Understanding the Aluminum Die Casting Process

The Fundamentals of the Aluminum Die Casting Process

The aluminum die casting process works by injecting molten metal at extremely high pressures into durable steel molds to create precise parts. When pressures go above 15,000 psi, the mold gets filled completely, which means walls can be made really thin, sometimes down to just 0.6 mm thick. The metal solidifies pretty fast too, usually within 3 to 10 seconds, and then the part is automatically ejected from the mold. Most cycles take less than 90 seconds overall, even when making complicated shapes. Surface finishes on these castings generally come out below 125 microinches or around 3.2 micrometers, which is quite smooth for industrial applications.

Key Stages in Precision and Efficiency in Aluminum Casting

Four optimized stages govern output quality:

- Alloy melting at 660°C ±5°C to maintain fluidity

- Injection velocity profiling (0.5–6 m/s) to minimize turbulence-induced porosity

- Controlled cooling rates (20–30°C/sec) to reduce residual stresses

- Robotic part removal cutting cycle interruptions by 40%

Foundries using infrared temperature sensors and AI-driven adjustments report 18% fewer dimensional outliers compared to manual operations.

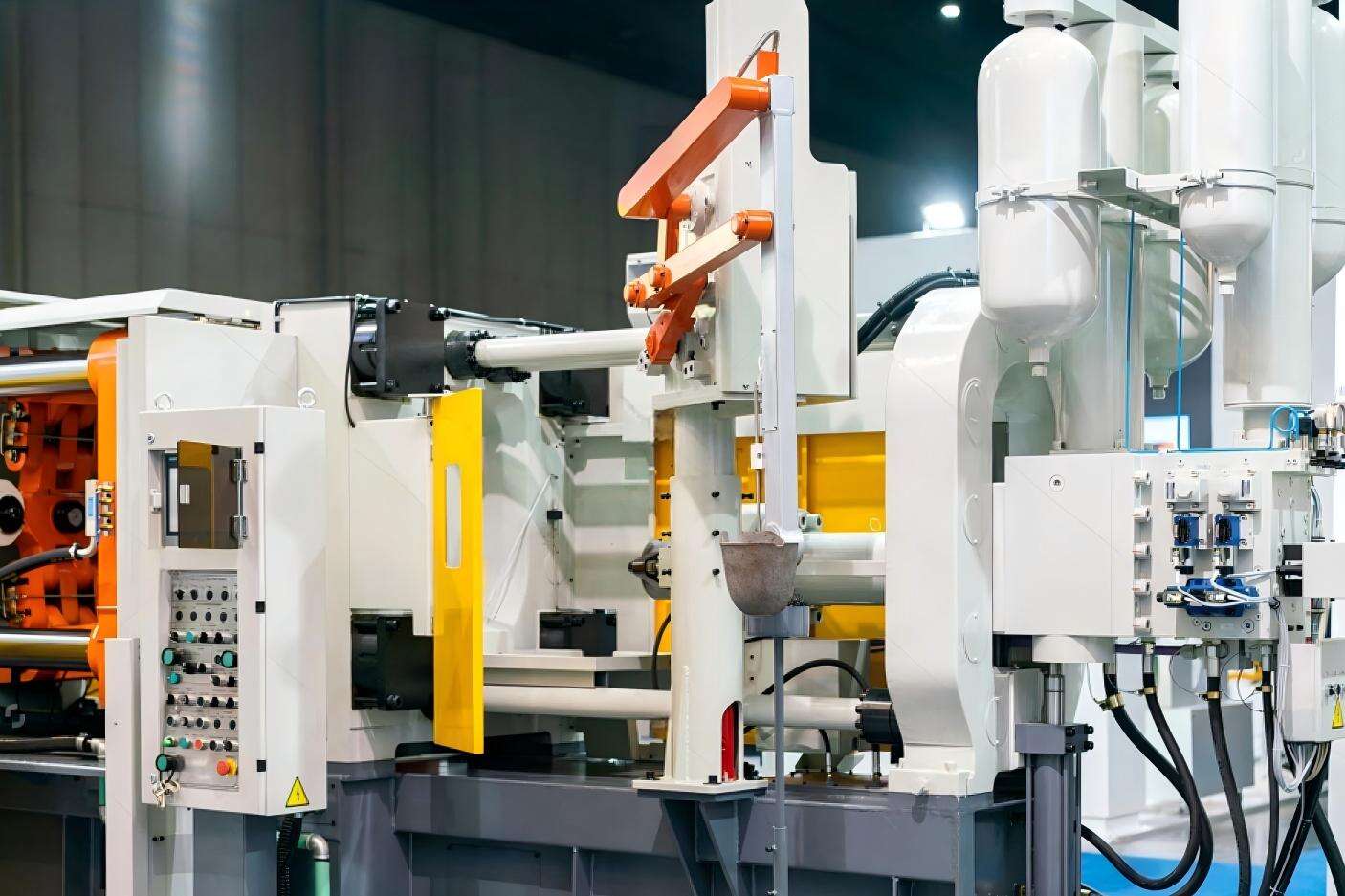

Role of Die Casting Techniques and Equipment in Output Quality

Cold chamber machines isolate molten aluminum from hydraulic systems, extending equipment lifespan by 300%. Hardened steel molds with chromium nitride coatings sustain ±0.001 inch tolerances over 100,000+ cycles, while vacuum-assisted casting reduces gas porosity by 52% in aerospace applications. These advancements support scrap rates below 1.8% in high-volume automotive production.

Optimizing Process Parameters for Higher Efficiency

Controlling Temperature and Its Impact on Aluminum Die Casting

