Jul 10,2025

0

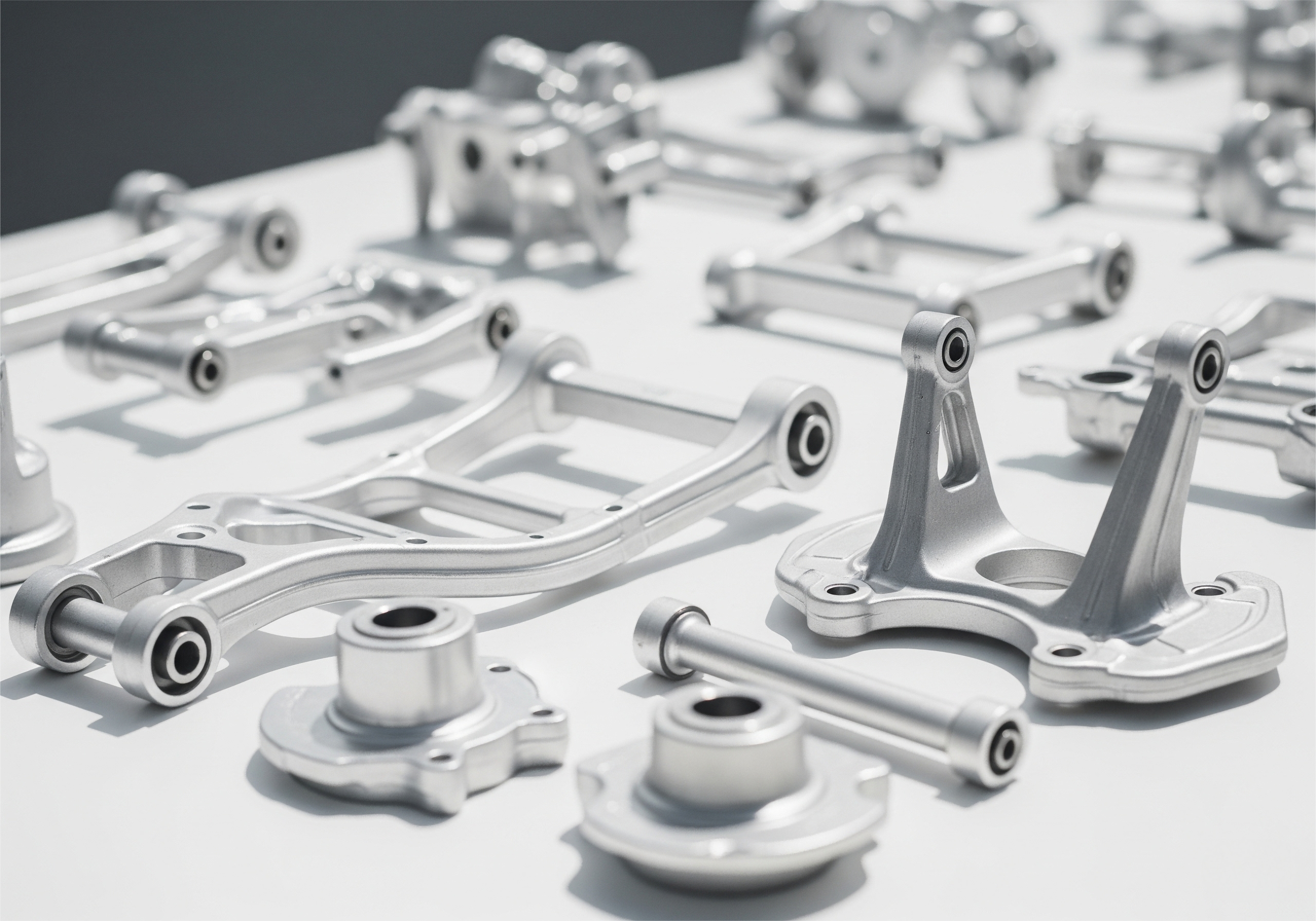

High pressure die casting stands out as one of the best methods around for creating detailed parts used in cars, including things like gearboxes and engine blocks. The process works by shooting molten metal into molds at really fast speeds while applying tons of pressure. This setup lets manufacturers churn out parts quickly with amazing accuracy sometimes down to just a few microns difference. According to research published somewhere academic looking, this technique gets so close to perfect measurements that it becomes essential when building car parts where even small errors matter a lot. How precise the final product turns out depends heavily on how fast and how hard they push that molten metal into the mold, which can actually boost performance metrics by about 20% in many cases. Recent improvements in mold designs have made all this possible, letting factories maintain consistent quality throughout entire batches of parts something the auto industry demands because their specifications leave no room for error.

