The Rise of Automation in Automotive Manufacturing

How Automation Is Reshaping Automotive Production

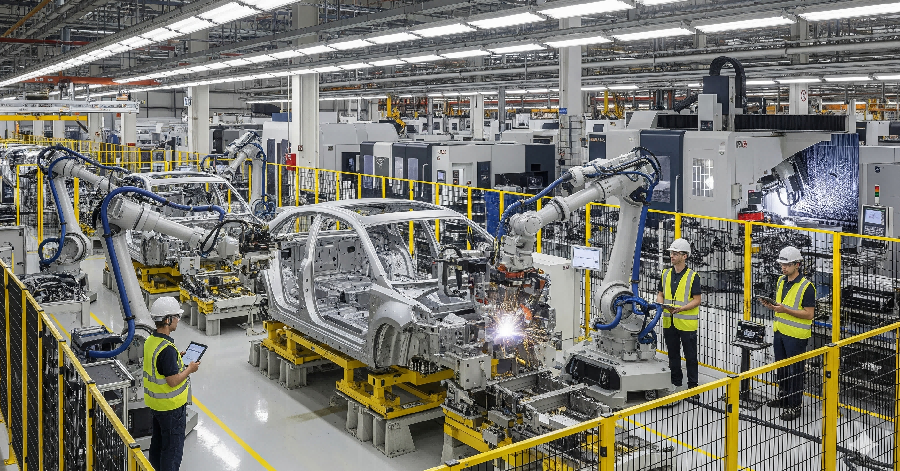

The automotive industry is seeing major changes thanks to automation technology, which cuts down on assembly line work by around 30 percent and makes everything much more accurate. These days, factories use robots for jobs like welding car parts together, applying paint evenly across surfaces, and putting components into place where mistakes used to happen all the time when humans did it manually. According to research published by the International Federation of Robotics back in 2024, smart inspection systems powered by artificial intelligence can spot defects at an impressive rate over 99.5%. What this means practically speaking? Less wasted materials and faster introduction of brand new vehicle models onto store lots nationwide.

