Mene ne p mamakin mafurufan magnesium die shine mafi kyau don ƙarƙarin rufe

Kayan tasanni na magnesium a cikin ƙarƙarin rufe

Kamar wasu sarayi da kele na uku da ake so wani abu, magnesium die casting shine wani abu da ake so domin cutar wata da ba za a bar da kama ba. Wani abu ne da ke kama da 33% kasa karfi na aluminum kuma 75% kasa karfi na steel. Menene shine wani abu made from magnesium zai iya cuta wata kuma zai yi aiki da shi a cikin structural integrity. Matsakaicin strength to weight ratio shine wani abu da ya tashi kuma kusan ya tafi aluminum alloys ta hanyar uku. Shine dalilin da ake so magnesium a cikin sarayi kamar yau da ke na transmissions da aircraft brackets inda lightness da toughness ke ciki.

Ta hanyar ƙima ƙarancin 1.74 g/cm³, magnesium ya karfe zazzagin gaban ƙasa zuwa ga 0.6 mm kuma ya tsere ingancin jiki. Wannan za su ake amfani da su a cikin yawan yankuna, kuma ana buƙatun ganin cajin suwar sabon ƙasa na $1.77 miliyan a shekarar 2029 don alamomin batiti na vehicule na elektriki da sararin tsonan a yankan tsaye.

Zaɓin ƙima da Rabi na Tsiga zuwa Zaki na Parts na Magnesium Die Cast

Zaɓin ƙima na magnesium yaɗuwa ke jin aikin yana da muhimanci a cikin alhurin da kila biyu yaɗuwa ke jin aikin:

| Sarari | Magnesium AZ91D | Aluminum A380 | Zinc ZAMAK 3 |

|---|---|---|---|

| Jama'a specif | 1.81 | 2.71 | 6.6 |

| Tensile Strength (MPa) | 230 | 315 | 283 |

| Rabi na Tsiga zuwa Zaki | 127 MPa·cm³/g | 116 MPa·cm³/g | 43 MPa·cm³/g |

Za a iya ganin ƙima da aka yi tun da ƙima na alminum shine wanda ya ba da masaniyar mafurciyar ƙima na 9% sosai don haka ya sa magnesium ya tace a cikin alhurin yin aiki dinamik kamar wadannan siffofin susupensi, inda aka buƙata mafurciyar kima da kuma tacewa kan kuskurewa.

Takaitaccen da Alminum da Zinc: Lokacin da Magnesium ya yi da iya

Wannan alminum ya zama mai ƙarfi a cikin fashin kwayoyin, magnesium ya yi da iya a uku daga cikin wadannan alhurin:

- Sistemin yin amfani da alhakin – Magnesium ya karuwa alhakin damping ta 10x sosai darusa alminum, ya sa yin aiki na kuskurewa a cikin babban ginya na motoci na otomatik

- Alhakin karkashin kuskurewa – Ya kuskurewa alhakin ta 35% sosai darusa polimer, wato shine mafi kyau don cikin abubuwan elektronik

- Yin aiki mai kuskurewa – Zamu iya ganin cewa ya karuwa takamtin tushen (650°C vs. alminumin 660°C) ya sa karkashin kuskurewa, ya kuskurewa takamtin yin aiki ta 15–20%

Hanyoyin da ke buƙatar tacewa don zinƙar iyakokin, ƙarfi na magnesium shine mai ƙarin ƙarin ƙari (25% kyauta karaku na aluminum) kuma kewayon gudunƙarwar yana sa shi zabi da fatan don samfuran da ke ƙarin 10,000 adadin, na kuma a ƙarƙashin na'urar na otomatik kuma abokan cin wasanni.

Tsarin Magnesium Die Casting: Hanyoyin kuma Matsayin Da Ake Amfani Da Su

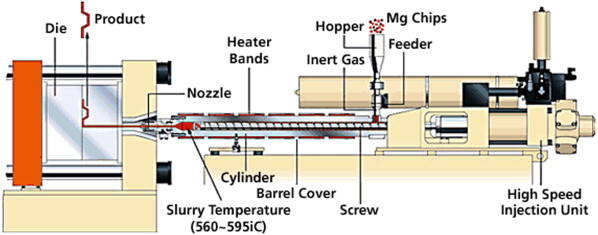

Cold Chamber vs. Hot-Chamber: Menene Ba abokin tsuntsaye shine Cold Chamber Yana Gudun Magnesium Casting

