Fahimtar Tsarin Aluminum Die Casting

Bambance-bambancen Tsarin Aluminum Die Casting

Yanayin ganyawa ta alaminiyum yana aiki ta wayarwa mai tsada abubuwan da ke yanke shari da zafi sosai cikin kwalabu na kidi domin samar da kayan ainihin. Lokacin da zafi ya yi fi 15,000 psi, kwalaba yana kama komletan, wanda yaya kayan dandansa na iya zatawa, kamar yadda aka samuwa daidai zuwa ga 0.6 mm. Abubuwa na zamna sosai kuma, yau da kullun a cikin miliyan 3 zuwa 10, sannan bayan haka ana bawarwa kayan cikin kwalaba. Yau da kullun makayan suna dauka adadin 90 seconds ko karanci, kamar yadda aka samar da kayan da zaune. Matsayin sama na kayan waɗannan ganyawan har ma babban 125 microinches ko kamar 3.2 micrometers, wanda yawa yana nawa don ayyukan masifa.

Matsayin Muhimmi da Saukinni a Cikin Ganyawa ta Alaminium

Ko'ina hudu da aka guddua suka kirkire kwalitin samun abubuwa:

- Rarraba alloy a 660°C ±5°C don ci gudumawar rabiwa

- Shafin kusantar waya (0.5–6 m/s) don kara karamin porosity mai haɓakar gurji

- Zaman lafiya da aka kirkire ( 20–30°C/sec ) don kara karamin alhakin da ba'a wasa ba

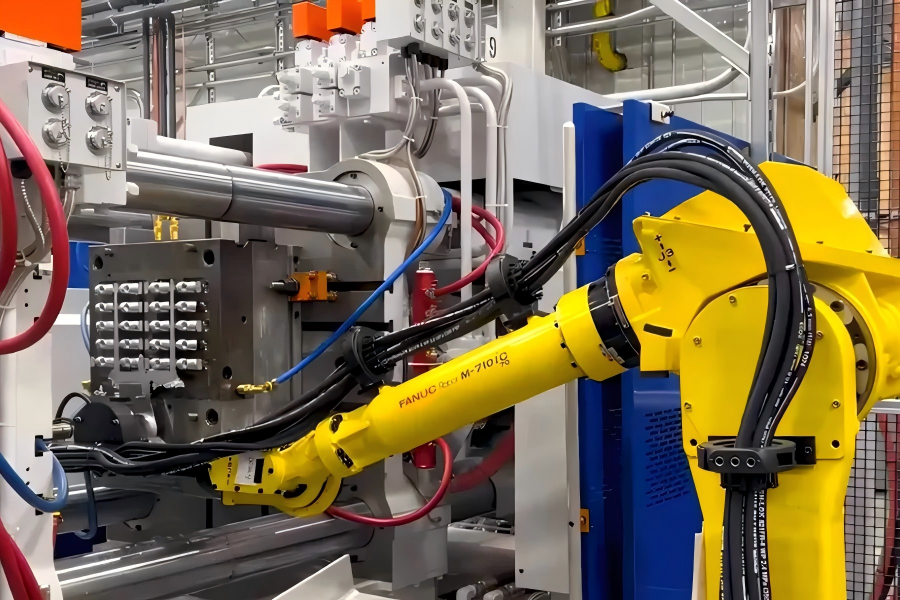

- Cutsar da abubuwan masu yawa na robot saboda 40%

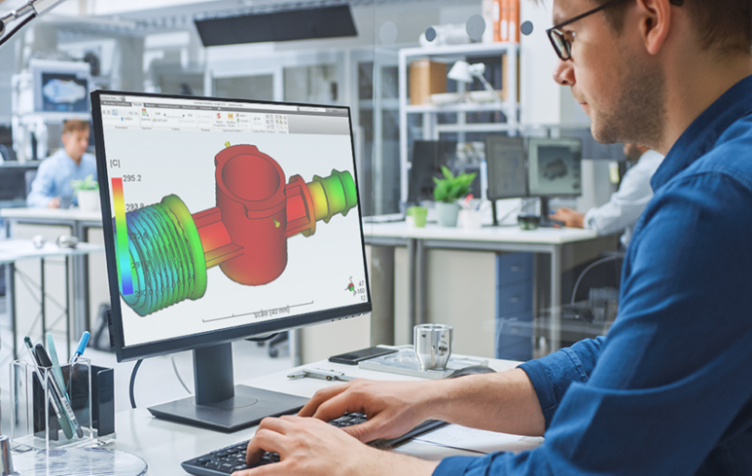

Wasu masu aikin garaje suke amfani da sensa’oyin rawa na infrared da saukunan AI sun kawo 18% ya fi karanci akan alamar wani abu kadafi ayyukan mai yaya.

