Gbalịaghachi Njikọta nke Aluminum Die Casting Process

Ndị isi nke Aluminum Die Casting Process

Ọrụ nchịkọta aluminom na-eji iji logbụsị mmiri ojii na ngwaahịa dị elu gaa na mkpụrụ osimiri dị mma iji mee ihe dị mkpa. Mgbe ọnụ ọgụgụ dị elu karịa psi 15,000, mkpụrụ osimiri ahụ na-agbanwe ya nile, nke pụtara na agba nwere ike iburu ụgbọ mmiri, mgbe niile ruo 0.6 mm. Ihe ojii na-aga n'ihu n'ụzọ zuru oke, ebe a na-eme n'ime sekọndụ 3 ruo 10, mgbe ahụ ihe ahụ na-agbanwe na mkpụrụ osimiri. Oke sekọndụ niile dabara n'ime sekọndụ 90, ma ọ bụrụ na eme ihe dị mkpa. Nsonaazụ akwadoro n'ime ihe ndị a na-abawanye n'ime microinches 125 ma ọ bụ micrometers 3.2, nke dị mfe maka njikọ ndustri.

Ndịdịda na Mmetụta na Aluminum Casting

Ihe anọ dị mma na-akontrolụ oke ọgụgụ:

- Ịmepụta alloy na 660°C ±5°C i ji mma ọrụ

- Ịkpọchi oke-injection (0.5–6 m/s) iji wepụ porosity nke mere ya turbulence

- Oke ọcha na-adịghị ( 20–30°C/sec ) iji wepụ ntụpọ residual

- Nkọwa ịgbachigara ihe nke na-enyere aka imeji oghom mkpụrụ ndị na-eme n'akụkụ 40%

Ndị na-enweta ihe nke na-enyere aka imeji oghom mkpụrụ ndị na-eme n'akụkụ iji sensors nhachi oyi na njikọta AI zaghachi ihe kacha dị elu n'ime 18% nke na-adịghị mmetụta dibeghịrị maka njikọta mmadụ.

