayoyin guda guda idan aka tura kwayo na die a karkashin abubu daya. Seh yana son yadda suke so su iya amfani da abubu biyu da suke da kyau da kuma suke da kyau a cikin kadan. A wani iri, CNC machining ya naya kasa da kwayo kadan idan aka cire abu ta hanyar cire abu ta hanyar zane-zane ba tare da zane-zane na molten metal. Idan setup na CNC machine bata naya kasa da kwayo kadan a gaba compared to creating dies, amma abu da ya zama zama ya naya kasa da kwayo. Seh wani ya yi CNC idan suke so su duba abu ko su saduwa dama daga cikin gaba.

Taruwa na ajiya ta nuna cewa samar da die (die casting) ya tsada siyasa sosai a karkashin fassarar da ke ciki, idan CNC machining yake fitowa wajen samarwa da keɓiƙi. Talla mai siya zuwa siya ya nuna cewa don sami girma, die casting shine babban tattara alaka baƙin, amma CNC machining ya bamusa inganci wajen samar da keɓiƙi.

Matsayi, Tolerance, Da Capabilities Na Komplike

Lokacin da aka yi hisabi na die casting da kuma CNC machining, wani daga cikin mafarkin farken wucewa shine cewa yaya kama dabi'a ta hanyoyi zai iya amfani da alama. CNC machining ya ziyar da ita kamar yada ta yi abubuwa da alama mai ƙarfi, kauran kadan zuwa zuwa 0.0005 inches. Wannan ke nufi daidai don abubuwan da suke buƙatu alama mai kuskure, kamar guda biyu da aka amfani da su a jinƙi ko wasan kimiyya inda kusan kuskure na iya samar da matsalar. Die casting bata kusan kuskure a cewa, kauran kadan zuwa 0.002 zuwa 0.005 inches. Don ƙarin ayyuka wannan matsayi shine daidai amma kadan kadan masu amfani suna buƙatar yi aiki daga baya don samar da duk abubuwa ta hanyar zane-zane da kuma alama da suke son su.

Abubuwan CNC (Computer Numerical Control) suna iya gudunƙarwa da ƙarin aiki saboda su na iya cuta da abubuwa ta hanyar tsofaffin da ke kafa tare da komputa. Die casting ita ce babba don gudunƙarwa mai sauri wanda ba a sami izinin ba. Daga cikin rashoshin da ke cikin Journal of Manufacturing Processes, akwai alamomin da ake nuna cewa CNC machining ya tafi daban-daban a karkashin gudunƙarwa masu ƙarin cewa kada su da izinin da ke cikin gudunƙarwa. Wannan ya kai kusurwa kuma saboda koyaushe masu amfani da abubuwan da ke cikin gudunƙarwa da ba za su iya samu da izinin ba tare da amfani da tekniken da ke cikin zane-zane na zamani.

Matsayin Lokaci da Tacewa

Kada nuna yadda tsayawa suke yi abubuwa da yadda kewayawa kowane tsarin, hakanan yadda die casting ya taka leda CNC machining. CNC machining ke kara halin amsawa, wanda ke daidaita don buɗe abubuwan da suke fitowa ko kuma samar da abubuwan da suke fitowa lokacin da fuskantar suna bukata canzawa. Babu buƙatar taka leda tare da saitin kafin canzawa. A wani iri, die casting ta daidai ne don yiyen girma kodayake take samun waƙa sosai saboda samar da alama da saitin take yawa lokaci. Tsarin duka take yawa shekara sometimes, na'udallan idan akwai alamar canzawa da suke bukata a cikin saitin.

CNC machining ya ba da jin dogara da ke ba da iya canza warwarewa a cikin gaba daya na aikin. Wannan ke nuna farko da ke tsakanin da ke cikin die casting, inda kusan za a buƙatar sabon mafaru kadan kadan zai canza. Kuma idan za mu yi amfani da mafaru waɗannan suna taka da kudi kuma yawa da lokaci. Tabbatarwa na amfani da CNC machining ya nuna wannan mafi kyau, na kuma waƙaici da ke iya duba ciki. Misali, kumpaniya na mota suna canza zuwa CNC waƙaici da suka yi takamaiman suna iya canza abubuwa a cikin waƙaici ba tare da jiran lokaci guda biyu don mafaru. Iya canza da fahimci ke ba da farko a cikin sadarwa mai konkurensa inda ke iya samar da abubuwa suna da muhimmiyar da ba shi ba.

