Surface Finish Standards and Grade Selection for Die Cast Parts

NADCA Surface Finish Grades: Utility, Functional, Commercial, and Consumer—Matching Expectations to Application

Selecting the appropriate surface finish grade for die cast components requires alignment with both functional and aesthetic requirements. The North American Die Casting Association (NADCA) categorizes surface finishes into five distinct grades:

| Grade | Classification | Primary Applications | Appearance Requirements |

|---|---|---|---|

| 1 | Utility | Internal components with no cosmetic needs | Unprocessed as-cast surfaces |

| 2 | Functional | Mechanically finished parts requiring paint adhesion | Shot-blasted or chemically prepped |

| 3 | Commercial | Structural elements with partial visibility | Uniform texture, minor defects |

| 4 | Consumer | Externally visible surfaces in appliances/electronics | Consistent texture, defect-free |

| 5 | Superior (High-End) | Automotive trim or medical devices demanding flawless appearance | Mirror-like finishes |

Prioritize the lowest feasible grade—e.g., Utility Grade (1) for internal brackets—to control costs while meeting performance needs. Each tier imposes stricter porosity and roughness tolerances: Consumer Grade (4) components typically require ≤0.8 μm Ra, whereas Utility parts may accept up to 3.2 μm Ra.

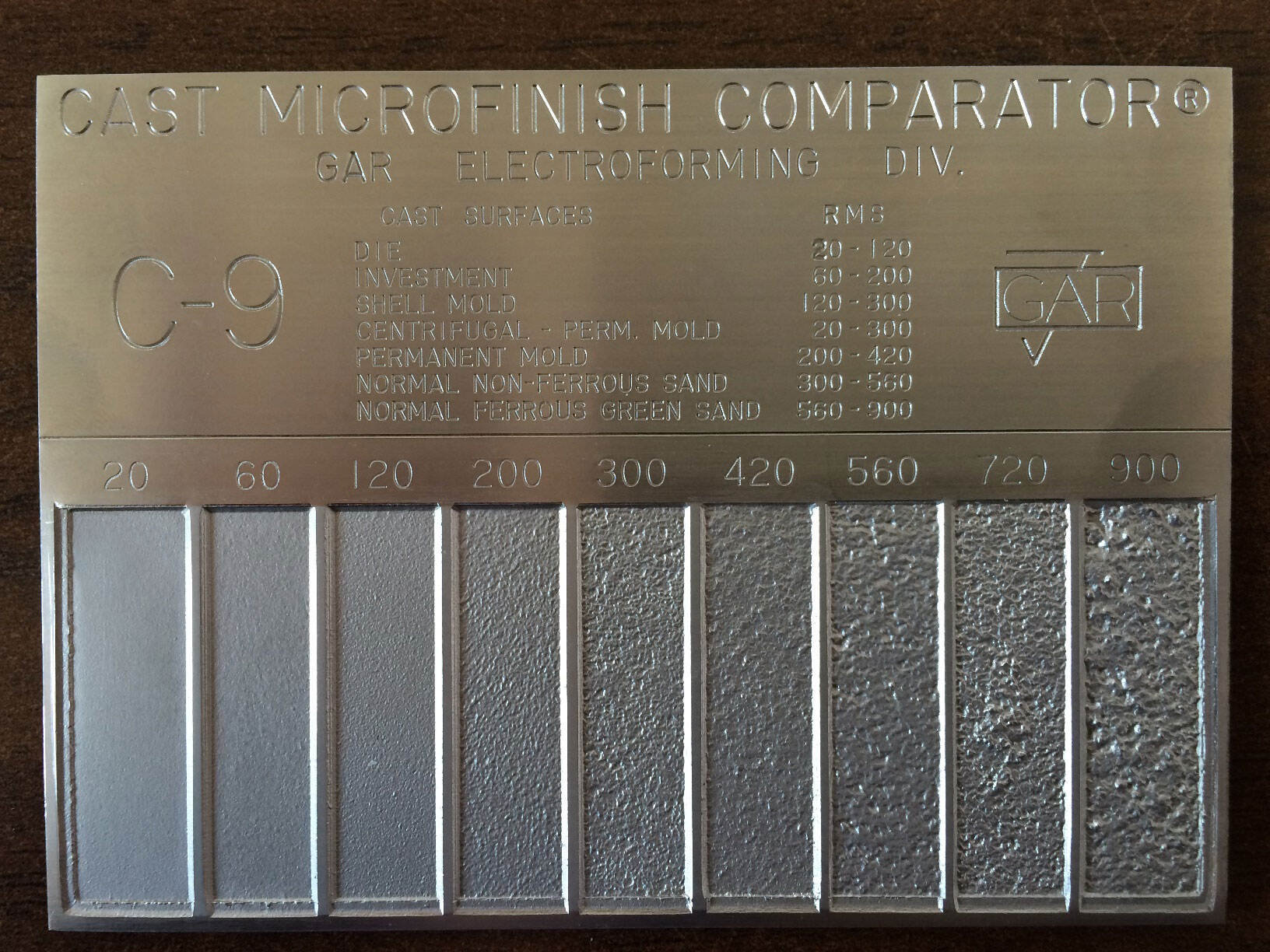

The Critical Role of As-Cast Condition in Defining Surface Finish Feasibility

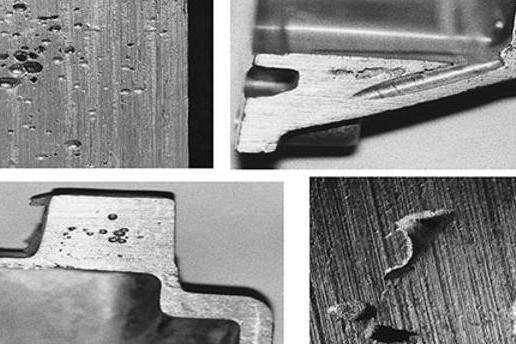

What happens on that first cast surface really determines what kind of finish we can get later on. Porosity levels, those flow lines from molten metal movement, and how metals separate within the mold all play their part. When gas bubbles form pores larger than 0.1mm, getting to Commercial Grade 3 standards becomes nearly impossible without doing some welding work afterwards. Temperature swings in the die over 30 degrees Celsius while casting actually make those surface craters worse by about 70 percent, which messes up both anodizing processes and those delicate thin film coatings manufacturers rely on. That's why good process control matters so much in production settings. Keeping cooling rates steady throughout and designing gates properly helps maintain better surface quality overall. Some factories report cutting down on extra machining steps by roughly 40% when they focus on these basics right from the start.