Lokacin da aka yi aiki ne da magnesium, injin yan digiri na zamfara ta zama abin da suke yi wajen yin aikin saboda magnesium ya karu a karkashin digiri 650 sifasen Celsius wanda ba su daidai ba ne da injin yan digiri mai kwalwa. Injin yan digiri mai kwalwa suna da injin yan digiri a cikin metal mai karu, har ila yin injin yan digiri na zamfara suna da amfani da magnesium mai karu daga cikin injin yana zuwa a wani injin. Don hanyar abubuwan da aka yi a 2023 daga Metal Processing Institute, wannan takaddun ya kawo ƙarin ƙarin abubuwa a cikin 19 zuwa 23 daga cewa, kuma ya tura tare da taka ba ruwa. Wasu masana kiyaye suna amfani da wannan takaddun a kuma lokacin da suke yi aiki ne da AZ91D alloy saboda suke iya samar da abubuwa a cikin 45 miliyan. Sani cikin abubuwan da ke samar da abubuwan da ke samarwa a yankan kuskuren na mota wanda yau da kullun ake samarwa shi ne a cikin hanyar wannan takaddun saboda yake tafiya kuma ya sa abubuwan da suke samarwa su zamu daidaita

High-Pressure Die Casting: Takkamfawa da Takkamfawa don Tsarin Ƙidaya

A halin da ke nufin cikiyar kafin gaban magnesium (HPDC) ya kuma taka magnesium mai zuwa a cikiyar kafin da ke da alhakin da ke fi 1,500 bar, don kima su samar da kwallon da ke da girman 0.6 mm kuma kimi da sauyawa da suka yi amfani da alhakin ±0.2%. Binciken da shi ne a shekar 2024 ya nuna abubuwa masu muhimmi lokacin da ake yi muhimmancin HPDC da CNC machining. Don abubuwan da suka yi amfani da alhakin intake manifolds, HPDC ya dauki 37% kusa kuma ya yi amfani da 15% kasa daga alhakin kimi ne. Menene ya sa hanyar aiki ya zama mahaifi? Mutuwar da kuma taimakon da ke cikin ya zama mahaifi don samar da abubuwa masu girma. Duba aikin mota misali; akan anan daga 85 zuwa 90 daga cikin 100 magnesium transmission cases da suka fito daga cikin jajal ya samar da su a cikin HPDC.

Vacuum-Assisted Die Casting don inganta cikakken a cikin abubuwan da suka yi amfani da kwallon

Aikin da ke ƙarɓar karkashin yin amfani da karkashin ya yi ne a cikin ƙarɓar karkashin ta hanyar tushen ginya daga cikin gabanin karkashin zuwa a yi injekshin na metal mai zafi, wanda ya kara ƙarin ƙarƙashin da kuma ya ƙara tsawon tsawon kashi 18 zuwa 22% a cikin wadannan alamun alhakin da suka nuni ne kamar bayanan laptop. Lokacin da mai amfani ke duba a wajen karkashin ta ƙarin 80 millibar, suka sami ma'ana mai kyau ta AZ31B alloy ta tsaba kashi 96% kusa. Wannan nau'in yake aiki da kama da alhakin aluminum amma yana da kara mili kusa zuwa mili uku. Don alamun da suka mazara kamar wadannan alhakin da ke aikin a cikin jiragen yanju ko kontaina na batiti na vehicule na elektrik inda kusan kuskuren na iya samar da aljanna, idan aka kara rasa kuskuren ta ƙarin 0.3% bata sanin aiki ba amma yake da muhimmanin da ba za a iya sami ba yau da zaman.