Keeping molten metal temps right around 660 to 710 degrees Celsius is pretty much essential for good flow properties and avoiding early solidification issues that mess with part dimensions and surface quality. Industry data shows something interesting too - if operators let the temperature creep up even 5%, porosity problems jump by nearly 20%. That's why most shops now rely on automated closed loop controls that tweak settings automatically within plus or minus 3 degrees. These systems constantly watch what's happening during production and make micro adjustments as needed, which helps maintain product consistency across batches while following standard industry guidelines for efficient manufacturing processes.

Pressure and Injection Speed: Balancing Performance and Defect Reduction

High-pressure injection (800–1,200 bar) enables rapid mold filling but risks gas entrapment due to turbulence. Leading foundries mitigate this by combining:

- Staged velocity profiles: 75% speed during initial fill, rising to 90% at midpoint

-

Intensification pressures: Minimum 950 bar to compensate for shrinkage during solidification

This strategy reduces porosity by 40% compared to fixed-pressure systems while maintaining cycle times under 12 seconds for automotive parts.

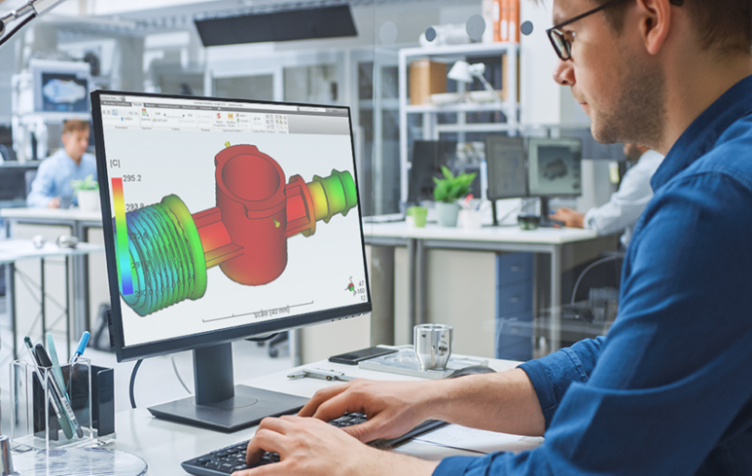

Data-Driven Adjustments in Optimizing the Die-Casting Process

Advanced methods like Design of Experiments (DOE) and machine learning guide parameter optimization. A 2023 case study at an automotive parts manufacturer showed that response surface methodology reduced scrap rates by 22% through predictive modeling of key variables:

| Parameter | Optimization Impact |

|---|---|

| Ejection timing | 8% cycle time reduction |

| Die lubrication | 15% fewer surface defects |

| Cooling rate | 12% improvement in hardness |

AI-powered systems now automatically adjust 14+ variables per cycle, enabling continuous refinement and tighter process control.

