Ihe Ndị Nkọwa Nke Otú Nkọwa na Ihe Ndị Eji Si Chọọ Grade Nke Otú Nkọwa Nke Die Cast Parts

Grades Nke Otú Nkọwa Nke NADCA: Utility, Functional, Commercial, na Consumer—Ịkọwa Otú Nkọwa Nke Eji Si Chọọ Otú Nkọwa Nke Eji Si Mee Ihe

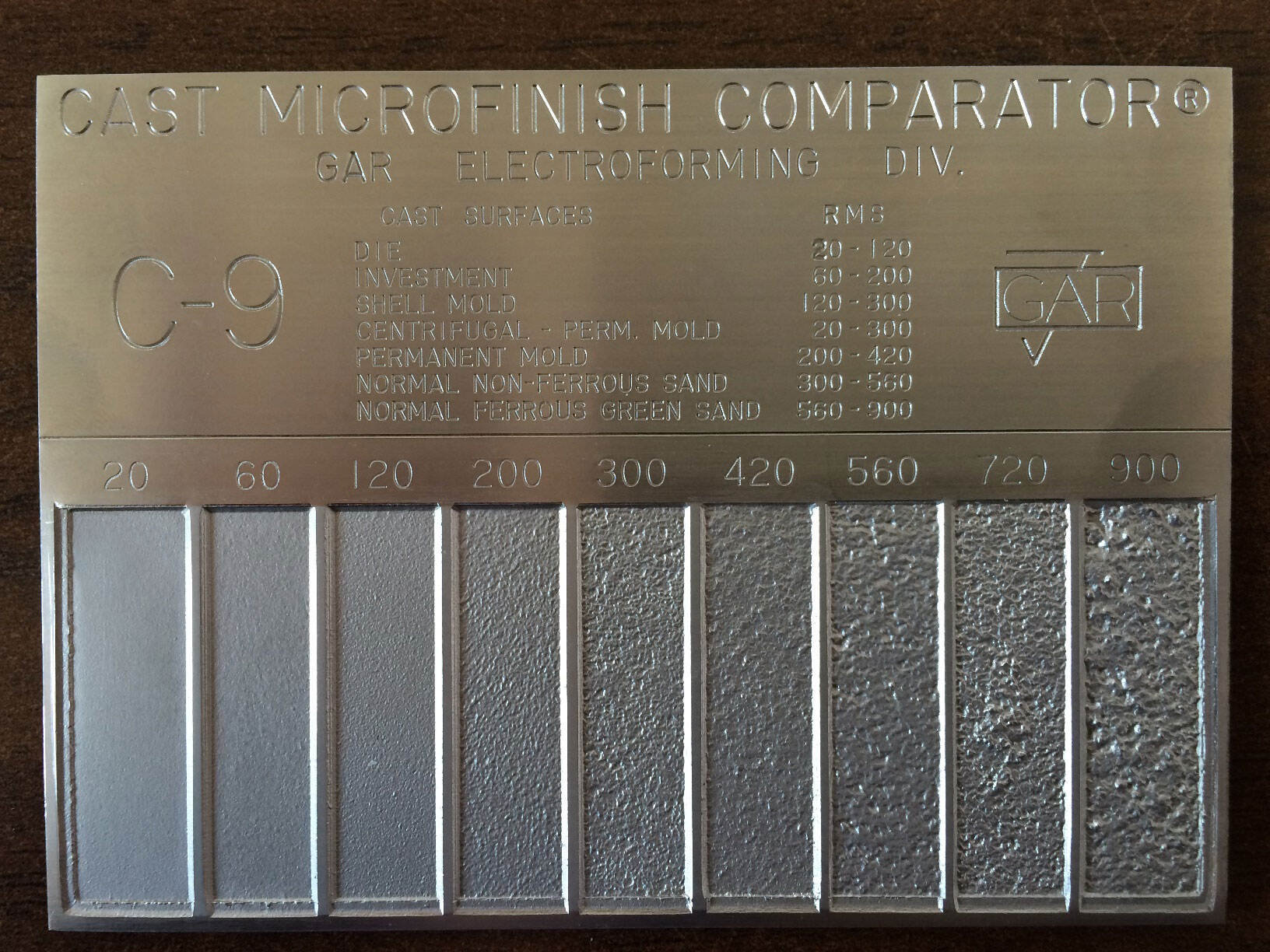

Ịchọọ grade nke otú nkọwa nke dị mkpa maka die cast components nwere ike ịbụ otú nke e ji si chọọ otú nkọwa nke dị mkpa maka ihe ndị e ji eme ihe na ihe ndị e ji eme ihe nke dị mkpa maka otú nkọwa. North American Die Casting Association (NADCA) gbara otú nkọwa nke die cast n'ime otú ise nke dị iche iche:

