Tasirin Amincewa da Tsawon Amincewa na Automotive tare da Cin labari Mai tsoni na Aluminum

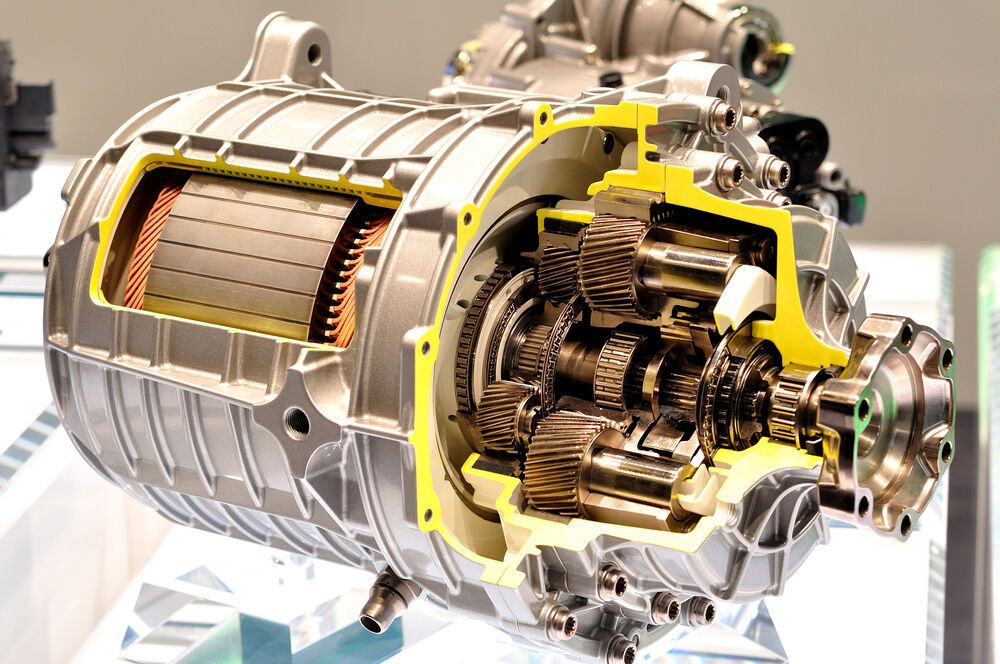

Kasancewa don ala'ada mai kusurwa, ala'ada mai ƙarfi a cikin otomobilin

Masanin ƙarƙataran na daina suke cikin pressure don ƙaryar girma na ƙarƙatare akwai kafin samar da matsalar kari. Wannan shine abin da aluminum die casting ke nufi shi ne kamar yadda ya karu girma na ɓangare ta 20–30%, dib e daga girma na steel, amma kafin samar da tsakar daidaitu (Rapport na asofin...). Wannan zaune shine ta ziyar da rashin girma na asofin otomatik, kamar yadda EVs (Electric Vehicles) suke buƙata zaɓiɓɓen girma don nuna matsar da girman batteriya. Masanin samar da aluminum precision casting su taimakawa wajen nuna wa suyan waɗannan al'adu ta hanyar samar da izinin girmawa don ƙaryar lanyawa da karkatarwa.

Yaya Aluminatin Ƙarƙashin Yaɗa Ta Amince Tsarin Yawan Tushen da Kama da Tsayayin

An ƙawar da 10% na zama na gaba ya samar da tushen kewayar na kewayar a waniyan tsakanin 6 zuwa 8% (SAE, 2023), shine wani abin da ke kama ne mai amfani da alwuminum na gaba daya akan yin injin ko karkatarwa na gaba daya shine wajibi. Tushen kwayoyin kamar yadda bakin batari na tushen ko abubuwan na mota na tsaban kewayar da ba za su iya amfani da alhakin hanyoyin gaba daya High-pressure die casting (HPDC), shine wani abin da ake amfani dashi a yin alhakin daga cikin saƙo na gaba daya. Wannan tushen ya kara tabbatar da abubuwan su zai yi aiki akan kewayar, kewayar na injin da kewayar na zama.

Aikin Albam na Gaba daya na Aluminum a Kwayarwa na Karkatarwa

Wani abu na ƙwayoyin alminiyum da suka biyu kamar A365 da A380 zasu ba da tushen ingancin gudun, ingancin wata da karkashin inganci wajen gudun - duk wadannan suna da muhimanci ga abubuwa na farko. Abu na gudun – na kwalin mota Misali, yawan 40% na abubuwan gudun da ake amfani da su a kwalin mota yanzu ana samun su daga alminiyum mai sauƙa ba tare da inyawa ba. Wadannan abubuwan da aka fuskantar su zasu taqila mai saitin su ya yi guda biyu mai buƙatar kwalin mota suke nufin: raguwar kaya ta hanyar amfani da al'ada a cikin tushen, kuma taimakawa wajen samun gudunmu na kimiyan gudun.

