Fundamentals of ISO 9001 in Die Casting

What Is the ISO 9001 Certification?

ISO 9001 certification stands as one of those international standards everyone knows about when talking about quality management systems (QMS). What it really aims to do? Boost customer happiness by making sure quality matters throughout every part of a business operation. Getting certified isn't just signing up somewhere though. Companies need to go through detailed audits and create thorough documentation showing they can reliably produce goods that satisfy both what customers want and what regulations demand. Beyond just looking good on paper, these certifications actually help run operations smoother day to day while giving clients peace of mind knowing the company takes quality seriously from start to finish.

Role in Aluminum and Zinc Die Casting Processes

ISO 9001 is essential for many aluminum and zinc die casting operations because it offers a framework for managing quality throughout production. When companies implement this standard, they set up consistent procedures that lead to better part consistency and tighter dimensional tolerances in aluminum castings. For zinc die casting shops too, the emphasis on ongoing improvements helps cut down on material waste while giving better control over manufacturing parameters. This leads to faster production cycles without compromising quality. Getting certified under ISO 9001 gives manufacturers an edge in today's crowded marketplace. Customers know what to expect from certified producers since their products generally perform reliably and consistently against established benchmarks across different applications.

Enhancing Quality and Precision in Die Casting

Improving Consistency in Aluminum Die Casting Parts

Implementing ISO 9001 standards helps manufacturers produce consistent aluminum die casting components because it pushes for reliable methods across the board. When companies keep track of their production numbers day after day, they spot problems before they become big issues in the workflow. The regular checkups on quality combined with detailed process evaluations make sure everyone on the manufacturing floor follows established protocols. This attention to detail leads to products that look and perform the same every time. Fewer defects mean less wasted material and happier customers who know exactly what to expect from each batch. Most importantly, when clients receive parts that meet specifications consistently, trust builds over time which is worth its weight in gold for any business looking to maintain long term relationships.

