Cost Efficiency in High-Volume Aluminum Die Casting

When it comes to making lots of parts quickly, aluminum die casting really stands out for how cost effective it can be. The method works by injecting molten metal into reusable molds at high pressure, which means each part can be made in just under a minute most of the time. What's impressive is that these parts still come out with very tight tolerances around plus or minus 0.002 inches. Because they're so accurate right from the start, there's much less need for extra work after casting. Factories report saving about 40 percent on machining costs when switching from sand casting to this technique according to industry data from NADCA in their 2023 report.

Cost-Effectiveness of Die Casting Processes in High-Volume Production

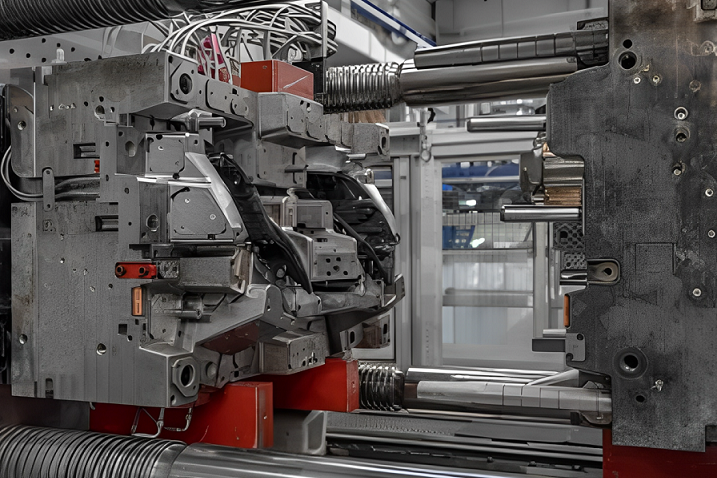

The automation-friendly nature of aluminum die casting enables 24/7 production with minimal supervision. Multi-cavity molds simultaneously produce 4–8 identical components, driving per-unit costs down significantly at scale. Material utilization exceeds 95%, with scrap aluminum immediately recycled into new casts, further enhancing economic efficiency.