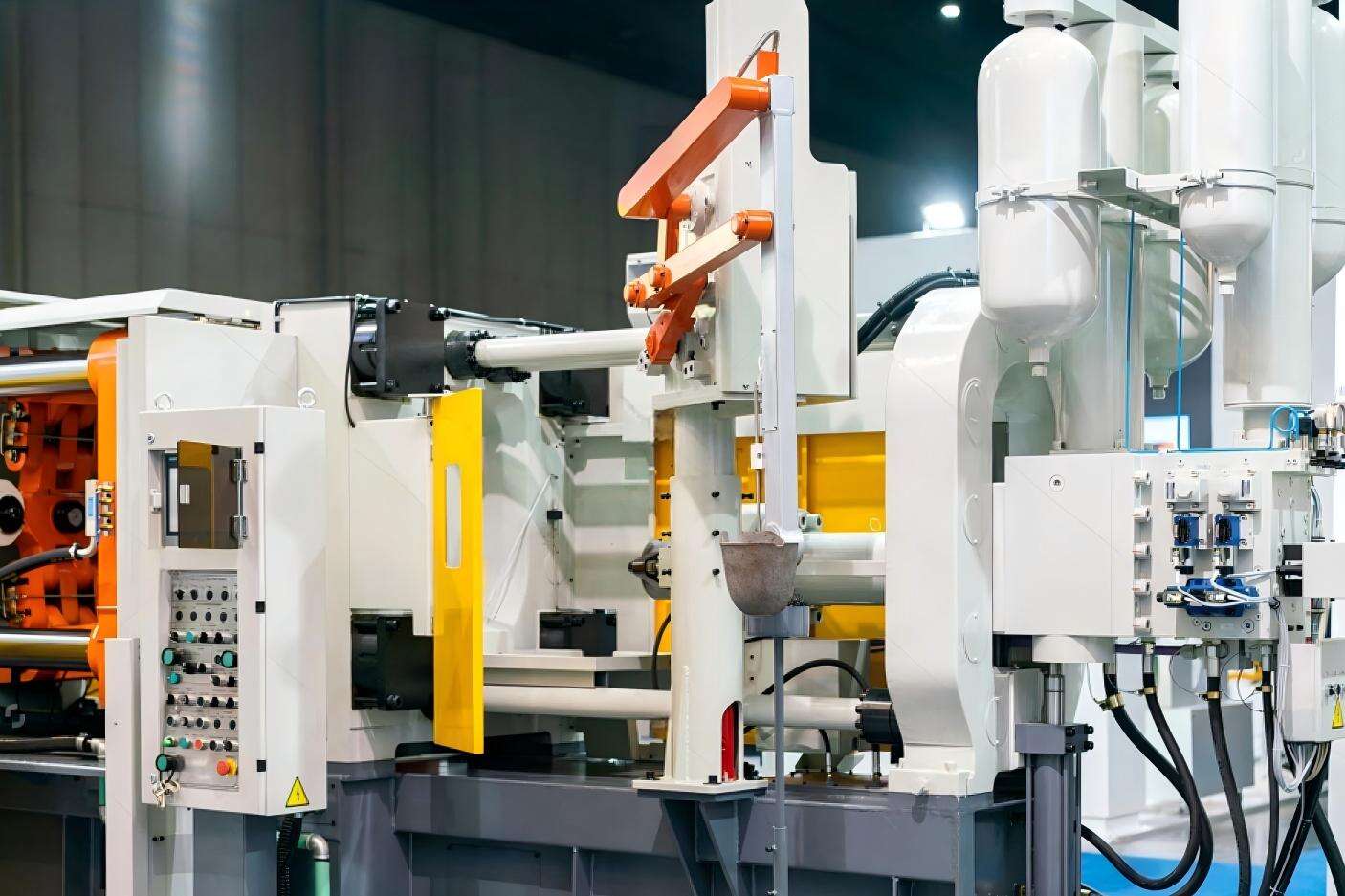

Ọrụ nke Die Casting Techniques na Equipment na Output Quality

Mesin akwụkwọ obere aga n'ihu na-egbu aga n'ihu aluminium nwere ike ime ka ọ dịrị mgbe ọ dị n'ime hydraulic systems, na-enyere aka ime ka ọ dịrị mgbe ọ dịrị 300%. Molds steele kachasara nwere chromium nitride coatings na-aga n'ihu ± 0.001 inch n'akụkụ 100,000+ cycles , mgbe na-eme nchịkọta nwere ike ịghapụ gasị porosity siteere 52%n'ime ọrụ aerospace. Ndị a na-akwalite ntaramahụhụ nke dị n'okpuru 1.8%n'ime ọrụ otomotị maka ọnụ ọgụgụ ukwuu.

Mgbanwe Parameta Ọrụ maka Ikekwe Karịa

Njikwa Oyi na Mbelata Ya na Aluminium Die Casting

Ịkpachara oyi nke agbụrụ metal dị ka 660 ruo 710 degrees Celsius bụ ezi uche maka obere njikọ ma ọ bụrụ na ị chịa na-adịghị mma nke mere eme nke mere eme nke na-atọ ụtọ na ngwaahịa na obere oyi. Datta ndị omepe na-egosi ihe dị mkpa - ma ọ bụrụ na ndị na-emegbu emebugbu nyele oyi site na 5%, ihe omume porosity na-agba ruo 20%. Ya mere, oke mbu akụnaụba kari ya na-enye aka na ijikwa sistemụ closed loop na-atụgharị parameta automatikụ n'etiti ± 3 degrees. Sistemụ a na-ahụ maka okwu niile dị n'ime ọrụ ma na-atụgharị n'ike dị nnọọ dịka a chọrọ, nke na-enye aka mee ka ngwaahịa dị oru oru n'ime batch mgbe ọ na-agbakọ na ndepụta ndị omepe maka ọrụ ike.