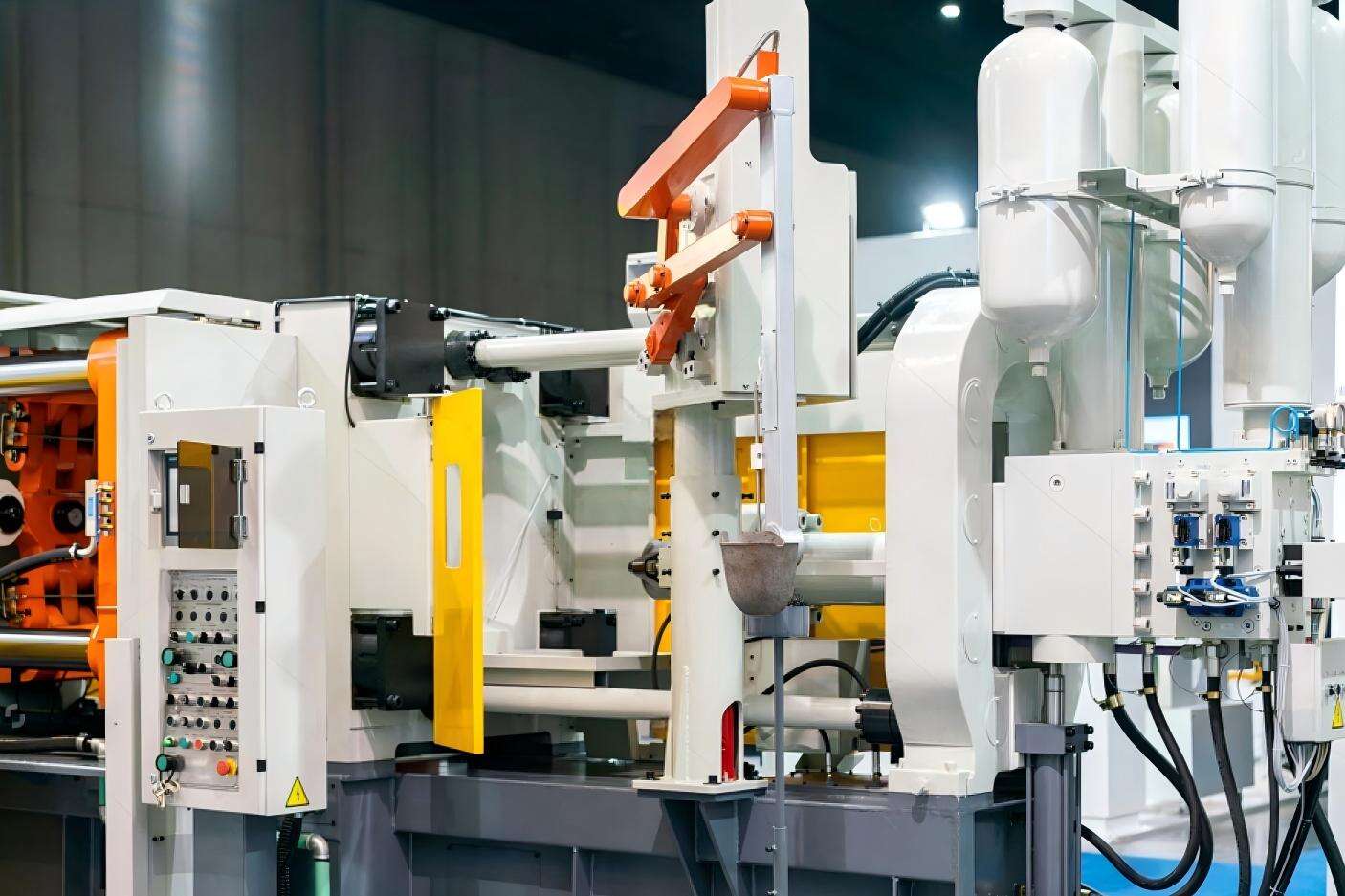

Rolle na Teknikai da Abubuwa na Die Casting a cikin Kwaliti na Samun Daraja

Mashinun cibiyar sanyi suna kula da alwuminum mai nauyi daga tsarin hydraulic, wanda yake ƙara tsawon shekarun amfani da wasan 300%. Molds na steel mai zurfi masu aluma na chromium nitride sun yi amfani da ± 0.001 inch tsakurin rashin taimako over 100,000+ cycles , yayin da castawayin tare da kwalon yake kwanso gas porosity ta 52%a cikin ayyukan aerospace. Wadannan inganci sun kawo tasowa zuwa kasa da adadin scrap mai gaba daya 1.8%a cikin production na otomatik mai yawa.

