The Surge in New Energy Vehicle Production and Its Impact on Die Casting Demand

Electric Vehicles and Rising Demand for Precision Die-Cast Components

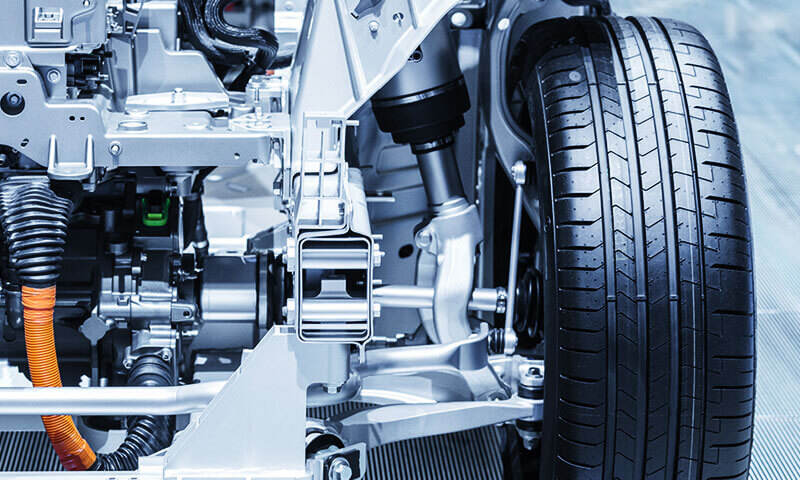

As we move toward new energy vehicles, the whole face of car manufacturing has changed quite a bit, and precision die casting has become really important in this process. Electric vehicles just aren't the same as those old gas burning machines. They need parts that are both light and strong so they can get better battery life out of them. Take a look at what's happening in China, for instance. Last year alone, around 8 million electric cars were sold there, and most manufacturers are now putting aluminum die castings into about 60 percent of the structural parts for their electric models, says the Asia Pacific Automotive Casting Market Report from earlier this year. Why? Because when we switch materials, things actually get lighter. Aluminum die cast parts can cut down on vehicle weight somewhere between 15 and 20 percent compared to regular steel parts, yet still pass all the crash tests required for safety.

Growth in EV Manufacturing and Its Direct Effect on Aluminum Die Casting

The rise in electric vehicle production has really boosted the need for aluminum die casting, especially since most battery cases and motor housing parts now use high pressure die cast (HPDC) methods. Take the US market for instance - last year saw EV sales jump by 40%, reaching around 1.4 million vehicles sold in 2023 alone. This spike pushed aluminum casting requirements for EV parts up to about 230,000 metric tons nationwide. Government programs such as the $7,500 tax break under the Inflation Reduction Act are definitely speeding things along, according to recent market reports from North America's automotive casting sector. Companies across the industry are starting to invest heavily in these big HPDC machines capable of 6,000 ton clamping force. These advanced systems let them manufacture those complex battery trays that come with built-in cooling channels right out of the mold, cutting down on assembly steps and improving overall performance.

Market Trends: Projected Increase in Die Casting Volume per New Energy Vehicle

| Component | ICE Vehicle Casting Weight | EV Casting Weight | Material Shift |

|---|---|---|---|

| Battery Housing | N/A | 85—120 kg | 100% Aluminum HPDC |

| Motor Casing | 8—12 kg (Steel) | 18—25 kg | Aluminum (+125% mass) |

| Structural Frames | 150—200 kg | 90—130 kg | Aluminum/Magnesium Hybrid |

Industry analysts project a 65% increase in die-cast content per EV compared to conventional vehicles by 2027, driven by gigacasting adoption. This technique consolidates 70+ stamped parts into single aluminum castings, reducing assembly time by 45% and improving dimensional accuracy to ±0.5mm.