Leveraging Automation and Industry 4.0 Technologies

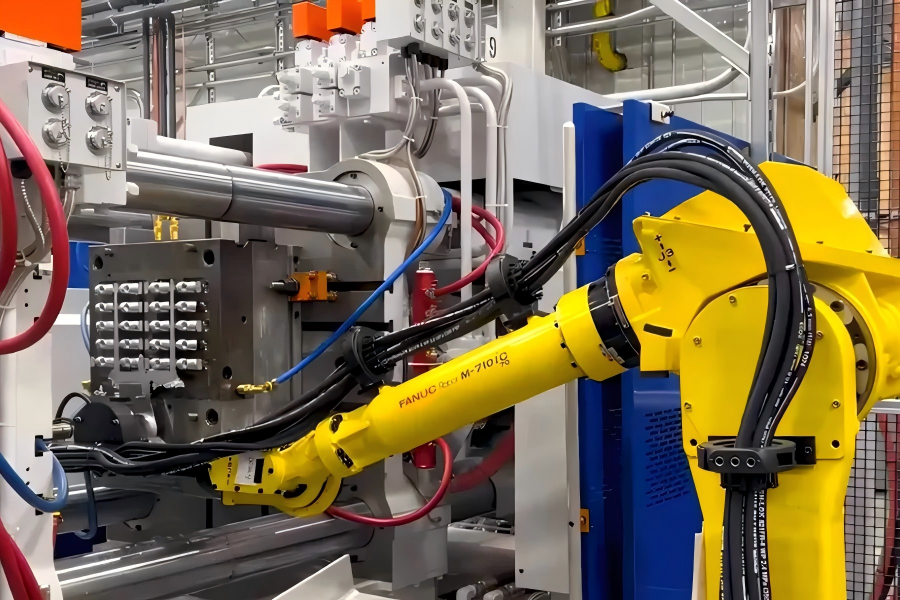

Transforming Operations Through Automation in Die-Casting

Robotic automation boosts productivity by 23% by handling repetitive tasks such as molten metal injection, part extraction, and trimming. According to a 2024 industrial automation study, automated cells reduce human error by 41% and achieve 99.96% dimensional consistency in high-volume runs (Yahoo Finance, 2024).

Integration of Industry 4.0 in Aluminum Die Casting Systems

Smart factories deploy IIoT-enabled machines that transmit over 150 real-time process parameters, including die temperature and metal flow rates. This data powers predictive algorithms that:

- Anticipate lubrication system failures up to 8 hours in advance

- Auto-calibrate injection pressures based on melt viscosity fluctuations

- Optimize die cooling patterns between cycles

Smart Sensors and Real-Time Monitoring for Process Stability

Embedded thermal sensors detect ±2°C variations in melt temperature, triggering immediate corrections to prevent cold shuts or porosity. Production teams using these systems resolve quality issues 67% faster than with manual monitoring (Smart Factory MOM, 2024).

Case Study: Fully Automated Die-Casting Cell Reducing Cycle Time by 30%

A North American auto parts manufacturer implemented a closed-loop automation system featuring:

| Component | Improvement Metric |

|---|---|

| Robotic shot control | 22% faster fill times |

| AI-powered X-ray QC | 93% defect detection rate |

| Energy recovery units | 18% power consumption drop |

The cell achieved a 2.1-second reduction in cycle time while meeting ISO 9001:2015 standards, demonstrating how integrated Industry 4.0 solutions enhance efficiency and quality.

