The Rise of Electric Vehicles and the Transformation of Die Casting

How Electric Automobile Growth Is Reshaping Manufacturing Demands

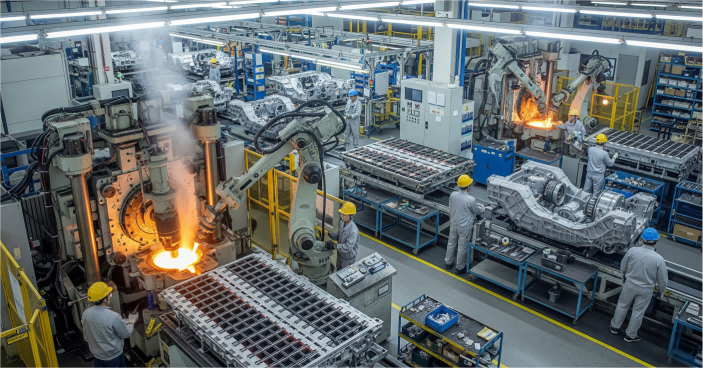

The rapid rise in electric vehicle sales across the globe has put pressure on die casting facilities to completely overhaul how they approach production. Traditional car engines used around 30 to 40 separate pieces just for the block itself, but now electric vehicles need far fewer parts that happen to be much bigger in size. Manufacturers are scrambling to get their hands on those massive high-pressure die casting machines capable of over 6,000 tons of force. These industrial beasts can churn out these enormous battery trays and motor housings all at once instead of piece by piece. For many plants, upgrading equipment isn't optional anymore if they want to stay competitive in this new market landscape.

Electric Vehicle (EV) Components as a High-Growth Segment in Die Casting

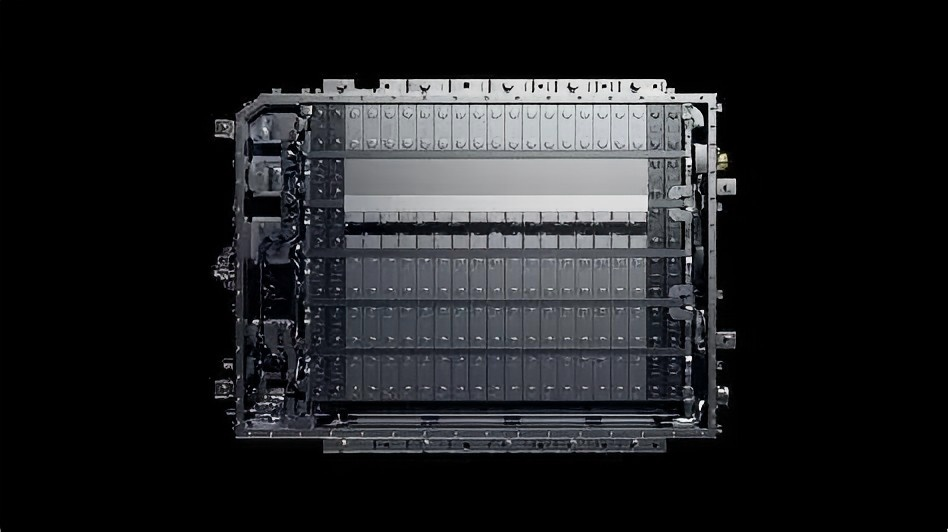

EV component manufacturing is now leading the charge in die casting growth, with estimates suggesting the worldwide market could hit around $24.1 billion by 2030 based on findings from the Automotive Parts Die Casting Report. Take a look at what's happening with battery enclosures made from aluminum die casting - these make up about 23 percent of all new electric vehicle parts being designed right now. Why? Because they manage heat really well while still holding together under stress, something manufacturers just can't ignore when building safer, longer lasting vehicles for consumers who want both performance and reliability.

