Why Responsiveness Is the Defining Trait of a Strategic Aluminum Casting Supplier

Supply Chain Resilience: How Timely Communication Prevents Delays and Enables Agile Production Adjustments

An aluminum casting supplier that responds quickly can actually turn those unpredictable supply chain problems into something good for business. We've seen from industry reports that when there are material shortages or last minute design changes happen, companies working with suppliers who get back within a day cut down their production downtime by about 35% compared to others who take longer to react. Getting real time info about what alloys are available, how molds are progressing, and where logistics might be stuck helps make smart adjustments possible. For instance, during shortages it's sometimes necessary to switch to alternative alloy grades while still maintaining the needed metal properties. This kind of flexibility stops small issues from becoming big problems throughout the whole production process. Good suppliers also have proper systems in place for handling emergencies. According to some research studies, these kinds of protocols help prevent those costly project overruns that typically run around $740,000 according to Ponemon's findings. When risks get spotted early enough, teams can work together to adjust schedules before things spiral out of control.

Operational Maturity Signals: Linking Responsiveness to Scalability, Diverse Market Experience, and Growth Alignment

Responsiveness functions as a litmus test for deeper operational maturity in casting partners. Suppliers handling aerospace, automotive, and energy projects simultaneously demonstrate:

- Scalable capacity: Buffer furnaces and cross-trained teams that absorb demand spikes

- Adaptive workflows: Digital job tracking that routes urgent orders ahead of schedule

- Growth alignment: Quarterly planning sessions anticipating your volume projections

The characteristics we see come from decades of fine tuning manufacturing processes for all sorts of different specs. For instance, there's a big difference between controlling how fast things solidify when making those thin wall parts for cars compared to the much heavier turbine casings. According to the latest Supply Chain Partnerships Study from 2024, suppliers who get back on technical questions within four hours hit their production goals about 68% more often than those who don't. What really stands out though isn't just how fast they reply, but the whole approach they take. Good partners have this ingrained habit of staying ahead of problems before they even arise, which shows deep rooted operational discipline rather than just quick responses.

Core Technical Capabilities: Equipment, Process Mastery, and Aluminum Casting Method Fit