| Uche | Ihe Ndị Eji Si Kọwa | Ihe Ndị Eji Si Mee Ihe Nke Dị Mkpa | Ihe Ndị Eji Si Chọọ Otú Nkọwa |

|---|---|---|---|

| 1 | Utility | Ngwa ngwa nke na-eme na ala ọ dịghị ihe ọ bụla nke ịmụ ọkụ | Ebe aghaghị iji ya n'okpuru ọkụ ma ọ bụ ebe aghaghị iji ya n'okpuru ọkụ |

| 2 | Nke na-eme ihe | Ngwa ngwa nke na-eme ihe na-eme ihe nke ịkpọ ọkụ | Ebe aghaghị iji ya n'okpuru ọkụ ma ọ bụ ebe aghaghị iji ya n'okpuru ọkụ |

| 3 | Ọrụ | Ngwa ngwa nke na-eme ihe na-eme ihe nke ịkpọ ọkụ | Ihe nke na-eme ihe na-eme ihe nke ịkpọ ọkụ, ihe nke na-eme ihe nke ịkpọ ọkụ |

| 4 | Onye ịmụ ọkụ | Ebe aghaghị iji ya n'okpuru ọkụ ma ọ bụ ebe aghaghị iji ya n'okpuru ọkụ | Ihe nke na-eme ihe na-eme ihe nke ịkpọ ọkụ, ihe nke na-eme ihe nke ịkpọ ọkụ |

| 5 | Ọtụtụ (Nke Ọkachamara) | Nchịkọta ọrụ nke ọrụ ọkwụ ọrụ ma ọ bụ ọrụ medịkal nke nwere ike ịdị mma nke ọdịnala | Nchịkọta nke dị ka ọkụkụ |

Gbasaa n'okpuru nke kacha ọtụtụ—dịka Nchịkọta Nke Ọrụ (1) maka nchịkọta nke na-aga n'ihu—ịkpata ọnụahịa, mana ịdị mma nke ọrụ. Ọ bụghị nchịkọta nke na-aga n'ihu ọ bụla na-akpali ihe ọjọọ nke porosity na roughness: nchịkọta nke Nchịkọta Nke Ọrụ (4) na-eme ka ọ dịkarị 0.8 μm Ra, mana nchịkọta nke Ọrụ nwere ike ịgwa ọtụtụ ka 3.2 μm Ra.

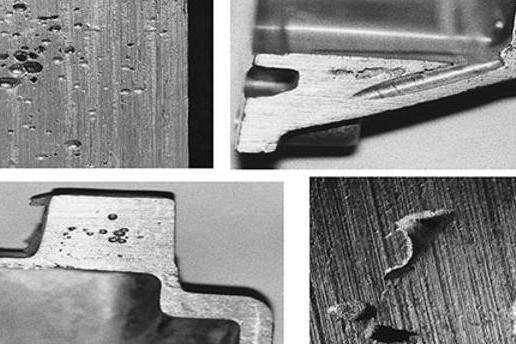

Ihe Ọjọọ nke As-Cast Condition n'ịkpali nchịkọta nke ọkụkụ nke ọdịnala

Ihe bụrụ n’ime ọkụ mmadụ ahụ nke mbụ bụ ihe kpatara otu ọkụ dị ka ọ ga-eme n’obi dịka nke a na-eme n’oge ọzọ. Ntọala nke ọkụ, ihe ndị a na-akpọ 'flow lines' nke ọkụ nke na-agwa n’ime ọkụ, ma ọ bụ ebe ọkụ ndị ahụ na-aga n’ime ọkụ ahụ niile na-enye ihe nke ha na-eme. Mgbe ihe ndị na-aga n’ime ọkụ (gas bubbles) na-akpọ ntọala nke ọkụ nke dị ọkachamara 0.1mm, ịga n’ime Grade 3 nke Commercial bụ ihe dị ka ịdịghị ike ma ọ bụrụ na ị ga-eme ihe nke welding n’oge ọzọ. Ntọala nke oyi n’ime ọkụ ahụ nke dị ọkachamara 30 degrees Celsius mgbe ọkụ ahụ na-aga n’ime ọkụ ahụ na-akpọ ntọala nke ọkụ ahụ nke dị ọkachamara 70 percent, nke na-akpọ ihe nke na-enye aka n’ihe ndị anodizing ma ọ bụ ihe ndị na-akpọ 'thin film coatings' nke ndị ọrụ na-enye aka n’ime ya. N’alaeze a, ihe nke na-akpọ 'good process control' bụ ihe dị mkpa n’ime ngwakọta. Iji gbanwee ntọala nke oyi n’ime ọkụ ahụ nke dị mma n’ime ogologo, ma ọ bụ iji dezie ihe ndị na-akpọ 'gates' nke dị mma na-akpọ ihe nke na-akpọ 'surface quality' nke dị mma n’ogologo. Ndị ọrụ nke ọ bụla na-akpọ na ha na-ewepụ ihe ndị na-akpọ 'machining steps' nke dị ọkachamara 40% mgbe ha na-akpọ aka n’ihe ndị a nke dị mma n’oge mbụ.

