How International OEMs Vet Die Casting Manufacturers for Long-Term Export Partnerships

When looking at potential die casting partners, OEMs tend to focus on actual results rather than just sales pitches. Most will send someone out to check facilities firsthand and ask for sample parts to see what they can really produce. For scalability, companies want to see numbers that tell a story about their capacity, like if they regularly churn out over half a million zinc alloy pieces each month. Engineering teams also get tested by how fast they can make changes to prototypes when needed. About four out of five procurement departments won't even consider working together internationally unless the partner has an ISO 9001 quality system in place. And these same teams usually insist on seeing at least 98% on time deliveries for more than two years straight before signing any contracts. Manufacturers who already have good distribution setups across Europe and North America have a real advantage here. Their established presence in these regions cuts down waiting periods by anywhere from a month to nearly two months compared to those scrambling to find shipping solutions last minute.

Red Flags vs. Green Lights: Transparency, Audit History, and Reference Validation

Red flags include inconsistent material traceability, refusal to share third-party audit reports, or inability to provide references from automotive or industrial OEMs. IATF 16949 certification is non-negotiable for automotive projects—its absence triggers immediate disqualification due to mandatory process controls for defect prevention.

Conversely, green lights signal operational maturity:

- Unrestricted access to real-time production dashboards

- Documented corrective actions from prior Tier-1 supplier audits

- Validated testimonials highlighting crisis response—such as maintaining supply during port closures or raw material shortages

A manufacturer’s openness to unannounced audits correlates with 42% higher buyer trust (Ponemon Institute, 2023), while verified defect rates below 0.2% reflect deep-rooted quality discipline. Transparent quoting—itemizing tooling, material, compliance, and logistics costs—further reinforces credibility for long-term export contracts.

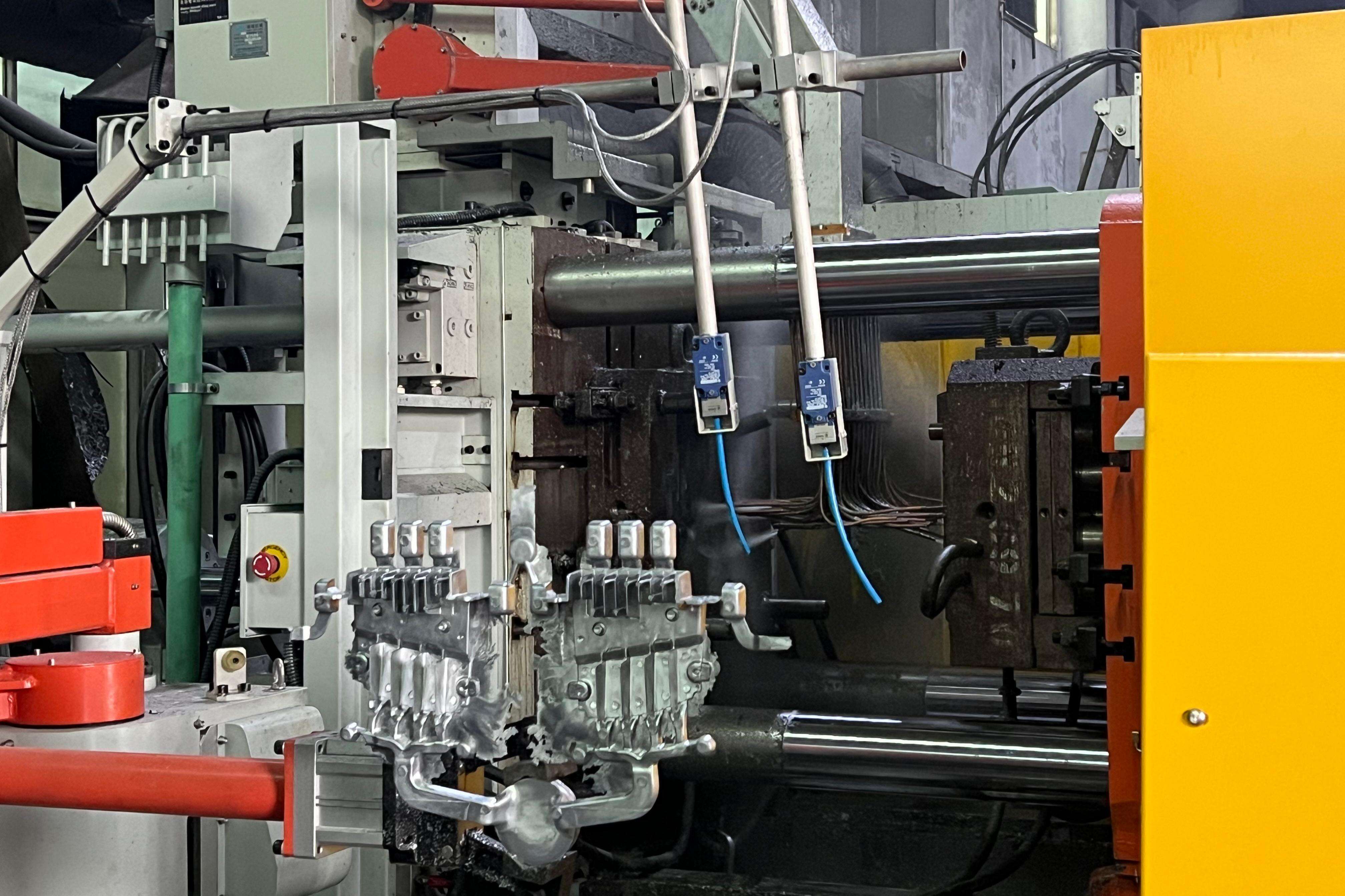

Advanced Technological Capability and Export-Scale Production

Automation, Precision Engineering, and Scalable Capacity: What Truly Supports Global Delivery Commitments