The Shift From Internal Combustion Engines to Die-Cast Electric Powertrains

Modern EVs use 60% fewer drivetrain components than combustion vehicles, with die casting enabling integrated designs that reduce assembly time by 45%. Where engines required sand-cast iron blocks, EV-specific die casting applications now dominate critical systems like:

- Lightweight motor stators with built-in cooling channels

- Crash-optimized battery containers replacing 70+ steel stampings

- Unified chassis components improving torsional rigidity by 30%

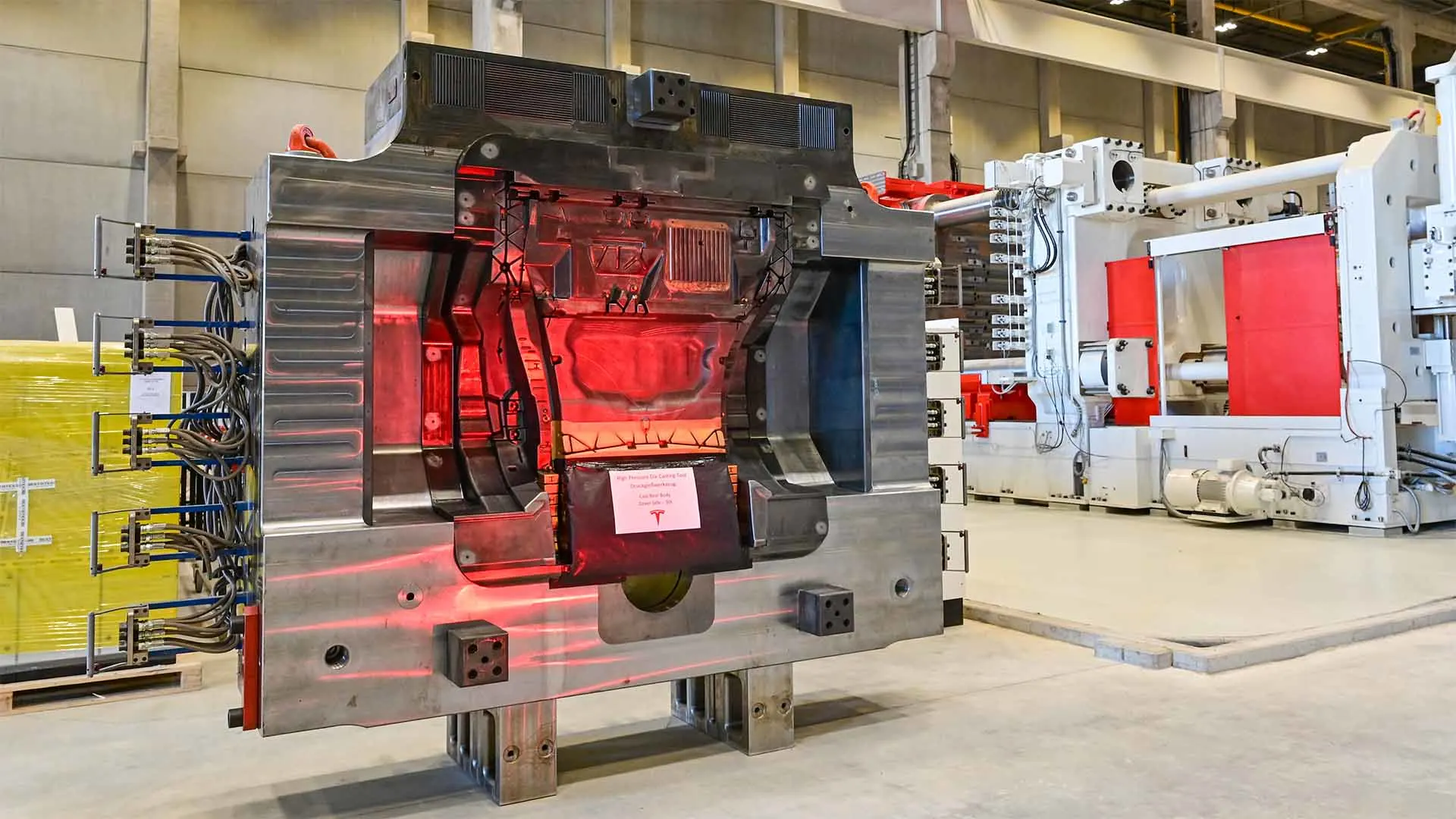

Gigacasting: Redefining EV Structural Design and Production Efficiency

Integration of EV Parts Through Large-Scale Die Casting

The gigacasting technique is changing how electric cars get made, basically merging hundreds of separate stamped and welded parts into one big piece of aluminum. Major car companies are already making these massive rear underbody castings that stretch over 2.5 meters long. When compared to old school internal combustion engine vehicles, this approach cuts down on parts by around 85%. According to some recent research from PwC back in 2023, these consolidated structures actually make the body stiffer by about 23%, and they free up space on assembly lines by roughly 40%. Groups working together in the industry, such as MeGiCast, have shown even more benefits. Their tests indicate that combining traditional casting methods with special reinforcement materials can save around 18% in weight for front modules. This kind of innovation is really shaking things up in automotive manufacturing right now.

