How ISO 9001 Drives Consistency Across Die Casting Processes

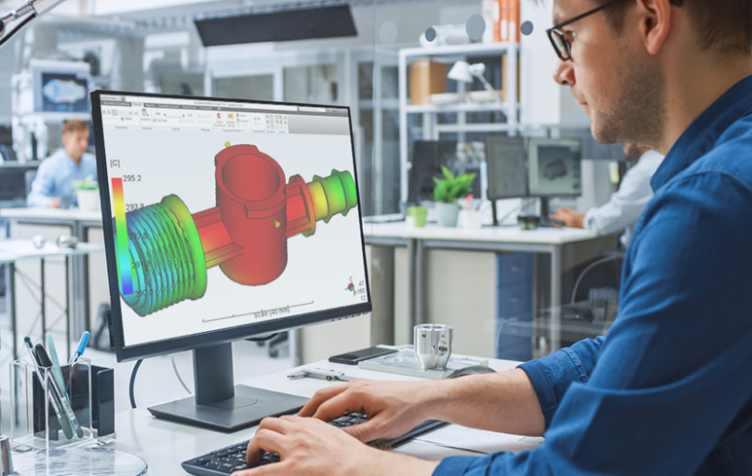

The Process Approach: Mapping Core Stages from Alloy Preparation to Finishing

The ISO 9001 process approach basically maps out each important step in die casting from start to finish. We talk about things like how the metal alloys are prepared all the way through to the final finishing touches. Most manufacturers keep careful records on what goes into their materials and exactly what temperature they melt at because getting those numbers right matters a lot for the quality of the final product. Standard operating procedures cover everything from maintaining the dies themselves to controlling how fast the metal gets injected into the mold and how it fills up the cavities inside. When it comes time for finishing work, there are still strict guidelines for trimming excess material, removing burrs, and applying coatings properly. All this detailed tracking helps cut down mistakes made by people and keeps parts within tight tolerances. Take alloy cooling as just one example where consistency makes all the difference. If we let the metal cool too quickly, it can solidify before it should and create problems like air pockets in the castings. Looking at how all these steps connect allows factories to tweak their production cycles, get better value from their resources, and produce consistently good quality products batch after batch.

Risk-Based Thinking in Practice: Preventing Variability in Mold Temperature, Shot Pressure, and Cooling Cycles