Reduced Cycle Time and Lead Time in Aluminum Die Casting Operations

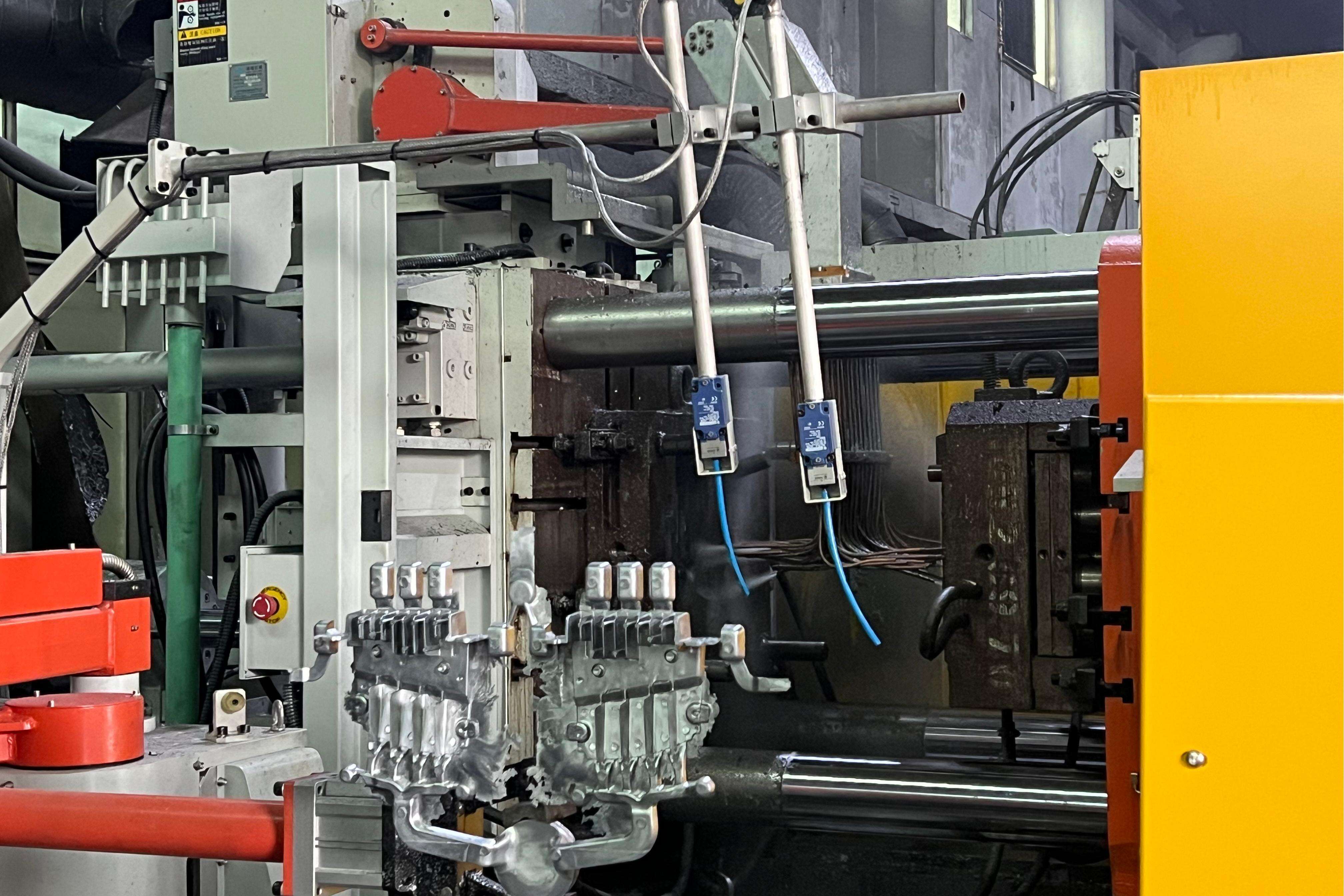

Modern cold-chamber machines achieve cycle times 30% faster than traditional methods through advanced cooling systems and real-time monitoring. One automotive supplier reduced lead times from 12 weeks to 3 weeks by switching to aluminum die casting for EV battery housings, demonstrating its impact on responsiveness and supply chain agility.

Economic Benefits Through Streamlined Manufacturing Workflows

Integrated robotic systems handle die lubrication, part ejection, and trimming in a single automated cell. This consolidation reduces labor needs by 55% while ensuring consistent output—essential for medical device manufacturers requiring FDA-compliant documentation and traceability.

Case Study: Cost Savings in Automotive Component Manufacturing

A Tier 1 supplier achieved a 28% annual cost reduction by switching from machined steel to die-cast aluminum steering knuckles. The change eliminated seven machining steps and improved the strength-to-weight ratio, saving $4.2 million annually across 1.2 million units produced.

Accelerated Production Cycles and Time-to-Market Advantages

Modern aluminum die casting achieves cycle times as low as 30 seconds per component through fully automated systems and high-velocity injection. This consistency allows manufacturers to produce over 50,000 identical parts monthly while maintaining ±0.25mm dimensional accuracy across automotive and aerospace applications.

Streamlining Production with Fast and Repeatable Aluminum Die Casting

Automated lubrication and temperature-controlled molds support uninterrupted 24/7 operations, cutting downtime by 60% compared to manual processes. Vacuum-assisted casting achieves 99.7% mold fill rates, minimizing porosity defects that traditionally require rework.

High Precision and Accuracy Reducing Post-Processing Requirements

CNC-machined dies with Ra 0.4–0.8μm surface finishes allow 83% of components to bypass secondary machining. Real-time pressure sensors adjust injection parameters mid-cycle, maintaining wall thickness within 0.15mm throughout production runs.

Consistent Quality Enabling Faster Product Launch Timelines

Manufacturers using automated die casting report 40% faster production ramp-ups compared to conventional methods, according to industry reports (2024). This precision slashes quality validation phases by 3–5 weeks, helping OEMs meet tight development schedules without compromising IATF 16949 compliance.