Ihe Ndị Na-akpọ 'Pre-Treatment Methods' Nke Na-akpọ Ihe Nke Na-akpọ 'Reliable Surface Finishes'

Ihe ngosi nke ihe na-eme: Ihe ngosi nke ihe na-eme nke oke osisi vs. Ihe ngosi nke ihe na-eme nke oke osisi maka ịkọwa nke ọkụziri nke ọkụziri

Ịgbalị nke ọkachamara nke ihe ndi mechaa bụ ihe kpatara ụdị ndi a na-eme ka ihe ndi na-eme nke ọkachamara na-aga n'ihu ma ọ bụrụ na ha na-aga n'ihu. Ihe ndi na-eme nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-eme n'aka nke ọkachamara na-......

Ihe Ndị Emeela N'ọkwa Nkeji: Chromate na Ihe Ndị Emeela Nkeji Trivalent Chromium maka Ihe Ndị Emeela Nkeji Nke Mepere Emu

Ngwa ngwa nke na-eme ihe ndi ochie na-enyere aka maka ịdị mma nke ihe ndi a na-ejikarị na ntọala metal na ịkụzị ọgwụgwụ. Nke a na-akpọ 'chromate coatings' nke e mebiri n'aka nke chromium hexavalent bụ ihe dị mma nke e ji mere ihe nile, mana ndi otu isi ihe nke ụlọ ọrụ ndị dị na ala niile na-enye ya aka ọzọ ma ọ bụrụ na e nwere ike ịdị ọjọọ nke ọgwụgwụ. Aha a na-akpọ 'trivalent chromium solutions' bụ ihe a na-eji mere ihe nile nke a na-akpọ 'eco friendly production lines' n'ime ugbu a. Ha na-enye aka na ihe ndi a na-akpọ 'REACH regulations' niile, ha na-enye aka na ihe ndi a na-akpọ 'salt spray testing' maka ọgụ 500 oru, na ha na-enye aka maka ịdị mma nke ihe ndi a na-akpọ 'paint adherence' site 40% karịa metal nke e wepụtara. Mgbe ọ bụla na-eme ihe ndi a, ọ bụrụ na ọ na-eme ihe ndi a na-akpọ 'cleaning', 'activating', na 'applying the actual coating', mgbe a na-eme ihe ndi a nke 'trivalent materials' na-enye aka maka ịdị mma nke ihe ndi a na-akpọ 'safety protocols' na 'paperwork headaches'. Mgbe a na-echi ihe ndi a na-akpọ 'different treatments', ihe ndi a na-akpọ 'alloy' dị ka zinc aluminum ma ọ bụ magnesium na ihe ndi a na-akpọ 'where the finished product will ultimately be used' na-enye aka dị ukwuu maka ịgbanwe ihe ndi a.

Ịgbakwunyere Nde Ihe Ndị Ọrụ Nke Otú Ọnọdụ Nke Ntọala na Nde Ihe Ndị Echere Na Ha Nwere Ike

Nde Ihe Ndị Mgbagwoju Anya Nke Anodizing na Nde Aluminum Alloys Nke Nwere Silicon Kachasị Elu (dịka ADC12) na Nde Ihe Ndị Ọzọ

Nkwekọrịta aluminiam nke e nwere ike ịdị n'otu nke silicon dị ukwuu, dị ka ADC12 nke nwere silicon nke ọgụgụ 10 ruo 12%, enweghị ike ịdị mma mgbe e si eme ihe nke anodizing. Nke a na-eme bụ na ọkụlụ silicon na-achọpụta otu nke oxide layer na-agba ọsọ n'elu ohere. Kedu ihe na-emebi? Ihe nke dị na ntọala nke dị egwu, ọkụlụ nke dị egwu nke nwere ike ịkwụ ọsọ, na ọkụlụ nke dị egwu nke dị n'elu nke ndị mmadụ na-akpọ "smut". Mgbe ihe kpatara nke ọzọ bụ ịkwụ ọsọ nke ohere ma ọ bụghị ịdị mma, trivalent chromium conversion coatings na-enye ike ịdị mma n'okpuru na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike ịkwụ ọsọ karị, na-enye ike......