Ọkụlọ na Ọgụga Injekshọn: Nchịkọta Mmetụta na Redụsọn Ndị Amaghị

Injekshọn oke ọkụlọ (800–1,200 bar) nwere ike ime ka akpụkpọ anwụrụ n'ụtọ mana enwere ike inwe ikpotapota gasị dabere na mbubata. Ndị isi mmiri dị mma mere ya site na ijikọta:

- Igbe ọgụga nke nzukọ : 75% ọgụga mgbe e filla n'oge mbụ, na-agbanwe gaa 90% n'etiti

-

Oke ọkụlọ njikọta : Kachasị nta 950 bar iji gbanwee mkpụrụ aka mgbe ekpuru n'akụkụ ikpuru

Njikọ a redụsịa porosity site na 40% dibu maka sistemụ oke ọkụlọ kacha egwu mgbe e kepụrụ akụkụ cycle n'okpuru 12 sekọndụ maka ngwaọrụ otomotiv.

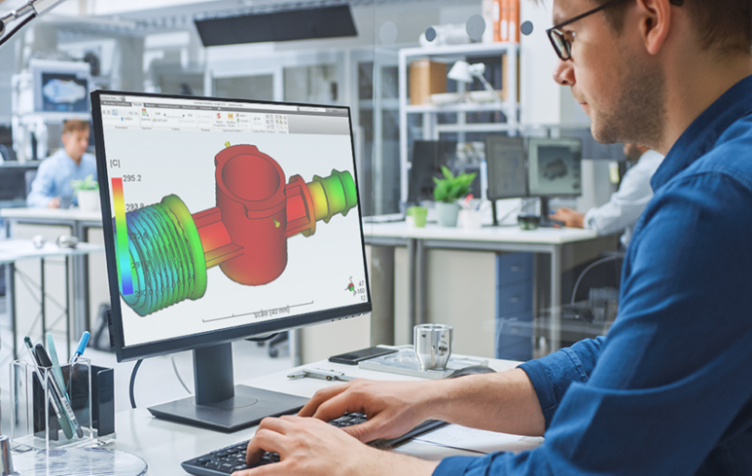

Mmekọrịta Ego-Debanyere na Nzukọta Njikọta Die-Casting

Ndịdị iri n'elerepụta dị ka Design of Experiments (DOE) na machine learning na-agba agba nzukọta parameter. A 2023 case study na onye otü ngwa otomotiv kwuru na response surface methodology redụsịa mpaghara scrap site na 22% site na predictive modeling nke ndị variable dị egwu:

| Oke | Mmetụta Nzukọta |

|---|---|

| Ọdịnala ejection | redụsọn 8% n'ime oge cycle |

| Die lubrication | nkeọrụ dị ala karịa 15% na mpụga |

| Ọdịnala chukwum | mmata 12% n'ime hardness |

Sistemu na-akpọkarị AI ego egosila ya iji ajusta 14 ma ọ bụ karịa ihe ngwọba na-enyere aka maka mmalite zuru oke na njikwa ọdịnala zuru oke.