Gigacasting Innovation: Transforming Large-Scale Aluminum Die Casting for EVs

What is gigacasting and why it's revolutionizing EV manufacturing

Gigacasting represents a major leap forward in manufacturing technology, allowing for massive single piece aluminum castings that are roughly 100 times bigger than what was possible before. When manufacturers swap out those 70 plus welded parts for just one solid piece, they see some pretty impressive results. Vehicles end up lighter by around 12 to maybe even 15 percent while also getting significantly stiffer, about 30% better in terms of torsional rigidity. Tesla really pushed this tech into mainstream production at their Shanghai Gigafactory, where they installed these enormous 9,000 ton die casting machines capable of making complete underbody sections in just two minutes flat. According to research from the FEV Consortium back in 2025, cars built with gigacast front and rear modules saved approximately 18% in weight compared to older multi material designs. That translates practically into extended driving ranges between charges, giving drivers an extra 6 to 8% mileage out of each full battery.

High-pressure die-casting (HPDC) in new energy vehicle production

Today's high pressure die casting (HPDC) systems run with clamping forces between 6,000 and 9,000 tons, which is actually around 25 to 40 percent more powerful compared to older models from just a few years back. This increased strength allows manufacturers to produce specialized parts needed for electric vehicles, including those massive battery trays that can stretch up to two meters long. The cooling technology has also gotten pretty sophisticated lately. These advanced systems keep dimensional accuracy within plus or minus 0.05 millimeters, something really important when making sure the battery casings stay watertight. Looking at production efficiency, most modern setups complete cycles in about 90 seconds while recycling nearly all the leftover material - we're talking about recovering close to 98% of aluminum scraps internally. This combination makes sense for companies wanting to balance exacting standards with environmental responsibility in their manufacturing processes.

Technological advancements enabling precision and scalability

Three key innovations have made gigacasting viable:

- AI-powered flow simulation software that predicts defects up to 18 hours before production

- Hybrid die materials with ceramic coatings enduring 850°C molten aluminum for over 100,000 cycles

- Real-time sensor arrays detecting micron-level shifts during solidification

These enable structural components with 2.5mm wall thicknesses while maintaining crash integrity—40% better than 2020 standards.

Challenges in adopting gigacasting at scale: Cost, quality, and supply chain

Setting up a gigacasting cell costs well over $62 million dollars, and companies should expect to wait between 12 to 18 months before seeing any return on investment, even if they produce around 100,000 units each year. There are still material challenges too. The current aluminum alloys used tend to develop about 15 percent porosity when cast into sections thicker than 120 millimeters. And then there's the whole supply chain issue. Manufacturers need to completely overhaul their approach from buying hundreds of separate components to working with just one casting partner instead. This means investing heavily in new equipment and coordinating closely with fewer suppliers than ever before.

Lightweighting: A Core Design Principle Driving Aluminum and Magnesium Die Casting

Why Lightweighting Is Critical for New Energy Vehicle Efficiency and Range

Every 10% reduction in vehicle weight improves EV range by 6—8% through lower energy consumption. This direct relationship makes lightweighting essential for consumer adoption. Aluminum and magnesium die casting enables complex structural parts that are 40—60% lighter than steel equivalents without compromising safety.

Role of Aluminum and Magnesium Alloys in Automotive Die Casting

Magnesium alloys offer superior fluidity, allowing 50% faster cycle times than aluminum in die casting. They also provide 30% higher impact strength than aluminum A380 in crash-relevant components. Magnesium is 33% lighter than aluminum while maintaining comparable strength, making it ideal for non-structural applications.

Comparative Benefits of Die-Cast Lightweight Materials in EV Platforms

Aluminum has a density of around 2.7 grams per cubic centimeter, which means it can save anywhere from 50 to 60 percent in weight compared to steel. Magnesium is even lighter at just 1.8 grams per cubic centimeter, giving roughly 65 to 75 percent weight reduction although it needs special coatings to protect against corrosion. When looking at how strong these materials are relative to their weight, both metals surpass 300 megapascals per gram - that's about 40 percent better than what we get from advanced plastics. Design engineers typically put magnesium where structural demands aren't so intense, such as outer casings, while reserving aluminum for parts under real stress like battery compartments. The result? Vehicles built this way end up being approximately 22 percent lighter than those made with combinations of different materials. Many automotive companies have started making this switch because lighter vehicles generally perform better and consume less fuel.

Key Applications of Die Casting in New Energy Vehicle Components

Battery Housings and Motor Casings: High-Integrity Die Casting Requirements

Die casting is critical for mission-critical EV components such as battery housings and motor casings, which require corrosion-resistant aluminum alloys capable of withstanding extreme thermal cycling. High-pressure die casting achieves <10 μm dimensional tolerances—essential for waterproofing and crash safety compliance.

