Tafiyar Girman Na'urar Na'ura da kai'iddan da ke cikin Amsawa zuwa Die Casting

Electric Vehicles da kai'iddan Yawa don Al'ada Component Daban-daban

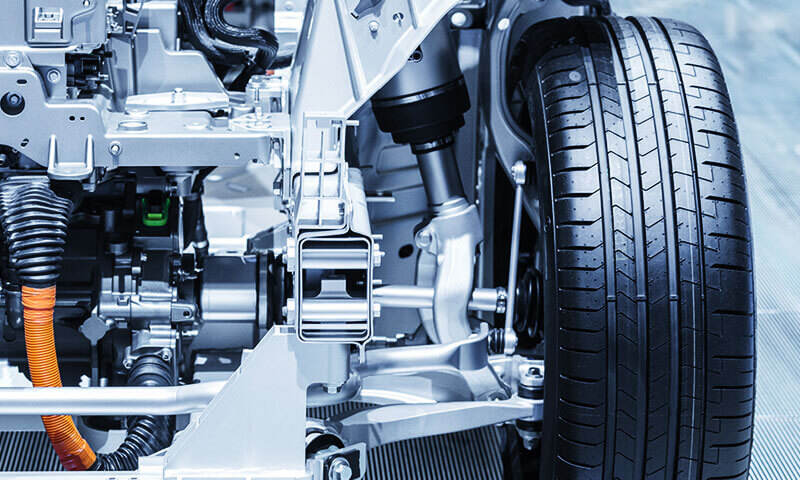

Yanzuwa zuwa zuwa zuwa masu na'ura na al'ada, bayanin tashar injin ya samu girma girma, kuma injin ƙarƙashin na gama girma ya zama karkatar da ake so ne a cikin wannan halin. Masu na'ura ba su daidai su ne da wadanda ke soke na gas na yau da kullun. Sune buƙatar abubuwa da ke ƙasa kuma da ke ciki don su samun al'ada mai yawa daga cikin battery wajibbace. Duba wasu abubuwa da ke happening a Cin, misali. A shekarar da ya tashi, kafin 8 juta na masu na'ura an kara su a Cin, kuma yau da kullun masu amfani ne a cikin aluminum na gama girma suna amfani da shi zuwa 60% na abubuwan da suka haifar da su a cikin model din na elektriki, shine sabon Asia Pacific Automotive Casting Market Report daga ranar da ya tashi. Menene sabon? Saboda idan muka yiye wani abu, abubuwa actually ya ƙare. Abubuwan aluminum na gama girma zai iya ƙaryawa wata ƙasa na bu'urun somewhere between 15 zuwa 20% dibba da abubuwan steel na yau da kullun, amma kuma ya tattara duk wadanda ke soke tests na kwalliya.

Tafiya a cikin amfani da masu na'ura na elektriki kuma wani abu da ke nufin aluminum na gama girma

Takaici na ƙimar ƙirar na yin batari mai elekiriƙi ya ƙara buƙatar ƙirar aluminum die, amma kuma yau da a ciki battery cases da motor housing parts a yau ke amfani da HPDC methods. Duba wuri na US - a shekarar da suya EV sales ya ƙadada 40%, kada su ƙadda ƙimar 1.4 million vehicles a 2023 kusa. Wannan ƙadadda ya ƙara buƙatar aluminum casting na EV parts zuwa ƙimar 230,000 metric tons a dutsen masu. Programmai na kasa kamar ɗalibin $7,500 a cikin Inflation Reduction Act suna taka leda, don mutanen da suka duba market reports na automotive casting sector na North America. Masu aikin a dutsen masu ke sakawa suka yi invest a cikin wadannan mesin HPDC mai 6,000 ton clamping force. Wadannan systems na iya gudunwa suna ba su iya ƙirar wadannan battery trays da suke da cooling channels a cikin mold, zanin aikin yin assembly da kuma takaici na performance.

Tsondayen Sura: Ike na Tafiya na Abubuwan Tsinkin Kusar per New Energy Vehicle

| Kumantaccen | Tsawon Abubuwan Tsinkin Na ICE Vehicle | Tsawon Abubuwan Tsinkin Na EV | Zurruntsa na Ganin Aji |

|---|---|---|---|

| Shafin Battery | N⁄A | 85—120 kg | 100% Aluminum HPDC |

| Kasurwar Motor | 8—12 kg (Steel) | 18—25 kg | Aluminum (+125% mas) |

| Fasaholin Ƙarƙara | 150—200 kg | 90—130 kg | Aluminum/Magnesium Na Tsaba |

Masanin ƙarƙarin sojin yawan ƙarin 65% a cikin abubuwa da ke die-cast per EV dibu zuwa zuwan na jiki ta 2027, wanda ke taimakawa gudunwa. Wannan takin ya kara 70+ abubuwa da ke ɗaukar cewa zuwa kan yi die-cast na aluminum, yin kama da yin aikin da ke 45% kuma taimakawa don tattara tama da sauri zuwa ±0.5mm.

