Defining Precision in Manufacturing with CNC Machining

CNC (Computer Numerical Control) machining transforms digital designs into physical components with micron-level accuracy. Unlike manual processes, CNC systems execute programmed instructions to control cutting tools with repeatable precision, achieving tolerances as tight as ±0.005 mm (International Journal of Advanced Manufacturing Technology, 2023).

This method eliminates human error through automation, enabling consistent production of complex geometries. By integrating CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, engineers can simulate and refine machining paths before production begins, ensuring parts meet exact specifications across high-volume runs.

Achieving Tight Tolerances and Complex Geometries

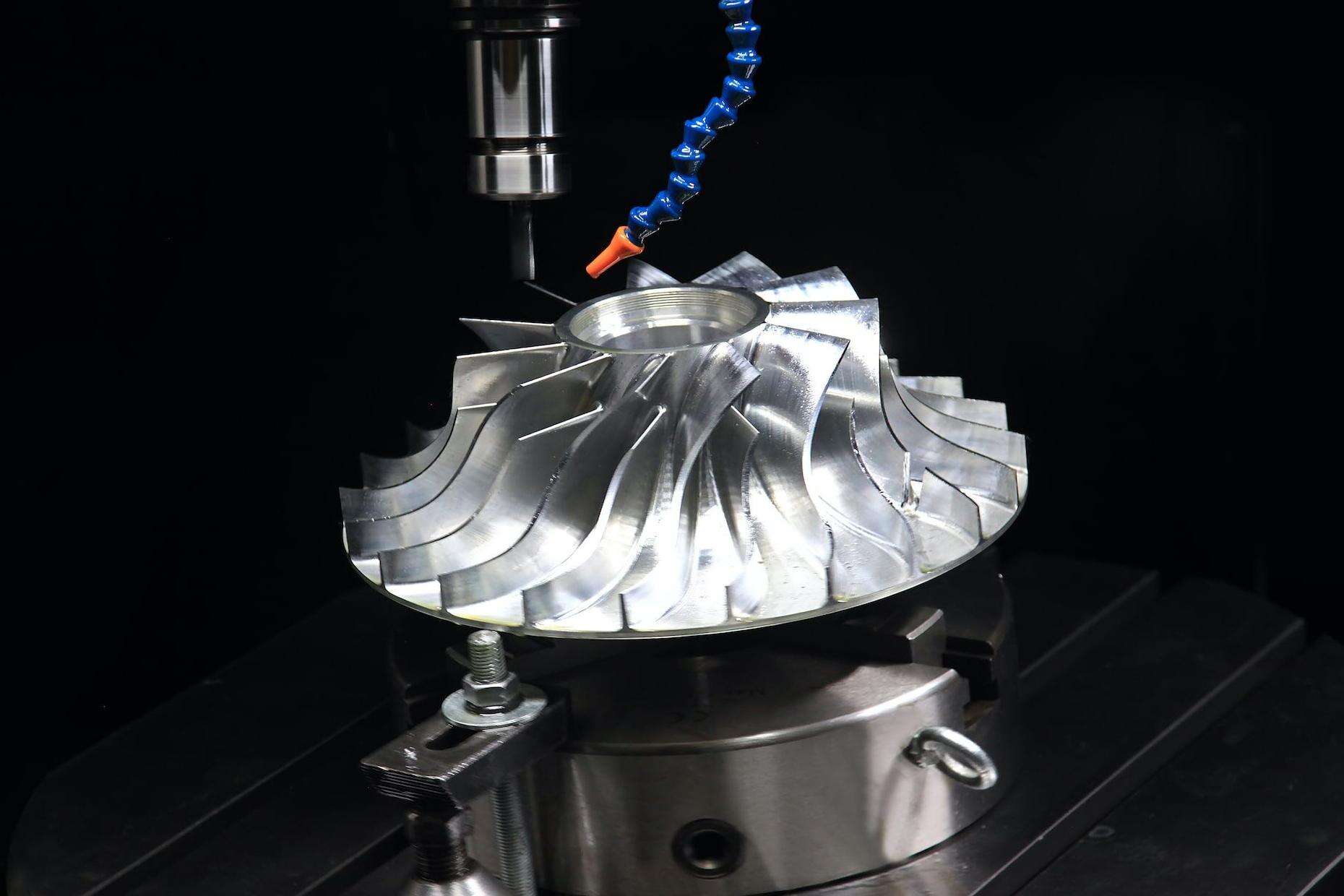

CNC machining’s multi-axis capabilities allow production of parts with tight tolerances and sophisticated shapes. A 5-axis CNC machine, for instance, can rotate a workpiece along five different axes simultaneously, reducing setup time and minimizing alignment errors—critical for components like fuel injectors where deviations over 10 microns could compromise performance.

