Meeting High Demand in the Automotive Industry with Precision Aluminum Die Casting

Rising Need for Lightweight, High-Strength Components in Vehicles

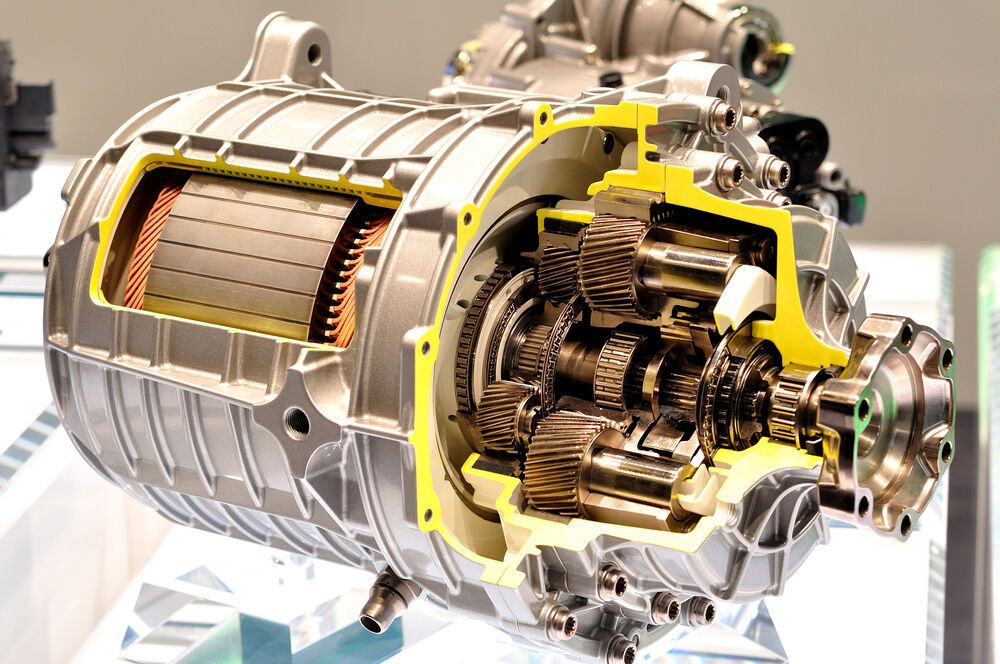

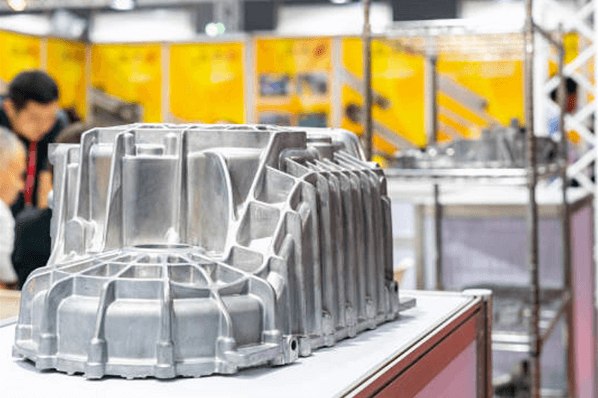

Vehicle manuf acturers are under increasing pressure to decrease vehicle mass without sacrificing structural performance. This is the need aluminum die casting fulfills as it allows reducing part mass by 20–30%, compared to steel parts, while maintaining similar strengths (Industry Report.....) This trend is even further accelerated by the automotive industry’s move to electrification, with electric vehicles (EVs) in need of lightweight designs to compensate against battery weight. Aluminum precision casting suppliers help manufacturers meet these goals with near-net-shape production to reduce material waste and secondary machining.

How Aluminum Die Casting Supports Fuel Efficiency and Performance

A 10% reduction in vehicle weight adds up to a fuel economy increase of roughly betweeen 6 and 8 % (SAE,2023), which is why the use of cast aluminum components on combustion or electric drivetrain are essential. Complex geometries such as the thin-walled battery housings or heat-resistant motor parts that can’t be produced by conventional methods High-pressure die casting (HPDC), in production use case for more than a decade. This accuracy guarantees that parts survive the rigors of operation, engine vibration and temperature stress cycling.

Role of Advanced Aluminum Alloys in Automotive Innovation

Contemporary aluminum alloys such as A365 and A380 provide improved corrosion resistance, thermal conductivity, and creep strength—all important characteristics for underhood parts. Casting material – automotive For instance, some 40% of the casting materials used in automotives are now made from recycled aluminium without compromising on required performance. These advancements enable suppliers to serve the dual mandates automakers are asking for: reducing costs by using resources efficiently, and helping them achieve their carbon-neutral manufacturing goals.

Superior Strength-to-Weight Ratio and Corrosion Resistance

Aluminum casting provides a competitive strength-to-weight ratio, which is why it's us in the car and aerospace industry. Contemporary aluminum based alloys have tensile strengths in excess of 330 MPa and are still 60% less dense than steel. Material’s natural oxide layer offers inherent corrosion resistance that actually becomes even higher after use in humid or salt-exposed environments and for such circumstances this steel may have up to 3 times more service life than non-coated steel.