Case Study: Adoption in High-Volume EV Production

One major electric vehicle company has streamlined its manufacturing process by introducing those massive 9,000-ton die casting machines to build single-piece chassis platforms. What used to take hundreds of parts now comes down to just two main castings for the battery enclosures. Assembly time dropped dramatically too—from around an hour and a half down to barely a minute and a half per car. The new method maintains incredible precision, keeping dimensions within fractions of a millimeter even on those long 8 meter chassis rails. This helps manage the tricky thermal expansion issues that come with lithium ion batteries. Scrap levels have also gone way down, hitting about 0.9% thanks to recycling systems that work directly with the giant casting operations. Pretty impressive stuff for anyone looking at how EVs are actually built these days.

High-Pressure Die Casting Enabling Complex Components

Today's high pressure die casting (HPDC) systems can shoot molten aluminum into vacuum sealed molds at speeds around 120 meters per second, which makes it possible to create battery housing walls thinner than 2.5 millimeters. The level of precision achieved allows manufacturers to produce entire motor compartments in one casting operation. These components include all sorts of features like built-in cooling channels, mounting points for various hardware, and structural elements designed to handle crashes. Back in the day, these same features would have needed no fewer than 14 different parts put together separately. When it comes to materials, advanced alloys such as AlSi10MnMg are making waves too. They offer impressive tensile strength of about 250 MPa while weighing only half as much as their steel equivalents. This weight reduction has a direct impact on electric vehicles, helping them travel farther between charges. Manufacturers are also implementing real time defect detection through X ray tomography technology. This keeps component failure rates down to just 0.03%, something that's becoming increasingly important as companies ramp up production of these giant cast structural parts.

Lightweighting and Material Innovation in Die-Cast Electric Automobile Components

Lightweight Components in Electric Vehicles and Their Impact on Range

Cutting down on vehicle weight is still one of the main goals when designing electric cars these days. The numbers back this up too - studies show that losing just 10% off the total weight means about 6 to maybe even 8 percent extra range before needing a recharge (Ponemon found this in their research from 2023). Manufacturers are swapping out old fashioned steel bits for die cast aluminum versions for things like battery cases and other structural elements. This switch knocks around 40% off the overall weight without sacrificing safety in crashes. Lighter vehicles mean manufacturers can get away with smaller batteries to cover the same distance. And here's where it gets interesting: smaller batteries save money upfront but also improve how efficiently the whole car works together, making EVs better value propositions over time despite all the tech involved.

Material Efficiency Gains Using Aluminum and Magnesium Die Casting Alloys

The shift toward aluminum and magnesium alloys addresses two key challenges in EV manufacturing:

- Aluminum die casting delivers 90% material utilization rates compared to 70% for steel fabrication

- Magnesium alloys reduce component weight by an additional 35% versus aluminum while maintaining structural integrity

These materials also support circular manufacturing practices, with over 85% of aluminum in modern EVs coming from recycled sources (International Aluminum Institute 2023). The high thermal conductivity of these alloys—up to 160 W/mK for aluminum—simultaneously improves heat dissipation in battery systems and power electronics.

Advanced Alloys Enhancing Strength-to-Weight Ratios in Battery Housings and Motor Casings for EVs

New aluminum-silicon alloys on the market today can reach tensile strengths above 310 MPa, which is pretty much what we see in steel parts but at about 40% of the weight. What this means for electric vehicles is that manufacturers can create one piece battery casings that hold up against crash forces measuring around 10 GPa. That's actually three times better than what was possible in those first generation EVs back in the day. When it comes to motor housing applications, there are these special hypereutectic aluminum versions containing between 18 to 22% silicon content. These materials resist wear just as well as good old fashioned cast iron does, making it feasible to build cooling channels right into the die cast rotor supports during production rather than having to add them later.

Precision, Sustainability, and Smart Manufacturing in EV Die Casting

Die-Cast EV Motor Housings and Battery Enclosures Requiring High Precision

Electric cars today need parts made with incredible precision, especially when it comes to things like motor casings and battery boxes. The die casting process can hit those tight specs around 0.1mm that are basically necessary for putting together all those high voltage bits without any gaps or misalignments. What makes this possible? Well, there's this fancy vacuum stuff they do during casting that cuts down on air pockets in the aluminum, which would otherwise weaken the final product. Big name car makers have started implementing these real time monitoring systems throughout their factories. These networks of sensors help keep every single part consistent even when producing tens of thousands of units at once, though some smaller operations still struggle to match that level of control consistently.

