Fahimtar Gudummawar Gudu da Duniya a Kan Abubuwan Otomat

Taimakon Gudu da Kariƙin Gwagwarmayar, Lahira, da Gudummawar Rofa

Abubuwan na kotun waya ke da sauri da rashin kama a tsawon ran. Tazara ta hanyar ophanging alone ke tafiya da yawa da 50,000 lokacin da aka yi test a lokacin da aka yi test mai tsada abada. Abubuwa kamar engine mounts da wheel bearings dole ne su kare da duk wadannan zane-zane masu girma na rana waɗanda suka kama a makamashi, wanda ya shiga biyan kasashen da $5.2 billion kowace shekara saboda marubutin durabilité sarari na 2024. Masu amfani suna amfani da abubuwan da aka yi test akan su ta hanyar yin nufin abubuwan da za su faru a cikin rana bayan mitin shekaru. Wadannan testo suna naka abubuwan baya daga cikin halayen normati domin nuna alhaja uku da bakwai uku karatu ga maoyi suke samunsa, don maimakon majennin ganin inda abubuwan za su iya kurumawa akhirin lokaci. Duba transmission housings misali, ana kirkiransu yau da kullun domin kare da at least 200 kilonewtons na force a cikin axis da ba za su karu ko su kalla ba.

Karin yanayi: Exposé na UV, Thermal Cycling, da Chemical Degradation

Cikiya ta sama da wasu canjin yara masu kama yawa suna iya samun karfin kayan aikin lokacin. Duba misali na plastik na dashboard, sun tenda in galibi su raba 38% na karfin tensile sai dai kawai ne aƙalla 1,000 sa’a bayan an goyan su da cikiyar UV. Lokacin da abubuwan zaiyi maɓallin sanyawa da zamuwa daga har zuwa -40 daraja Silizas zuwa 120 daraja, mafitaɗi sun kasancewa gaban shaida labarin ilimi suna barin karfi gabaɗaya. Binciken kan canjiyar stress na tsarin hankali taron tushen bayani mai sauƙi: game da 25% na batun plastik na otomotika ya kamata ne daga saboda kimiya ta yi fasaha da saltun ruwan jirge da wasu nau’ikan wuro. Masu amfani sun kawo sabon coatings mai zurfi na farko wanda ke taimakawa wajen karyar test na spray na salt zuwa 500 sa’a, wato yanzu yana nuna takaitaccen karfi ga 70% dibup ga abin da aka iya yin a shekara 2018.

Tace Kudi: Abubuwan Na Iyaka Da Kayan Dashboard Bayan Ma'aunin Halayyen Yanayi

An sanin bincike na 2023 ya fada kuskuren farko a cikin ayyukan da aka yi:

- Kayan dandamalin alarminyum an kallafa su ne a 0.12 mm/year a yankuna ta hagu compared to 0.8 mm/year a yankuna maso sauti

- Dashboards na polypropylene wanda aka tsaya UV sun zama da 92% na sayyan launi baban hudu shekara, suka tafi kama da kayan aiki masu yawa a 67%

Wadannan bincike suka sa OEMs su yi amfani da kayan aikin alaƙa na yaukidan da kayan lafiya masu yaukidan, su kara ciki koƙin aikin tacewa ta hanyar 82%.

Haɗin Yanke Lissafi Na Tsawon Lokaci Da Kuma Testa A Cewa Yake Zama Magana

Albarkatun maye kayan suna daba IoT gauges don duba aikin kayi bisa 12+ kayan tsari na gini , saka ruwa da zane-zane na harmonic. Kayan testa na aging sun kama shekaru mai yawa zuwa testa na uku koma ta hanyar yin simulation na kyau:

| Paramita na Gwaji | Daidaiton Simulation | Benchmark na sarrafa |

|---|---|---|

| Zane-Zane Na Guduwar Tushen Hadi | 98% | 50 zane-zane/koma |

| Kama da Kyau Mai Yawa | 95% | 0.7 Grms RMS |

| Juriya na Lalata | 89% | ko da kama 1000 sawa da ruwan gishiri |

Wannan tsarin bayani ya kare wasanni masu alaƙar da dutsen abubuwan tserewa ta 41%daga 2021 sai kuma ya kare kusurin kwamfuta ta $18k per vehicle platform .