Core Technologies Powering Automation: Robotics and AI

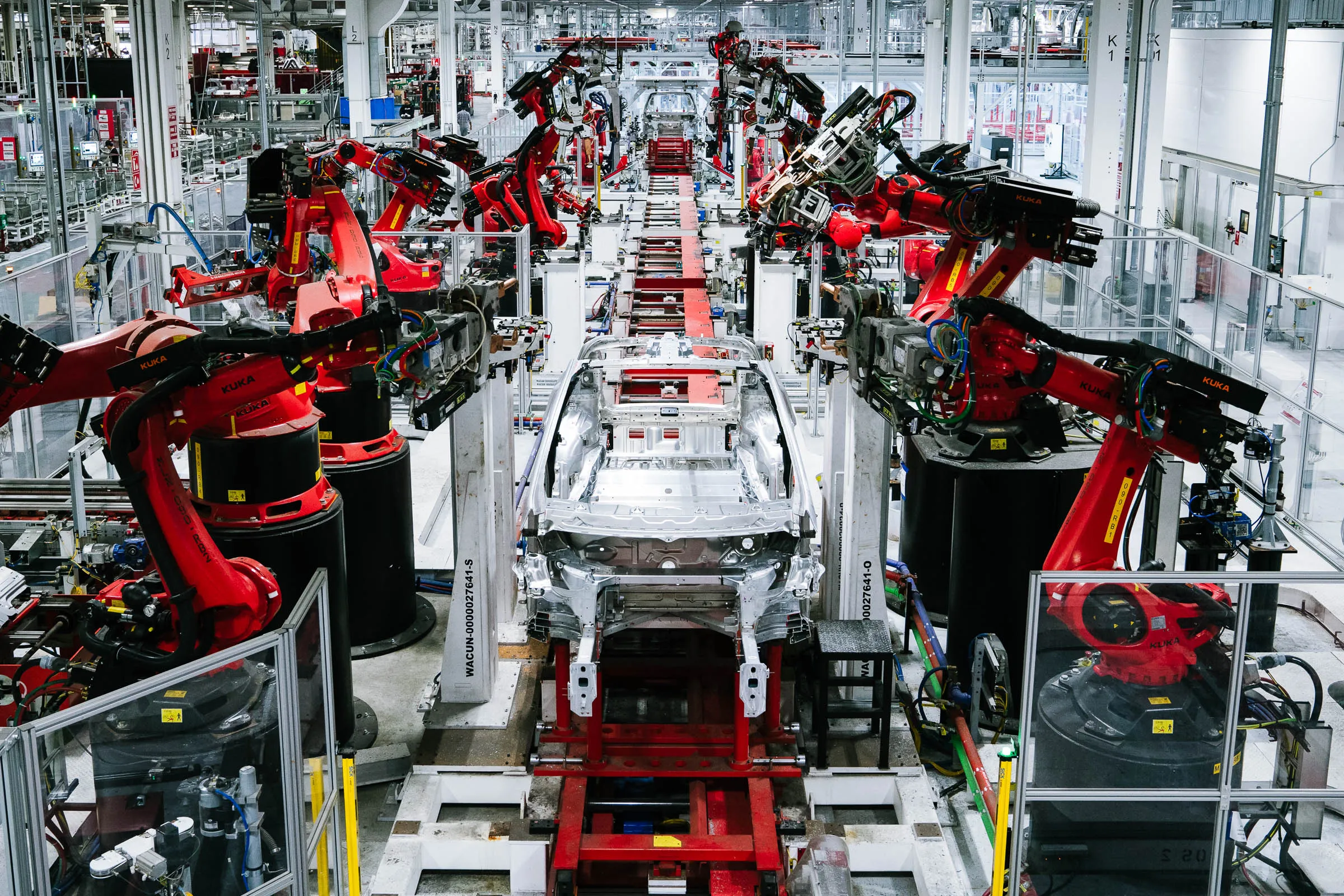

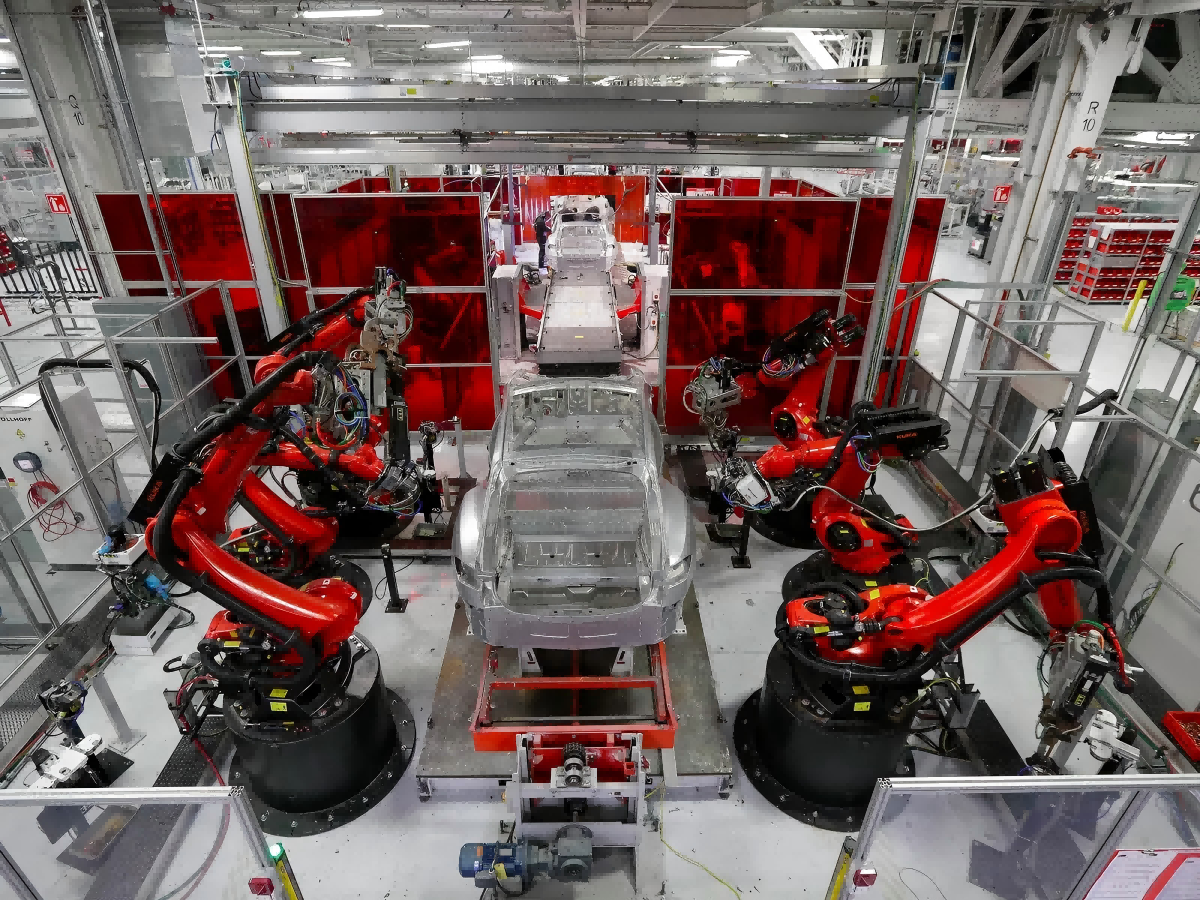

Modern car manufacturing just wouldn't work without robotics and AI these days. We're talking about those fancy robotic arms with smart eyes and sensitive touch that can put together EV battery modules with amazing precision. The machines aren't just following scripts anymore either. They learn on the fly using clever algorithms that tweak everything from heat levels to how materials move through the factory floor. What's really impressive is how tight these new robot systems can get. Some plants report errors under 0.1mm, which matters a lot when it comes to keeping those expensive EV batteries safe and working properly over time.

Case Study: A Leading EV Manufacturer's Gigafactories

A prominent EV manufacturer's Gigafactories demonstrate scalable automation, where 95% of assembly processes are fully automated. Their production method integrates modular robotics stations, reducing factory footprint requirements by 40% while maintaining 24/7 output. This approach decreased per-vehicle labor costs by 60% between 2022 and 2024, as validated by third-party analysts.

Global Trends in Robotics and AI Adoption Across Auto Plants

Regional adoption patterns reveal stark contrasts:

- Asia-Pacific: 63% of automotive plants use AI-driven predictive maintenance (2024 McKinsey data)

- Europe: 58% have integrated collaborative robots (cobots) into final assembly lines