Gigacasting Innovation: Tattara Tsarin Aluminum Die Casting Don EVs

Menene gigacasting kuma dalili ya sa ta girma tsarin manufacture na EV

Gigacasting ita ce taƙaitaccen ƙididdiga a tsarin teknolijin ƙirƙirar, ta ba da izini don ƙirƙira alwuminum na ɗau guda daya wanda ke cira shine 100 bar zuwa ta hanyar da ake iya samar da su a baya. Lokacin da maimakonin suka canza su daga 70 kuma fai su na ƙarfafawa zuwa guda guda daya, suka ganin alaƙa mai kyau. Makarni suna guda da kusa zuwa 12 zuwa 15% kuma suna da izinin ƙarƙashin, kuma ƙarƙashin 30% a cikin rigidity torsional. Tesla ya yi wajibi a cikin ƙirƙirar na jahar da ake amfani da shi a Shanghai Gigafactory, inda aka ƙarfawa su daga ɗauƙƙaƙƙan 9,000 ton die casting machines wanda ke iya ƙirƙira samfuran ƙarƙashin ƙasa a hanya goma biyu kawai. Don haka, a cikin bayanin FEV Consortium daga 2025, makarni wanda aka kirƙira su da gigacast na farko kuma farko ta ziyar da kusa zuwa 18% na gudun dib wajen zaɓi na farko. Wannan shine taƙaita zuwa cikin ƙarin tafiyar jiki a tsakanin karkashin batiri, ta ba da izini don ƙarin 6 zuwa 8% na tafiyar jiki daga karkashin batiri mai ɓangware.

Die-casting mai tsawo a tsarin samfurwa na sabbin na'ura na buƙatu

A yau, tsarin digiri na high pressure die casting (HPDC) suna wajen da alakar da 6,000 zuwa 9,000 tons, wanda shine kafin 25 zuwa 40% karanci ne ga wasu tsari na yau da baya ce. Wannan ƙarancin tama rai ta memba suwa suwa da ke buƙatar vehicular electrified, kamar wadanda battery trays da ke saman iri daya da mada 2 meters. Takkamfawa na cooling kuma tana faruwa ne a yau. Wadannan tsarin digiri na uku na iya amfani da accuracy na dimensional a cikin plus ko minus 0.05 millimeters, wanda shine masu muhimmi a lokacin da ke tabbatar da battery casings suna da tauraro. A lokacin da ke duba gaba daya da efficiency na production, karkashin tsarin yau da baya suna buƙatar mili 90 seconds sannan suna da alakar da karkashin abubuwan da a ba su amfani ba - haka ne suka fitar da kira kafin 98% na aluminum scraps a cikin gida. Wannan raba na buƙata amsa ne ga shagunan da ke so su wasu alaƙa da alƙawari da kuma tattara a cikin tsarin uwar gudunawa.

Takamta na teknolijin da ke kara iya ƙarfi da kara yawa

Matsalar uku na innowasiolin da suka sa gigacasting ya zama mai amfani shine:

- Software na flow simulation powered by AI da yake tunawa akan bukku zuwa zuwa 18 hours zuwa ƙarshia production

- Matsalar dabba na hybrid da ceramic coatings da suka yi 850°C aluminum mai zuwa zuwa da yawa zuwa 100,000 cycles

- Sensor arrays na real-time da suka gani akan canzawa na micron-level a lokacin solidification

Wannan suka ba da iya komunin ƙasa da takaddun 2.5mm idan aka tura crash integrity - 40% mai kyau karshi na standard din 2020.

Matsalar a wajen yin amfani da gigacasting a yankan girma: Karfi, maita'a, da supply chain

Saita don ƙurƙura da cell giga ta fi ƙarshi 62 million dɔlɔr, kuma koma siyanan dole ne su jira daga 12 zuwa 18 wakati kafin samun saƙo na investmen, tun da suka yi ƙirƙira kafin 100,000 alamar kowanne shekara. Hakanan yana da saƙo na abubuwa kuma. Alloys aluminum da aka amfani da su yanzu suna da ƙarin 15% na porosity idan aka ƙirƙira su a cikin ƙasa da yawa fiye da 120 millimeters. Sannan kuma tana da saƙon tsere na uwar gudun. Doletan koma suyi canzawa guda na filaye da suka nuna daga siya na ƙirƙirar ƙarin 100 zuwa amfani da ƙirƙira mai gaba daya kawai. Wannan shine nufin inyawa a matsayin cikin abubuwan sabbin kuma kuma kirkiran tare da kadanin mai siya fiye da ke cikin zamantakewa.