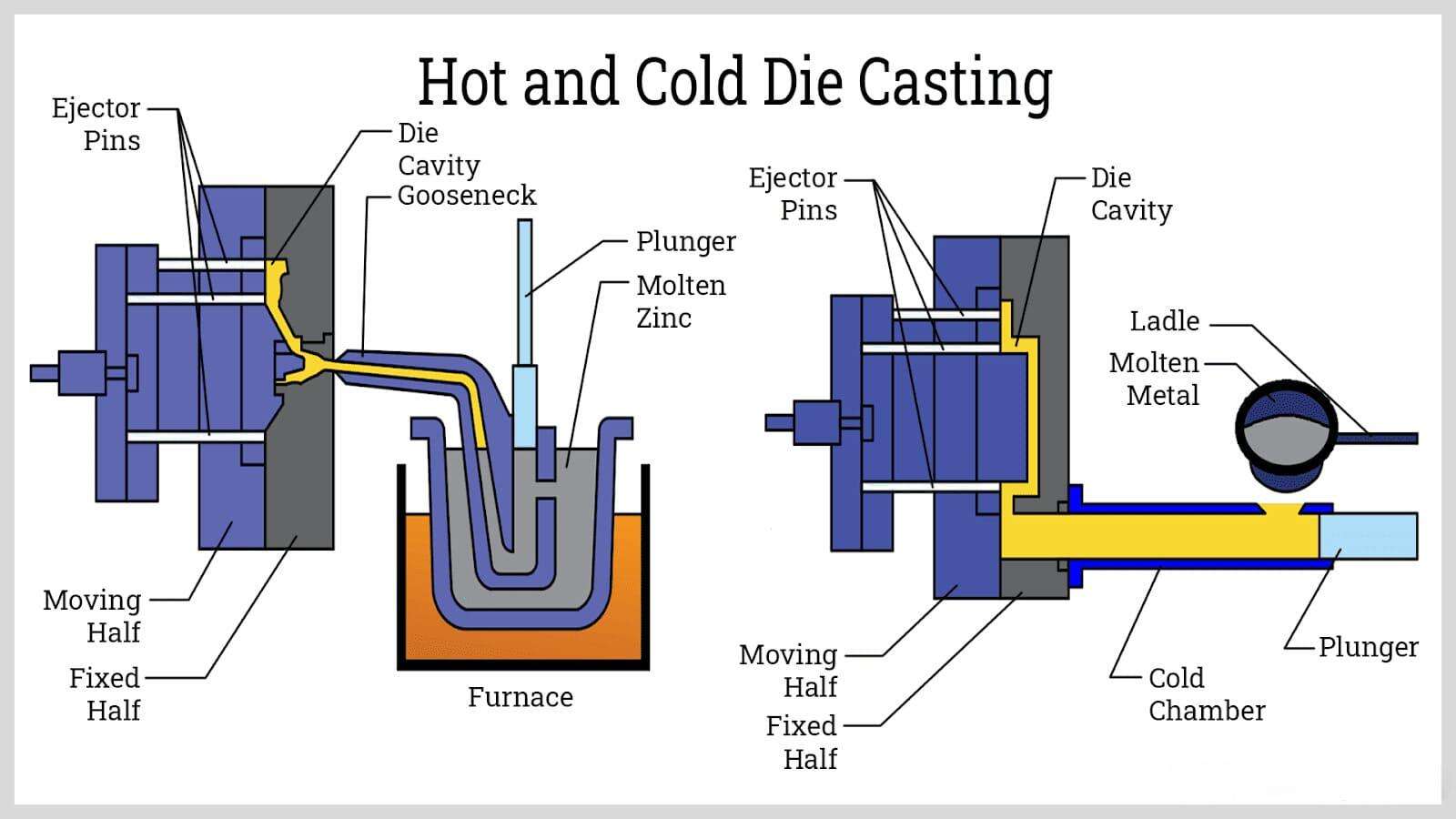

In automotive manufacturing, cold chamber and hot chamber die casting serve different purposes depending on what kind of metal we're working with. Cold chamber works best for metals that need higher temperatures to melt, like aluminum. It can create really complex parts with thick walls and good strength, which makes it popular for certain car components. But there's a catch - getting the metal into the mold has to be done just right or else we end up with defects. Hot chamber casting is better suited for softer metals such as zinc and magnesium. These systems have built-in melting chambers that let them work much faster, sometimes producing thousands of parts every hour without many issues. For big production runs where cost matters most, hot chamber casting wins out. However, when manufacturers need something exceptionally strong and precise, they'll go with cold chamber despite the extra effort involved. Choosing between these two isn't always straightforward since each comes with tradeoffs that depend heavily on what exactly needs to be made for cars.

