Why Magnesium Die Casting Is Ideal for Lightweight Design

Unique Advantages of Magnesium in Lightweight Engineering

For industries where every ounce matters, magnesium die casting stands out among manufacturers looking to cut weight without compromising on durability. We're talking about a material that weighs in at roughly 33 percent less than aluminum and nearly 75 percent less than good old fashioned steel. What does this mean practically? Parts made from magnesium can shed serious weight while still holding their own when it comes to structural integrity. The strength to weight ratio here gets pretty impressive too some tests show it beats aluminum alloys by around threefold. That's why we see magnesium showing up in places like car transmissions and aircraft brackets where both lightness and toughness are absolute must haves.

With a low density of 1.74 g/cm³, magnesium supports wall thicknesses as thin as 0.6 mm while maintaining mechanical stability. These properties are fueling growing adoption, with the 2024 Magnesium Market Analysis projecting $1.77 billion in market growth through 2029, particularly in electric vehicle battery trays and aerospace seat frames.

Specific Gravity and Strength-to-Weight Ratio of Magnesium Die Cast Parts

Magnesium’s favorable specific gravity is crucial in applications where every gram matters:

| Property | Magnesium AZ91D | Aluminum A380 | Zinc ZAMAK 3 |

|---|---|---|---|

| Specific Gravity | 1.81 | 2.71 | 6.6 |

| Tensile Strength (MPa) | 230 | 315 | 283 |

| Strength-to-Weight Ratio | 127 MPa·cm³/g | 116 MPa·cm³/g | 43 MPa·cm³/g |

The 9% higher strength-to-weight ratio compared to aluminum allows magnesium to excel in dynamic applications like suspension systems, where both lightness and fatigue resistance are essential.

Comparison with Aluminum and Zinc: When Magnesium Outperforms

While aluminum remains dominant in general casting, magnesium outperforms in three key areas:

- Energy absorption systems – Magnesium offers 10x greater damping capacity than aluminum, improving crash performance in automotive door beams

- High-thermal-conductivity requirements – It dissipates heat 35% better than polymers, ideal for electronics housings

- Rapid-cycle production – Its lower melting point (650°C vs. aluminum’s 660°C) enables faster solidification, reducing cycle times by 15–20%

Despite requiring specialized handling to prevent oxidation, magnesium’s superior flowability (25% better than aluminum) and machining efficiency make it cost-effective for production runs exceeding 10,000 units, especially in premium automotive and consumer electronics.

The Magnesium Die Casting Process: Techniques and Best Practices

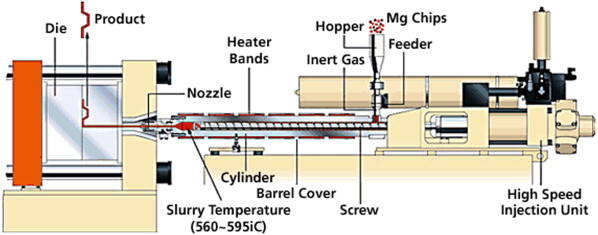

Cold Chamber vs. Hot-Chamber: Why Cold Chamber Dominates Magnesium Casting

When working with magnesium, cold chamber die casting has become the go to approach because magnesium melts at around 650 degrees Celsius which just doesn't play well with hot chamber systems. Hot chamber machines have their injection parts sitting right in the molten metal, while cold chamber setups actually move already melted magnesium into another chamber first. According to recent studies from Metal Processing Institute back in 2023, this technique cuts down on equipment wear somewhere between 19 and 23 percent, plus it helps keep oxidation at bay. Manufacturers love this method especially when dealing with AZ91D alloy since they can get those parts made in under 45 seconds flat. Think about automotive steering columns for instance these days most are produced this way thanks to how fast and reliable the process has proven t