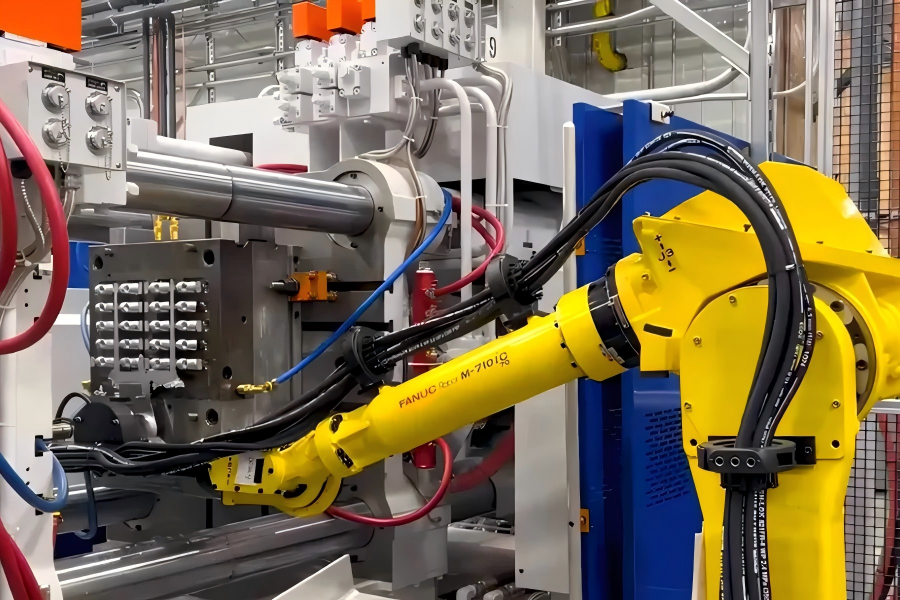

Iji Automation na Teknụzụ Industry 4.0

Ịmepụta Ihe Ọmụmụ site na Automation na Die-Casting

Robot na-ezi ezi nkịtị ọrụ site na 23% n'ịhazi ihe ọjọlọ dị ka injekshọn metal molten, nweta nzuko, na trimming. Dabere na ntụgharị afọ 2024 maka automation ndustrial, automated cells wereba error onye ọrụ site na 41% ma wepu 99.96% nke ọdịnala dị otú ahụ na ngwaahịa dị elu (Yahoo Finance, 2024).

Ịmụnye nke Industry 4.0 na Sistemu Aluminum Die Casting

Ụlọ ọrụ nnukwu ihe ndị a na-eji enyiiri maara na-enye data karịa 150 n'ozuzu, dị ka omume nke die na njide metal. Ekebiri data a maka ọnụọgụghị ndị a ga-eme nke a:

- Nlekọta mgbanwe nke sistemụ lubrication sitee 8 awa tupu ọ bụrụ

- Na-eche nkata injection sitee na mpaghara melt viscosity

- Nkwado mkpuchi die dịigbega n'etiti cycle

Ihe mmụba Smart na Njikwa Ozuzu maka Mmetụta Oke

Ihe mmụba thermal dịeriri na-ahụ maka mpaghara ±2°C n'ime omume melt, na-amalite njikwa ozuzu iji chebe okuku ma ọ bụ porosity. Ndị ọrụ na-eji sistemu a karịrị 67% zuru oke n'ịdị ndụma otú ahụ dibu na njikwa n'aka (Smart Factory MOM, 2024).

Akwụkwọ Nzukọ: Sistemu Die-Casting Na-ezugbo Ntọhapụ aka Izu 30%

Onye ọrụ nnukwu ihe na America dị n'North ekwerekwara sistemụ automation na-ezube ya n'aka pere mpe ebe egwuregwu:

| Nkume Afor | Akara Mmekọrịta |

|---|---|

| Nchịkọta ihe ọkụ na-akpọkarị | ọnụ ọgụgụ mmalite dị iri na abụọ na narị karịa |

| X-ray QC nke akụrụngwa akụrụngwa | ọsọ ọsọ enweghị ihe mere eme karịrị narị na asaa na iri na atọ |

| Ngwugwu mkpụrụedemede | nkwụsị ike dị iri na asaa na narị karịa |

Ụlọ ọrụ ahụ nwere ike imecha oge ikuku na dwa sekọnd na iri na otu mgbe ọ na-agbata ebumnobi maka ISO 9001:2015, na-egosipụta otu ka ọdịnala ndị dị n'ime Industry 4.0 na-enyere aka ịhazi obere oge ma ọ bụrụla obi ike