Automation in CNC reduces dimensional errors by 72% compared to conventional methods (National Institute of Standards and Technology, 2023). For complex geometries requiring undercuts or internal channels, CNC milling and electrical discharge machining (EDM) achieve sub-millimeter precision while reducing material waste.

Technological Advancements Driving CNC Precision: AI, IoT, and Automation

CNC machining achieves unprecedented precision through integration with Industry 4.0 technologies like artificial intelligence (AI), IoT connectivity, and advanced automation systems—key for meeting tightening tolerance requirements across aerospace, medical, and automotive sectors.

AI and Machine Learning for CNC Process Optimization

AI enables real-time adjustments to cutting parameters and tool paths. Machine learning algorithms analyze historical data to predict tool wear, reducing unplanned downtime by up to 40%. Self-correcting systems automatically compensate for thermal expansion, maintaining tolerances under ±0.001 mm.

IoT and Real-Time Monitoring for Predictive Maintenance

IoT-enabled CNC machines transmit operational data, allowing manufacturers to identify potential failures 72 hours in advance. Tracking variables like spindle vibration and coolant pressure helps prioritize maintenance without interrupting production.

Digital Twin Technology in CNC Machining Simulation

Digital twins create virtual replicas of CNC workflows, enabling engineers to test machining strategies before production. Manufacturers report 30–40% faster setup times for complex parts like turbine blades, while optimizing material removal rates reduces scrap in high-cost materials.

Advanced CAD/CAM Integration for Seamless Automation

Modern CAD/CAM software converts 3D models into machine instructions with near-zero manual intervention. Automated toolpath generation ensures consistency across production batches, reducing time-to-market by 65% for medical device prototypes where accuracy impacts regulatory compliance.

Multi-Axis CNC Machining: Enabling Complex and High-Precision Components

From 3-Axis to 5-Axis: Evolution of CNC Machining Capabilities

5-axis CNC machines introduce rotational A and B axes—allowing tools to approach workpieces from nearly any angle. This eliminates manual repositioning, particularly beneficial for components with undercuts or multi-plane features, improving geometric accuracy by 30% in medical implants.

Impact of Multi-Axis Centers on Accuracy and Efficiency

Multi-axis CNC machining delivers improvements in:

- Error Reduction: Consolidated setups minimize positioning errors, achieving surface finishes up to Ra 0.2 μm

- Cycle Time Optimization: Complex automotive parts see 45% faster machining times

- Material Conservation: Near-net-shape machining reduces aluminum waste by 22%

Case Study: 5-Axis CNC in Aerospace – Reducing Setups and Improving Precision

Aerospace manufacturers achieve single-setup production for turbine blades using 5-axis CNC machining centers, improving accuracy by 40%. This reduces blade rejection rates from 12% to 2.8% while cutting production time from 18 to 8 hours per unit (PRNewswire 2024).

Key Industry Applications of High-Precision CNC Machining

CNC machining is vital for industries where precision impacts performance and safety.

Aerospace: Meeting Extreme Tolerance and Reliability Standards

CNC produces turbine blades with cooling channels thinner than 0.15 mm from superalloys like Inconel 718. Surface roughness below Ra 0.4 μm for hydraulic components reduces fluid turbulence by 18% (AeroDef 2023).

Automotive: CNC Machining for Engine, Transmission, and Mass Production

| Application | CNC Advantage | Impact |

|---|---|---|

| Engine blocks | Boring within ±0.015 mm | 12% fuel efficiency gain (EPA 2023) |

| Transmission gears | Hard milling reduces heat treatment steps | 40% faster cycle times |

Medical Devices: Biocompatible Materials and Micron-Level Precision

Titanium spinal implants feature 800-μm porous surfaces that promote 30% faster bone integration. The global market for CNC-machined medical components is projected to reach $7.2 billion by 2027 (Global Market Insights 2024).

FAQ

What is CNC machining?

CNC machining involves using computers to control machine tools that create intricate parts and components with high precision, guided by digital designs.

How does CNC improve manufacturing accuracy?

By executing programmed instructions, CNC minimizes human error and automates processes, facilitating consistent and precise production of complex geometries.

What are the advantages of multi-axis CNC machining?

Multi-axis CNC machines allow tools to approach workpieces from various angles, refining accuracy, reducing setup times, and enabling production of complex geometries.

How is CNC machining used in different industries?

It's employed across sectors like aerospace for producing high-tolerance components, automotive for enhancing efficiency, and medical for creating precision implants.

Table of Contents

- Defining Precision in Manufacturing with CNC Machining

- Achieving Tight Tolerances and Complex Geometries

- Technological Advancements Driving CNC Precision: AI, IoT, and Automation

- Multi-Axis CNC Machining: Enabling Complex and High-Precision Components

- Key Industry Applications of High-Precision CNC Machining

- FAQ