Gwajawa Parametar na Tsarin Damuwa ga Kama-ko da Iyaka

Gwajawa Harara da Tasowarsa ga Aluminum Die Casting

Kama da abubuwan da ke tsakanin 660 zuwa 710 daraja selsias (Celsius) shine wajibi don samun alhali mai kyau na flow kuma ka barke wa idan ya zama mai karfi da yawa wanda zai kulle daga natsuwa kuma za a yi la'akari da girman abubuwa da kwalitun sahun. Bayani na sarayi tana nuna abin da babban mutane ba su san - idan mutum ya kalli harara mai karfi ne 5%, matsalolin porosity sun godiya har ma 20%. Don haka dukomai masu amfani da automaic closed loop controls wanda ke canza saitiyo a cikin +/- 3 daraja. Wadannan tsistemana ke duba abubuwan da ke bayyana a lokacin production kuma ke canza shi kusan kuskuren, wanda ke taimakawa wajen kawo kama-ko na abubuwa a cikin batch kamar yadda aka halartar da standard na sarayi don tsarin manufacturing mai iyaka.

Tsarin Dabaruba da Speedi na Injection: Tsarken Aiki da Raguwa a Sayawa

Injekshin mai tsauri (800–1,200 bar) yana ba da damar fullo waƙaƙin cikin lokaci amma yana zama abin da ke kama da tattalin arziki ta hanyar gudu-gudu. Wasu masu amfani masu ukuwa sun kula da wannan halayyin ta hanyar hadawa:

- Tsari mai kyau na velocity : 75% speedi bayan farawa, sannan ya yi yawa zuwa 90% a nisar tare

-

Dabaruban Intensification : Babu ƙasa da 950 bar don kawowa sabon wani abu yayin yankiwa

Wannan tsarin yana ruwawa porosity biyu da 40% dibu da wasu tsarin da aka dora dabaruba komai, yayin da yake tsarken lokacin cikin 12 seconds don kayan otomatik.

Gudanawa kan Lissafi a Tsarken Tsarin Die-Casting

Wasu hanyoyin kiyaye kamar Design of Experiments (DOE) da machine learning suna guddurar da saiti na iko. Wani jerin binciken farko a shekara 2023 a masu amfani da kayan otomatik ya rage faɗin kashewa biyu da 22% ta hanyar gwagwarmaya alamar muhimmiyar ikokun:

| Paramita | Ma'aurata na Optimization |

|---|---|

| Wakar kuskuren ganyi | rashin tsawon sikili 8% |

| Ganyiyata mai rage | kayan inganci na sauke 15% |

| Saukar kula | tarauni 12% a cikin tafalawa |

Yanar gizon AI yanzu ke canza otomatikin 14+ kayayyaki per sikili, kuma ta ba da damar gyara sosai da kuma kontin shirye-shiryen aiki.

Amfani da Kwatantacciyar Aiki da Teknologiyoyin Larabta 4.0

Ƙarfafa Ayyuka Tare da Kwatantacciyar Aiki a Cikin Tsarin Ganyiwa

Kwatantacciyar robot makamci tadada biyuwa ne 23% ta hanyar yin ayyukan da aka dace tare da su kamar injekshin abubuwa mai rage, kimiyyar kayan ganyi, da guro. Ga wasikan kwatantacciyar larabta 2024, selarotun otomatik sun kama kuskuren mutum 41% kuma suka sami taimakon girman 99.96% a cikin runutattun sigogin (Yahoo Finance, 2024).

Haɗin Tattalin Arziki 4.0 a Cikin Sistemin Aluminum Die Casting

Faburikin da ke da mahimmanci suna amfani da kayan aikin da ke da IIoT wanda yana nuna kamar yadda ya fi 150 dabi'u na tsarin lokaci mai zurfi, kamar yadda ya fi shafin dare da yawan zabin abubuwa. Wannan bayani tana amfani da algorithum mai karfi wanda:

- Yana gaskiya sabon kuskuren farkon yanayin lubrication takamata 8 sa'a zuwa baya

- Yana iya canza tsarin injection pressure bisa damar taushe na melt viscosity

- Yana inganta tsarin cooling na die tsakanin ma'aji

Smart Sensors da Real-Time Monitoring don Tsaro na Tsari

Kayan sensor masu juzuwa suna ganin canjin ±2°C a cikin shafin dare, suna fara gyara hanyoyin ilimin sai bayan sai domin kula darar cold shuts ko porosity. Alakar aikin da ke amfani da wannan system suna kawarar batun kwaliti 67% sosai karfi duk da amfani da gyara manufofin (Smart Factory MOM, 2024).