Lightweight Performance and Material Optimization

Lightweight and High-Strength Properties of Aluminum Die Castings

Compared to their steel counterparts, aluminum die castings weigh about 40 to 50 percent less but still maintain similar strength characteristics according to recent research from Springer in 2023. When it comes down to actual benefits, this difference in weight makes a real impact on vehicle performance. For cars with traditional engines, we're talking around 6 to maybe even 8 percent better fuel economy. Electric vehicles get an even bigger boost, gaining roughly 15 up to 20 percent extra driving range from the same battery pack. What makes all this possible? The die casting process itself allows manufacturers to create parts with walls as thin as just 0.6 millimeters thick while also incorporating intricate internal ribs that distribute stress more evenly across the component. All these features work together so engineers can design parts that perform exceptionally well without adding unnecessary bulk.

Superior Strength-to-Weight Ratio for Structural Efficiency

Aluminum has an impressive strength to weight ratio around 100 kN m per kg which makes it better than many engineering plastics and magnesium alloys on the market today. Engineers often find they can replace several steel components with just one aluminum die casting component. This allows bridge beams to span roughly 30 percent further distances while maintaining the same structural integrity requirements. When subjected to heat treatments such as T5 or T6 tempering methods, the material reaches yield strengths near 270 MPa. That's comparable to mild steel but at only about a third of the weight, making aluminum a smart choice for applications where both strength and lightweight properties matter.

Material Optimization in Aerospace and Automotive Applications

Automakers use die-cast aluminum to reduce closure panel mass by 30–40% while meeting FMVSS 214 side-impact standards. In aerospace, topology-optimized turbine blade housings achieve 25% weight savings with integrated cooling channels. Over 70% of production aluminum is recycled during manufacturing, and reprocessing requires 90% less energy than primary aluminum (Springer, 2020).

Key material optimization strategies:

- Phase diagram adjustments for silicon content (6–12%)

- Vacuum-assisted porosity reduction (<0.1% void content)

- Hybrid structures combining cast aluminum with CFRP inserts

Energy efficiency improvements in transportation systems using optimized aluminum die castings reduce lifecycle CO₂ emissions by 12 tons per vehicle. Material scientists employ computational modeling to simulate stress distribution in complex castings, achieving 18–22% weight reductions without compromising crash performance.

Design Flexibility for Complex, Large-Scale Components

Design Freedom for Intricate Geometries and Integrated Features

Aluminum die casting makes it possible to create shapes that just cant be done with regular machining or sheet metal work. The process works even for really thin walls, sometimes as small as 3mm with about plus or minus 0.25mm wiggle room. What's cool is how all those little details like cooling channels, structural ribs, and places where things mount get built right into the part itself during casting. When everything comes together this way, there's no need for extra assembly steps after the fact. And according to some industry numbers from last year, this approach cuts down on possible weak spots in the final product by somewhere between 40 to 60 percent when compared to stuff that gets welded together later.