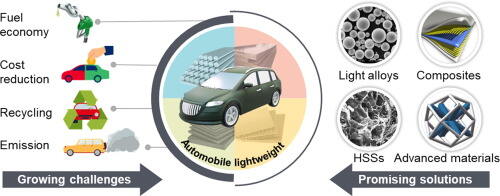

Kimakon Ginya da Polymers mai kyau don Daidaitowa

Masu amfani da kayan mota suna sha'awar neman abubuwan da ke iya tsaua shekaru iri de suka yi a cikin yawan yanayin zafi ba tare da kama wanda baya shiga danger. Fili na ci gaba shine mai sarauta a makon mota saboda yawa yawa daga cikin 380 zuwa 550 MPa kuma babu shi ya fi sallama sosai. Amma nan yanzu akwai wasu masu karfe daga cikin plastik mai zurfi kamar abun samun PA6-GF30. Dole ne ake amfani da turbochargers misali, waɗannan sababbin koma sabon cut down on weight by about 40 percent dib dap diya mai amfani yayin da ke iya karyawa har zuwa 220 degrees Celsius saboda buƙukuwa da aka buga baya na year in automotive material studies. Abin da muka ga anna ita ce yadda kullum indaustiran otomatik tana iya ganin wurin da ke da alaka game da nisauni da sauƙi don kiyaye ma'auni mai zurfi don kiyaye ma'auni mai zurfi.

Abubuwan da Ba za a sarre ba: Filin Galvanized, Aluminum, da Alkwayoyin Mai Zurfi

Mafurufuru mai zaman kanso yana amfani da tsari mai goyon kima don kula da kankara:

- Fatarar Gidamai Galvanized tare da layer na zinku na 10–25 µm yana ba da amincewar kankara labarin 15 shekara zuwa ga alatakai

- alloy na alwuminum na 6000-series yana kama masa waje na brake caliper ne biyu 35% dibu cast iron yayin kula da gaskiya ta salti na hanyar sama

- Alkawalin Plasma-electrolytic oxidation yana karƙara ingancin abubuwan alwuminum na mesin takamfe game da 300% (ESD-SAT 2023 testing)

Wadannan abincin sarrafa suna karkasta biyan $740,000 don karkara kankara per mafurufuru a cikin Tambaya ta Materials Analysis.

Takardawa Masa waje, Kusurin Kuɗi, da Ingancin Abubuwa a Cikin Zaɓi Na Abubuwan Mafurufuru

Mabudin materials suna tafi da trilemma:

- Binciken kwayoyi – kowane 10% reduction yana inganta kwayoyin kuɗi na 6–8%

- Tamewa da kudaden biyan kuɗi – alwuminum yana zukawa biya 2.5x karfi dai ga kilogram daraja na steel mai zurfi

- Buƙatar dacewa – kwararun nuna dacewa na shekara 25 suna canzawa zuwa ainihin halin yanzu

Furuci mai tsauri masu uku (AHSS) anan suna ba da wani matakan da ke kama, sune ba da kayayyaki da suka lemuwa ne 30% karfi daraja na furuci mai zurfi sai dai 15–20% biyan kuɗi mai hagu. Aiki masu ci gaba akan nano-coatings da self-healing polymers suna kira aboki don samun dacewa mai amfani da kwanciyar gaskiya a cikin masa.

Mafuta na Testa Dacewa da Hanyoyin Girma Wasso ga Kayan Oto

Shawara kan mafuta mai aiki na dacewa da testa na kayan dabbobi

Abubuwan tsin abinci suna bukatar watsi gama gari masu harshen kuma suna iya amfani da su a makwabtansu. Hakanan akwai shari’oayyen da aka hada kamar ISO 16750-3 wanda ya goyan yadda za a yi lafiyar tsarin batiri a lokacin da ya kamata, kuma SAE J2380 wanda ya goyan abubuwa kamar dabi’ar rana a cikin lokaci. Yi amfani da sharuddan da aka saka ta alakar NHTSA da EPA bai shine amfani da kanunonu kawai ba, amma hakan zai kare mutane kuma ya sauke waɗanda ke yawa. Yanar gizo ta otomotiva tana neman yin kokarin yin gwaji-game da za a iya amfani dashi a makwabtansa. Gwajin wurin ruwa mai namnamda bisa ASTM B117 da kuma duba kayan ajiyya a juyawa mai girman harshen daga -40 daraja Silisasi zuwa +85 suna zama abubuwa masu mahimmanci a alƙawarin takamfe.