Tushe Na Kashi: Cell na Die-Casting Mai kyau wanda aka girma yana rage waƙatin ma'aji ne 30%

Wani mai amfani a Najeriya ta Arewa ya gudanar da closed-loop automation system wanda yana da:

| Kumantaccen | Ma'auni na inganci |

|---|---|

| Robotic shot control | 22% karfi a cikin lokacin bakiwa |

| AI-kyama X-ray QC | 93% nisbi na karkashin kuskuren kuskure |

| Ayyukan gyara daidaitawa | 18% tonkwargi a cikin yawan amfanin hankali |

Tattalin arziki ya samu 2.1 seconds satsaukar zuwa tsawon lokaci yayin tabbatar da ayyukan ISO 9001:2015, wanda ya nuna yadda ayyukan Industry 4.0 masu haɗi sun kara abubuwan da ke da muhimmanci da kwaliti.

Shawarar Tattalin Arzikin (DFM) don Kama Karfin Tattalin Arziki

Muhammancin Draft, Daidaiton Ginya, da Fillets da Radii

Yi tsari na kayayyaki yana iya canza hanyar ayyukan su zama. Abubuwan kamar yanayin daidaita, kwallon da ke tafiya gurbin dabin daya, da kuma sharuɗɗan da muka amfani da su a cikin tsarin fillet suna da matuƙar mahimmanci. Don yanayin daidaita, amfani da wani abu daga 1 zuwa 3 daraja yana taimakawa wajen baya kayayyaki dake cikin tsarin ba za a barin, wanda ya bada inganci da rarraba lokaci. Lokacin ƙirƙirar kayayyakin alwuminum, karɓar kwallon da ke tafiya gurbin dabin daya a 2 zuwa 5 mita millimeter suna da mahimmanci saboda gurbin dabin daya ba ta haka yana haifar da matsaloli na hada. Wannan yana haifar da sakamako ga kashi 30 kowace ilahan matsalolin warping a cikin kayayyakin da ke kwallon mai zurfi kamar yaddazai aka fahimci daga jerin abokan kasuwanci na Ponemon a shekarar 2023. Kuma kada ku forgete fillets. Shafin da ke 1.5 mm ko fiye ne a sharuɗɗani yana ba da damar samun ƙwayoyin metal mai nemi a cikin tsarin, kuma yana kare wa ƙwayar bayanai su shiga cikin kayayya.

| Unsurra na Shiryawa | Nisa na Idris | Abin da ke iya reduce defects |

|---|---|---|

| Yanayin Daidaita | 1-3° | 40% less ejection failures |

| Tsaye wall | 2-5mm | 35% lower warping risk |

| Shafin Fillet | ≥1.5mm | 50% less porosity |

Kayan Dabi'u na Tsaro (DFM) don Ragu Wurin Sauƙi

Yanayin farawa a baya na DFM ya cire takaitaccen 60% daga cira abubuwan bayan tsaron. Duk dukiyoyin masu mahimmanci sun haɗa da:

- Karyar kulle mai adadin alamuwa da ke buƙata kayan aikin zane-zane

- Tsaro wuri na sama’i don ragu canjin kayan aiki

- Zane-zane na nufin tafarka don tsammanin gudu na hankali

Albarkatu da ke amfani da dubawa na DFM na yanzu sun rago karancewar sauƙi ta $740k kowace shekara ta hanyar gwadawa a sarari.

Yaya Zane-Zane na Abubuwa Ya Aiwata Da Fuskoki da Kwatancin Aikin a Tsaron Aluminiyam

Zane-zane mai inganci yana nema lokaci na aikin 25–40% saboda lokacin sanya mai tsawo. Abubuwan kamar kwallon mai girma fiye da fuskar da ke sa, canje-canjen fuskoki ko kayan da aka fitar da su ne a waje, wasu lokuta suna buƙata aikin makini. Bayaniyan mai banbancin tsaron makinta a baya suna nuna cewa magana zane-zane yana goronkar da fuskokin mita 0.02 kuma yana rage shiga na nasara kowace kayan 18%.

