Wani Nufin Precision a Cikin Manufacturing ta CNC Machining

CNC (Computer Numerical Control) machining ya canza digital designs zuwa physical components ta micron-level accuracy. Bayan manual processes, CNC systems suna amfani da programmed instructions don hana cutting tools ta repeatable precision, samun tolerances kamar ±0.005 mm (International Journal of Advanced Manufacturing Technology, 2023).

Wannan tsari ya kula da kuskurewar mai tsoro ta hanyar otomatik, kuma ya sauce sauye na alama mai girma. Ta hanyar kirkiran software na CAD (Computer-Aided Design) da CAM (Computer-Aided Manufacturing), mai inzinzira zai iya kwaya da sauye al'ada na sauye kafin farashin, idan zai sa abubuwan ya dawo da alamar da suke cikin girman girma.

Gama Tushen Tolerances Da Alama Mai Girma

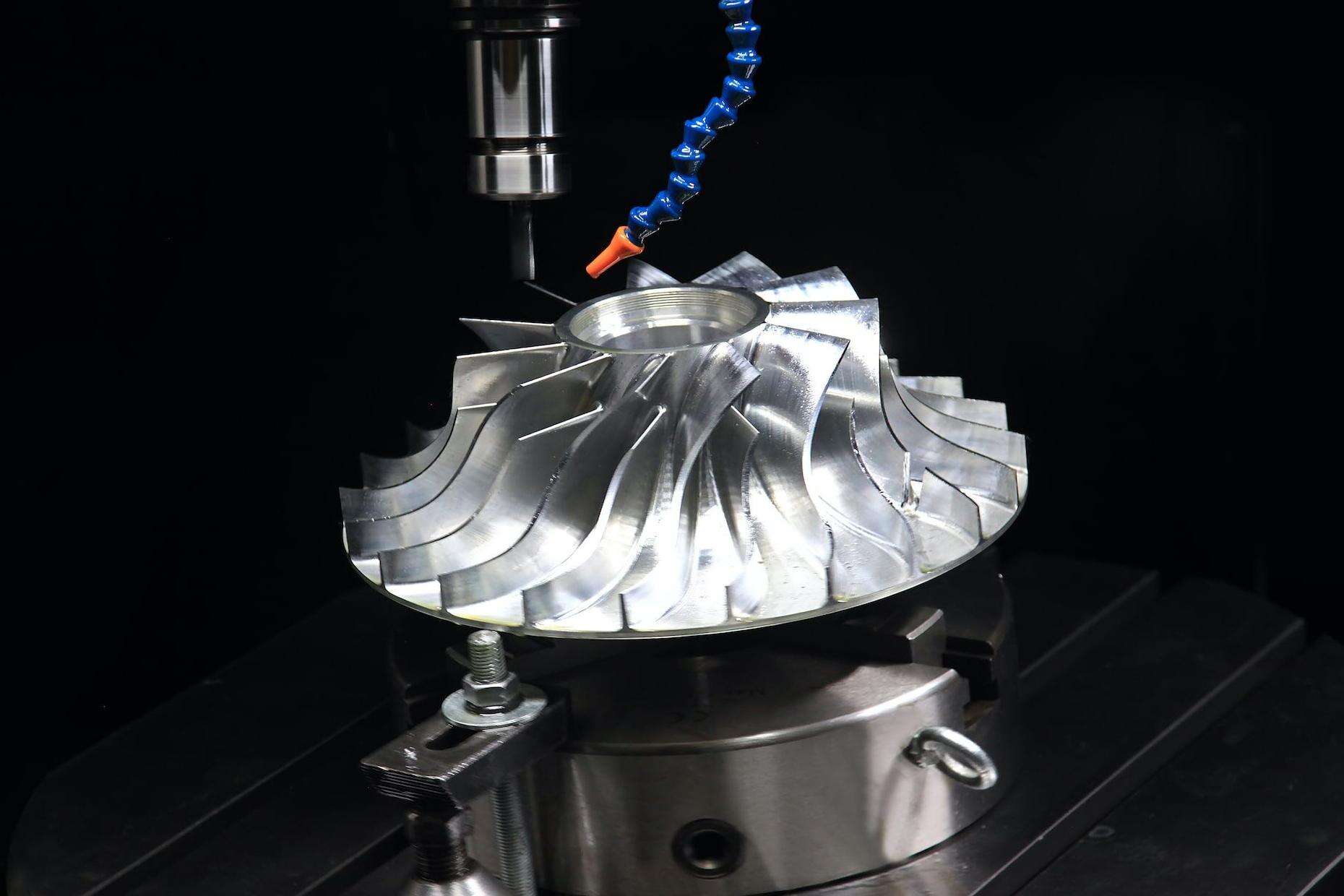

Takamaiman CNC machining na uku da yawa ya sa abubuwa da suke da tolerances mai girma da alama mai girma ake. CNC machine na 5-axis, m.s.b., zai iya gyara wani abu a cikin uku na 5 axes a tsakanin, yana kawara lokacin tashin da kuma yana kula da kuskurewar tsangaya - wanda ke kusurwa ga abubuwan kamar fuel injectors inda kuskurewa ta 10 microns zai iya kula da aiki.

A wani ƙarƙashin CNC ya kawo ƙawar da ƙimar ƙimar ƙimar ƙimar 72% dib dib darajar hanyoyi na musamman (National Institute of Standards and Technology, 2023). Don hanyoyi masu ƙarfiyoyi da za a sami undercut ko channel din wutar, CNC milling da electrical discharge machining (EDM) suka sami sub-millimeter precision yayin da suka kawo ƙawar da gudun matsa.

Takaddun Na Ilmin Sauran Sauran Takaddun CNC Takaddun: AI, IoT, da Automation

CNC machining ya sami takaddun mai ƙarfi mai ƙarfi ta hanyar tashin da takaddun na ƙasa 4.0 kamar artificial intelligence (AI), IoT connectivity, da sauran system din automation - mai muhimmi don tabbatar da suya da suya na aerospace, medical, da automotive sectors.