High-Pressure Die Casting: Precision and Repeatability for Complex Geometries

The process of high pressure die casting (HPDC) pushes molten magnesium into molds at pressures exceeding 1,500 bar, allowing manufacturers to create walls as thin as 0.6 mm while maintaining tight tolerances around ±0.2%. Recent research from 2024 shows some interesting results when comparing HPDC with traditional CNC machining methods. For intricate components such as intake manifolds, HPDC was clocked about 37 percent quicker and used roughly 15% less material overall. What makes this technique so valuable? The level of detail and consistency it delivers works wonders for mass production runs. Take the automotive industry for instance; somewhere between 85 and 90 out of every 100 magnesium transmission cases currently rolling off assembly lines were made through HPDC processes.

Vacuum-Assisted Die Casting for Enhanced Integrity in Thin-Walled Components

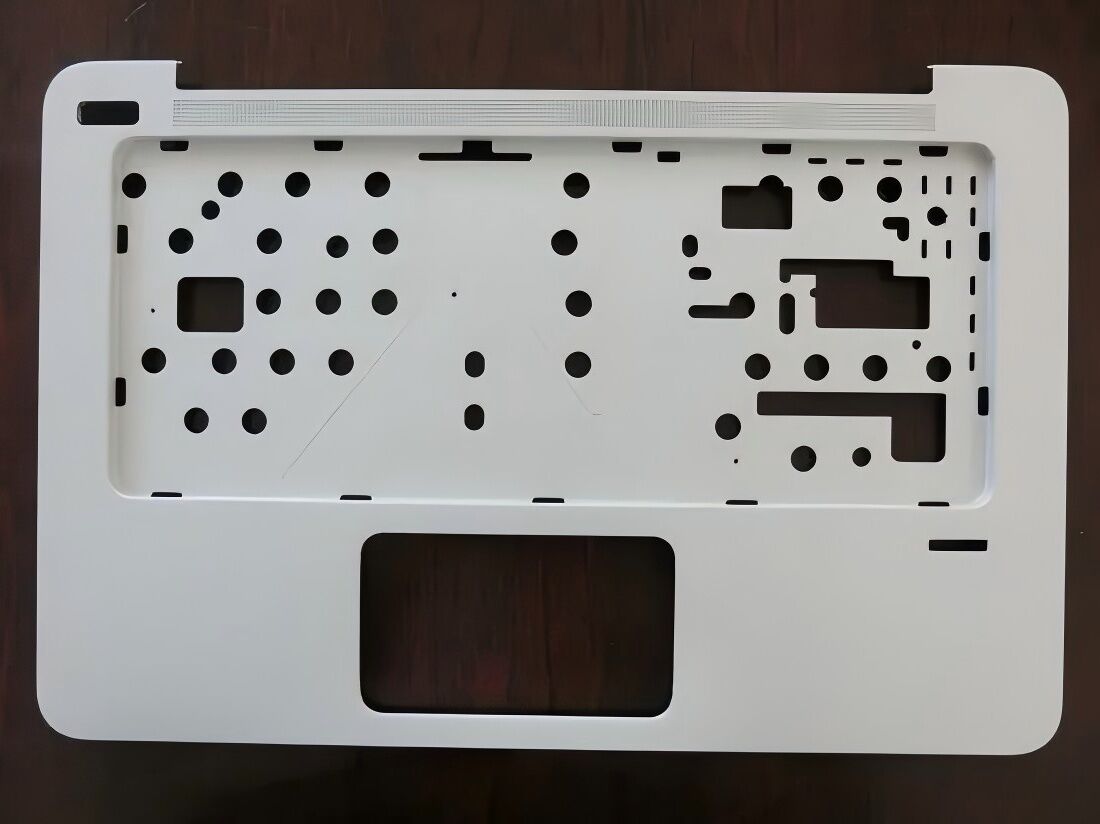

The vacuum assisted die casting process works by pulling air out of the mold cavity prior to injecting molten metal, which cuts down on internal voids and boosts tensile strength anywhere from 18 to 22 percent in those tricky thin walled components such as laptop cases. When manufacturers ran tests at vacuum levels under 80 millibar, they got impressive results with AZ31B alloy reaching nearly 96% density. These parts perform just as well structurally as aluminum counterparts but come in at around one third the weight. For critical applications like aircraft mounting brackets or electric vehicle battery containers where even minor flaws can be disastrous, keeping defect rates under 0.3% isn't just good practice it's practically non negotiable these days.

