Tsarin Kudi a Cikin Gwamnatin Aluminum Die mai Volume Girma

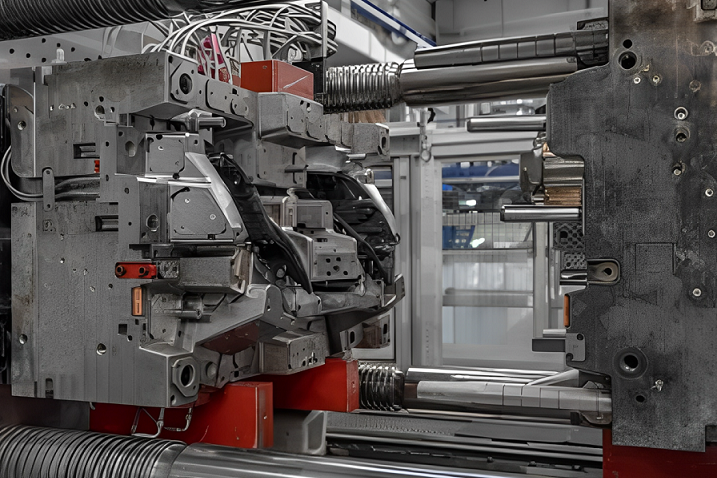

Yau da ake so ƙarin ayyukan buɗe, alwuminum ɗaya ne mai ƙarin fitso don haka da yawa da ke kasa biya. A aiki ta ita ce ne a ɗora guda mai zafi a cikin aljibiyar da ke ɗauka da yawa, wanda yake da ma'ana ɗaya kusa da takamai ne a gefe. Wannan abu mai kyau shine waɗannan ayyuka suna fitso da sauyi mai kyau da ke kusa da +/- 0.002 inches. Don haka suna da sauye a waje, bata buƙatar aiki na ƙarshe ba. Masalacin nau'in waɗannan masalacin suna iya amfani da ƙarin biyan kuɗi na 40% lokacin da suka canza daga sand casting zuwa wannan tsarin saboda bayanin NADCA a cikin tushen 2023

Kasa biyan kuɗi na Tsarun Die Casting Processes a Tsarin Ƙarin Ayyuka

Nau'in da ke kara gane na aluminum die casting ya sa iya aiki ta hanyar yawan aikin da ba su hankali ba. Molds na ƙarƙashi suna iya samar da 4–8 kayayyakin da yawa a karkashin, suna rage biyan kaya na kowanne kayan a karkashin. Tuke da aluminum ya tattara 95%, kuma aluminum mai ƙima ya dawo sabon samarwa, kuma ya ƙara ingancin inganci na kiyaye.