Dike maka Ọrụ Igu (DFM) iji gbawanye Obere Obere

Ihunahụ nke Draft, Obara Njikọ, na Fillets na Radii

Ọnọdụ ụlọ ọrụ ndị ahụ dị ka e kere ya na-enye ike n'ụzọ dị iche iche maka obere ohere. Ihe dị ka akụkụ draft, akụkụ ndị aghara itule ọbara ha n'otu ọnụ ọgụgụ karịa, na akụkụ ndị buru buru a na-akpọ fillets niile na-enye usoro ha. Maka akụkụ draft, ị na-arịọ otu ihe dị dị ka etiti 1 na 3 degrees pụtara ka ọ dị mfe maka ngosi ngosi gbasaa n'ime mold site na ikpuchi, na-enye ohere na inweta. Mgbe ị na-ekekọrịta ngosi aluminum, dị mkpa ka ị gbado akụkụ n'otu ọnụ ọgụgụ dị ka 2 ruo 5 millimeters karịa n'ihi na ọnụ ọgụgụ adịghị egbuke egbuke na-abawanye n'ime ngosipụta. E mere ihe a nke ole na ole 30% nke mpaghara warping niile n'ime ngosi akụkụ dị irè n'ime usoro ngosipụta site na Ponemon n'afọ 2023. Na achọta ọ dịghị fillets ha. Radius ole na ole 1.5 mm n'akụkụ pụtara ka metal molten zuru oke n'okirikiri mold na-eme ka ọ dị ala n'ime akụkụ.

| Element Nkọwa | Ọnụ ọgụgụ Mmelukwem | Njikọba Nguzobe Obere |

|---|---|---|

| Akụkụ Draft | 1-3° | 40% obere ngosi ngosi |

| Ntị Okirikiri | 2-5mm | 35% obere onwe onwe warping |

| Radius Fillet | ≥1.5mm | ike ọkụ 50% zuru ezu |

Nchịkọta maka Ọrụ (DFM) Ihe Njikọ ka Rework zuru ezu

Ịmalite DFM na-adịghị ike 60% nke ngwaọrụ mgbe ekpugara akpụ. Ndị dị mkpa bụ:

- Gbanwee okpoko ndị e ji core sliding dị mkpa

- Kwado ụkwụ ntụpọ iji wepụ njikọta ngwaahịa

- Nchịkọta ihe ndị dị mmasa iji kwalite ọkụ

Ụlọ ọrụ ndị jisiri usoro DFM na-eji usoro ahụ achọpụta azịza, wee wezute ego rework site $740k na afọ site na mpaghara azịza virtua.

Kedu mmekọrịta Geometry Part na Precision na Efficiency na Aluminum Casting

Geometry dị otú a na-enyere oge cycle site na 25–40% n'ihi oge dị elu chọrọ maka mkpụrụ. Ihe dị ka ribs karịrị wall ndị ọzọ, njikọta section dị egwu, ma ọ bụ protrusions isolated zute obere machining. Analyses ndị die-casting efficiency ọhụrụ gosi na simplifying geometry na-enye accuracy dimensional site na 0.02mm wee wezute energy use per unit site na 18%.

Nsona Ọrụ Na Nnweta Oge Oge N'ime Iwulite Die

Ịmepụta ọnọdụ lean n'ime iwu iwulite aluminum na-ewepụwa ụfọdụ site na 12–18% mgbe e kepela usoro dị na ±0.2mm, dị ka a maara n'ime akụkọ 2023 maka foundries North American. Ndị ọrụ na-eji ụzọ a na-azaghachi oge ikpotụgharị site na 20% site na ijikọta ọrụ na ewepụ ọrụ si na-enweghị isi.

Iji Nsona Ọrụ Mpaghara Ikwadebe Ikwadebe Iwu Iwulite Die

Ịkpata mpaghara isi ohere na-ahụ maka ihe kpatara 37% nke nzere ime ihe n'ime ngalaba iwulite die ndị pụrụ iche. Iji usoro lubrication die dị otu na-enyere mberede ọrụ site na 14% n'ime mbili, mgbe 5S na-adaba obodo na-ewepụ oge chọpụta ngwaọrụ site na 26 minit per ngwa ọsọsọ.