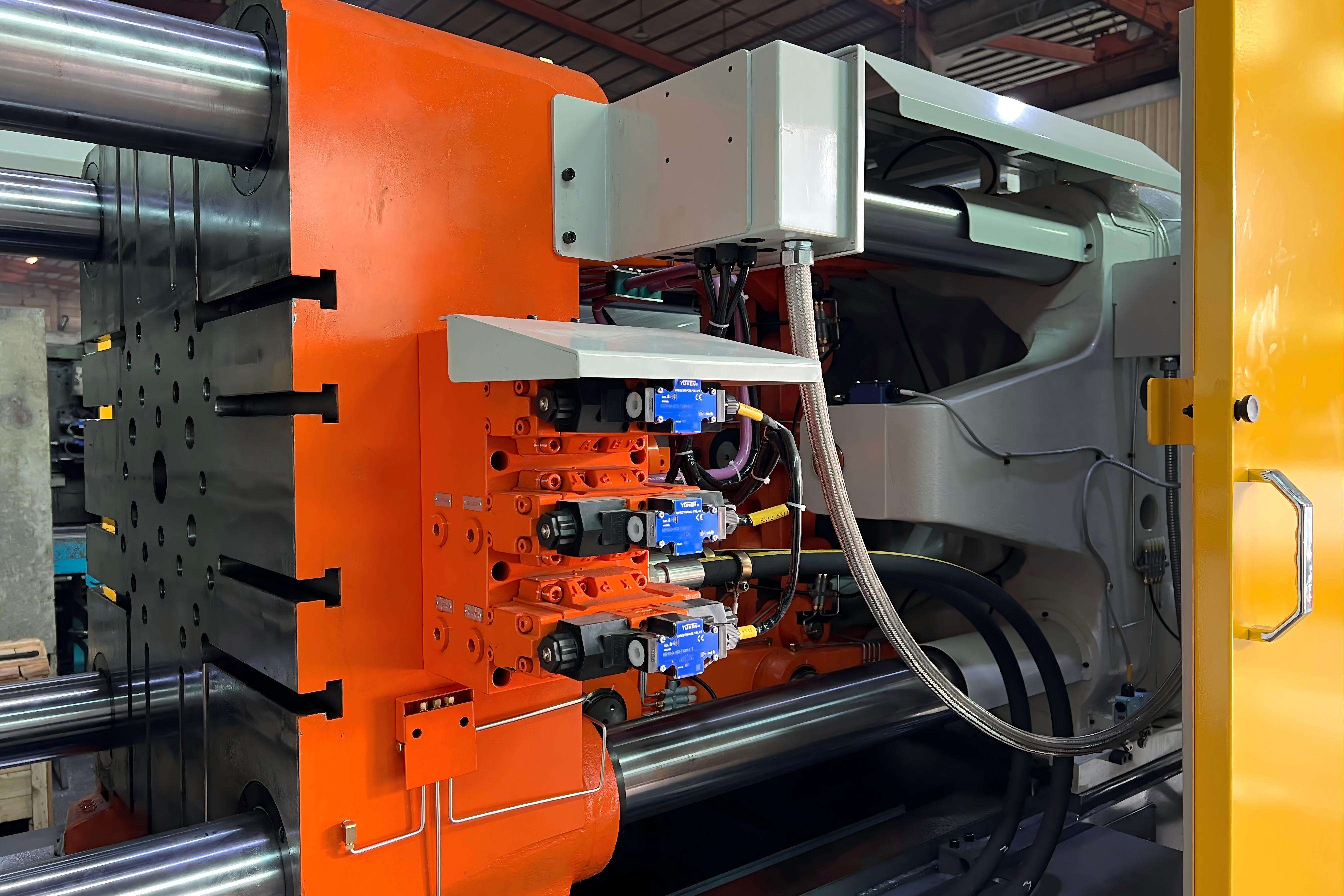

Modern Infrastructure Benchmarks: Automated Molding, Precision Sand Control, and Real-Time Process Monitoring

These days, most aluminum casting companies have switched to automated molding systems because they cut down on mistakes made by humans and keep parts consistent throughout the whole production process. Getting the sand just right is super important too. When the grain size and binder mix are properly controlled, it helps prevent those annoying air pockets that form inside sand castings. The smart foundries actually install thermal sensors and pressure gauges right at the mold so they can watch what happens as molten metal flows in. If something looks off, workers can tweak things mid-pour instead of waiting until after the fact. Statistics show that this tech-heavy method cuts waste by around 15 to 20 percent when compared with old school manual methods. For shops that integrate all these tools together, the results speak for themselves: parts come out with much tighter measurements (about plus or minus 0.010 inches) and smoother surfaces. That means less time spent on finishing work later on, which saves money in the long run for whoever ends up using those components.

Alloy & Process Expertise: Matching Gravity, Die, and Sand Casting Methods to Your Design and Performance Requirements

When choosing between different casting methods, there are basically three things manufacturers need to consider: how complex the part is, how many they need to produce, and what kind of strength properties are required. Gravity casting works best for big parts with thick walls that need serious structural strength, which makes it great for stuff like airplane frames. Die casting produces those super thin walled parts with really tight tolerances when companies need thousands of them, thanks to fast cooling times that make mass production possible for things like car parts. Sand casting remains popular for smaller batches or really heavy components over 500 pounds where changing molds isn't such a big deal. The choice of metal matters too. A356-T6 aluminum stands up well against saltwater corrosion, so it gets used a lot in boat hardware. Meanwhile A380 flows better during pouring, making it ideal for complicated shapes like computer heat sinks. Good suppliers will look at what kind of loads these parts need to handle plus how many will eventually be made before suggesting combinations that work both economically and functionally in the long run.

Full-Service Integration: Why In-House Secondary Processes Reduce Risk and Accelerate Time-to-Part

Heat Treatment, FPI, CNC Machining, and NDT – How Vertical Capabilities Eliminate Handoff Gaps for Aluminum Casting Supplier Partnerships

Working with an aluminum casting supplier who has those secondary processes right on site makes all the difference when it comes to managing project risks and getting things delivered on time. When there's no need to pass parts back and forth between different companies, we avoid those frustrating shipping delays, schedule clashes, and misunderstandings that happen during handoffs. Take heat treatment or precision machining for instance - having these services available immediately means we can tweak designs as needed without waiting days for outside vendors. The whole operation stays under one roof from start to finish, which keeps quality consistent throughout every stage of production. Parts don't get damaged in transit as often either since they stay within controlled environments. Plus, when something goes wrong, everyone knows exactly where responsibility lies. These kinds of suppliers adapt much quicker to changing requirements, which helps maintain flexible manufacturing operations. Ultimately, this kind of integration cuts down how long products take to reach market, especially important for making those complicated parts that demand tight tolerances.