- North America: 47% of automotive robotics investments target EV component manufacturing

Strategic Integration of Scalable Automation for Competitive Advantage

Forward-thinking manufacturers prioritize modular automation systems that adapt to multiple vehicle platforms. A 2025 Boston Consulting Group study found companies using scalable robotics achieve 50% faster production line reconfiguration, enabling rapid pivots between gas-powered, hybrid, and EV models. This flexibility reduces capital expenditure risks by 35% compared to fixed automation systems.

AI-Driven Efficiency and Quality in Vehicle Production

Smart Assembly Lines: Automation in Manufacturing Processes

Modern factories leverage AI to coordinate robotic arms, conveyor systems, and IoT sensors into interconnected ecosystems. Machine learning algorithms optimize workflows, reducing idle time by 22% compared to traditional setups (McKinsey 2023). Adaptive robotics adjust welding patterns in real time based on material thickness, minimizing waste while maintaining structural integrity.

AI in Quality Control: Real-Time Defect Detection Using Machine Vision

AI-powered machine vision systems scan up to 500 vehicle components per minute with 99.7% accuracy, identifying micro-fissures or misalignments invisible to human inspectors (Fraunhofer Institute 2024). By cross-referencing defects against historical data, these systems pinpoint root causes and reduce quality control cycles from 48 hours to just 15 minutes in advanced plants.