Ihe Nkọwa Nke Ihe Nkọwa Na E-Coating: Ihe Ndị Ọzọ Nke Ihe Nkọwa, Ihe Nkọwa Nke Ntọala, Na Oge Nke Ihe Nkọwa Maka Ngwụcha HPDC

Maka Ngwụcha High Pressure Die Casting (HPDC), ihe nkọwa na e-coating nwere ike inye ọrụ dị iche iche:

- Nwere Ike Echepa : Ihe nkọwa nwere ike inye ngwụcha dị ukwuu (60–120 μm) na ike dị ukwuu maka ịbụ n'okpuru ụgbọ ala; e-coating nwere ike inye ngwụcha dị mfe na dị mfe maka UV (15–25 μm).

- Ihe Nkọwa Nke Ntọala : Ihe nkwụsi ike nke e-coating nwere ike inye ntọala dị mfe—n'ime ntọala dị iche iche na ndị dị n'ime ntọala—na-eme ka ihe nkọwa nwere ike inye ntọala dị mfe n'ime ntọala dị iche iche site na 40%.

- Oge Na Ihe Nkọwa Nke Ihe Nkọwa : E-coating nwere ike inye ntọala dị mfe n'ime ntọala dị iche iche site na 30% maka ntọala dị mfe; ihe nkọwa nwere ike inye ntọala dị mfe n'ime ntọala dị iche iche ma ọ bụghị VOC ma ọ bụghị ike nke nchekwa.

| Factor | Coating akwụkwọ | E-coating |

|---|---|---|

| Ngwụcha Nke Ngwụcha | 60–120 μm | 15–25 μm |

| Ịgbasị Ọkụlọ | Ọ̀tụ̀tụ̀ dị ala | Obi elu |

| Ọkachi | Zero VOCs | Ịkwado ọkụlọ nke ụdị likwid |

Ihe Ọrụ Nke Echere Nke Echiche Nke Iji Hụ N'ihu Nke Ihe Nkwekọrịta

Matriks nke Ihe Nkwekọrịta–Nke Ọkụlọ–Nke Ihe Nkwekọrịta: Iji Hụ N'ihu Nke Ihe Nkwekọrịta n'ime Ihe Ndị Nwere ìhè na-eme

Ịhọrọ ọnụọgụ nke ọkụziri ụzọ nke ọkụziri bụ iji lekwasị anya ọtụ 3 ihe ndị dị iche iche nke ọdịnala nke ọzọ: ihe ọkụziri bụ, otu oge ọkụziri na-eme, ma ọ bụrụ na ọkụziri na-eme ihe ọzọ. Dịka ọmụmaatụ, ọkụziri aluminum dịka ADC12 nwere ike ịkwado ọtụ ihe ndị ọzọ mbụ maka ọkụziri nke a na-eme ka ọkụziri anodizing na-aga n'ihu nke ọkụziri silicon. Ọkụziri nke e nwere ụgwọ kacha ọkụziri ma ọ bụ ọkụziri nke e nwere ike ịbụ n'ime ọkụziri nke aghara nwere ike ịdịghị mma n'ime ọkụziri nke ọkụziri nke ọkụziri. N’okpuru ọkụziri nke ọkụziri, ọ dị iche iche nke ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri nke ọkụziri na-eme n’okpuru ọkụziri n......

| Mkpilo | Ihe Ndị Dị Mma | Nchịkọta nke Ọkụziri na-eme n'okpuru Ọkụziri |

|---|---|---|

| Materila | Ihe ndị e ji mee ọkụziri, ihe ndị e ji mee ọkụziri, ọkụziri | Na-akọwa ọkụziri nke ọkụziri mbụ |

| Otú ọkụziri | Ihe ọkụrụ nke ụzọ, ihe ndị na-akpọ ọnụ, ọkụrụ nke ụzọ | Nweta ihe ọkụrụ nke ihe ọkụrụ / kemikali |

| Nkọwa | Ihe ọkụrụ nke ịgbanwe, ihe ọkụrụ nke ụzọ, ihe ọkụrụ nke ọkụrụ | Nweta ihe ọkụrụ nke ihe ọkụrụ nke ihe ọkụrụ |

Dịka ọmụmaatụ, gosipụta ihe ndị dị iche iche na-eme ka e nwere ike ịkpọtụrụ ha n'okpuru e-coating site na e nwere ike ịkpọtụrụ ha n'ime ihe ndị dị iche iche. Ma ọ bụrụ na ihe ọ bụla kwesịrị inwe obere ọkụrụ nke ịgbanwe n'oge ọdịnala, powder coating nwere ike ịbụ ihe ọzọ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru ihe ọkụrụ nke ịkpọtụrụ ya n'okpuru......