Key Magnesium Alloys and Their Performance Characteristics

Overview of Common Magnesium Alloys: AZ91D, AM60B, and AE44

The main alloys found in magnesium die casting applications include AZ91D, AM60B, and AE44, each designed for particular performance requirements. Take AZ91D for instance it contains around 9% aluminum plus about 1% zinc, which gives it pretty good tensile strength reaching approximately 230 MPa along with decent corrosion protection. That makes AZ91D a popular choice when manufacturing components such as powertrain housings or various types of brackets. Moving on to AM60B, this alloy stands out because of its ability to stretch before breaking somewhere between 10 to 15% elongation and absorbs vibrations well too. These characteristics make it especially valuable for parts where safety matters most, think steering column assemblies for example. Then there's AE44, which gets boosted with some rare earth additions that significantly improve its resistance to gradual deformation even when heated up to roughly 150 degrees Celsius. This property has made AE44 increasingly common in electric vehicle battery enclosures that face considerable heat during operation.

Tensile Strength, Creep Resistance, and Corrosion Behavior of Die Cast Alloys

These alloys are engineered to balance lightweighting with durability:

| Property | AZ91D | AM60B | AE44 |

|---|---|---|---|

| Tensile Strength | 210–230 MPa | 220–240 MPa | 240–260 MPa |

| Creep Resistance | Moderate | Low | High |

| Corrosion Rate* | 0.25 mm/year | 0.30 mm/year | 0.15 mm/year |

*Salt spray testing per ASTM B117 (2024 Magnesium Casting Report). AE44’s rare-earth additives reduce galvanic corrosion by 40% compared to AZ91D, as shown in high-temperature material studies.

Balancing Ductility and Strength: Trade-offs in AZ91D Applications

AZ91D has around 3% elongation, which is actually quite low compared to AM60B's impressive 15%. But what AZ91D lacks in flexibility it makes up for in stiffness, clocking in at 45 GPa versus 38 GPa for AM60B. This makes AZ91D pretty good for things that need to hold weight or support structures. When designing with this material, engineers often add ribs inside laptop frames to make up for its tendency to snap under stress. Some recent changes at the microscopic level have helped too. Now AZ91D can stretch to about 5% without losing its strength characteristics, so the difference between how strong it is versus how much it can bend before breaking isn't quite as big as it used to be.