Getting tight tolerances right is really important when making car parts, especially for engines and transmissions where even small mistakes can affect how well the whole vehicle performs. These days, factories use advanced machining methods along with strict quality checks to hit those exact measurements that matter so much. When manufacturers follow IATF 16949 guidelines, they're basically saying their production lines meet certain quality benchmarks that help keep everything consistent across different batches. Take cylinder blocks or transmission gears for example these parts need to be made within very narrow specifications. If they're off just slightly, cars might not run as smoothly, burn more fuel than necessary, or suffer from premature wear issues down the road. Real world testing shows that sticking to these tight specs can actually make engines work better by around 15% and also extend how long various components last before needing replacement. Modern car makers invest heavily in cutting edge technology and stick closely to established industry norms because consumers demand nothing less than top notch performance from their vehicles today.

The role of aluminum die casting in electric vehicle development cannot be overstated because of how light it is compared to other materials. Car companies are really pushing for better efficiency and greener options these days, so they're turning to aluminum more and more for making various car parts. Market reports suggest we'll see a big jump in aluminum usage across the auto industry over coming years, mainly because lighter cars burn less fuel. Industry insiders point out that switching to aluminum cuts down on overall vehicle weight, which means better battery range and lower energy consumption. We're seeing aluminum take over key spots in modern cars too - think engine blocks, transmissions, even structural elements where every ounce saved translates into real performance gains. Anyone looking to get their hands on quality aluminum die castings should check out specialty manufacturers who understand exactly what goes into creating parts that meet today's demanding specifications for both weight reduction and durability.

Zinc alloys are known for their strength and good mechanical characteristics, which makes them great choices for critical safety systems in cars. Automotive systems need materials that hold up under pressure situations, and zinc die castings meet those requirements pretty well. Studies show that using zinc alloys actually lowers component failures compared to other options, which obviously helps keep vehicles safer on the road. We see zinc die cast parts all over the place in modern cars from structural supports like door frames to important safety features such as seat belt anchors and airbag housings. Major car makers and groups like NHTSA regularly point out how important it is to pick these kinds of materials if we want to hit those tough safety benchmarks. Car companies putting zinc components into these vital spots shows they're serious about improving safety through better material choices in their manufacturing processes.

Pressure casting creates really tough parts that can handle all sorts of stress in vehicles. When manufacturers run their tests, they find that parts made through pressure casting last much longer than those from older casting techniques. This extra strength means cars need less fixing over time, which cuts down on both repair bills and overall ownership costs. Car makers are starting to see how pressure casting changes things for them. It lets designers build stronger frames without breaking the bank. The auto industry has been watching closely as pressure casting becomes more common, especially since it produces components that actually stand up to real world conditions and still meet those tough performance requirements that engineers demand.

By leveraging pressure-casting, manufacturers are able to extend the lifespan of critical automotive components, ensuring they withstand the rigors of daily use and environmental factors without compromising integrity.

IATF 16949 certification stands out as one of those important quality marks in the world of automotive die casting. It helps maintain consistent production standards throughout the industry. Basically, what it does is combine the core ideas from ISO 9001 quality management with extra rules specifically for cars and trucks, which really improves how things get made on factory floors. Getting certified requires quite a bit of work though. Companies need to create tons of paperwork, keep a close eye on every step of their processes, and train staff properly so everyone knows what needs doing. Take CPC Machines for instance they're known for cutting edge casting tech and have become pretty good examples of how to apply IATF standards effectively. Naturally, adopting something this comprehensive comes with its share of headaches. Many plants struggle when trying to fit old ways of working into new systems while dealing with rising costs along the way. But there are ways around these issues. Going slow with implementation makes sense rather than jumping in headfirst. Keeping employees educated about changes helps too. All these efforts pay off in better quality control and ultimately give businesses a stronger position against competitors worldwide.