Lightweighting: A Core Design Principle Driving Aluminum and Magnesium Die Casting

Why Lightweighting Is Critical for New Energy Vehicle Efficiency and Range

Ƙума 10% na saman zaɓi na kara tushen EV a ƙarin 6-8% ta hanyar ƙarin shaida na amfani da alaka. Wannan tuntuɓar zabi ya sa saitin ƙarin saman ya zama mahaƙiyya don gudun kiyaye. Samfurin aluminum da magnesium die casting zama samfurin ƙarin ƙasa da yawa wanda aka saman 40-60% kara shi ne daga steel equivalents wajen kai tsaye.

Aikin Aluminum da Magnesium Alloys a cikin Samfurin Die na Gidan Jigo

Magnesium alloys suna da aladuwa mai tsauri, ta ba da izinin 50% mai yawan takarda daga aluminum a cikin die casting. Suna da kuma 30% mai tushen tafiyar tushen daga aluminum A380 a cikin saman da ke cikin crash-relevant components. Magnesium shine 33% kara shi ne daga aluminum wajen saman da yawa shine mai iya amfani da yawa don alaƙai.

Tafiyar Mai Sauƙi na Samfurin Die-Cast Lightweight a Cikin EV Platforms

Aluminum ya da karatun kusa da kira ɗaya na 2.7 gramu per cubic centimeter, wato zai sami sauri na 50 zuwa 60% a cikin mafawa na dibu zuwa steel. Magnesium ita ce babba da kira ta 1.8 gramu per cubic centimeter kuma zai sami sauri na 65 zuwa 75% a cikin mafawa amma dole ne a yi amfani da coatings masu ƙarfi don hana corrosion. Lokacin da muka duba tsawon wadannan abubuwan da suka dace da mafawar su, wadannan biyu metal suka tafi 300 megapascals per gram - wato kusan 40% mai yawa ne dibu zuwa plastics na iya. Mai tsoro na farko ya kea magnesium inda babu tsangayar tsoro, kamar wadannan abubuwan da ke sanya, amma ya kama aluminum don abubuwan da suka zuba kamar battery compartments. Sauran nawa? Mafar da aka yi shi yayin da aka yi amfani da wadannan abubuwan yana zabi 22% mai mafawa dibu zuwa mafar da aka yi daga cikin wasu abubuwan. Aƙalla daga wasu shagaran jiragen suka fara yi waƙar da wannan sabon aiki saboda mafar da suke mafi mafawa duk suke iya amfani da suke da kara kuma suke tura sauri na gani.

Akkwayoyin Na’iyya na Die Casting a Cikin Komponinsu na Kantin Na'asa na Kantin Na'asa

Battery Housings da Motor Casings: Za'awar Za'awar Die Casting

Die casting ita ce babba don komponinsu masu muhimmiyya a cikin EVs kamar battery housings da motor casings wanda su hana za'awar alloys na aluminum wanda ke taimakawa wajen ganiyan zuwaƙi. High-pressure die casting ya samar da alamomin <10 μm dimensional tolerances - wanda ke yawan tattara taka da kariya don tattara taka da kariya.

Komponinsu na Structural Die-Cast: Reducing Assembly Complexity

Maimakon EV manufacturer ya nuna cewa a single-piece die-cast rear underbody ya kawo adadin komponinsu daga 70 zuwa 2, kuma ya kawo zaman ƙwafin ƙwafi ta 35%. A cirewa kariya na welding joints ya fara tattara rigidity ta 15% dib dib zuwa gaba daya da stamped steel designs.

Die-Casting Molds don Production mai girma na Komponinsu na Kantin Na'asa

Matsar daidaitaccen na iya ƙirƙirar karshen EV masu ƙarfi da suka fi 500 kusa yana pakan kada, tare da ƙirƙirar da ke cikin auta mai ƙarfi ya ƙare yin gwajin gabanin aikin. Matsar a yau na iya samun zamantakewa 200,000 ko fiye daga 2021 shine 30% da suka fiye, kuma yana tattara aikin fatar da suka fi 500,000 ita kusa kadan kusan yau da kullun.

Takaddun Sauran Kadan Da Kuke Ci Gaba Da Kiyaye Na Irtiƙai A Cikin Siffoin Da Kuke Tsara Da Kiyaye Na EV

Takaddun Sauran Kadan Da Kiyaye Na Irtiƙai A Cikin Siffoin Da Kuke Tsara Da Kiyaye Na EV

Aboki na sarrafa suna iya cewa gwiwa na die casting a tsakanin world for electric vehicles zai iya samun kuma $24.1 billion bayan shekarar 2030, kuma zai iya caddamar da kuma 12.3% compound annual growth rate. Parts da suka yi amfani da EVs suna iya ƙara wajen sasashen na otomatik, suna iya ƙara waje na uku na kwalliya, wato shine daya daga cikin ƙarin cewa suka samu a shekarar 2020. Menene dalilin haka? Masanin gidan jiki suke yi effort yin kawo wajen jiki na otomobil 18 zuwa 22% ta hanyar amfani da abubuwan da suke kama kamar aluminum da magnesium alloys, amma kuma suke buƙata su yi aiki don yin aiki a fadin jiki a duniya.