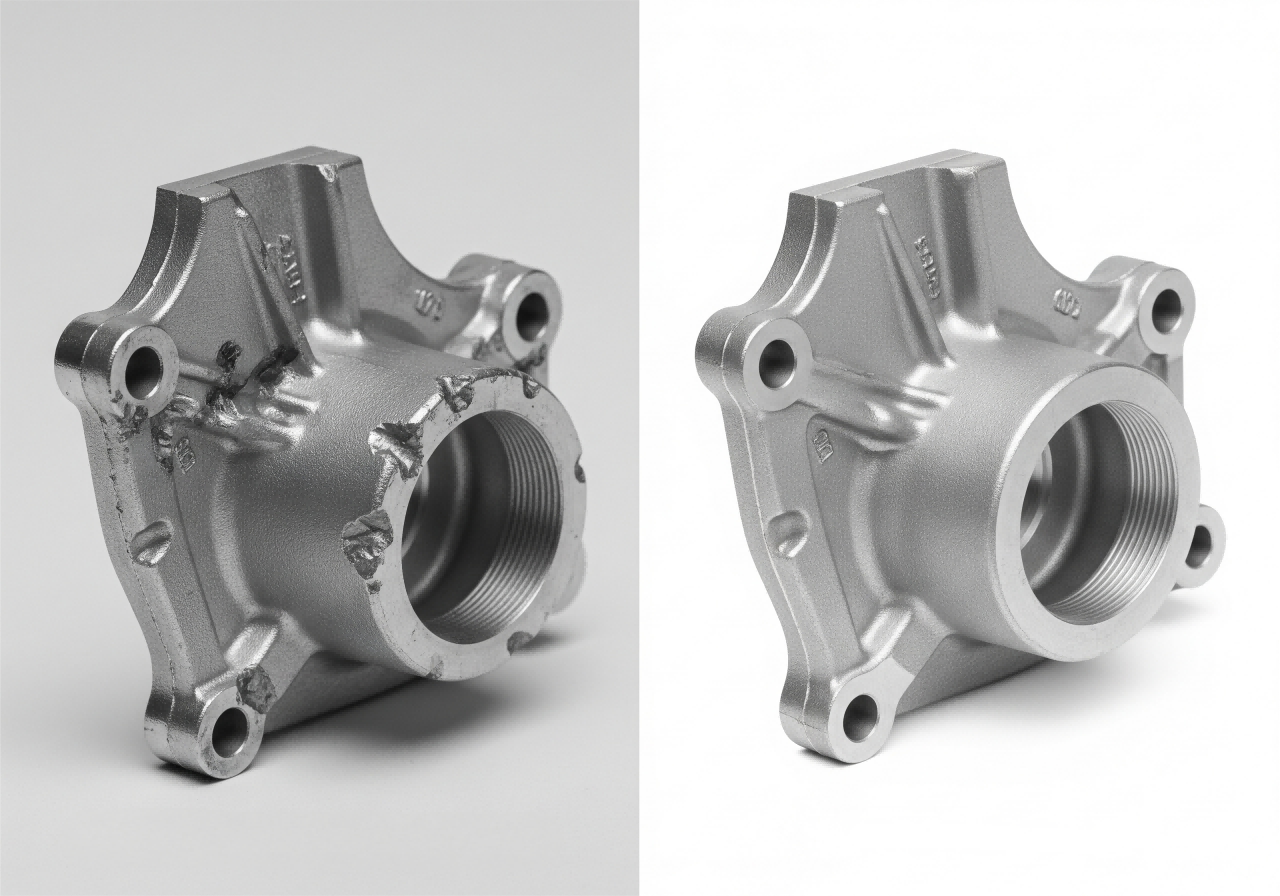

Minimizing Defects in Zinc Die Casting Production

What sets ISO 9001 apart is its focus on stopping defects before they happen rather than just catching them after the fact, which makes quality control much more effective in zinc die casting operations. When manufacturers implement root cause analysis along with proper corrective actions, they get to the heart of why certain defects keep showing up again and again. Training line workers on what quality really means creates a workplace where everyone looks out for problems from day one. Many shops now use Statistical Process Control or SPC for short. These tools let managers watch key numbers during production and catch when things start going off track. Beyond keeping products up to spec, this kind of forward thinking builds trust with customers who want parts that last and perform reliably over time.

Operational Efficiency and Cost Management

Streamlining Processes with Aluminum Die Casting Machines

Getting aluminum die casting machines running better is pretty much a must for anyone in manufacturing who wants to get more done while spending less money. The ISO 9001 standard gives companies something tangible to work with when trying to improve their processes. It basically creates rules that everyone follows so machines perform consistently day after day, which means production runs don't fall apart unexpectedly. When shops implement standardized procedures alongside regular maintenance checks and ongoing quality inspections during operation, they tend to see fewer breakdowns and smoother workflow overall. These practices work hand in hand to keep operations moving forward without unnecessary delays.

Beyond just optimizing machines, managing dies and tooling is essential for keeping die casting operations running smoothly. According to ISO 9001 standards, regular maintenance isn't just about machines anymore but also covers all those dies and molds that get used daily. When companies schedule their die maintenance properly, keep records of repairs, and track how much wear happens over time, they end up with consistently accurate dimensions, better surface finishes, and all those quality characteristics that matter most in production. Good tooling maintenance cuts down on defective products, keeps tools working longer before replacement, and stops unexpected shutdowns that disrupt production schedules. Following these maintenance routines actually supports what ISO 9001 stands for: constantly getting better, anticipating problems before they happen, and making sure resources aren't wasted. The result? Factories produce more good parts while spending less money overall.

Cost Reduction for Competitive PV Inverter Components

Aluminum and zinc die castings find their way into structural supports and heat dissipation systems within photovoltaic inverters, so controlling costs becomes really important when trying to stay competitive in today's solar market. The ISO 9001 standard gives manufacturers a roadmap to spot where they can save money across all stages of production. For PV inverters specifically, bringing down manufacturing expenses directly affects how much customers pay at the end of the day while still keeping profit margins intact. When companies streamline their workflow processes, cut down on repeat work, and waste less raw materials, the production costs for those zinc die cast parts naturally drop. These savings translate into better pricing options that keep businesses ahead of competitors. Given how fast the solar sector is changing, having solid cost control strategies isn't just helpful it's basically necessary for staying relevant and profitable over time.