Process verification according to IATF 16949 isn't just recommended it's essential for keeping manufacturing quality at its peak. What this really means is constantly checking how processes perform and what results they produce so everything stays within those strict quality specs. Looking at numbers matters a lot here too. Things like how many good parts come out versus bad ones, how often defects happen, and how long each production cycle takes give manufacturers clear signals about their operations after getting certified. Companies that actually put these checks into practice see better products coming off the line time after time, which makes customers happy. Just ask anyone in the automotive sector where quality can make or break business relationships. Industry pros keep pointing out that when companies stick with ongoing verification, they end up with far fewer faulty products and much more reliable deliveries. This makes sense given where manufacturing standards are heading these days nobody wants second rate goods anymore.

IATF 16949 certification makes a big difference when it comes to running smooth global supply chains for die casters looking to stand out in the marketplace. Research shows companies that get certified tend to perform better against their competition. Suppliers working with OEMs find that having this stamp of approval builds trust and opens doors for international collaborations, basically saying to partners "we know our stuff and follow good manufacturing practices." Real world examples from the industry point to noticeable improvements in how efficiently parts move through the supply chain. When manufacturers stick to IATF 16949 standards, they see better coordination between departments and clearer visibility into production processes. The result? Companies can operate more effectively while still growing their business despite all the challenges facing today's global manufacturing environment.

Closed loop systems play a major role in making die casting processes more efficient when it comes to materials. These systems take care of scrap metal and leftover materials instead of letting them go to waste, which means better use of resources overall. Companies save money on raw materials this way while helping protect the environment at the same time. Take the automotive industry for example many top manufacturers now run these closed loop operations and have seen real drops in how much new material they need to buy. Beyond just saving costs, these systems cut down on carbon emissions from manufacturing too, which makes them essential for anyone looking to make cars in a more sustainable way going forward.

Aluminum die casting plants are getting a major makeover thanks to energy efficient tech, making manufacturing much greener than before. Smart systems now track and control energy use throughout production processes. Some factories report cutting their power bills by nearly 30% after installing these systems, which helps the bottom line while reducing carbon footprints. Many operations are also adding solar panels or wind turbines to their facilities, slashing emissions even further. The big manufacturers aren't just talking about sustainability anymore they're investing real money into energy management solutions that work day in and day out across their production lines.

Zinc alloys can be recycled multiple times, which makes them really important for sustainability in car manufacturing. The automotive industry sees high recycling rates for these materials, helping protect the environment at the same time. Statistics show that most zinc parts get recycled again, cutting down on waste and saving energy compared to producing new materials from scratch. Modern recycling techniques work well with existing manufacturing systems, making it easier for companies to adopt greener practices without major disruptions. Plus, government rules and industry guidelines encourage better recycling habits, showing that manufacturers care about protecting nature even as they develop newer, faster production methods.

Bringing artificial intelligence into die casting operations has really transformed how efficient and good quality products come out of manufacturing lines. These smart systems do things like predict when equipment might break down and fine tune production schedules, which cuts down on defects and makes everything run better overall. Real world tests show pretty impressive results too. Some factories report cutting their cycle times by almost 30% while defects dropped by half after implementing AI solutions. The biggest wins tend to happen in quality checks and planning maintenance work, so production keeps moving without constant stoppages. Most people working in the field think there's still plenty of room for growth here, especially as companies start combining AI with other technologies like IoT sensors and advanced analytics platforms.

The automotive manufacturing landscape is changing fast thanks to mega-casting technology that simplifies production while making cars stronger overall. What makes this approach so revolutionary? Well, it cuts down on the sheer number of components needed for assembly, which means fewer pieces to handle during manufacturing and ultimately leads to vehicles that can better withstand stress points. Companies like Tesla have already implemented these methods successfully, cutting weeks off production timelines at their factories. Looking ahead, most experts believe we'll see mega-casting take over more factory floors across the industry. The math just adds up when considering both material savings and labor reductions. Plus, who doesn't want cars built with fewer welds and joints? Manufacturers are starting to realize that these one-piece castings not only save money but also create safer structures that hold up better over time.

Bringing collaborative robots (often called cobots) into high mix production settings has completely changed how die casting operations run day to day. These adaptable machines boost both flexibility and efficiency, making it much easier to handle all sorts of different production batches without constant retooling. Factories that have started using cobots are seeing real boosts in output numbers, sometimes doubling their throughput on certain parts while still keeping quality standards intact. Looking ahead, we can expect to see more automotive manufacturers turning to these working partners as automation progresses. Industry experts predict that coming years will bring deeper integration of these systems alongside more advanced capabilities designed specifically for meeting growing demand across various segments of the market.