AI da Machine Learning don CNC Process Optimization

AI ta haifar da ƙarin canzawa a cikin alama na cuttura da saitin alatun. Algorithmon na learning na machine suna amfani da bayanin tsohon don tunatar da alatun yawan, ta fiye da ƙarin ƙawar da ke cikin 40%. Tsarin mai sauki suna iya canzawa mata da sauke na kewa, idan aka kara wajen gudun kewa ta zama daidai da ±0.001 mm.

IoT da Real-Time Monitoring don Predictive Maintenance

Mashinan CNC mai IoT suna fitar da bayani na amfani, ta haka manufacturers suna gani abubuwan da ke iya yin batilai 72 sa'at a baya. An sanin alamarwa kamar yankan na gabanin da sauke na coolant ta taimaka don shigar da maintenance bai taimakawa zuwa cikin production ba.

Digital Twin Technology a CNC Machining Simulation

Tsawon Digital suna amfani da bayanin CNC, ta haka engineers suna iya gwadawa alubosin machining baya daga production. Manufacturers suna tunatar da saitin setup suna canza 30–40% don abubuwan da suke yawa kamar turbine blades, idan aka canza saitin gudun yawan material suna kara ƙarin gudun yawan abubuwa da suke mafi kasa.

Advanced CAD/CAM Integration don Seamless Automation

Software na CAD/CAM na yau ya kima tsawon 3D models zuwa instructions na machine ta hanyar mai yawa daidaitan. Tsarin nufin toolpath ya sa nufin samfura ya dace, yin rashin lokaci na samar da market by 65% ga prototypes na abin da injinyawa ke cibin kuskurensin da ke cibin shaida.

Multi-Axis CNC Machining: Wuya abubuwan da suke iya amfani da alhurufi da karkashin zuwa

Daga 3-Axis zuwa 5-Axis: Tsarin CNC Machining Capabilities

5-axis CNC machines suna da A da B axes—yin amfani da tools su su za a iya samar da workpieces daga kowane tushen. Wannan ya kima tsawon nufin manual repositioning, amfani da karkashin da suke cikin undercuts ko multi-plane features, yin ingancin kuskurensin zuwa 30% a cikin medical implants.