Design Freedom for Complex Geometries in High-Volume Production

HPDC processes allow manufacturers to create intricate components with wall thicknesses under 2mm—a feat unattainable with traditional machining. This supports:

- Integrated cooling channels in EV battery housings

- Thin-walled structural components with honeycomb reinforcement patterns

- Zero-draft angles for aerodynamic exteriors

Such precision reduces post-casting machining by 70% while maintaining tolerances within ±0.2mm.

Part Consolidation and Reduced Assembly NeedsBy combining multiple steel or plastic parts into single aluminum castings, manufacturers eliminate 25–40% of assembly steps. A 2023 study demonstrated how replacing 12 welded steel components with one aluminum casting cut assembly labor costs by $18/unit in truck chassis production.

Cost-Effectiveness and Long-Term Value of Partnering with a Reliable Aluminum Casting Supplier

Lower Total Manufacturing Costs Through Efficient Casting Processes

Automakers achieve up to 30% lower production costs through aluminum casting’s near-net-shape manufacturing. HPDC produces components with 90%+ material utilization rates, significantly lowering raw material expenditures. According to the 2025 Aluminum Casting Market Report, the industry is projected to grow at an 8% CAGR through 2029.

Economies of Scale in High-Volume Production Runs

High-volume production runs amplify cost benefits, with per-unit expenses decreasing by 12–18% when order quantities exceed 50,000 units:

| Metric | Value |

|---|---|

| 2025 Market Size | $75 Billion |

| 2029 Projected Market | $101.95 Billion |

| CAGR (2025–2029) | 8% |

Reduced Waste and Rework Due to Precision Tooling and Quality Control

Advanced quality control systems reduce material waste by 40–60%. Real-time process monitoring detects deviations within 0.05mm tolerances, enabling immediate corrections. Industry leaders achieve <2% defect rates through automated optical inspection and X-ray testing.

Sustainability and Innovation: How Leading Suppliers Advance Green Manufacturing

Use of Recycled and Low-Carbon Aluminum Alloys

Leading suppliers integrate recycled content into over 70% of their aluminum alloys, slashing energy consumption by up to 95%. Closed-loop systems recover 98% of scrap from casting processes, enabling automakers to meet EU taxonomy requirements.

Energy-Efficient Furnaces and Closed-Loop Recycling Systems

Modern foundries employ induction furnaces that use 30-40% less energy than traditional systems. The global market for intelligent manufacturing systems is projected to exceed $400 billion by 2025.

Digital Transformation and Industry 4.0: AI, Predictive Maintenance, and Process Optimization

AI-driven quality control systems reduce scrap rates by 18% through real-time porosity detection. Predictive maintenance algorithms extend mold life by 35%, while digital twin simulations improve yield rates by 12%.

Ensuring Quality and Reliability: The Role of Expertise in Mission-Critical Applications

Rigorous Quality Assurance and Testing Protocols

Leading manufacturers implement real-time process monitoring and NDT methods like X-ray analysis. Suppliers adhering to ISO 9001-certified workflows demonstrate 34% fewer warranty claims (Automotive Quality Benchmark 2023).

Supplier Expertise in High-Pressure Die Casting (HPDC) and Advanced Tooling

Mastery of HPDC processes minimizes porosity while achieving 90-second cycle times. Proprietary mold coatings extend tooling lifespans to 150,000+ cycles without dimensional drift.

Building Long-Term Partnerships Based on Consistency and Technical Support

Top-tier partners provide 99.85% on-time delivery rates and identify 15-20% cost-saving opportunities during prototyping. Monthly audits ensure continuous improvement aligned with automakers’ annual cost-reduction roadmaps.

FAQ

What is aluminum die casting?

Aluminum die casting is a manufacturing process that involves injecting molten aluminum into a mold to produce complex and precise components, primarily used in the automotive industry for its light weight and durability.

Why is aluminum die casting preferred over steel?

Aluminum die casting is preferred over steel because it reduces vehicle part mass by 20-30% while retaining similar strength. This contributes to improved fuel efficiency and performance in vehicles.

What are the benefits of using recycled aluminum in die casting?

Using recycled aluminum in die casting offers significant energy savings, helps achieve cost efficiency, and supports sustainability goals such as reducing environmental impact and carbon emissions.

How does aluminum die casting contribute to green manufacturing?

Aluminum die casting contributes to green manufacturing by incorporating recycled aluminum, utilizing energy-efficient practices during production, and implementing closed-loop recycling systems to reduce waste.

Table of Contents

- Meeting High Demand in the Automotive Industry with Precision Aluminum Die Casting

- Superior Strength-to-Weight Ratio and Corrosion Resistance

- Design Freedom for Complex Geometries in High-Volume Production

- Cost-Effectiveness and Long-Term Value of Partnering with a Reliable Aluminum Casting Supplier

- Sustainability and Innovation: How Leading Suppliers Advance Green Manufacturing

- Ensuring Quality and Reliability: The Role of Expertise in Mission-Critical Applications

- FAQ