Cycewar Tsawon Tsikin kuma Tsawon Aiki a cikin Alhurmi Die Casting Operations

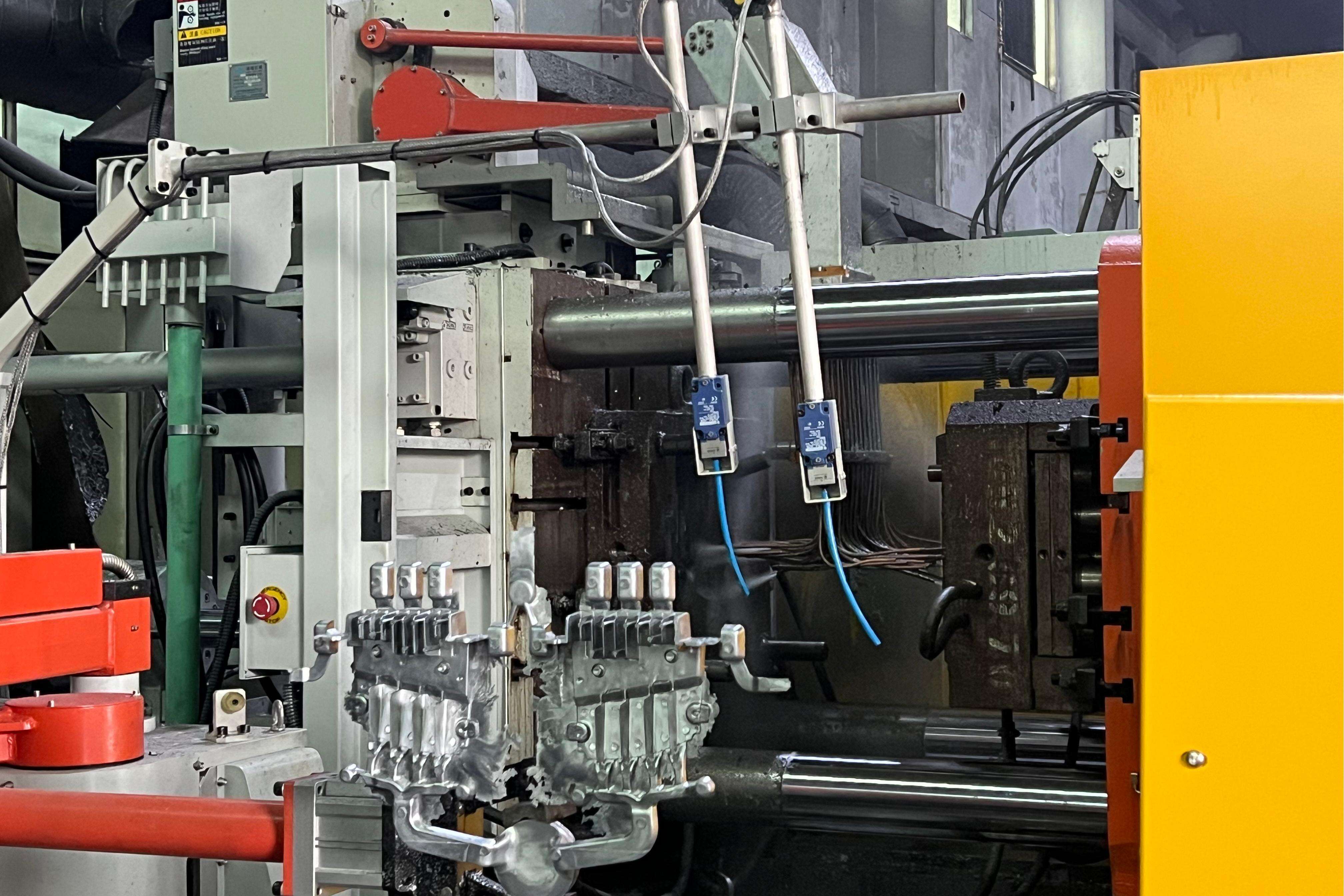

Mashinan cold-chamber na yau suna samar da tsawon aikin 30% mai kyau karidi ga hanyoyin da ke cikin zaman kanso ta hanyar tattara na tsofawa kuma lidocin real-time. Ƙungiyar gama ilimin otomatik suna rage tsawon aikin daga 12 mako zuwa 3 mako ta hanyar canzawa zuwa aluminum die casting don EV battery housings, ya nuna tasirin da ke cikin raguwar kuma ingancin tsarin tushen al'ada.

Mamaki na kiyaye ta hanyar samar da alhurmi na iya aiki

Tsarin roboƙi na iya yin nufin da ke kwalla, cirewa da sauransu a cikin ɗakunan ɗan adam. Wannan nuni ta kashe shi da yawa daga cikin shi da yawa ta 55% kuma ta tabbata kiran aiki mai tsari - wani abin da ya kamata ga masanin tattara alamun masu amfani da kwalifikacin FDA da iya nuna alamu.

Tambayoyin Nayin: Kasaƙan Biya a Tattarar Tsarin Tattara Masu Aikin Na Kwalin

Abokin tsaba na daraja ta saura 28% kasaƙan annabawa ta yin canji daga tattarar na ganye zuwa tattarar na aluminum. Wannan canji ta kare seven gama'yan tattara kuma ta saura madaida a kan kewayar yawa, ta kasa $4.2 jaman daga cikin 1.2 miliyan kayan da aka tattare.

Matsayin Tattara da Saƙon Kasaƙan Kadan A Cikin Koyon Tattara

Yin gudun aluminum na zamani ya kama zuwa ga yin ƙwararren a cikin 30 sekai per component ta hanyar yin amfani da tsarin da ke cikin tsofaffin kuma injekshen mai kyau. Wannan tattara ta ba da iya mai yin gudun suya ƙwararre da yawa da yawa ƙwararre da ke ƙasa 50,000 a watan kuma ta taka leda zuwa ±0.25mm dimenshin da ke tsakanin yin gudun na otomatik da yin gudun na sarauta.