Predictive Maintenance: Reducing Downtime with AI Analytics

AI analyzes vibrations, thermal patterns, and power consumption to forecast equipment failures 14 days in advance with 89% precision (Deloitte 2022). This capability prevents unplanned stoppages, saving automakers $740k annually per production line (Ponemon 2023).

Workforce Impact: Job Displacement vs. Upskilling in Automated Plants

While automation has displaced 8% of repetitive roles since 2020, it has simultaneously created 1.3 million AI engineering and robotics maintenance positions (World Economic Forum 2023). Leading manufacturers now invest $7,500 per employee in reskilling programs focused on AI supervision and hybrid human-machine workflows.

Autonomous Driving and AI-Powered Safety Innovations

From ADAS to Level 5: Evolution of Autonomous Driving Technologies

Looking at how the car industry has moved from simple driver aid systems to completely self-driving cars shows just how much automation has changed things. Back when cars first got features like cruise control that adjusted speed automatically and helped keep them in their lanes, accident rates dropped about 57 percent according to NHTSA data from 2023. These early safety techs basically paved the way for more advanced driving capabilities down the road. Now we're seeing cars that can actually understand complicated traffic situations thanks to artificial intelligence maps and those fancy neural network systems. Some high end models already have what's called SAE Level 3 autonomy on board. Most analysts think around 45 out of every 100 new cars sold in 2026 will have at least Level 2 plus features. That suggests we're slowly moving towards a future where our cars drive themselves most of the time.

AI in Driver Assistance Systems: Enhancing Real-Time Decision-Making

Today's driver assistance tech uses artificial intelligence to handle all sorts of sensor data coming in from around the car, which helps react really fast when something dangerous happens on the road, like if someone slams their brakes or a pedestrian steps out suddenly. According to a recent 2024 industry study, these AI systems actually spot when drivers get distracted about 2 full seconds before anything bad might happen, and they intervene correctly about 92 times out of 100. The latest versions are starting to connect up with what's called V2X networks too, so vehicles can basically see what's going on miles ahead where regular drivers just can't perceive it. Automotive companies are working hard right now on making intersections safer by aiming for cutting down accidents there by almost 40 percent using special software that looks at old traffic data to figure out what might go wrong next.

Sensor Fusion and Deep Learning: AI's Role in Autonomous Vehicles

Self-driving cars use a mix of lidar sensors, radar equipment, and regular cameras all working together through special software called sensor fusion. Tests have shown these systems can recognize objects with nearly 99.8% accuracy which is pretty impressive. The cars are powered by deep learning models that have been trained on around 14 million different crash scenarios. This helps them decide what to do first when facing multiple dangers at once. These systems react much faster than humans too, cutting response time by about 400 milliseconds. Looking at recent tests, we see that modern AI systems cut down those annoying false brake warnings by roughly 73% compared to models from just two years ago. This improvement tackles one of the biggest complaints people had about earlier versions of self-driving technology.

Case Study: Waymo's AI-Driven Autonomous Fleet Performance Metrics

According to folks running autonomous vehicle operations, there's been around a 90 percent drop in those really dangerous incidents since they started using AI for navigation. These smart systems constantly adjust driving paths roughly every hundred milliseconds or so. Looking at actual road tests, most of these self-driving cars manage about 97 out of 100 tricky city situations all on their own. Think things like making left turns when no one is looking and navigating through construction areas where signs keep changing. The companies have also seen some pretty good results in terms of power usage. Across entire fleets, energy needs went down by approximately 18% for each mile driven. This shows that while we're talking about safer roads, we're also making progress toward greener transportation solutions at the same time.

Predictive Diagnostics and Connected Mobility Solutions

AI in Predictive Maintenance: Machine Learning for Failure Forecasting

Car manufacturers are starting to use artificial intelligence to spot potential breakdowns long before they actually happen. The smart systems analyze data coming straight from sensors in engine compartments, transmission units, and battery packs. They pick up on weird stuff like strange vibrations or when parts get hotter than normal for no good reason. According to some recent research published last year, cars equipped with this predictive tech spend about a third less time sitting idle because of unexpected problems. Plus mechanics report saving around four hundred dollars each year per car on warranty repairs thanks to early detection warnings.