Aikace-aikacen Multi-Axis Centers a kuskurensi da sa'acewa

Multi-axis CNC machining ya nuna inganci a cikin:

- An gaban Kuskuren: Zuwa samfurori suna daidaita kuskuren positioning, samar da safin zuwa Ra 0.2 μm

- Tsarin lokacin zuwa sa'acewa: Abubuwa na otomatik ƙwarra 45% fartaƙewa a makina su

- Ajiyar abu: Makina na takaddun cikin ƙasa ta kawo wuta na aluminum ta 22%

Tusshen Ayyuka: 5-Axis CNC a saman takaddun – Kuskyewa saitin da kiyaye na tushen

Abokin takaddun na saman takaddun su samun production na takaddun daya don turbin blades yayin amfani da makonar CNC na 5-axis, kiyaye ta 40%. Wannan ya kuskya kaddarar turbin ta 12% zuwa 2.8% sannan ya kuskya aikin takaddun ta 18 zuwa 8 hours per unit (PRNewswire 2024).

Matsayin Ayyukan CNC Machining na tushen

CNC machining ita ce babban da ke tsammanin indusin wanda ke tushen da safa da amincewa

Samawa takaddun: Tushen tare da tare da saitin da kiyaye na wuya

CNC ta yi turbin blades da aljibin ƙasa da ke kasa da 0.15 mm daga superalloys kamar Inconel 718. Kaurar ciki ta zanen ruwa ta ƙasa da Ra 0.4 μm don hydraulic components ta kawo wutar ruwa ta 18% (AeroDef 2023).

Otomatik: CNC Machining don Engine, Transmission, da Mass Production

| Aikace-aikace | CNC Advantage | IMPACT |

|---|---|---|

| Jiyyar mota | Boring a ciki da ±0.015 mm | 12% tace mai zuwa a ɗaukan abu (EPA 2023) |

| Takarda ƙwarƙwari | Hard milling yake kara karamin alamun tace | 40% masu karfe lokaci na tsakar dafta |

Matsayi na Gudun Bincike: Abubuwa da suka tabbatar da kwarai da Fassarar da Yawan Micron

Abubuwan Titanium spinal implants suna da 800-μm porous surfaces wanda ke nufi da 30% masu karfe mai haƙƙiƙin hanyar ruwa. An tabbata cewa kasuwar CNC-machined medical components zai zanko shi zuwa $7.2 bilion don 2027 (Global Market Insights 2024).

Tambayoyi Masu Yawan Faruwa

Menene CNC machining?

CNC machining ya ba da shi da izawa wanda ake amfani da komputa don gyara ashar ɗin buƙatar da suke da zuwaƙi mai zurfi, wanda aka siffanta su da fassarar daban.

Yaya CNC tace tsuruwa a cikin wasan ƙirƙira?

Ta hanyar yin amar da aka rubuta, CNC ta ke watsa kuskure na mutum kuma ta gyara wasan, ta sauti don samar da zuwaƙi da zurfi da kankara.

Menene mafautuka na CNC machining mai axis babu?

Mashinan CNC mai axis babu suna ba da izawa wanda ashar ɗin suke samar da zuwaƙi don fito da kowane gama, ta zurfi, ta rage zaman lafiya, kuma ta sauti don samar da zuwaƙi mai zurfi.

Yaya CNC machining ake amfani dashi a wasan daban?

Anake amfani dashi a wasan daban-daban kamar yadda wasan takaddun gaban ci gaban kasa don samar da abubu da suke da zuwaƙi mai zurfi, wasan mota don rage zaman kusurwa, kuma wasan tibbin don samar da abubu da suke da zurfi mai amfani.

Teburin Abubuwan Ciki

- Wani Nufin Precision a Cikin Manufacturing ta CNC Machining

- Gama Tushen Tolerances Da Alama Mai Girma

- Takaddun Na Ilmin Sauran Sauran Takaddun CNC Takaddun: AI, IoT, da Automation

- Multi-Axis CNC Machining: Wuya abubuwan da suke iya amfani da alhurufi da karkashin zuwa

- Matsayin Ayyukan CNC Machining na tushen

- Tambayoyi Masu Yawan Faruwa