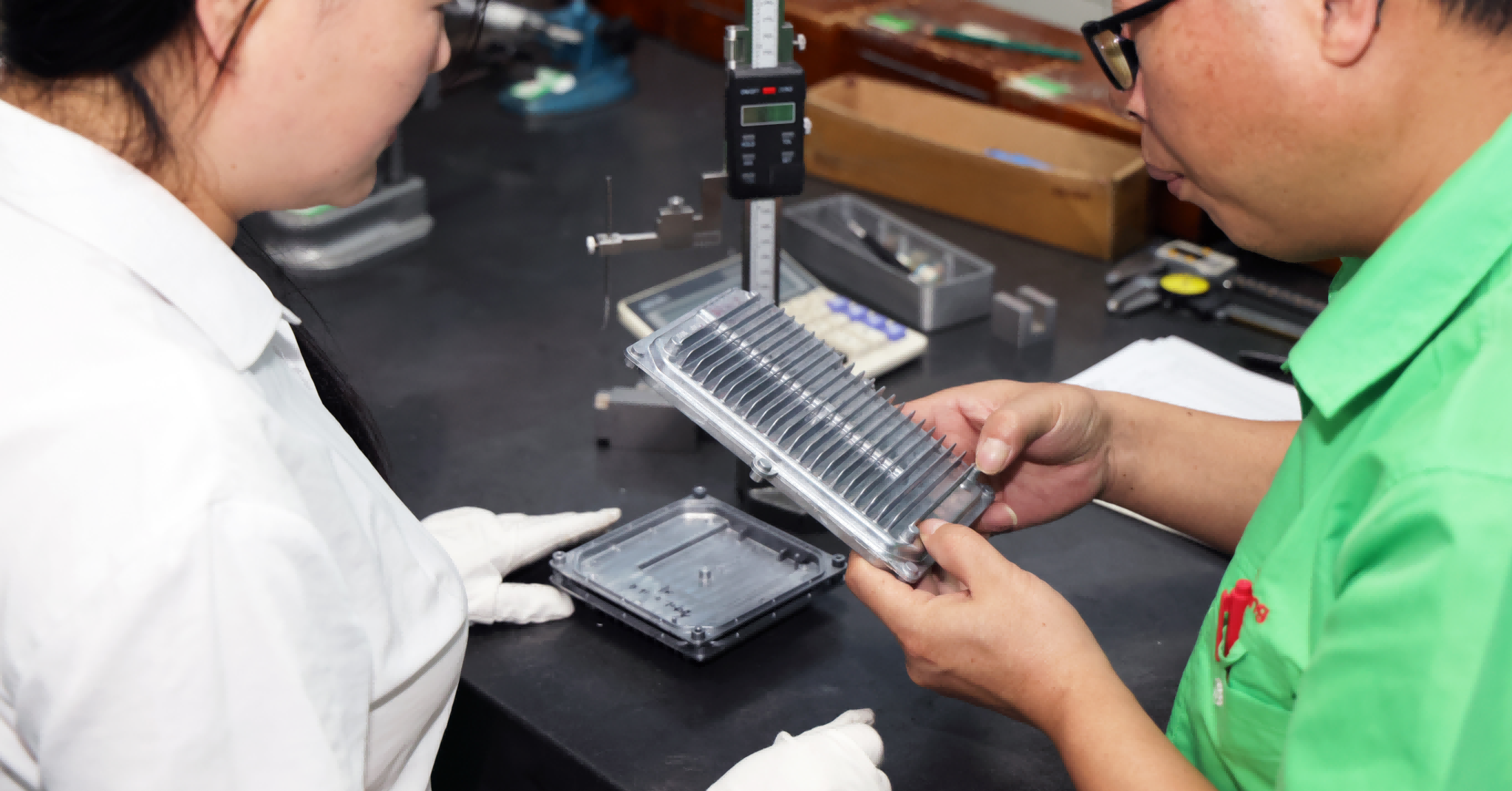

The risk-based approach of ISO 9001 focuses on three critical factors in die casting processes: mold temperature, shot pressure, and cooling cycles. Small changes in any of these can lead to big problems down the line. For mold temperatures, automated thermal sensors help catch variations early while regular maintenance keeps things running smoothly. Surface defects and premature die wear often come from temperature inconsistencies after all. When it comes to pressure, real-time monitoring makes sure injection stays pretty close to target settings, usually within about 2% either way. This prevents those frustrating issues where parts don't fill properly or trap air bubbles because the pressure was off. Cooling cycles get controlled through calibrated timers and flow meters, and good documentation helps adjust for when temperature fluctuates unexpectedly. Manufacturers who incorporate these checks into their daily routines report around a 30% drop in defects based on recent studies. Instead of waiting for something to go wrong, companies are tightening up their process ranges, cutting down on wasted materials from rework, and maintaining better consistency between production runs regardless of shift changes or batch differences.

ISO 9001 Certification as a Benchmark for Die Casting Quality Assurance

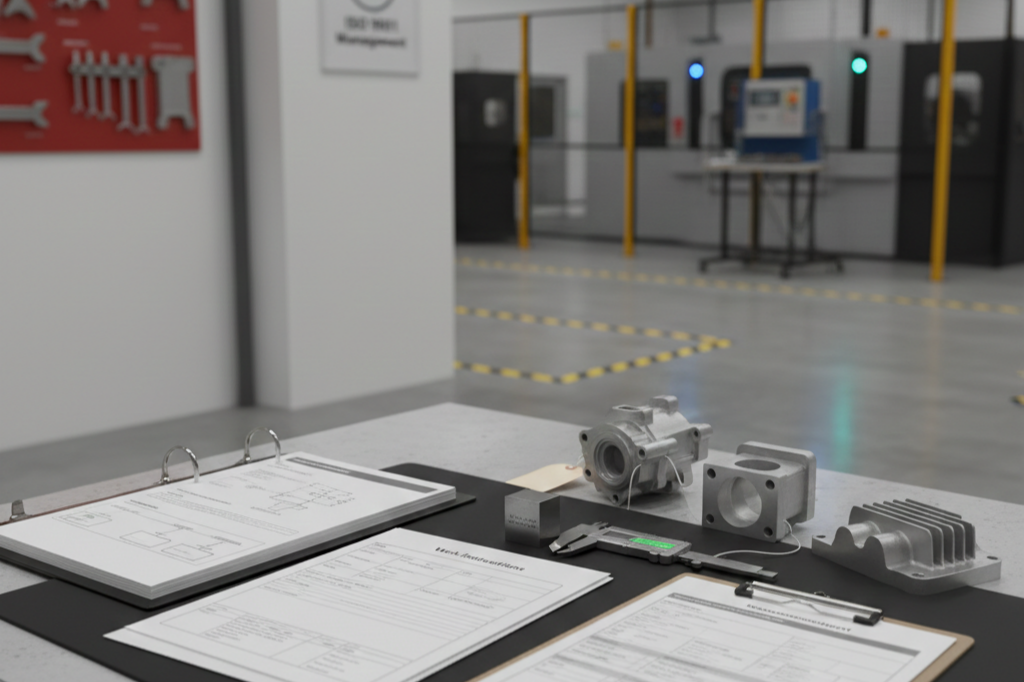

Documented Controls That Matter: Work Instructions, Calibration Logs, and Nonconformance Tracking