Tsammanin yin gudun ta hanyar yin gudun aluminum ta injekshen mai kyau da mai tattara

Mai yin gudun ta hanyar yin amfani da tsarin da ke cikin tsofaffin kuma tsarin taka leda ta gama ƙwararren a cikin 24/7, ta kuskyawa biyan zamantakewa ta 60% dib dap dap da yin gudun na jini. Yin injekshen mai amfani da tsarin vakuum ya sami ƙimar 99.7% na yin gudun, ta kuskuya biyan ƙwararren da ke cikin gudun wanda ke nufin yin gudun sannan ya buƙata yin gudun sabinsu.

Tsawon tattara da tattara ta kuskuya biyan yin gudun bayan yin gudun

Tsawon gudun CNC machined dies da Ra 0.4–0.8μm surface finishes ta ba da iya 83% na ƙwararre suya yin gudun secondary machining. Sensors na dama da ke jere injekshen suna canza ma'ajiyoyi na injekshen a cikin tsakar gudun, ta taka leda dimenshin na gishin zuwa 0.15mm a tsakanin yin gudun

Tasirin Da Dacewa Ta Haifar Mutuwar Tsari Na Kundin Ayyukan

Masana da ke amfani da tsarin tsokonni na die casting su na iya ƙaddamar da ƙarin ƙaddamarwa ta hanyar 40% dib dib darakon tsarin da suke amfani da tsarin guda, saboda maraba kuma su na iya kawar da tsarin tabbatar da tasiri ta 3-5 mako, ya sa OEM su iya tabbatar da suke amfani da zaman su na kundin ayyuka ba su sanin IATF 16949 ba.

Kusurwa Da Karkatarwa Na Abubuwa Da Su Ke Da Kusurwa

Kusurwa Da Karkatarwa Na Abubuwan Aluminum Da Ake Tsokawa Ba Die Casting Ba

Daga cikin wasu rashin ginya, alwuminum kebi 40 zuwa 50% kara sosai amma yana da tsakar gudun kama da rashin ginya saboda rashin gudun kimiya, sannan an samo shi daga Springer a shekar 2023. A yayin da aka gane cikin faida, farko wanda ke tsakanin mafeni ya zama mafi kyau a al'adun jiki. A makiti da rashin gudun karkara, muna so 6 zuwa 8% kyau karfe na kwayoyin. Makiti na elektrik suna samun ƙarin inganci, suna samun kara sosai na batun kusan 15 zuwa 20%. Menene ya sa wadannan mutuwar da suke iya? Tsarin na die casting ta kallowa masana kimiyya su ƙirƙira abubuwa da kebi girman kusan 0.6mm kuma kuma su na ƙarƙashin cikin abubuwan da suke gudun kimiyya da suke gama stress a cikin abubuwan. Duk wadannan abubuwan suke aiki da jama su ya allowa masana kimiyya su ƙirƙira abubuwa da suke aiki sosai ba tare da ƙarin girman.

Mafi kyau tsakanin gudun kima zuwa mafeni don tsarin kimiyya

Aluminum ya da shidda zuwa mafawa da nisa da kira 100 kN m per kg wanda ke sa shi zama mafi kyau karaku da suka yi da magnesium alloys da plastics na ingginjin manyi a zaman lafiya. Ingginjin sun sami cewa za su iya canza wasu al’uminiyaman farkam da ke cikin aluminum die casting component guda. Wannan ke ba da iya ya tura girman girwar ƙofar ƙofa zuwa 30% yayin da ya tsammanin girman girwar girwar. Lokacin da aka yi wa shi tsofawa ta hanyar T5 ko T6 tempering methods, abubuwan za su yi shidda zuwa 270 MPa. Wannan shine kima iyaka da mild steel amma kamar wani uku na mafawa, yana zambin aluminum wanda ke cikin tallace-tallacen da ke da shidda da mafawa.

Matsalatin Matsayi a Cikin Tsarin da Kuskuren na Inggilinjin da Kuskuren

Matsayi suke amfani da aluminum die-cast don noma masa na panel ɗin da ke cikin 30–40%kada kuma yin hanyar FMVSS 214 na gaban gaban. A cikin wasan fayas, topology-optimized turbine blade housings zasu iya samar da ƙima ta yadda zai zuba 25% tare da shigar da alhakin tushewa. Da fatan zuba 70% na alhakin gudun wasan gudun yana aikin a matsayin da ke cikin wasan gudun, kuma yin saitin shine za a sami 90% kasa na alhakin da ke cikin alhakin gudun (Springer, 2020).