Pre-Treatment Methods That Enable Reliable Surface Finishes

Mechanical Profiling: Shot Blasting vs. Sand Blasting for Optimal Anchor Pattern Development

Getting the right mechanical profiling is what creates those anchor patterns coatings need to stick properly. Shot blasting works by throwing around spherical media like steel beads, which knocks out pretty even surfaces with about 1.5 to 3 mil roughness. This makes it great for operations running at high volumes where keeping dust down matters and parts need to last longer. On the flip side, sand blasting throws angular stuff against surfaces, creating these rougher, jagged profiles around 3 to 5 mil deep. These give coatings much better grip for tough jobs, though they do create more mess to clean up afterward. According to industry numbers, around seven out of ten coating failures happen because surfaces weren't profiled correctly from the start. When choosing between methods, factors like how complex the part geometry is, how many pieces need processing, and meeting environmental regulations often matter just as much as getting that perfect bond between coating and substrate.

Chemical Pre-Treatments: Chromate and Trivalent Chromium Conversion Coatings for Enhanced Adhesion

Pre treatment chemicals work wonders for improving how well things stick to metal surfaces and protecting against rust. Chromate coatings made with hexavalent chromium have long been reliable performers, though manufacturers around the world are pulling back because of health concerns related to toxicity. These days, trivalent chromium solutions are becoming the go to choice for eco friendly production lines. They pass all the necessary REACH regulations, hold up against salt spray testing for over 500 hours, and boost paint adherence by roughly 40% compared to bare metal. While both types go through similar steps involving cleaning, activating, then applying the actual coating, working with trivalent materials just makes life easier in terms of safety protocols and paperwork headaches. When choosing between different treatments, factors like what kind of alloy we're dealing with zinc aluminum versus magnesium for instance and where the finished product will ultimately be used play a major role in decision making.