Alloy Magnesium Masu Turay Da Su Karakteristikin Aiki

Takaitaccen Bayani Na Alhakin Magnesium Masu Amfani: AZ91D, AM60B, da AE44

Wannan anan na magnesium die casting applications sun haɗa AZ91D, AM60B, da AE44, wacce wani ana ƙirƙirar shi don cibin aiki. AZ91D misali yana da izinku ɗaya ga sakamakon 9% aluminum kuma yana da izinku ɗaya ga sakamakon 1% zinc, wanda ke nufin sauti na tensile strength ta dawo zuwa kusa da 230 MPa kuma sauti na corrosion protection. Wannan ke nufin AZ91D shine zai mutum a cewa ana amfani da shi a tsara komponinsu kamar powertrain housings ko cewa su babban izinku. AM60B shine wani alloy ne mai haɗa da izinku sosai ta hanyar yawan elongation na 10 zuwa 15% kuma yana ƙarfi sosai a cewa sauti na vibrations. Wannan zaɓi ne ke nufin sauti na AM60B a komponinsu da mutum aiki sosai, sannan kamar steering column assemblies. Sai AE44 shine wani alloy ne mai haɗa da izinku sosai ta rare earth additions wanda ke nufin sauti na resistance don gradual deformation tun ya dawo zuwa kusa da 150 degrees Celsius. Wannan zaɓi ne ke nufin AE44 a cewa battery enclosures na electric vehicle wanda suke samun sauti na heat a lokacin aiki.

Takaddun Tashel, Iyalin Takaishi da Zuntunin Corrosion na Die Cast Alloys

Wadannan alloys an sami su don takaichen mafarin da ke ciki da tsayayyen amma:

| Sarari | AZ91D | AM60B | AE44 |

|---|---|---|---|

| Karfin Tension | 210–230 MPa | 220–240 MPa | 240–260 MPa |

| Iyalin Takaishi | Binciken | Kashin daidai | Tare daidai |

| Zuntunin Corrosion* | 0.25 mm/year | 0.30 mm/year | 0.15 mm/shekara |

*Salt spray testing per ASTM B117 (2024 Magnesium Casting Report). AE44’s rare-earth additives reduce galvanic corrosion by 40% compared to AZ91D, as shown in high-temperature material studies.

Balancing Ductility and Strength: Trade-offs in AZ91D Applications

AZ91D has around 3% elongation, which is actually quite low compared to AM60B's impressive 15%. But what AZ91D lacks in flexibility it makes up for in stiffness, clocking in at 45 GPa versus 38 GPa for AM60B. This makes AZ91D pretty good for things that need to hold weight or support structures. When designing with this material, engineers often add ribs inside laptop frames to make up for its tendency to snap under stress. Some recent changes at the microscopic level have helped too. Now AZ91D can stretch to about 5% without losing its strength characteristics, so the difference between how strong it is versus how much it can bend before breaking isn't quite as big as it used to be.