Automation and precision engineering are not differentiators—they’re prerequisites for export-scale reliability. Robotic cell integration reduces human error by 47% in high-complexity castings (2023 manufacturing efficiency benchmark), while real-time sensor–guided tooling achieves micron-level repeatability—meeting international tolerance standards of ±0.05mm or tighter, essential for aerospace and powertrain applications.

When talking about scalable capacity, we're not just looking at extra floor space. What really matters is how flexible the whole system can be. Think about production lines that can switch tools quickly, inventory systems connected to the cloud, and workforce plans that work through busy periods without breaking down. With IoT sensors doing predictive maintenance, most machines stay running around 99% of the time, which keeps shipments on track. Putting everything together in one facility makes a big difference too. When die casting, CNC finishing, and surface treatments all happen under the same roof, production times drop by roughly a third compared to spreading these processes across multiple suppliers. This kind of setup isn't just convenient it's actually necessary for keeping up with Just-In-Time requirements in European and North American markets. Many companies there simply won't tolerate delays, and research shows that over half will walk away from partnerships after just two missed delivery windows.

Rigorous Quality Compliance: Certifications That Unlock EU, US, and Automotive Export Markets

IATF 16949, ISO 14001, and PPAP Readiness — Non-Negotiable Credentials for a Trusted Die Casting Manufacturer

For global buyers around the world, internationally recognized certifications aren't just nice to have they're basically table stakes these days. Take IATF 16949 for example. This certification shows suppliers stick to those strict automotive quality standards. Companies with this certification tend to see roughly 40 percent fewer defects according to recent industry data from 2023. Then there's ISO 14001 which focuses on environmental responsibility. Getting this one has become almost mandatory for businesses wanting to sell products into the European Union, especially with new carbon border rules coming into effect. And let's not forget about PPAP readiness. When manufacturers can demonstrate their processes, measurement systems, and production capabilities have been thoroughly tested and proven reliable, that becomes the starting point for nearly every contract in the US automotive sector. These certifications really do matter in practice, not just on paper.

These standards are interdependent gatekeepers:

- IATF 16949 mandates defect prevention, statistical process control, and continuous improvement

- ISO 14001 ensures measurable progress in energy efficiency, waste reduction, and regulatory compliance

- PPAP documentation provides auditable evidence of production stability—not just design intent

Third-party audits against these frameworks expose systemic gaps; unresolved non-conformities cost manufacturers an average of $740,000 in lost opportunities (Ponemon Institute, 2023). Automotive OEMs require 100% certification alignment before onboarding—uncertified suppliers carry five times the recall risk and are excluded from bidding on qualified programs.

End-to-End Export Readiness: Integrated Supply Chain and Logistics Execution

An export ready die casting company connects all parts of the supply chain from where they get raw materials right through to when products reach their destination. They remove those separate departments that usually work independently like procurement, manufacturing floors, and shipping operations. With real time tracking systems in place, businesses can see exactly where their shipments are at any given moment. Smart planning ahead helps deal with problems before they happen, whether it's crowded ports causing delays, slow customs clearance processes, or running out of needed materials. When everything works together smoothly across these different stages, companies typically save around 25-30% on overall delivery time. Plus, proper documentation and procedures prevent expensive legal issues that often hold up international shipments for weeks or even months.

Core capabilities include:

- Customs expertise, ensuring accurate HS coding, origin declarations, and duty optimization per trade agreement

- Strategic warehousing, placing finished goods near key distribution hubs to compress transit windows

- Carrier-agnostic transportation coordination, selecting optimal routes and service tiers for reliability and cost balance

- Performance analytics, feeding delivery data back into scheduling and capacity planning

Without this level of orchestration, even technically capable manufacturers erode buyer confidence through missed deadlines or inconsistent documentation. Only seamless, integrated execution enables global scale—without compromising quality, compliance, or contractual delivery commitments.

FAQ Section

What are OEMs?

OEMs, or Original Equipment Manufacturers, are companies that produce parts and equipment that may be marketed by another manufacturer.

Why is ISO 9001 important for international collaborations?

ISO 9001 sets the standard for quality systems, ensuring consistency and quality in product manufacturing, which is crucial for international collaborations.

What does IATF 16949 certification signify?

IATF 16949 is a quality management standard specifically for the automotive sector, focusing on defect prevention and continuous improvement.

How do automation and precision engineering enhance production?

Automation and precision engineering enhance production by reducing errors, ensuring repeatability, and meeting stringent tolerance standards.