Evaluating Surface Finishes for Performance and Aesthetics

Anodizing Challenges on High-Silicon Aluminum Alloys (e.g., ADC12) and Alternatives

Aluminum alloys with high silicon content, such as ADC12 containing around 10 to 12% silicon, just don't play well when it comes to anodizing processes. The silicon particles basically mess up how the oxide layer forms across the surface. What happens? Uneven thickness, weaker protection against corrosion, and those annoying dark spots or what people call "smut" showing through. When the main concern is actually protecting the part rather than looking good, trivalent chromium conversion coatings tend to stick better and offer stronger corrosion resistance too, all while costing less money upfront. Sure, some shops try mechanical polishing first to fix these issues before anodizing, but that approach typically bumps production costs by somewhere between 15 and 25%. For parts where appearance doesn't matter much, especially when silicon levels go above 9%, powder coating or ceramic treatments generally work better than traditional anodizing methods both in terms of how well they perform and what they cost to apply.

Powder Coating vs. E-Coating: Trade-offs in Durability, Edge Coverage, and Cost for HPDC Components

For High Pressure Die Casting (HPDC) components, powder coating and e-coating serve complementary roles:

- Durability: Powder coating delivers thicker films (60–120 μm) with superior impact resistance—well-suited for automotive exteriors. E-coating provides thinner, more UV-stable films (15–25 μm).

- Edge coverage: E-coating’s electrodeposition ensures uniform coverage—even on sharp edges and recesses—outperforming powder coating by 40% in complex geometries.

- Cost & sustainability: E-coating reduces material waste by 30% via liquid recycling; powder coating eliminates VOC emissions but demands higher curing energy.

| Factor | Powder Coating | E-Coating |

|---|---|---|

| Film Thickness | 60–120 μm | 15–25 μm |

| Edge Protection | Moderate | Superior |

| Environmental | Zero VOCs | Liquid waste recycling |

A Practical Decision Framework for Surface Finish Selection

Material–Geometry–Function Matrix: Aligning Surface Finishes with Real-World Requirements

Choosing the right surface finish really comes down to looking at three main things that all affect each other: what material we're working with, how the part is shaped, and what it needs to do functionally. For example, aluminum alloys such as ADC12 often need special treatments before finishing because the silicon content makes anodizing unstable. Parts with thin walls or lots of undercuts just don't work well with certain mechanical finishes. When it comes to actual function, there's a big difference between needing something that can stand up to saltwater corrosion for boat parts versus getting that sleek look required for consumer electronics. These different needs point us toward specific options like trivalent chromium conversion coatings, powder coatings, or e-coatings depending on what works best both technically and economically.

| Dimension | Key Considerations | Impact on Finish Selection |

|---|---|---|

| Material | Alloy composition, porosity, hardness | Dictates pre-treatment feasibility |

| Geometry | Wall thickness, undercuts, surface area | Limits mechanical/chemical application |

| Function | Wear resistance, aesthetics, cost targets | Prioritizes coating performance metrics |

Take complex parts with lots of corners and edges for instance they really work well with e-coating since it gets into those hard to reach spots. But when something needs to last through constant wear and tear, powder coating might be worth the extra energy spend even though it costs more. Getting this right at the design stage makes a huge difference. Most engineers see around 80% better results on their first try when specs are met properly. And nobody wants to waste time and money on fixing things after machining. About half of all rework happens because the wrong surface treatment was chosen initially, so getting this decision right from day one saves headaches down the road.

FAQ

What is the best surface finish for internal components without cosmetic needs?

Utility Grade (1) is the best surface finish for internal components without cosmetic needs as it features unprocessed as-cast surfaces.

How does alloy composition affect surface finish selection?

Alloy composition affects surface finish selection by dictating pre-treatment feasibility, as certain compositions may require specific treatments to ensure finish integrity.

What are the environmental benefits of e-coating compared to powder coating?

E-coating reduces material waste by 30% via liquid recycling, while powder coating eliminates VOC emissions but requires higher energy for curing.

Why might anodizing not be suitable for high silicon aluminum alloys?

Anodizing might not be suitable for high silicon aluminum alloys because silicon particles disrupt the oxide layer formation, leading to uneven thickness and reduced corrosion protection.