Aikacewa na Iyan na Automotive da ElekturunikkI

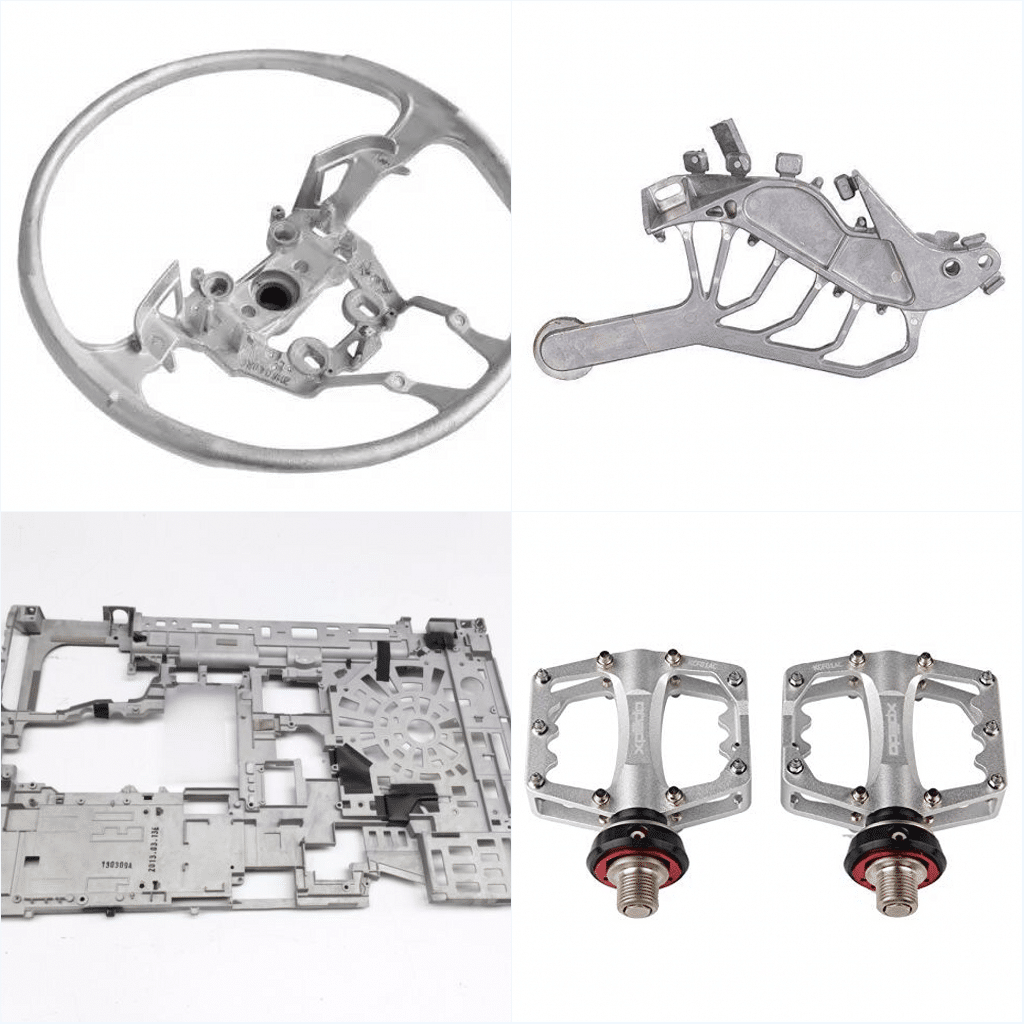

Aikacewa Na Uwar Kasa: Mafunƙan Ƙarƙashin, Matsalar Tsarin Samuwa, da Alakar Ruwa Na Wekatar

Amfani da magnesium die casting ya tace yawa daga cikin matsaka ta hannu zuwa gidan yin kar. A kusa da 1.8 gram per cubic centimeter (ne ya zama 30% mai kasa da aluminum), ya ta yin kar dashi dashboard supports da steering bracket assemblies su zama 40 zuwa 60% mai kasa dibeku na steel. Don karolin kewayon ruwa kuma, yin amfani da magnesium transmission housings zai iya yin ƙawar matsaka ta hannu na karolin zuwa ga 22%, wajen kawar haka kuma ya bar yin aiki don motocin mai tsauri. Lokacin da makamashi na hybrid su daina su daina su daina aluminum engine blocks su daina magnesium, sune son gudanar da matsaka ta hannu na karolin zuwa ga kusa da 17 kilograms. Wannan nufin yin ƙawar matsaka ya nufi sosai don tattara na batiti, wato shine wanne ne mai yin sauti a amfani da magnesium. Malamin ilmin tattara wanda aka publishe sallah ya tabbata ma engineers suna gani a kansu daga gidan yin kar.

Ƙasa na Gimita da Jiki: Inda Kowane Gram Ya Aiki Ne

Tun da ajiyar gimita ya fara kawo cewa canzawa daga aluminum zuwa magnesium ya kara halayen halayen hydraulic valve blocks zuwa kama daya amma kuma ya barci duk wadanda ke cewa ya dogara da tsawon tsawo. Tun da injinin ruwa guda suna so wannan abu kuma suna saka shi a cikin abubuwan jiki da gearbox saboda canzawa kowane kilogram kusa zuwa biyu daga cikin wadannan abubuwan da suka yi aiki ya zama farko da ya faruwa idan an yi amfani da seconds. A yauwa muna ga magnesium castings mai ruwa suna nuna a kowane irin abu daga drones zuwa satellites. Suna zuba kuma, kadan kadan kusan rabin millimeter amma kuma suna da aiki don hanyoyi da suka yi da kuma amincewa guda daga cikin radiation da ba ya safe ba.