Applications in Automotive and Electronics Industries

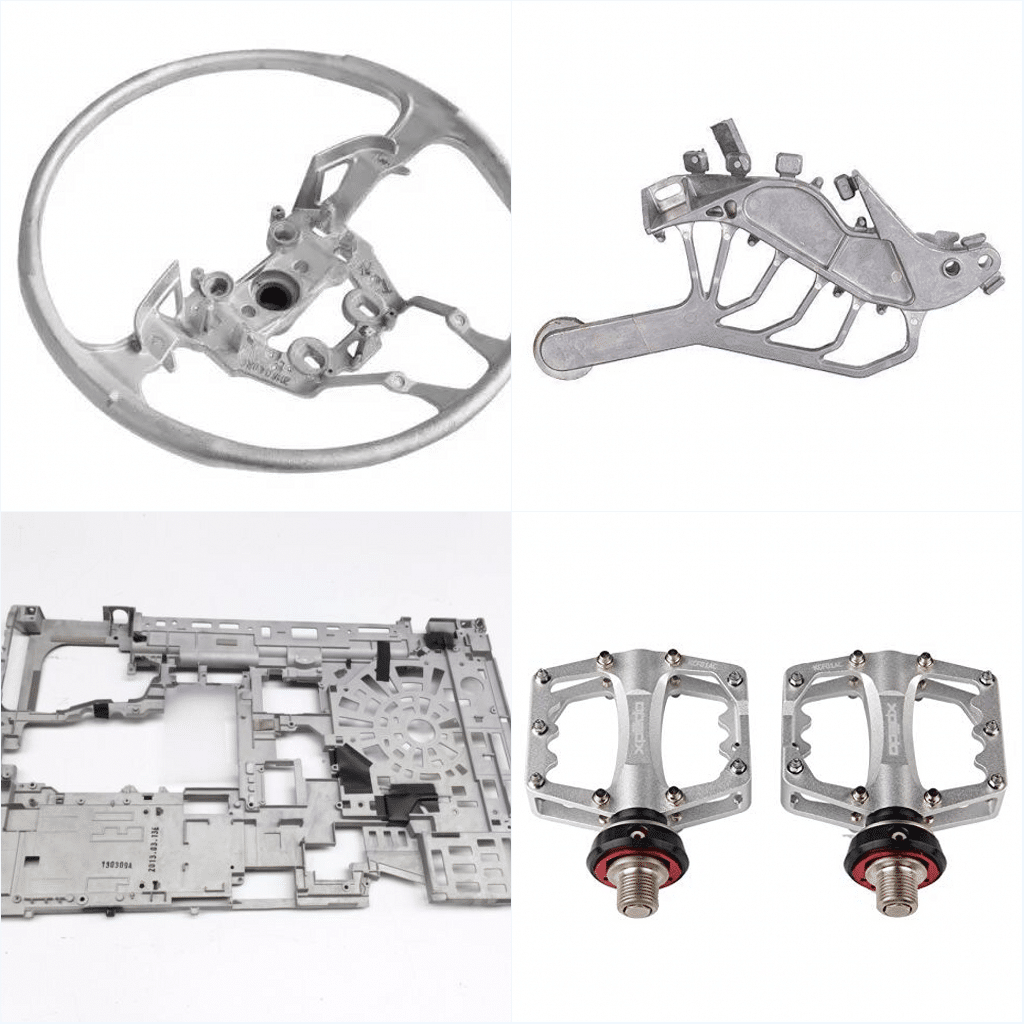

Automotive Uses: Structural Components, Transmission Cases, and Weight Reduction Benefits

The use of magnesium die casting brings significant weight reduction benefits to car manufacturing. At just 1.8 grams per cubic centimeter (about 30% less dense than aluminum), it allows parts such as dashboard supports and steering bracket assemblies to weigh anywhere from 40 to 60 percent less compared to their steel counterparts. For electric vehicles specifically, switching to magnesium transmission housings can cut overall vehicle mass by around 22%, all while keeping the structural integrity needed for powerful motor systems. When hybrid manufacturers replace traditional aluminum engine blocks with magnesium alternatives, they typically see reductions of approximately 17 kilograms in total vehicle weight. This kind of weight saving makes a real difference for battery efficiency, which explains why so many automakers are now seriously considering magnesium options. Recent research published last year on lightweight materials confirms what engineers have been observing on factory floors across the industry.

Aerospace and Performance Vehicles: Where Every Gram Counts

The aerospace industry has found that switching from aluminum to magnesium cuts down the weight of hydraulic valve blocks about half while still keeping all the necessary pressure strength intact. Racing car engineers love this material too, putting it into suspension parts and gearboxes because cutting just one or two kilograms off those moving parts makes a real difference when trying to shave seconds off lap times. These days we see thin magnesium castings showing up everywhere from drones to satellites. They're getting thinner too, sometimes as little as half a millimeter thick but still strong enough to handle both vibrations and protect against harmful radiation exposure.