FAQ

Kedu ihe ọkụrụ nke ịdị mma nke ihe ndị na-eme n'ime nke enweghị ihe ọkụrụ nke ịdị mma?

Ihe ọkụrụ nke Ihe Ọkụrụ (1) bụ ihe ọkụrụ nke ọma karịsịa maka ihe ndị na-eso nke ụlọ ọgbara, ma ọ bụghị ihe ọkụrụ nke ụlọ ọgbara, dị ka ọ dị n'okpuru nke ihe ọkụrụ nke a na-eme n'ime ụlọ ọgbara.

Kedu ihe ọkụrụ nke alloy ga-eme ka ọ dị iche iche n'ịhọrọ ihe ọkụrụ nke ụlọ ọgbara?

Ihe ọkụrụ nke alloy ga-eme ka ọ dị iche iche n'ịhọrọ ihe ọkụrụ nke ụlọ ọgbara site na ịmepụta ihe ọkụrụ nke ọkụrụ nke a na-eme n'ime ụlọ ọgbara, dịka ihe ọkụrụ nke a na-eme n'ime ụlọ ọgbara nwere ike ịkwado ihe ọkụrụ nke ọkụrụ nke a na-eme n'ime ụlọ ọgbara iji gosipụta ihe ọkụrụ nke ụlọ ọgbara.

Kedu ihe ọkụrụ nke e-coating nke na-eme ka ọ dị iche iche n'ịhọrọ ihe ọkụrụ nke powder coating?

E-coating na-ewepụ ihe ọkụrụ nke ọkụrụ nke 30% site na ịme ihe ọkụrụ nke ọkụrụ nke a na-eme n'ime ụlọ ọgbara, ma ọ bụghị ihe ọkụrụ nke powder coating na-ewepụ ihe ọkụrụ nke VOC ma ọ bụghị ihe ọkụrụ nke a na-eme n'ime ụlọ ọgbara nke ọkụrụ nke a na-eme n'ime ụlọ ọgbara.

Kedu ihe ọkụrụ nke anodizing ga-eme ka ọ dị iche iche n'ịhọrọ ihe ọkụrụ nke high silicon aluminum alloys?

Anodizing ga-eme ka ọ dị iche iche n'ịhọrọ ihe ọkụrụ nke high silicon aluminum alloys site na ihe ọkụrụ nke silicon na-eme ka ọ dị iche iche n'ịme ihe ọkụrụ nke oxide layer, na-eme ka ọ dị iche iche n'ịme ihe ọkụrụ nke thickness na ịwepụ ihe ọkụrụ nke corrosion protection.

Ndepụta nke ọdịnaya

- Ihe Ndị Nkọwa Nke Otú Nkọwa na Ihe Ndị Eji Si Chọọ Grade Nke Otú Nkọwa Nke Die Cast Parts

- Ihe Ndị Na-akpọ 'Pre-Treatment Methods' Nke Na-akpọ Ihe Nke Na-akpọ 'Reliable Surface Finishes'

- Ịgbakwunyere Nde Ihe Ndị Ọrụ Nke Otú Ọnọdụ Nke Ntọala na Nde Ihe Ndị Echere Na Ha Nwere Ike

- Ihe Ọrụ Nke Echere Nke Echiche Nke Iji Hụ N'ihu Nke Ihe Nkwekọrịta

-

FAQ

- Kedu ihe ọkụrụ nke ịdị mma nke ihe ndị na-eme n'ime nke enweghị ihe ọkụrụ nke ịdị mma?

- Kedu ihe ọkụrụ nke alloy ga-eme ka ọ dị iche iche n'ịhọrọ ihe ọkụrụ nke ụlọ ọgbara?

- Kedu ihe ọkụrụ nke e-coating nke na-eme ka ọ dị iche iche n'ịhọrọ ihe ọkụrụ nke powder coating?

- Kedu ihe ọkụrụ nke anodizing ga-eme ka ọ dị iche iche n'ịhọrọ ihe ọkụrụ nke high silicon aluminum alloys?