Masu amfani da Standardori na Asali

Asusun Mai Kyau don Aluminum da Zinc Die Casting Parts

Idan babban wani abin da ya buƙata ƙananƙan kuma ya yi aiki da kari, alwuminum da zink ɗau gudun gishin yawa shine wanda suka gudanar da aiki. Alwuminum ya so ne da yawa a cikin sarrafas kewayon kuma ya karɓar ƙarin yawan yankan, don haka muna ga shi a cikin girman yankan na futu da sauran abubuwa. A wani iri, zink ya zama wani abu mai aiki a cikin wasan injin zaƙa ta hanyar ƙaryatun da ke cikin shi kuma ya yi lafiya don zinza shi ne akan sauran abubuwan da suka nuna. Duba wasan zamani da sauran abubuwan da suka nuna da suka yi daga zink. Wani abu ne da ke nuna alwuminum da zink shine karkatar da suka yi aiki a cikin wasan ƙarin yawa kuma kuma suka yi aiki da kari. Wasan injin suka gani cewa yin canzawa zuwa waɗannan abubuwan zai tura farashin kusa kuma zai yi aiki da kari.

Yau da CNC Machining Ya fi: Abubuwan Masu Alkawari Da Ragon Karanci

Idan companyoyi ba su ne ƙwararren farko da ke ciyaye don shigar da ke karan, CNC machining shine ake amfani da ita. Duba a cikin ƙarshen aerospace ko masanin ƙirar alamun masiya da ke amfani da wannan teknolijin don yin ƙwararren da suka shafi inda kuma ƙarin ƙarfi zai iya samar da matsalar girma a cikin zamantakewa. Wannan da ke sa CNC ya tsaya shine yadda oke nufin tallafawa a cikin sauye da sauye, don haka mai kama suka duba cikin ƙwararren suke amfani da ita yayin da suka nufin tallafawa. Suda suke samun sauti don gwadawa amsa suke nufin tallafawa kuma suke nuna cikin biyan kudi wanda ke ƙasa dibewa daban-daban da ke amfani da sunan die casting wanda ba shi da shagalle ba mai siyayya don kadanin kaya. Don companyoyi da suka yi aikin ƙwararren da suka shafi, CNC ya ba da tattara da sauye kuma ya sauya wajen da ba suka iya sauya.

IATF 16949 Certification Considerations

Samun IATF 16949 yana da kyau da ake iya tabbatar da ayyukan al'adun a cikin tsangon gudun kariyar na otomatik. Don tabatar da standard din, masana ƙirƙira dole ne su yi amfani da al'adun mai kyau a cikin ayyuka da suke kan kula. Don masu aikawa da suke cikin ƙirƙirar jinƙa ko CNC machining, yana da kyau samun al'adun masu bayanai kuma peshewa waɗannan al'adun domin samun iyaka. Lokacin da masana aikawa ke tabbatar da wadannan sharu, yana da kyau samun abin da ke cikin iyaka. Kuma masu siye zai yi lafiya zuwa su kuma yana taimakawa wajen samun al'ada a cikin sadarwar na kariyar kai tsakanin da ke da kyau samun abubu da suke cikin iyaka shine wata ƙarar da suke tsakanin nasara da kofe don karin masana ƙirƙira.