Gwajin nahawa: Fasashen makwabta, kayan cire, da abubuwan da za’a iya warwurta

Masu kirkirar yin maganaƙan yanayi na kuma daya akan kayan mota masu mahimmanci don tabbatar da suwa a cikin shafin halayen duniya mai kyau. Saya zuwa ga matakan dare misali, wadannan kayi suna buƙatar sauya ne aƙalla ƙofin ɗaukar da dare da sake raguwar ta, wanda ke nuna idan takalmi ya samu sauya ko dai ba sai an yi masa wasan ganyawa. Kayan juyawa na farko suna da zaɓiɓɓen makamashi kamar yadda yasuwa sunke, don haka muna amfani da takaitaccen yanayi bisa ASTM D4060 don mu tambayi yadda kayan aikin zai samu sauya bayan shekaru da yawa a cikin mota masu amfani. Ga kayan aikin tsere, ma'auni mu itace ne aƙalla miyaya da yawa na load cycles don kawo abin da zai faru yayin an tsere mota a kan wuru marasa soyayya. Matakan fagenwa tana bista wasan kumama sosai, kamar 500 hours na humudity exposure don tabbatar da cewa ruwan sama bata za ta shiga cikin wuri inda zai iya haifar da matsaloli a gaba.

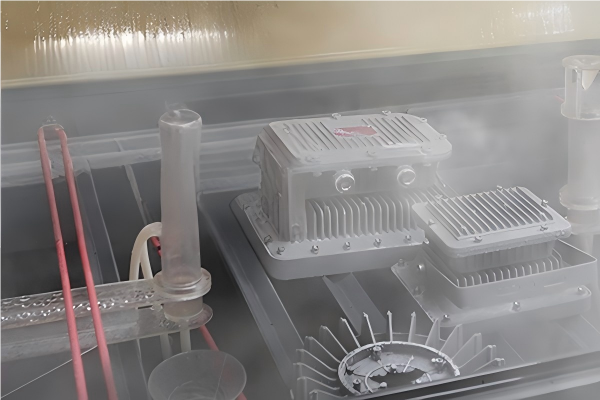

Wasan kumama na accelerated da dabarren su ne a cikin aiki na duniya mai kyau

Takamunan kewaye da ke kara kacewa canjin shekara zata iya hada abin da zai take shekaru iri de su ne a wajen makonni. Saituna matsin gari misali suna kula da yaki na 1500 na kwana na sarote na xenon arc UV, wanda ya nuna shekaru biyar masu hannu a cikin halayyen zuwa. A hanyar wasu, an kauke bushings na ophanging ta hanyar yawan 50,000 na tsarin compress a kan wasu rigging testing masu alaƙa. Wasu labarai na gabaɗaya sun fada abubuwan da suka faru: suna da kyakkyawa 92% tsakanin kayan aikin da aka testa a laboratoriyan bayan canjiwa mai sauƙi da samfuran dabi'a daga gidajen da aka watsa bayan aiki mai tsawo. Wannan yanzu yake faruwa lokacin da muka haɗa canje-canjen yanayin dari -30 daraja selsiasu zuwa +120 tare da yawan canje-canjen girman girma a lokacin gwagwarmaya.

Amsawa ga furuci: Testa sosai vs. abubuwan da ke da mahimmanci

Ƙalla da cewa 78% na maƙiwaɗawa sun yi amfani da ASTM G154 don kuyar da yanayin hawan sama, 40% sun sanar da yadda ya ci gaba da yanayin ayyukan testing bayan tsawon shekara 15 na abubuwan nisfanya. Dabarun addini masu cânse sun hada da:

- Haɗin tsawon testing da yankunan yin amfani (misali, maɓiki 200,000 na North American benchmarks vs. km 150,000 na European thresholds)

- Haɗin bayanan kasancewar sharuɗɗan kuskure don sake sauya shafin lab

- Zinare modilolin AI-driven don kama da redundant testing ta 18% (2023 Automotive Materials Symposium)

Wannan takiti tana kiyaye yawan kuskuren tsarin muhimmiyar saman zai fi karanci 0.5%—tuntube da abubuwan dabi'u da wajen haɗuwa—wanda ke kama da kudaden shirye-shiryen shiga.

Kontin Karin Kwamitawa da Kiyaye Hanyoyin Girma don Kama da Tsawon Ayyukan Abubuwa

Haɗin durability testing zuwa cikin girman kwamitawa

Masu ƙirƙira makina suna fada zuwa wajen ƙarin nemo kuskuren abubuwan da ke tsakanin yankin da suke ƙirƙira a yankinsu. Suna kirkiren da rashin taimakawa da abubuwan da ke yanke yanke da suke iya canzawa kama da hali na yara. Yau da kullun, tsarin Six Sigma ya taimaka wajen rage matsalolin garanti masu alaƙa da transmission ta hanyar kowa 18% saboda suna neman matakan clutch plates har maƙasa. A wadansu lokuta, wasu kamar wadansu camera inspection systems suna neman gabanai gabaɗayan 9 daga cikin 10 mai zurfi a cikin brake calipers kafin an kirkire shi, wato wasu masu ƙirƙira baya basu kiran matsaloli kawai sai dai suna buƙatar irin waqtarsu. Hadan waɗannan teknologijin suna ƙara ingancin makinar da ke yi a halayyin da suke daidaita kuma a halayyin da suke daidaita kamar yadda za a samuwa kan wuraren da ke fara da salt a kwanan watan Disamba.