Structural Die-Cast Parts: Reducing Assembly Complexity

A leading EV manufacturer demonstrated that a single-piece die-cast rear underbody reduces component count from 70 to 2, cutting assembly time by 35%. Eliminating welding joints improves torsional rigidity by 15% compared to stamped steel designs.

Die-Casting Molds for High-Volume Production of EV-Specific Components

Multi-slide molds enable production of over 500 complex EV parts per hour, with automated trimming minimizing post-processing. Modern molds now last 200,000+ cycles before refurbishment—30% more than in 2021—supporting factory outputs exceeding 500,000 vehicles annually.

Market Expansion and Economic Opportunities in the EV-Driven Die-Casting Sector

Revenue Potential and Market Growth Forecasts for EV-Related Die Casting

Market forecasts indicate that the worldwide die casting sector for electric vehicles could hit around $24.1 billion by the year 2030, expanding at approximately 12.3 percent compound annual growth rate. Parts specifically designed for EVs already make up about one third of total automotive casting sales, which represents a significant jump from just under 20 percent back in 2020. The reason behind this surge? Car manufacturers are working hard to cut down on vehicle weight by roughly 18 to 22 percent through the use of lighter materials like aluminum and magnesium alloys, yet they still need to keep those cars strong enough to perform well structurally on roads everywhere.

Regional Shifts in Casting Infrastructure Due to New Energy Vehicle Demand

Asia-Pacific leads with 63% of global EV die-casting capacity, driven by China's production of 8 million new energy vehicles in 2023. Foundries in the region are investing $4.2 billion in HPDC upgrades to meet OEM gigacasting demands. North American capacity grew 28% year-over-year in 2023, supported by federal policies favoring localized EV supply chains.

Strategic Transformation for Traditional Foundries in the EV Era

Older foundries are now spending around 41 percent of their capital expenditures on electric vehicle casting tech, which is way up from just 9% back in 2019. Money is going into things like X ray inspection systems so they can get defect rates down under 0.2%, plus there's investment in artificial intelligence controls that cut energy usage somewhere between 15 and 18%. And this whole transition means most workers need new training too. About seven out of ten employees have to learn these advanced simulation techniques and lean manufacturing methods. They're also getting used to working with much tighter specifications for EV parts, sometimes as small as plus or minus 0.05 millimeters in precision.

FAQ

What is gigacasting in the context of electric vehicles?

Gigacasting is a manufacturing process that enables the creation of massive single-piece aluminum parts for electric vehicles, significantly reducing the number of individual welded components needed.

Why is lightweighting important in new energy vehicles?

Lightweighting is crucial because it reduces the overall weight of the vehicle, thereby improving the driving range and energy efficiency of electric vehicles.

What advantages do magnesium alloys offer in die casting for EVs?

Magnesium alloys provide superior fluidity, allowing for faster cycle times in die casting. They also offer higher impact strength and are much lighter than aluminum, making them suitable for non-structural applications.

How is the die casting industry changing with the rise of EVs?

The industry is seeing increased demand for aluminum and magnesium die-cast parts, driving investments in high-pressure die casting technology and gigacasting processes to meet the needs of electric vehicle manufacturers.

What are some of the challenges of adopting gigacasting technology?

Challenges include the high cost of setting up gigacasting cells, material porosity issues with aluminum alloys when cast into thick sections, and overhauling supply chains to accommodate fewer but more complex components.

Table of Contents

- The Surge in New Energy Vehicle Production and Its Impact on Die Casting Demand

- Gigacasting Innovation: Transforming Large-Scale Aluminum Die Casting for EVs

- Lightweighting: A Core Design Principle Driving Aluminum and Magnesium Die Casting

- Key Applications of Die Casting in New Energy Vehicle Components

- Market Expansion and Economic Opportunities in the EV-Driven Die-Casting Sector

-

FAQ

- What is gigacasting in the context of electric vehicles?

- Why is lightweighting important in new energy vehicles?

- What advantages do magnesium alloys offer in die casting for EVs?

- How is the die casting industry changing with the rise of EVs?

- What are some of the challenges of adopting gigacasting technology?