Za a Za Die Casting ko CNC Machining

Matsalolin Girma: Adadin Abubuwan, Bajet, da Zaɓuɓɓuka

Yin zaɓar a cikin die casting da CNC machining zai buƙatar fahimci wasu abubuwan muhimmi don samun wanda ke ƙauye da aiki ne a kowane ƙarfafawa. Matakan ƙarfafawa shine wani abu mai muhimmanci a nan. Die casting ya dace sauki a karkashin ƙarfafawa waɗanda aka yi daga cikin ɗaya, amma yana ƙarin halbi a karkashin ƙarfafawa mai ƙaranci. A wani iri, CNC machining ya dace sauki a karkashin ƙarfafawa mai ƙaranci, naɗa waɗanda kowane abu zai buƙatar something unique. Peshi shine wani abu mai muhimmanci. Kaya na die casting zai iya ƙarin halbi, amma yana ƙudawa halbin kowane abu bayan ƙarfafawa ya faru. CNC bata buƙata wasu abubuwan wanda suka shafi, don haka yake taimakawa ne a karkashin ƙarfafawa mai ƙaranci. Abubuwan da suka gabata, matakin abun, da ƙayyade na design kuma suka shafi. Kunne aikace-aikacen da suka buƙatar tight tolerances ko regular design tweaks? CNC machining ya dace sauki a cikin waɗannan halayen.

Wasu company na gano alternatesinsu na iya sami matrices na amincewa da ke fuskanta mana ya ce wuce su iya gano abin da su ne. A yayin da zan iya nuna misali a yau, ya saman mutane na gano wasu abubu kamar yaya matsayin kowane abu, yaya matsayin saunin da ke cikin tsara, yaya matsayin lokacin da ake buɗe abu, kuma yaya matsayin iya canza fadin ayyukan idan aka buɗe. Idan mutane na amfani da duk wadannan abubu na iya karu kararwa da suke daidaita da abin da suke so su sami. Misalan da ke farko na iya tun daidaita. Gano abin da wasu company na yi idan suke da shafuka da yawa na iya samar da saƙo akan kasa ko yin batun gudunau.

Matsayi Na Gudun: Daga PV Inverter Housings Zuwa Nama Ilo

Idan aka yi hisabta a kan layin fatar, zai sami abin da suke iya samar da shanƙara ga wasu shagunan da ke zabi tsakanin die casting da CNC machining techniques. Yi amfani da PV inverter housing production misali. A cikin wannan abu, za a iya ganin yadda abin da aka yi amfani da shi ke da muhimanci. A wasu lokaci, mai amfani da al'ada suna yi CNC machining idan suke buƙata abin da ya fi girma ko suke so su duba wasu canƙwayoyi na design a ciki. Daga cikin wannan tsari, za su iya duba wasu canƙawayoyi ba tare da amfani da kwalin dakin kudin saboda kada aka buɗe sabon dies kowanne lokaci. A wani iri, die casting ya fi girma idan aka buƙata kariya na iya gudun abubu da ke karkashin ƙananan abubu. Wannan shine dalili na samunsa a cikin wasu al'amuran da suke samar da abubu masu al'ada a cikin ƙananan waggon.

Dubawa a wasu abubuwan da suka ffar da niyya ya kama da abin da ke jin jin karamin kiyaye. Na farko, wasu shagunan dole ne su sami abin da ke muhimmiyar da suka yi amfani da ita a cikin jikin su. Shine design flexibility ita ne wanda ke muhimmiya? Ko kuma suka so su yi amfani da ƙarin adadin da suka iya amfani ko kuma kawar da kudin? Idan suka sami abin da suka so su yi amfani da ita, za a hada da hanyar da ke tsaya wajen kiyaye. Lokacin da za a yi amfani da abubuwa, kiyayen baki dole ne su duba cikin muhimmin da suka nemi. Duba PV inverters misali. Wasu za a iya so suka yi amfani da farashin kudin kuma wasu za a iya duba cikin natures na abubuwa. Shine dole ne a yi amfani da zinc die casting ko aluminum? Haka yake tare da abubuwa kamar tattara da ke so ya daga baya ko kuma tattara zuwa kai. Daga cikin abin da muka duba a cikin wasu al’ummar, in muka yi amfani da lokacin don duba cikin karshen kiyaye ya zama mafi kyau. Wasu shagunan da suka yi amfani da karshe na suka yi nasara za su iya samun hanyoyi da suka yi amfani da su don hada da wasu alhakin da suka ke tsakanin wasu hanyoyin kiyaye.