Collaboraive Engineering Support: From Castability Guidance to Validated Prototyping

When companies form real strategic relationships with aluminum casting suppliers, they go way beyond simple order taking. These partnerships involve actual engineering work together from day one. Foundries look at CAD models during the initial design stage to spot potential manufacturing issues. They check for things like areas where heat might cause stress, walls that are too thin in some spots but thick elsewhere, or shapes that just won't cast properly and might lead to holes or cracks later on. Getting this kind of feedback early saves money because engineers can tweak designs before problems become expensive fixes. For really complicated parts, suppliers run computer simulations to see how metal will flow and where weaknesses might appear when weight is applied. Once prototypes are made, they get tested thoroughly. This includes checking dimensions with 3D scanners and seeing if components actually work as intended in real life situations. Only after all these tests pass do manufacturers proceed to make the molds for full production runs. According to recent research published in Additive Manufacturing Today last year, this back and forth process cuts down on delays by around 40% compared to making changes after everything has already been set in stone.

Trust Indicators: Certifications, Financial Health, and Partnership-Ready Behaviors

ISO 9001, ASTM, and MIL-Spec Compliance as Evidence of Repeatable Quality in Aluminum Casting Supplier Operations

When looking for an aluminum casting supplier, industry certifications such as ISO 9001, ASTM, and MIL-Spec act as important indicators of reliability. These standards basically confirm that a factory has proper quality control processes in place, tests materials properly, and follows strict manufacturing guidelines similar to those used in military applications. Companies that get third party audits show they stick to these requirements consistently. Some research suggests this kind of certification can cut down defects by almost half compared to non-certified operations. From a purchasing standpoint, having these credentials means there's actual proof that products will be made consistently, which helps reduce problems in the supply chain. Think of certifications as a sort of shortcut that shows a company takes its operations seriously. This saves time during the approval process since potential partners don't need to spend so much effort verifying quality themselves.

Frequently Asked Questions (FAQ)

Why is responsiveness important for an aluminum casting supplier?

Responsiveness from an aluminum casting supplier is crucial because it allows for timely adjustments and communication that can prevent production delays and enable agile responses to supply chain disruptions.

What are the benefits of in-house secondary processes in aluminum casting?

In-house secondary processes reduce project risks, accelerate time-to-part, eliminate handoff gaps, maintain consistent quality, and allow for immediate design adjustments if needed.

Why are certifications important for aluminum casting suppliers?

Certifications such as ISO 9001, ASTM, and MIL-Spec are important as they indicate a supplier's adherence to quality control processes, ensuring reliable and consistent product manufacturing.

How do aluminum casting suppliers support collaborative engineering?

Aluminum casting suppliers support collaborative engineering by providing feedback on CAD models, checking for manufacturing issues early, and validating prototypes using simulations and testing, which reduces delays and costly errors.

What factors should be considered when choosing a casting method?

The complexity of the part, production volume, and required strength properties are key factors in deciding between gravity, die, and sand casting methods.

Table of Contents

- Core Technical Capabilities: Equipment, Process Mastery, and Aluminum Casting Method Fit

- Full-Service Integration: Why In-House Secondary Processes Reduce Risk and Accelerate Time-to-Part

- Collaboraive Engineering Support: From Castability Guidance to Validated Prototyping

- Trust Indicators: Certifications, Financial Health, and Partnership-Ready Behaviors

-

Frequently Asked Questions (FAQ)

- Why is responsiveness important for an aluminum casting supplier?

- What are the benefits of in-house secondary processes in aluminum casting?

- Why are certifications important for aluminum casting suppliers?

- How do aluminum casting suppliers support collaborative engineering?

- What factors should be considered when choosing a casting method?