Meeting Industry-Specific Standards

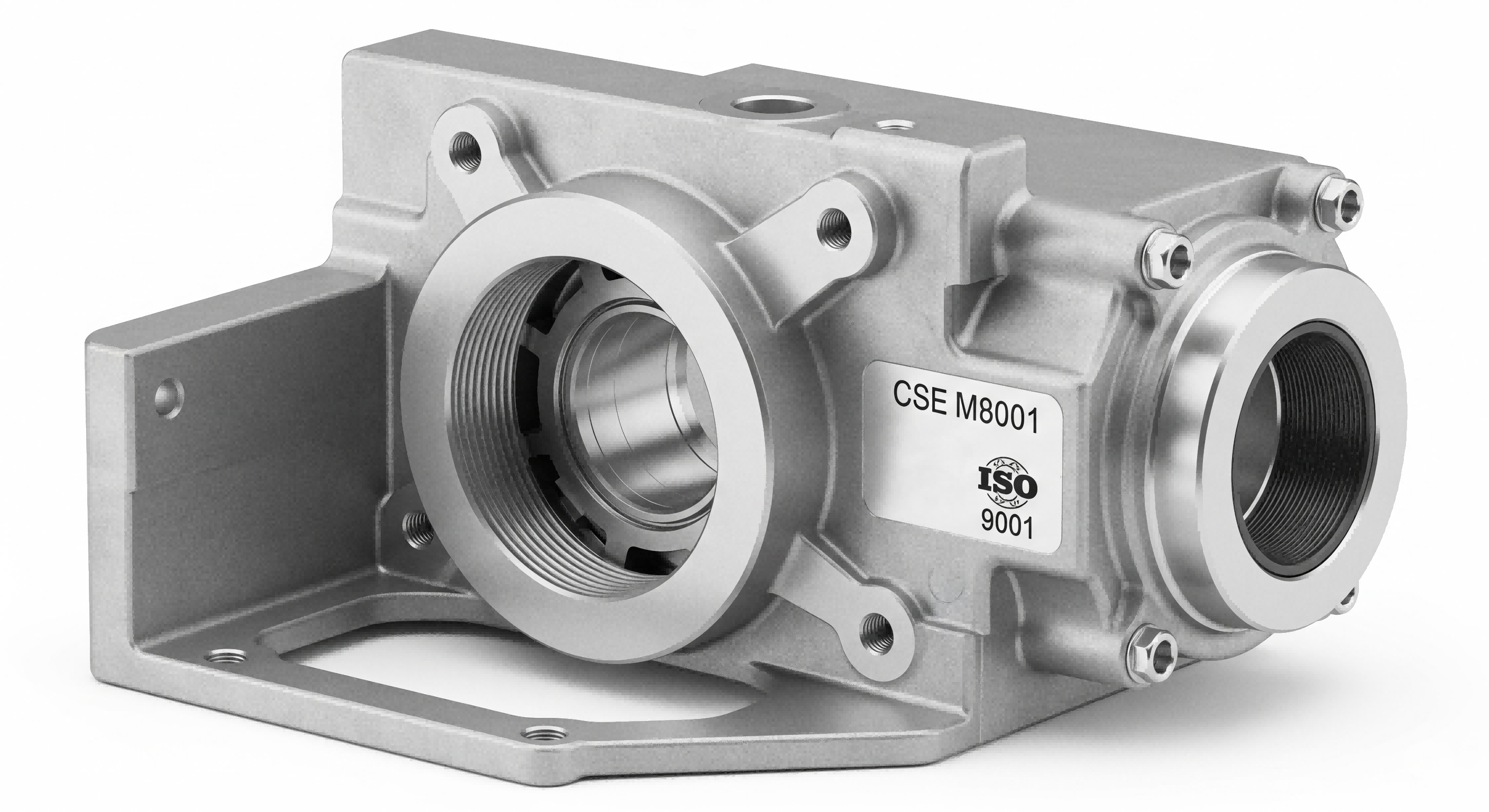

Compliance in Automotive and Solar PV Inverter Applications

For suppliers making aluminum and zinc die cast parts, getting ISO 9001 certified matters a lot especially when dealing with strict industries like cars and solar panels. When a business follows ISO 9001 standards, it shows they're on track with regulations while also proving their commitment to good quality work, workplace safety, and always trying to get better at what they do. Think about auto manufacturers who need every part to meet exact specs down to the last decimal point. That's where ISO 9001 becomes a real trust builder. Clients see the certification and know the supplier takes seriously things like avoiding defects, managing risks properly, and keeping production processes stable over time. These aren't just nice to have qualities either they're pretty much required if companies want to build lasting relationships with major players in these demanding markets.

Global Market Access Through Certification

Getting ISO 9001 certified basically becomes a requirement for accessing most global supply chains these days. A lot of overseas buyers, especially those in automotive and aerospace sectors, won't even consider working with suppliers who don't have this certification on file. When die casters meet the ISO standards, they become much more appealing partners for major OEMs and first-tier suppliers around the world. What makes this certification valuable isn't just paperwork it actually shows clients that proper quality checks exist within operations and that the company genuinely cares about making ongoing improvements. Companies with ISO certification tend to see better results in international markets, often finding themselves able to work with customers from different continents while building relationships across multiple time zones. For many manufacturers, obtaining and maintaining ISO 9001 status isn't just good practice it's becoming essential for staying competitive in today's tightly connected manufacturing world.