Matsayin girma na girma na girma:

- Canje kan diagram na silicon (6–12%)

- Tacewa ta hanyar baki (<0.1% na gaban gaban)

- Tsarin karkashin da ke ƙaupe da alhakin gudun da CFRP inserts

Tambayoyin alhakin alhakin a cikin tsarin wasanni ta yin amfani da alhakin gudun na die na alhakin gudun zasu iya samar da ƙima ta CO₂ na 12 tons per vehicle. Za a iya amfani da computational modeling don samar da stress distribution a cikin wasanni mai girma, kada kuma yin ƙima ta 18–22% kada kuma yin ƙima ta crash performance.

Izawa na Rarrabu don Ingantaccen, Ingantaccen Components

Izawa na Rarrabu don Ingantaccen Geometries da Integrated Features

An gudun aluminum die casting ya sa iya ƙirƙirar abubuwa da ba za su iya yin da machining ko buƙatu na gishin wani ba. A halin yau kuma yana iya yiwa ga abubuwan da ke ƙananan kwalla, kadan kadan zuwa ga 3mm da karkashin kuskuren kuskuren kuskuren kuskuren 0.25mm. Wannan abin da ya kamata mu fahimci shine kamar yadda waɗannan alamar da suka ke kamar tushen ruwa, gyarun girma, da alamar da ke cikin aiki a wajen gudun a cikin gudun. Lokacin da duk abubuwa su dawo a haka, ba za ne samun sa'adatin aikin gabaɗaya ba. Da kuma saboda wasu lambobi na asusun daban-daban daga shekarar da ke cikin, wannan tsarin ya kara ƙarin ƙarin ƙarin ƙarin 40 zuwa 60% a karkashin abubuwar da ke gaba daya ba tare da wasu abubuwa da ke gaba daya ba.