Remote Vehicle Diagnostics: Over-the-Air Updates and Alerts

Over-the-air (OTA) diagnostics enable manufacturers to remotely resolve 63% of software-related issues, eliminating dealership visits for minor fixes. This capability is now standard in 82% of 2024-model EVs, alerting drivers to issues like battery degradation or charging system faults through mobile apps.

Mobility as a Service (MaaS): Shared Autonomous Fleets Enabled by Automation

Autonomous vehicle fleets are becoming the backbone of urban MaaS platforms, reducing private car ownership in metro areas by 18% since 20222. These AI-coordinated networks use demand forecasting to dynamically reposition vehicles, cutting average wait times to 2.7 minutes during peak hours.

Integration with Smart Cities: AI for Traffic Optimization and Coordination

| Technology | Impact Metric |

|---|---|

| V2I Communication | 22% faster emergency vehicle response times |

| Adaptive Traffic Signals | 41% reduction in intersection congestion |

| Fleet Routing AI | 15% lower urban transport emissions |

Energy Efficiency and Sustainable Innovation Through AI

AI in Electric Vehicles: Battery Management and Range Optimization

Electric vehicles are getting a major boost thanks to AI systems that help improve how batteries work and how far they can go between charges. Smart computer programs look at all sorts of information as cars drive around - things like outside temperatures, how often people charge their batteries, and even driving habits. This analysis helps prolong battery life sometimes by around 20 percent or so while also cutting down on wasted energy. For car manufacturers looking into automated solutions, these improvements mean EVs can manage their power better without losing any strength when needed most. The automotive sector is really starting to benefit from this kind of intelligent energy management across different models now appearing on dealership lots nationwide.

Revolutionizing Manufacturing: Sustainable Gains with AI and Robotics

Car manufacturers have managed to slash energy use at their factories by around 15 to maybe even 30 percent thanks to those smart robots powered by artificial intelligence. They help save resources by making sure materials get used properly and keeping assembly lines running smoothly without waste. According to some research published last year about energy savings, these fancy computer programs actually managed to bring down heating, ventilation, and air conditioning expenses in car manufacturing facilities by almost half. That's pretty impressive when they adjust things on the fly based on what's happening with production timelines and machinery demands. Looking at all this shows why so many companies are jumping on board with automated solutions. Not only does it help protect the planet, but it also gives them an edge over competitors who haven't made similar investments yet.

AI's Role in Reducing Environmental Impact Across the Vehicle Lifecycle

From design to recycling, AI minimizes resource waste at every phase:

- Generative design tools create lighter vehicle components (7–12% weight reduction)

- Machine vision sorts end-of-life materials with 99% accuracy for circular manufacturing

- Route optimization algorithms lower logistics-related emissions by 18%

Research in a 2024 building lifecycle analysis shows similar AI principles reducing industrial energy waste by 26% when applied systematically, providing a roadmap for automotive sustainability efforts.

FAQ Section

What is the impact of automation on automotive manufacturing?

Automation has significantly improved the accuracy and efficiency of automotive manufacturing, reducing manual assembly line work by about 30% and minimizing human errors.

How do robotics and AI enhance vehicle production?

Robotics and AI optimize manufacturing processes by performing complex tasks such as welding and assembling with high precision, lowering errors to under 0.1mm in some cases.

Are there any notable case studies demonstrating automation success?

Yes, a leading EV manufacturer's gigafactories have integrated scalable automation in 95% of their assembly processes, reducing labor costs by 60% from 2022 to 2024.

What role does AI play in quality control and maintenance?

AI-powered systems offer real-time defect detection with 99.7% accuracy and predictive maintenance, preventing equipment failures and reducing downtime.

How does automation affect the automotive workforce?

While automation has displaced some roles, it has also created new jobs in AI and robotics maintenance, with companies investing in reskilling programs for employees.