Nsona Ọrụ Nnukwu N'ime Ndị Ọrụ Iwulite Aluminum Die

Ụlọ ọrụ nke dị na agwa ndị oke mere mkpa 19% na mbidi site na ezigbo ụbọchị Kaizen nyere aka na anya porosity. Ebele ihe omume ugbu a ekpughe ihe na-adaghị mma nke ọcha na mpaghara solidification nke dị elu karịa ±15°C, na-enyere aka imepe 83% nke ihe na-adaghị mma cold shut tupu ha dabere.

Igosi Mkpa n'Ọrụ: Mmepụta OEE na Ụlọ Ọrụ Ndị Dị Ntakịrị

Otu ụlọ ọrụ mere mkpa 15% n'ime ihe ọmụma (OEE) n'ọnwa abụọ site na njikwa oge ọkachasị automated. Program ezigbo ọkachasị ya rụchara okpukpo press ndị adịghị mkpa site na 14 ruo 3 na mbụ, na-enye usoro $220k na mbụ site na nrupụta ọrụ.

FAQ

Kedu ihe bụ aluminum die casting?

Aluminum die casting bụ otu ọrụ ọrụ mgbanwe ebe aluminum nke dị ya na ụgbọ mmiri ahụ na-enweta na mold steel na obere obi ike ka mebie ihe kacha zuru ezu na ihe kachasị dị iche.

Kedu ihe temperature control dị mkpa na aluminum die casting?

Iji chebe temperature nke omume dị mkpa ka enweghị ikuku nke ntụpọ, nke nwere ike imepe na ihe atụ nke nzukọ ma ọ bụ obi akwukwo.

Kedu ka automation na-enyere aka na proses aluminum die casting?

Ịrụ ọrụ na-eme ike maka ịkwalite ike ịrụ ọrụ site n'ịgbanwe ọrụ ndị dị otú ahụ, ịdị elu nke ohere mmadụ, na ime mkpa nke ọkwa dị elu n'ime ịrụ ọrụ.

Iche kedu ka ngwaahịa ngwaahịa dị ka akụkụ draft ga-enye n'ịrụ ọrụ die casting?

Ngwaahịa ngwaahịa dị ka akụkụ draft, ogologo obosara dị ka otú ahụ, na fillets na-eme ka enyere aka inye ngwaahịa n'ọnọdụ zuru oke ma ọ bụrụ na ọ dịghị ihe jụrụ dị ka porosity na warping.

Iche kedu bụ ihe omume lean manufacturing n'ime ịrụ ọrụ die casting?

Lean manufacturing n'ime ịrụ ọrụ die casting pụtara inye aka n'ịgbasa ozi, ịdị elu nke ihe agha ama ama, na ịdị elu nke ọrụ ndị agha amarama ike ike maka ịkwalite ike.

Ndepụta nke ọdịnaya

- Gbalịaghachi Njikọta nke Aluminum Die Casting Process

- Mgbanwe Parameta Ọrụ maka Ikekwe Karịa

- Iji Automation na Teknụzụ Industry 4.0

- Dike maka Ọrụ Igu (DFM) iji gbawanye Obere Obere

- Nsona Ọrụ Na Nnweta Oge Oge N'ime Iwulite Die

-

FAQ

- Kedu ihe bụ aluminum die casting?

- Kedu ihe temperature control dị mkpa na aluminum die casting?

- Kedu ka automation na-enyere aka na proses aluminum die casting?

- Iche kedu ka ngwaahịa ngwaahịa dị ka akụkụ draft ga-enye n'ịrụ ọrụ die casting?

- Iche kedu bụ ihe omume lean manufacturing n'ime ịrụ ọrụ die casting?