Design for Manufacturing (DFM) to Enhance Casting Efficiency

Importance of Draft, Wall Thickness, and Fillets and Radii

The way parts are designed makes a real difference when it comes to how well they cast. Things like draft angles, walls that stay about the same thickness throughout, and those rounded corners we call fillets all play their part. For draft angles, going with something between 1 and 3 degrees really helps parts come out of the mold without getting stuck, saving time and frustration. When making aluminum parts, keeping walls consistent at around 2 to 5 millimeters thick is important because inconsistent thickness leads to problems with cooling. This actually causes about 30% of all warping issues in thin walled components according to industry research from Ponemon back in 2023. And don't forget those fillets either. A radius of at least 1.5 mm on corners lets molten metal flow better through the mold and cuts down on air pockets forming inside the part.

| Design Element | Ideal Range | Defect Reduction Potential |

|---|---|---|

| Draft Angle | 1-3° | 40% fewer ejection failures |

| Wall Thickness | 2-5mm | 35% lower warping risk |

| Fillet Radius | ≥1.5mm | 50% less porosity |

Design for Manufacturing (DFM) Principles to Reduce Rework

Early implementation of DFM eliminates up to 60% of post-casting modifications. Key strategies include:

- Avoiding undercuts that require complex sliding cores

- Standardizing hole sizes to minimize tooling changes

- Designing symmetrical features to balance thermal stress

Facilities using simulation-driven DFM checks have reduced rework costs by $740k annually through virtual defect prediction.

How Part Geometry Affects Precision and Efficiency in Aluminum Casting

Complex geometries extend cycle times by 25–40% due to longer cooling requirements. Features such as ribs thicker than adjacent walls, abrupt section transitions, or isolated protrusions often necessitate secondary machining. Recent die-casting efficiency analyses show that simplifying geometry improves dimensional accuracy by 0.02mm and cuts energy use per unit by 18%.

Lean Practices and Continuous Improvement in Die Casting

Implementing lean methodologies in aluminum die casting reduces waste by 12–18% while maintaining tolerances within ±0.2mm, according to a 2023 study of North American foundries. Facilities adopting these practices report 20% faster cycle times through streamlined workflows and reduced non-value-added activities.

Applying Lean Manufacturing Principles to Streamline Die Casting Operations

Value stream mapping identifies bottlenecks responsible for 37% of production delays in typical die-casting cells. Standardizing die lubrication processes increases equipment uptime by 14% across shifts, while 5S workplace organization reduces tool search time by 26 minutes per changeover.

Continuous Improvement Practices in Aluminum Die Casting Facilities

A midwestern plant achieved a 19% annual reduction in scrap through daily Kaizen meetings focused on porosity analysis. Real-time monitoring now flags solidification-phase temperature deviations exceeding ±15°C, preventing 83% of cold shut defects before they occur.

Measuring Efficiency Gains: OEE Improvements in a Mid-Sized Foundry

One facility increased Overall Equipment Effectiveness (OEE) by 15% over two years via automated downtime tracking. Their predictive maintenance program cut unplanned press stoppages from 14 to 3 per month, saving $220k annually in lost production.

FAQ

What is aluminum die casting?

Aluminum die casting is a manufacturing process where molten aluminum is injected into steel molds at high pressures to create precise and complex parts.

Why is temperature control important in aluminum die casting?

Maintaining accurate temperature control is crucial to prevent early solidification, which can affect part dimensions and surface quality.

How does automation benefit the aluminum die casting process?

Automation enhances productivity by handling repetitive tasks, reducing human error, and maintaining high dimensional consistency in production.

What role do design elements like draft angles play in die casting?

Design elements such as draft angles, consistent wall thickness, and fillets help ensure smooth part ejection and reduce defects like porosity and warping.

What are lean manufacturing principles in die casting?

Lean manufacturing in die casting involves streamlining processes, reducing waste, and minimizing non-value-added activities to enhance efficiency.