The ISO 9001 standard turns quality assurance from something companies talk about into actual practices that can be measured and checked during audits. Three main controls make this happen. First, standardized work instructions cut down confusion around things like setting mold temperatures, calibrating shot pressures, and determining finish parameters so results stay consistent even if different operators run the machines. Second, regular calibration logs check whether equipment remains reliable across all parts of the system including hydraulics, cooling lines, and measuring instruments. These logs catch small changes early before they lead to problems with product dimensions. Third, when defects occur, nonconformance tracking makes sure we don't just fix what went wrong but actually figure out why it happened in the first place and stop similar issues from happening again. Put together, these controls create a quality management system that stops variation right at the start rather than dealing with consequences later. According to industry reports, manufacturers who implement this full approach find root causes of problems about 40 percent quicker compared to those who only react after issues appear. What's really valuable is how predictive this system gets over time. For instance, if calibration records show an injection pressure sensor starting to drift off course, automatic work instructions kick in immediately to correct the issue long before any defective products get made.

Measurable Impact: ISO 9001’s Role in Reducing Scrap, Rework, and Delivery Delays

Data-Backed Consistency: Linking ISO 9001 Compliance to 62% Lower Scrap Rates (NADCA 2023)

Facilities certified under ISO 9001 standards report around 62% fewer scraps compared to those without certification according to recent NADCA research from last year. This improvement comes down to how these standards force plants to document everything from shot pressures to cooling cycles and even how they prepare alloys before casting. When all this info is tracked properly, operators can tweak processes as things happen on the floor instead of waiting until something goes wrong. The system also helps spot trouble spots early on, such as molds that aren't heated consistently or machines where timing settings drift out of spec over time. By constantly monitoring data against set limits, teams catch issues before they become big problems. Regular checks on equipment keep everything running smoothly too. All these practices together reduce the need for fixing mistakes later by about 27%, and get rid of those frustrating delays that hold up shipments. What starts as just following quality rules ends up making the whole operation run better day to day.

From Audit Readiness to Customer Trust: How Certification Strengthens B2B Contracts

Getting ISO 9001 certified basically gives businesses third party validation that their quality control is solid and based on real data, which makes all the difference when building trust with other companies. When suppliers have proper documentation for things like work instructions, equipment calibration records, and what happens when products don't meet standards, buyers spend less time inspecting everything themselves and get through their due diligence much quicker. Suppliers who hold this certification often see contracts approved around 15 percent faster because procurement folks already know the processes are checked off before anything gets signed. During contract talks, showing actual numbers about how much waste gets cut down plus consistent delivery times can lead to about 23 percent more long-term deals getting sealed. What really matters though is the part about fixing problems properly. The standard requires companies to actually address issues instead of letting them happen again and again. This kind of transparency creates stable partnerships over time and keeps good suppliers coming back year after year. So while many still think of ISO 9001 as just another box to check for regulations, smart businesses know it actually sets them apart from competitors who aren't taking quality seriously enough.

Practical Implementation: Aligning ISO 9001 with Foundry Floor Realities

Lean-QMS Integration: Simplifying Documentation Without Sacrificing Control

Most die casting shops see ISO 9001 documentation as just another paperwork headache at first glance. But things change when these systems get paired with Lean manufacturing concepts. Lean-QMS swaps out all those bulky paper forms for visual guides, digital checklists, and control processes that actually make sense to the people working on the floor day to day. Calibration records happen automatically now, and issues get tracked in real time so nobody has to waste time filling out forms manually. What's interesting is how shop floor workers start getting involved in making things better too. They help refine their own workflows, cutting down on documentation by somewhere between a third and almost half without sacrificing any quality standards. The end result? A quality management system that really works for foundries. It cuts down on the admin hassle, helps solve problems faster, and keeps production running smoothly. Turns out good quality control doesn't hold back manufacturing speed after all. Instead, it actually makes operations more dependable, quicker to respond to changes, and able to handle whatever comes next.

FAQ

What is ISO 9001?

ISO 9001 is an international standard for quality management systems, providing a framework for organizations to ensure consistent quality in their processes and products.

How does ISO 9001 improve die casting processes?

ISO 9001 improves die casting processes by providing structured guidelines that enhance consistency, reduce errors, and streamline operations through focused documentation, risk management, and standardized procedures.

Why is risk-based thinking important in die casting?

Risk-based thinking is important in die casting as it identifies potential variables, such as mold temperature and shot pressure, that could affect product quality, allowing for proactive adjustments and reduced defects.

What role does ISO 9001 certification play in customer trust?

ISO 9001 certification builds customer trust by validating a company's quality control processes, ensuring they meet rigorous standards, and providing transparency in operations, leading to more confident business partnerships.

How can Lean-QMS integration benefit die casting operations?

Lean-QMS integration benefits die casting by simplifying documentation, improving real-time issue tracking, involving workers in process improvements, and maintaining quality without sacrificing production speed.