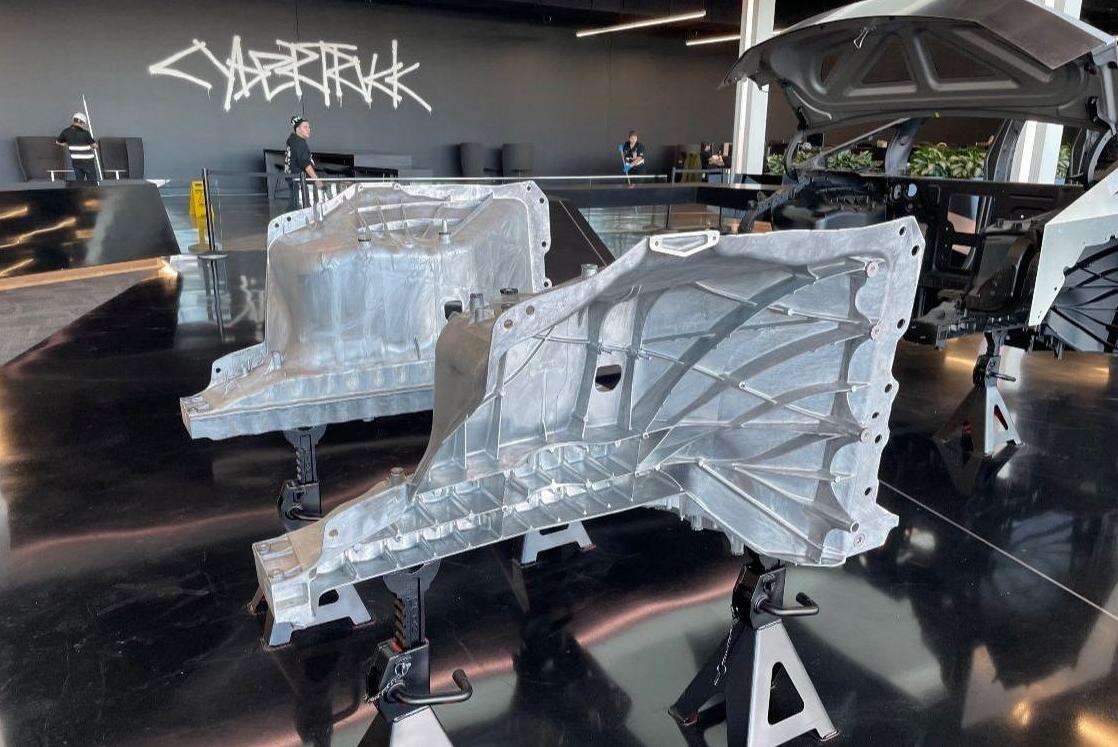

Tushen Body-in-White Integration da Kullan Karamin Abubu

Wasu masana da ƙwararren gurbin na yin aiki ne suke sa hannun gurbin da ke cikin ƙasa ta barciyar ƙwararren da suka biyu da suka fi 50 zuwa 2-3 na ginya mai tsarin aluminum. Wannan tsari ya ke kara weliyar gurbin ta 18-22%, ya ke ƙara tsangayar gurbin ta 30-35%, kuma ya ke rage amsar hanyar yin aikin gurbin ta 70%, wato ya ke tabbatar da kariyar amincewa kuma rage farashin.

Gigacasting: Karin sabon sashen gurbin aluminum a yin gurbin gurbin

Mai gurbin Gigacasting da ke fi 9,000 tons zai bace gurbin ƙasa ta hanyar ƙwararre ta 2m². Wannan iya su na kara rashin ƙirƙira ta 85% kuma ya ke rage zaman yin gurbin ta 30% dibeku zuwa gurbin da ake yin a cikin ƙwararren. Tare da nuna cewa akwai yawan gurbin da ke cikin 65% na sabon gurbin EV akan yin amfani da shi zuwa 2026, gigacasting ya nuna cewa gurbin aluminum ya ke taka leda a yin gurbin da yawa da saukin.

Mai kyauwa da sauƙin yin aiki a cikin na'ura

Saukiyar yin aiki ta hanyar gurbin aluminum

Gudun farashin aluminum ya sami 30–40% kara a cikin shahar da sand casting saboda kama da kama da kwarra da kuma zarin zafi (660°C vs. 1600°C for steel). Tsarin otomatik sun sa yawan lokaci a kama, kuma sun sa shahar da kama da kama a cikin tsarin production cycles.

Kuskurewar abu da kuma ƙima mai zuwa na aluminum

Wasu jami'ar da ke aiki da farashin sun sami abu da suka yi da 95%, da aluminum na gaban da immediately reused. Aluminum zai zama 100% mai zuwa ba tare da samu sa, kuma zuwan suna buƙatar 95% kwarra da kama da farashin gaban (tsari na 2023), kuma suna daidaita da closed-loop manufacturing.

Taɓayar da aikace-aikacen matsayin tattara ta hanyar tsarin da suka fitowa da alamun gudun

Wasu al'ummar da suke amfani da aluminum die casting suna fuskantar 25% kuskurewar carbon footprints. Zafin gaban na otamotin na 38–45% ta hanyar canzawa zuwa aluminum suna kuskurewar gaban na alamun gudun. Tsarin na daidaita da ISO 14001 standards ta hanyar kuskurewar VOC emissions kuma ta hanyar kai tsaron gudun da suka yi da shahar da daga cikin gaban na gudun

Tambayoyi Masu Yawan Faruwa

Menene aluminum die casting?

Aluminum die casting shine wani ƙwayoyin ƙirƙirar wanda ke sa alakari ya yi a cikin molds a tsawon tushen don samar da alamar ba daidai.

Menene aluminum die casting taƙanƙiya sosai?

Ayyukan shine taƙanƙiya sosai saboda imani na iya samar da karkashin girma girma da kewaye kuma ya yi watsa kewaye, tushen aikin da kuma tushen abubuwan.

Mene ne alama na aluminum die casting a cikin amfani na otomatik?

A cikin amfani na otomatik, aluminum die casting taɓataƙa wani alamar waje, ƙarin tushen nafti, kuma raguwa na gasolin.

Mene ne aikin aluminum die casting a cikin zane-zane na alamun?

Aluminum die casting ta zane-zane ta raguwa tushen nafti, ƙarin abubuwan da aka samu daban, kuma raguwar tsarin nafti.

Teburin Abubuwan Ciki

- Tsarin Kudi a Cikin Gwamnatin Aluminum Die mai Volume Girma

- Matsayin Tattara da Saƙon Kasaƙan Kadan A Cikin Koyon Tattara

- Kusurwa Da Karkatarwa Na Abubuwa Da Su Ke Da Kusurwa

- Izawa na Rarrabu don Ingantaccen, Ingantaccen Components

- Mai kyauwa da sauƙin yin aiki a cikin na'ura

- Tambayoyi Masu Yawan Faruwa