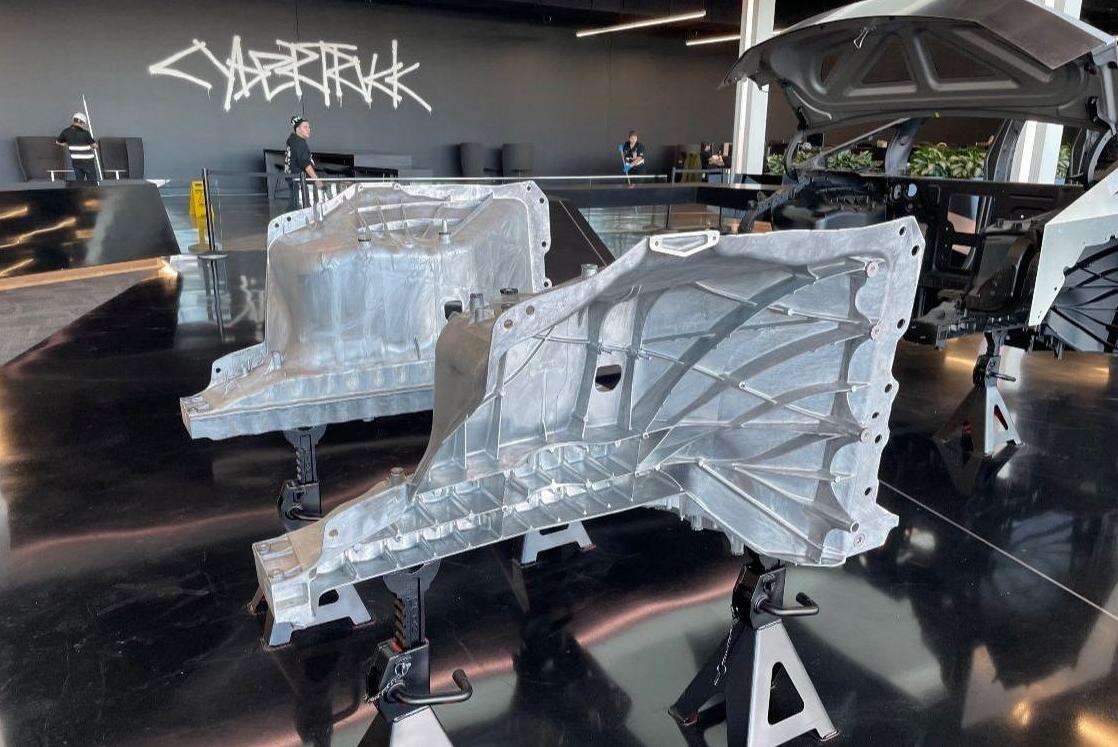

Enabling Body-in-White Integration and Part Consolidation

Automotive manufacturers now consolidate body-in-white structures from 50+ stamped parts into just 2–3 large aluminum castings. This approach reduces weight by 18–22%, increases torsional rigidity by 30–35%, and cuts assembly line requirements by 70%, improving both safety and cost efficiency.

Gigacasting: Revolutionizing Large-Scale Aluminum Die Casting in Automotive

Gigacasting presses exceeding 9,000 tons enable single-piece underbody platforms larger than 2m². This innovation reduces weld points by 85% and shortens production cycles by 30% versus multi-part assemblies. With projections indicating adoption in 65% of new EV platforms by 2026, gigacasting underscores aluminum die casting’s role in scalable, efficient vehicle manufacturing.

Environmental and Energy Efficiency Benefits

Energy-Efficient Manufacturing with Aluminum Die Casting

Aluminum die casting uses 30–40% less energy than sand casting due to rapid heat dissipation and lower melting temperatures (660°C vs. 1600°C for steel). Automated systems minimize idle time, further optimizing energy consumption during production cycles.

Minimal Material Waste and High Recyclability of Aluminum

Die casting facilities achieve material utilization above 95%, with scrap aluminum immediately reused. Aluminum remains 100% recyclable without degradation, and recycling requires 95% less energy than primary production (2023 study), supporting closed-loop manufacturing.

Supporting Sustainable Production Goals with Eco-Friendly Processes

Industries using aluminum die casting report 25% lower carbon footprints. Automotive weight reductions of 38–45% through aluminum substitution directly cut emissions. The process aligns with ISO 14001 standards through low VOC emissions and compatibility with renewable energy-powered foundries.

FAQ

What is aluminum die casting?

Aluminum die casting is a manufacturing process in which molten metal is injected into molds at high pressure to create precise parts.

Why is aluminum die casting cost-effective?

The process is cost-effective due to its ability to produce high volumes quickly with minimal machining, reducing labor and material costs.

What are the benefits of aluminum die casting in automotive applications?

In automotive applications, aluminum die casting offers lightweight properties, enhanced fuel efficiency, and reduced emissions.

What role does aluminum die casting play in environmental sustainability?

Aluminum die casting supports sustainability by reducing energy consumption, recycling materials, and lowering carbon footprints.