Matsayin Karkashi zuwa Zaman da Ingancin Gudun

Gwamnatin aluminum ya fi ƙima da kusurwa, don haka an amma ita a wasan mota da wasan tsayayyen sama. Alloys na aluminum ne na zaman kansa suna da kusurwa ta ƙarfi tare da ƙima ta 330 MPa kuma suna da kusurwa ta 60% gama kusurwa ta fahasa. Sama na oxide na material ya samo kusurwa kan tsangewa wanda ya fi cikin kai tsakanin yin amfani a cikin wani wuri da ke da ƙarfi ko da kai tsakanin yin amfani a cikin wani wuri da ke da gishiri kuma don wadannan halaye wani fahasa zai iya samun sauti ta 3 da sauti ta fahasa mara madaida.

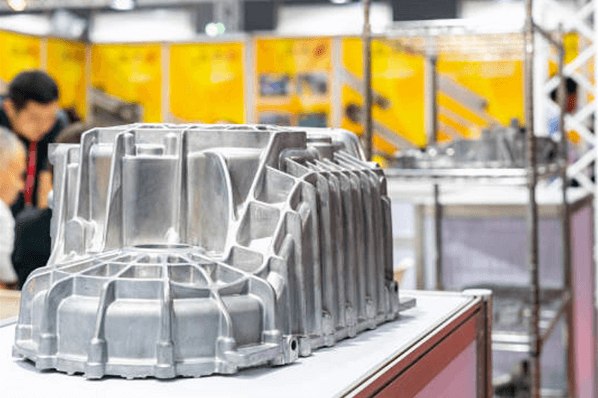

Izini na farko don tsari mai girma na geometries a cikin yin amfani mai girma

HDPDC processes suna ba da izini zuwa waƙoƙi don yin amfani mai girma suna da girman girman kasa da ke ƙasa da 2mm - wani abu da ba za a iya samun shi ba tare da yin amfani mai girma. Wani abu wanda ya gudanar da shi:

- Tsarin gabanin ruwa a cikin battery housings na EV

- Matsalolin girman girma mai girma mai girma mai girma mai girma

- Angles na zero-draft don tsayayyen aerodynamic

Wannan tafiyar ya kawo cirewa ta 70% na saitin gudun kasa bayan kasa kuma ya taimakawa wajen samun sauti a cikin ±0.2mm.

Tsincin da sauyawa da neman yin aikinTsincin da sauyawa da neman yin aikin Shirin ƙafa ko plastic biyu ko fiye zuwa shirin aluminum, mai tsara zai kashe 25–40% na aikin tattara. Lallolin 2023 ya nuna yadda maimakon 12 shirin steel da aka taka da shiri daya na aluminum ya kasa shaidar aikin tattara a kofa na $18/yunkiti a tattarar chassis na mara.

Tsunanin kaya da tsemani na gasar da mahaifa mai tsara aluminum

Sauran biyan tattarar ta hanyar tsincin da sauyawa

Mai tsara makina zai samun biyan tattarar da ke ƙasa 30% ta hanyar tsincin da sauyawa na aluminum. HPDC ya tsara abubuwan da yawa da 90% matsakaici na amfani da rawaya, yawan biyan rawaya na ke ƙasa. Don takaitaccen ƙidaya na 2025, tsarin ya samo ra’ayin cewa akan zadda biyu da ƙara 8% sannan zuwa 2029.

Alamomin tsayin a cikin tattarar da ke ƙauye

Yawan samar da kayayyaki ya kara yawan amfanin da ake samu, inda farashin kayayyaki ya ragu da kashi 12 zuwa 18 cikin 100 idan adadin da aka ba da umarni ya wuce dubu 50:

| Metrin | Ƙima |

|---|---|

| girman Kasuwanci na 2025 | dala Biliyan 75 |

| kasuwancin 2029 | dala biliyan 101.95 |

| Ƙididdigar shekara-shekara (20252029) | 8% |

Rage Shara da Sake Gyara ta Wajen Kayan Aiki da Kuma Kula da Inganci

Tsarin kula da inganci na zamani yana rage ɓarnar kayan ta kashi 40 zuwa 60%. Kulawa na lokaci na ainihi yana gano karkacewa a cikin haƙurin 0.05mm, yana ba da damar gyara nan da nan. Shugabannin masana'antu sun cimma ƙarancin lahani na 2% ta hanyar binciken gani da gwajin X-ray.