Electronics Enclosures: Thin-Walled Magnesium Castings for Portable Devices

Magnesium is becoming increasingly popular in electronics because it blocks electromagnetic interference really well (about 60 to 120 dB reduction) and conducts heat efficiently at around 156 W per meter Kelvin. This makes it great material choice for building high performance device casings. High pressure die casting allows manufacturers to create incredibly thin laptop covers as little as 0.45mm thick that still work reliably from freezing temperatures down to -20 degrees Celsius all the way up to scorching 120 degrees Celsius. When it comes to smartphones, AZ91D magnesium frames provide roughly 35 percent more protection against impacts compared to plastic alternatives. And they're surprisingly light too, coming in at only 12 grams. In today's world of mobile devices, where even small improvements in weight and size can make a big difference in market success, these advantages are absolutely essential for staying competitive.

Innovations and Future Trends in Magnesium Die Casting Manufacturing

Advancements in Thin-Walled Casting and Design Flexibility

Magnesium die casting these days can produce parts with walls thinner than 1.5 mm without sacrificing strength, which opens up possibilities for shapes that used to be possible only with plastic components. The latest computer modeling software helps engineers design molds better, so manufacturers end up wasting significantly less material during production runs. For electric vehicles and gadgets we carry around daily, this ability to create lighter parts makes a real difference. Lighter components mean better battery life in cars and less strain on batteries in consumer devices, plus just feels nicer to handle overall.

Addressing Safety Concerns: Oxidation and Flammability Management

New alloys with cerium or calcium additives raise ignition temperatures by 150°C–200°C, significantly reducing fire risk during processing. Vacuum-assisted casting lowers porosity by 60%, improving durability in corrosive environments. Inert gas shielding during melting and casting further suppresses oxidation, helping overcome historical safety concerns raised by OEMs.

Growing Adoption in High-Volume Production Despite Industry Skepticism

Market research indicates the magnesium casting sector could hit around $24.1 billion in value by 2030 according to BusinessWire data from 2025. This growth comes as manufacturers increasingly need materials for electric vehicle batteries and enclosures for next generation 5G devices. Material pricing continues to be something companies watch closely, but recent advances in automation have changed things quite a bit. Cold chamber systems today actually keep pace with aluminum when it comes to production cycles. And interestingly enough, most major automotive component makers are already working on magnesium prototypes these days. That suggests we might see this metal moving from niche applications into regular mass production sooner than many expected.

Frequently Asked Questions

What are the main benefits of magnesium die casting for lightweight engineering? Magnesium die casting offers significant weight reduction benefits compared to aluminum and steel, while maintaining high structural integrity. Its low density and high strength-to-weight ratio make it ideal for applications where lightness and durability are required, such as car transmissions and aerospace brackets.

How does magnesium compare to aluminum and zinc in die casting? Magnesium outperforms aluminum and zinc in energy absorption systems, high-thermal-conductivity requirements, and rapid-cycle production due to its superior damping capacity, thermal conductivity, and faster solidification.

What are the key magnesium alloys used in die casting, and what are their characteristics? Common magnesium alloys include AZ91D, AM60B, and AE44, each designed for specific performance requirements. AZ91D offers good tensile strength and corrosion protection, AM60B stands out in elongation and vibration absorption, and AE44 provides high resistance to deformation at elevated temperatures.

What are the future trends in magnesium die casting? Innovations in thin-walled casting, design flexibility, and improved safety measures are driving the growth and adoption of magnesium die casting in high-volume production, particularly in automotive and electronics industries.

Table of Contents

- Why Magnesium Die Casting Is Ideal for Lightweight Design

- The Magnesium Die Casting Process: Techniques and Best Practices

- Key Magnesium Alloys and Their Performance Characteristics

- Applications in Automotive and Electronics Industries

- Innovations and Future Trends in Magnesium Die Casting Manufacturing