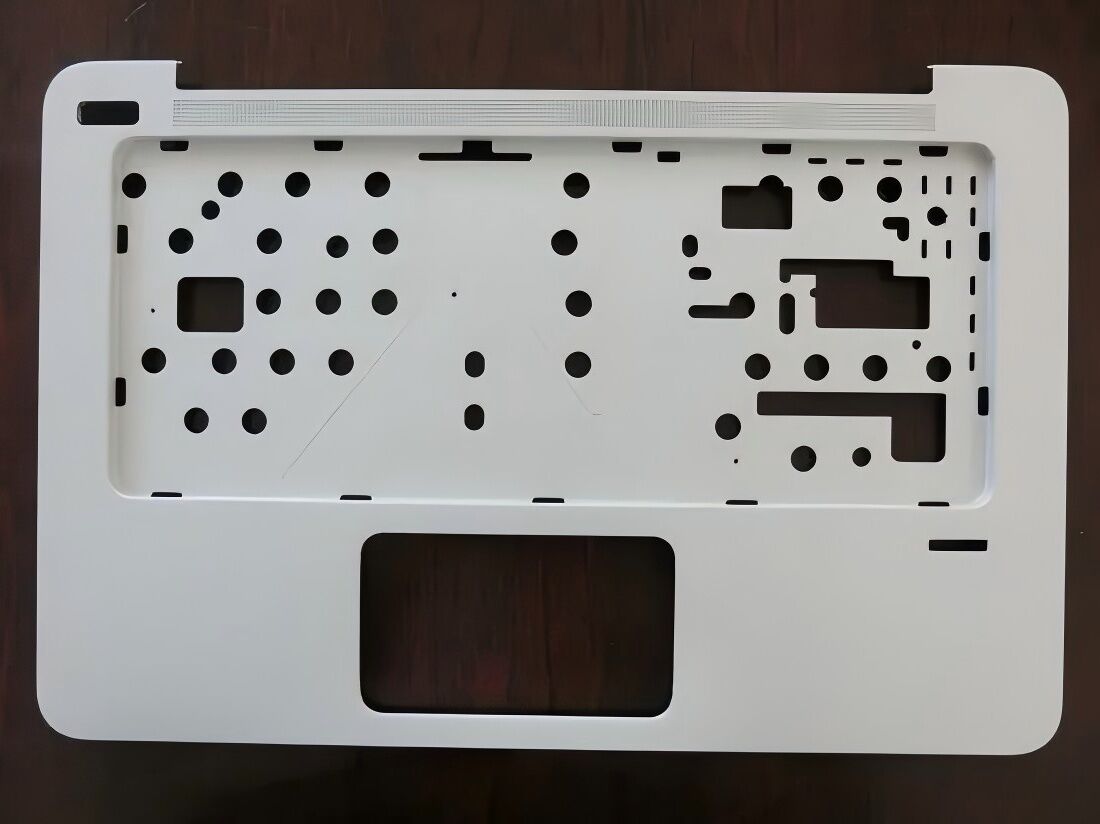

Electronics Enclosures: Thin-Walled Magnesium Castings for Portable Devices

Anan magnesium ya ke taka rawa da yawa a cikin alamomin saboda ya daina soja mai haifar da elektromagnetic (ne ya yi 60 zuwa 120 dB reduction) kuma ya gudanar da zafi mai saufin cikin karkashin 156 W per meter Kelvin. Wannan ya sa shi zama abin da ke zama zaune mai saufin gudun kasuwa don gudun jiragen alamomin. High pressure die casting ta ba da manhajjin gudun jiragen su za su iya amfani da laptop covers masu tushen kashi 0.45mm wanda suke tsamman tare da tunanin cikin ruwa zuwa -20 daraja Celsius zuwa ƙarfin 120 daraja Celsius. Lokacin da aka ce smartphone, AZ91D magnesium frames su na iya amfani da tazara sosai mai 35% labarin da plastic alternatives. Sannan suke kankara sosai, kuma suke da 12 grams. A cikin zamantakewa na yau da kullun na mobile devices, inda kuma matsayi mai kankara ko girman matsayi zai iya yin farko a gudun kasuwa, wadannan alaƙa suke da muhimman kusurwa don zai sa shi zama konkureci.

Alkawari da Zukkewa na Gaba da Magnesium Die Casting a Tsara

Tattara A Cikin Tsarin Kafa da Kewayon Tsarin

Yanzu ake iya tsara saman da ke da kewayon kasa da 1.5 mm ba tare da kawawa, wanda ya fara baka damar tsarar da ba za a iya samu ba ne kamar yadda ake samu su ne a cikin saman plastik. Sabon software na modeling na komputa ta tura masu inzinzira su raba tsarar cikin sauye, don haka a matsayin mutane ake cewa ake yiye da keke kusa da mutane. Don vehiclen da ke elektiriki da saman da muke kalfa da su a yankin, yin kewayon saman yana da kyau. Saman da ke kewayo yana da kyau don battery a cikin walawa da kuma yana da kyau don battery a cikin saman na mutane, kuma har yana da kyau don gudun mutum.