Kontin gyaran adadin da kuma ingancin girma a yankin

Software na SPC yana kama abubuwan duniya a cikin wani range mai tsauri na ±0.005mm ga sakamakon 1.2 jiragen bushing na ophanging kowace watan ta hanyar dubawa da bayanan CNC machining duka. Yi wasu makarantun Kaizen kowace week kuma masu amfani suna samun batun matsalolin 40% ka wurin cirewa game da shekara na cylinder head casting, duk lokacin da suka kama biyan kuɗi domin ba su fuskata karshen 2% kowace shekara. Daga 2022 kafin, shuwanci suna iya kula da fasaha na bearing yayin da suke faruwa a factory floor. Wannan yana nufin cikin mayar da hankali zuwa waƙaƙan karkashin kowane mako, masu amfani za su iya gano matsalar da kuma kuskuren sa yayin da babu kama kowace batch zai barci.

Tambayoyi Masu Yawan Faruwa

Wane shahenshahi ne mai muhimmanci ga mechanical stress testing don abubuwan zurfi na otomobil?

Tacewa mai zuwa mechanical stress yana taimakawa wajen gano alamar da ke iya kwancewa a cikin abubuwan otomobil ta hanyar nuna halayyen mai zurfi, tare da tabbatar da inganci da tsaro a cikin lokacin mai labari.

Yaya kayan aikin sama kamar UV exposure ke iya tasowa kayan zurfi na otomobil?

Za a iya ƙarewa da shakatacciyar yaya da kuma launin abubuwan na ‘yan rukkun waya ta hanyar samun guduwar UV, wanda ya bada sharuɗin sauya tsarin abubuwan da kuma alkaru.

Wanne ne role ga strain gauges na IoT a cikin amfani da faburika na mota?

Strain gauges na IoT suna ba da damar dubawa a lokacin da ake amfani da kayan dabi'a a kowane halayyin kwando, wanda ya sauƙaƙe karin tsauraran kayan dabi'a da kuma ingancin su.

Wanne ne muhimmin abubuwan da ke taka farawa a cikin amfani da faburika na mota?

Abubuwan da ke taka farawa suna muhimmiyar rawa wajen kara shekaru na amfani da kayan mota, kama biyanin girma na zaman kansa, da kuma kiyaye ingancin mota.

Wanne ne alhali na tests na accelerated aging?

Tests na accelerated aging suka taimaka wajen nuna durawar abubuwan a kai tsaye a lokaci mai kurudansa, wanda ya ba da damar ganin ingancin su baya lafiya.

Teburin Abubuwan Ciki

- Fahimtar Gudummawar Gudu da Duniya a Kan Abubuwan Otomat

- Kimakon Ginya da Polymers mai kyau don Daidaitowa

- Abubuwan da Ba za a sarre ba: Filin Galvanized, Aluminum, da Alkwayoyin Mai Zurfi

- Takardawa Masa waje, Kusurin Kuɗi, da Ingancin Abubuwa a Cikin Zaɓi Na Abubuwan Mafurufuru

-

Mafuta na Testa Dacewa da Hanyoyin Girma Wasso ga Kayan Oto

- Shawara kan mafuta mai aiki na dacewa da testa na kayan dabbobi

- Gwajin nahawa: Fasashen makwabta, kayan cire, da abubuwan da za’a iya warwurta

- Wasan kumama na accelerated da dabarren su ne a cikin aiki na duniya mai kyau

- Amsawa ga furuci: Testa sosai vs. abubuwan da ke da mahimmanci

- Kontin Karin Kwamitawa da Kiyaye Hanyoyin Girma don Kama da Tsawon Ayyukan Abubuwa

-

Tambayoyi Masu Yawan Faruwa

- Wane shahenshahi ne mai muhimmanci ga mechanical stress testing don abubuwan zurfi na otomobil?

- Yaya kayan aikin sama kamar UV exposure ke iya tasowa kayan zurfi na otomobil?

- Wanne ne role ga strain gauges na IoT a cikin amfani da faburika na mota?

- Wanne ne muhimmin abubuwan da ke taka farawa a cikin amfani da faburika na mota?

- Wanne ne alhali na tests na accelerated aging?