Thermal Management Challenges in Die-Cast Battery Housings

The housing for electric vehicle batteries needs really complex cooling channels because they generate so much heat when charging quickly, sometimes over 150 watts per kilogram. Some recent research into materials has found that certain aluminum-silicon alloy modifications can boost how well heat moves through them by around 18 percent compared to what we typically use in die casting. This kind of improvement makes a big difference in keeping battery temps under control, staying below 45 degrees Celsius even when things get tough on the system. Plus there's another benefit too these new materials cut down the weight of parts by about 22% when compared to steel options which is pretty impressive for manufacturers looking to lighten their vehicles without sacrificing performance.

Sustainability and Recyclability in Die Casting Supporting Electric Automobile Eco-Goals

The automotive die casting industry has achieved 92% material utilization rates through optimized runner systems and digital twin simulations. Aluminum alloys dominate EV component production due to their infinite recyclability—recycled aluminum die casting scrap reduces manufacturing energy consumption by 95% compared to primary aluminum production.

Closed-Loop Recycling of Aluminum Die Casting Alloys in EV Production

Major foundries now operate on-site recycling centers that reprocess 98% of production scrap within 72 hours. This closed-loop approach slashes material costs by 40% while meeting strict OEM sustainability targets. A 2023 study revealed that implementing alloy separation technologies enables repeated reuse of aluminum without compromising mechanical properties in critical EV structural components.

Automation and Industry 4.0: Driving the Future of Die-Casting for Electric Vehicles

The integration of Industry 4.0 technologies is revolutionizing die-casting processes for electric automobiles, enabling manufacturers to meet stringent quality and volume requirements. Advanced automation systems now achieve defect rates below 0.8% in high-pressure casting operations.

Smart Foundries Using Real-Time Monitoring for Defect Reduction

Modern die-casting facilities employ IoT-enabled monitoring systems that track 15+ process variables simultaneously, from molten metal temperature to injection velocity. This data-driven approach has reduced scrap rates by 42% in EV component production since 2022, particularly in critical parts like motor housings and battery trays.

Predictive Maintenance and AI-Driven Quality Control in Gigacasting

AI algorithms now analyze historical production data to predict equipment failures 72 hours in advance with 89% accuracy. Machine learning-powered vision systems detect micro-porosity defects in gigacast components 40% faster than human inspectors, crucial for maintaining structural integrity in single-piece EV chassis.

Integration of Automation to Meet High-Volume EV Manufacturing Demands

Robotic cell integration has increased production rates by 35% in leading die-casting plants, with automated cells achieving cycle times under 90 seconds for complex battery enclosures. This automation surge supports the industry's need to produce 2.5 million EV-specific cast components monthly by 2026.

FAQ

What is gigacasting in electric vehicle manufacturing?

Gigacasting is a process where large sections of an electric vehicle's structure are cast in a single piece using high-pressure die casting machines. This approach integrates multiple parts into one, reducing the number of parts and increasing production efficiency and structural strength.

How does die casting contribute to electric vehicle sustainability?

Die casting contributes to sustainability by utilizing recyclable materials like aluminum, achieving high material utilization rates, and implementing closed-loop recycling processes that significantly reduce manufacturing energy consumption and costs.

Why is lightweighting important for electric vehicles?

Lightweighting is crucial for improving electric vehicle range. Reducing the weight of a vehicle means smaller batteries can be used for the same distance, resulting in cost savings and improved energy efficiency.

What advancements have been made in materials for EV die casting?

Advancements include the use of aluminum-silicon alloys with high tensile strength and low weight, magnesium alloys for further weight reduction, and materials with improved heat dissipation properties for better thermal management in battery systems.

Table of Contents

- The Rise of Electric Vehicles and the Transformation of Die Casting

- Gigacasting: Redefining EV Structural Design and Production Efficiency

- Lightweighting and Material Innovation in Die-Cast Electric Automobile Components

- Precision, Sustainability, and Smart Manufacturing in EV Die Casting

- Automation and Industry 4.0: Driving the Future of Die-Casting for Electric Vehicles

- FAQ