Hulumar Hulun Aiki da Ci gaba Ci gaba a Tsaron Makinta

Ayyukan yin amfani da tsari mai zurfi a cikin tsarin gurji na aluminum sun koshi dumiyan kashewa ta hanyar 12–18% yayin da suka tsaya da iyaka a cikin ±0.2mm, saboda tallafin shekara 2023 na masu gurji a Najeriya. Alajukuma da ke amfani da wadannan ayyukan sun kira cikin 20% yawa a lokacin tsarin buƙatar sabon abubuwa ta hanyar saukake shigarwa da koshin ayyukan da ba za su iya ƙara kyauta ba.

Yin amfani da Koyon Gudummawar Tsarin Faburika don Saukake Ayyukan Gurji

Tacewar natsuwar kayan aikin ya faɗi gargadi mai amfani da 37% na kasaƙo a cikin tsarin gurji na yau zuwa yau. Yaddan tacewa na yin amfani da kayan gurji ya kara lokacin amfani da wasanƙi ta hanyar 14% a karkashin zaman kansu, yayin da 5S sauyin wurin aikin ya koshi lokacin bincike na kayan aikin ta hanyar 26 mitinuta kowace rarraba.

Ayyukan Ci gaba a Alajukumai Masu Gurji na Aluminum

Tarihi na tsakiyar amfani ta samun tarin karaƙar 19% a kowace shekara ta hanyar mitingan Kaizen kowace rana wanda ya focused zuwa tadon lissafi na porosity. Yanzu tadon gwaji ya ke nuna tafarka na girma na yankin solidification da ta fi ±15°C, wanda yaƙewa 83% na batun cold shut kafin su fara.

Giniyar Barkiten Kama: Tacewa a cikin OEE a cikin Tarihin Daƙin Tsauri

Wani doka ya kara Tacewar Ayyukan Doka Duk (OEE) ta 15% a kowace shekara biyu ta hanyar iƙoƙin karɓar kashewa. Programm din gwagwarmayar sa ta kare shigogon mashekan da ba za a iya kula da su ba daga 14 zuwa 3 kowace wata, wanda ya kasa $220k kowace shekara a matsayin ayoyin da ba za su yi bane.

Tambayoyi Masu Yawan Faruwa

Menene aluminum die casting?

Aluminum die casting ita ce prosassin faburika wanda zai halitta aluminumsun daga cikin steel molds a girman pressure mai zurfi don samar da abubuwan da ke da ma'anar da kayan ajiyar mahimmi.

Me yake tsarin girma tana muhimci a cikin aluminum die casting?

Kiyaye tsarin girma tana da muhimmanci don kare kafofin gishin gurji, wanda zai iya kuskuren girman abu ko kwaliti na surface.

Yaushe automation ke kawar da albarkatu zuwa aluminium die casting process?

Karin aiki na iko yana ƙara abubuwan da aka samuwa ta hanyar gwagwawa abubuwan aikin da aka yi kafin, neman kuskuren mutum, da kuma tsauraran girman abubuwan da aka samuwa.

Wanne ne mabudin kayan aikin kamar yanayin zane-zane a cikin zane-zane na die casting?

Kayan aikin kamar yanayin zane-zane, girman dandalin da ke dogo, da fillets su taimakawa wajen tabbatar da saukin fitar da abubuwan da aka samuwa, kuma neman alamar kama da porosity da warping.

Wanne ne kayan aikin lean manufacturing a cikin zane-zane na die casting?

Lean manufacturing a cikin zane-zane na die casting yana iya kara saukin ayyuka, neman darumi, da kuma neman ayyukan da ba za su ba da kyau ba don kara mahimmanci.

Teburin Abubuwan Ciki

- Fahimtar Tsarin Aluminum Die Casting

- Gwajawa Parametar na Tsarin Damuwa ga Kama-ko da Iyaka

- Amfani da Kwatantacciyar Aiki da Teknologiyoyin Larabta 4.0

- Shawarar Tattalin Arzikin (DFM) don Kama Karfin Tattalin Arziki

- Hulumar Hulun Aiki da Ci gaba Ci gaba a Tsaron Makinta

-

Tambayoyi Masu Yawan Faruwa

- Menene aluminum die casting?

- Me yake tsarin girma tana muhimci a cikin aluminum die casting?

- Yaushe automation ke kawar da albarkatu zuwa aluminium die casting process?

- Wanne ne mabudin kayan aikin kamar yanayin zane-zane a cikin zane-zane na die casting?

- Wanne ne kayan aikin lean manufacturing a cikin zane-zane na die casting?