Canje-Canjen a cikin tsarin gwiwa ta hanyar saboda New Energy Vehicle Demand

Asiya-Pasifik ya gabata ta 63% na gwiwar EV die-casting a duniya , da keɓaƙƙiya da matsayin tsarin na China na samar da 8 million na yankin na farko na 2023. Masalitin a wucin suna invest 4.2 billion dollar don samar da saƙo na HPDC don kama da shawarwar na gigacasting. Matakan na amurka ta cikin ta 28% a shekarar 2023, ta hanyar politikan na federal pabada matakan na yankin na amfani da EV

Matsayin Tsarin na Masalitin Na Zaman Iya Rana a zamanin EV

Wasannan ganyawa na yau sun yi shi 41% na kudin su na amfani da teknollijin cast na vehiclen da ke ciki, wanda ke tattara daga 9% na 2019. Peshi sun yi amfani da abubuwa kamar yarxadun auyukan X ray don samun kuskurewa da ke ƙasa da ƙasa zuwa ƙasa ƙasa, kuma akuya sun yi invest in controls na artificial intelligence wanda ke kara amfani da alaka na 15 zuwa 18%. Kuma wannan canjiyar da ke cikin yau ya nufi ne a matsayin mutane a aiki su hanyar sabon ilimi. Wani 7 daga cikin 10 na aikin mutane zai buƙatar taƙaita wadannan teknikun samfawa da ma'ajin gudun samfawa. Suna kuma samun aiki tare da specifications mai ƙarfi don EV parts, ana kawo su da kusa da ƙasa zuwa 0.05 millimeters.

Tambayoyi Masu Yawan Faruwa

Menene gigacasting a cikin kontekstin electric vehicles?

Gigacasting shine proses na samfawa wanda ke ba da izinin samar da abubuwan aluminum na ƙarƙashin ɗan adam na vehiclen da ke ciki, wanda ke kuskure amfani da ƙayyukan keɓaɓɓen da ke ciki.

Mene ne za ake so ne a ƙara mafaru a cikin na'urar na'ura ta yankan elektriki?

A ƙara mafaru shine waje mai muhimmi saboda ya kara ƙarin gama na'ura kuma ya ƙara aikace-aikacen na'ura ta elektriki.

Wanne dacewa ke ba da alun magnesium a cikin die casting don EVs?

Alun magnesium tana ba da inganci mai zurfi, ta hanyar da ke ba da tsawon lokacin a cikin die casting. Kuma tana ba da alhakin takaici kuma suna ƙarin mafaru dib dib zuwa zuwa ga aluminum, ya hakan shine suka sa su ta yawa don alhakin ba su da alhaka.

Yake sucan kusan die casting yake canzawa a cikin rashin EVs?

A yawan kusan yake ga aluminun kuma alun magnesium die-cast parts, wanda ke kara aikace-aikacen a cikin teknololin high-pressure die casting kuma processes na gigacasting don yi gane da shugaban na'ura ta elektriki.

Wanne ne kawalolin adopsin teknololin gigacasting?

Wasanni masu ƙauye shine biyan daƙƙen samfatan saiti na gigacasting, masalin porosity na alloys na aluminum lokacin da aka kafa su a cikin kwalluka, da kuma canzawa tsangon gudun tattara don samar da sauyan da ake iya amfani da su.

Teburin Abubuwan Ciki

- Tafiyar Girman Na'urar Na'ura da kai'iddan da ke cikin Amsawa zuwa Die Casting

- Gigacasting Innovation: Tattara Tsarin Aluminum Die Casting Don EVs

- Lightweighting: A Core Design Principle Driving Aluminum and Magnesium Die Casting

- Akkwayoyin Na’iyya na Die Casting a Cikin Komponinsu na Kantin Na'asa na Kantin Na'asa

- Takaddun Sauran Kadan Da Kuke Ci Gaba Da Kiyaye Na Irtiƙai A Cikin Siffoin Da Kuke Tsara Da Kiyaye Na EV

-

Tambayoyi Masu Yawan Faruwa

- Menene gigacasting a cikin kontekstin electric vehicles?

- Mene ne za ake so ne a ƙara mafaru a cikin na'urar na'ura ta yankan elektriki?

- Wanne dacewa ke ba da alun magnesium a cikin die casting don EVs?

- Yake sucan kusan die casting yake canzawa a cikin rashin EVs?

- Wanne ne kawalolin adopsin teknololin gigacasting?