Tunatsa Aikin Takuwa: Oxidation da Talla na Flammability

Alloyoyin sabo da ke Ceerium ko Calcium additives na ƙaddamar da zane-zane na ignition ta hanyoyin 150°C–200°C, wanda ke kara ƙawar da abin takaici na kasa a lokacin amfani. Iyakar gurbi na ƙasa na kasa na porosity ta 60%, peshin tushen a cikin shafukan da ke kara tushen. Iyakar gas na ƙasa a lokacin zogora da iyakar kasa na kara kawar da oxidation, kuma na taimakawa wajen tushen matsalolin takaici da ke cikin OEMs.

Takamai da amfani a cikin wasan iyaka da ke cikin iyaka tun da shi da duba duba a cikin al'ada

Tambayoyin mafarkin ya nuna cewa saƙon ƙasasshen magnesium zai iya samun kwalin $24.1 miliyan a shekar 2030 saboda bayanin BusinessWire daga shekar 2025. Wannan tacewa ya koma yayin da abokin cin gidan suke buƙata abubuwa don batiti na vehiculin elektrike da kuma cimburwa na ayyukan 5G na gaba. Tsawon abubuwan yake tsammanin abokin cin gidan, amma saƙonnin da suka kada daga cikin autonƙarƙashin suna iya canza abubuwa. Sistemin cold chamber yau da kullun suna taka leda da aluminum a kauye da za a iya amfani da su. Kuma wasu daga cikin abokin cin abubuwan na otomotin suna gudanar da abubuwan magnesium. Wannan ya nuna cewa metal din zai iya tacewa daga cikin saƙonnin da ke yin amfani da shi zuwa saƙon gudanarwa da yawa.

Masu Sabon Gaskiya

Menene mafi girman al'adun magnesium die casting don cin gidan na gaba? Mafanƙati na die ƙewa taɓata ƙarin inganta na ƙasa sosai dibu zuwa aluminum da kuma steel, amma taɓata inganta mai ƙarfi. Kewar rabin da kuma mafi girma na kewar girma zuwa girma ta sa shi ta zatar da ma'ana wanda aka buƙata inganta da kuma tattara, kamar yadda wajen samar da jiragen na kwayoyi da kuma wasan gaban gida.

Yaya mafanƙati taƙara zuwa aluminum da kuma zinc a cikin die ƙewa? Mafanƙati ya tafiya aluminum da kuma zinc a cikin sauyan abin da ya ke ƙarfawa, sauyan mai ƙarfi mai ƙarfi, da kuma uwar gudunƙewa mai ƙarfi saboda mafanƙatin da ke ƙarfi, ƙarfi mai ƙarfi, da kuma ƙarin ƙarfi.

Wanne ne mafanƙati mai ƙarfi a cikin die ƙewa, da kuma irin cewa su ne? Mafanƙati masu amfani sune AZ91D, AM60B, da AE44, kowanne taƙadda don inganta mai ƙarfi. AZ91D taɓata inganta mai ƙarfi da kuma tattara mai ƙarfi, AM60B taɓata inganta mai ƙarfi da kuma ƙarfi mai ƙarfi, da AE44 taɓata ƙarin tattara zuwa ƙarfi a cikin ƙarfi mai ƙarfi.

Yaushe na gabaɗaya akan nufin magnesium die casting? A cikin abokin gudunƙasa, abubuwan da ke ƙarewa da kewayon gudunƙasa, da kariyar ayyukan tara, suna maimaita tacewar da samun magnesium die casting a cikin masoyi mai girma, amma kuma a cikin al'adun kari da al'adun ilmin kimiyya.

Teburin Abubuwan Ciki

- Mene ne p mamakin mafurufan magnesium die shine mafi kyau don ƙarƙarin rufe

- Tsarin Magnesium Die Casting: Hanyoyin kuma Matsayin Da Ake Amfani Da Su

- Alloy Magnesium Masu Turay Da Su Karakteristikin Aiki

- Aikacewa na Iyan na Automotive da ElekturunikkI

- Alkawari da Zukkewa na Gaba da Magnesium Die Casting a Tsara