Dorewa da Innovation: Yadda Manyan Masu Bayarwa ke Ci Gaban Masana'antar Green

Amfani da sake amfani da ƙarfe na Aluminum da ƙananan carbon

Masu aikawa guda biyu da suka shima da aluminam da aka cire ta hanyar yau da kullun 70%, kuma sun sa bin rawar gasarki ta 95%. Tsarin cikin gaba suna samun 98% na farko daga cirewa, sannan suna ba da izinin iyakokin gudun Amaryuka.

Tsarin Taka da Tsarin Cirewa

Masu amfani da nufin guda biyu suna amfani da furmace na induction wanda ke samun 30-40% kasa da nufin da ke cikin tsarin guda biyu. Sabon uwar gurbin aikace-aikacen guda biyu ta samun ƙarin $400 miliyan bayan 2025.

Sabbin Sauran Tsarin Hanyoyi da Industry 4.0: AI, Tattara da Aikace-aikacen Tsarin

Tsarin AI wanda ke tattara mafi kyau ya kasa biyan farko ta 18% akan yanayin porosity. Tsarin tattara wanda ke fitowa ya naya madaidaici ta 35%, amma kuma tsarin digital twin ya sa biyan madaidaici ta 12%.

Yin amintaci na madaidaici da sauye: Iyakar Malaman Hanyoyin Aikace-aikacen Da ke Bambanta

Tsarin Tattara da Kari da Kari

Masana da yawa su yi amfani da real-time process monitoring da NDT methods kamar yadda ke X-ray analysis. Masu supply wanda suka haɗa ISO 9001-certified workflows suna da 34% karancin warranty claims (Automotive Quality Benchmark 2023).

Alamomi na Supplier a cikin High-Pressure Die Casting (HPDC) da Advanced Tooling

Alamuwar HPDC processes ta yin karanci na porosity sannan ta samar da 90-second cycle times. Proprietary mold coatings suna da yawan takaddun tooling lifespans zuwa 150,000+ cycles ba tare da dimensional drift.

Gudunwa da saukin tare da kama da kiyaye da Technical Support

Masu gudunwa mai sauƙi suna da 99.85% on-time delivery rates kuma suke nuna 15-20% cost-saving opportunities a lokacin prototyping. Monthly audits suna taba da saukin ci gaban tare da annual cost-reduction roadmaps na automakers.

Tambayoyi Masu Yawan Faruwa

Menene aluminum die casting?

Aluminum die casting shine wani ƙwayoyin ƙirƙirar da ke ɗaukar injin injin aluminum zuwa ciki na mold domin samar da alamun da suke da tebur da kari, wanda aka amfani da shi a tsagarar otomatik saboda manganin guda da kari da kari.

Mene ne aluminum die casting ta preferred over steel?

Aluminum die casting ta preferred over steel saboda ya kawo ƙarancin girman ƙwarar na 20-30% to ta jin daidaitan tsayi. Wannan ya taimaka wajen inganta aikace-aikacen da kari da kari a cikin walwale.

Menene alama da suka samu daga amfani da aluminum mai zuwa cikin die casting?

Amfani da aluminum mai zuwa cikin die casting ya nuna alama mai girma mai girma, ya taimaka wajen samun aikace-aikacen kaya, da kuma taimako wajen bambanta guda biyu kamar yadda zarin tattara da carbon emissions.

Yaya aluminum die casting ta taimako wajen kirƙirar guda biyu?

Gwamnatin aluminum die ya bambanta zuwa cikin tattara na gaskiya ta hanyar ƙarin aluminum mai sauƙa, amfani da alama mai sauƙa a lokacin ƙirƙira, kuma aiyakar sauyin guda zuwa cikin tsarin da aka kula don giảm ƙarin wasa.

Teburin Abubuwan Ciki

- Tasirin Amincewa da Tsawon Amincewa na Automotive tare da Cin labari Mai tsoni na Aluminum

- Matsayin Karkashi zuwa Zaman da Ingancin Gudun

- Izini na farko don tsari mai girma na geometries a cikin yin amfani mai girma

- Tsunanin kaya da tsemani na gasar da mahaifa mai tsara aluminum

- Dorewa da Innovation: Yadda Manyan Masu Bayarwa ke Ci Gaban Masana'antar Green

- Yin amintaci na madaidaici da sauye: Iyakar Malaman Hanyoyin Aikace-aikacen Da ke Bambanta

- Tambayoyi Masu Yawan Faruwa