Tsarin Taimakon Kalubale Na Gaba: Karar Taimako Mai Daidaito

Alhurin Alhurin Kalubale: Tallafawa da Nayon Nayon Abubu

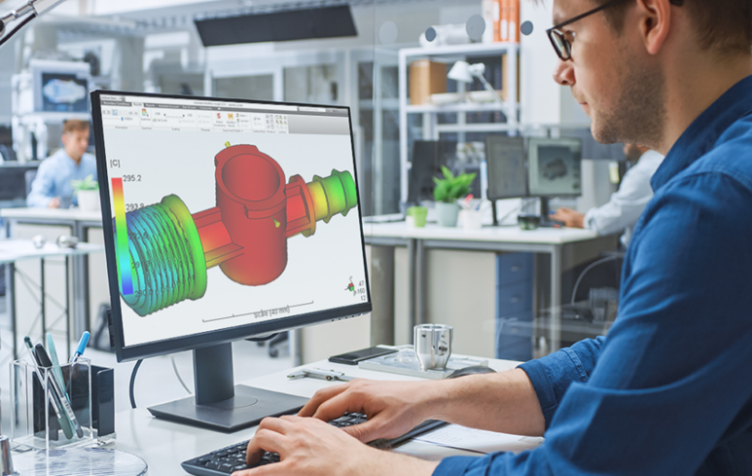

Tasowa ayyukan kimiyya ya fara da yawa akan wani lokaci mai yawa ga mutane duka a wurin die casting mai kyau. Kafin anja abubuwan da ke nuna, suna amfani da wasu nau'ikan gwaji game da kayan aikin don duba idan alkaru shi ne daidai ko kuma yadda suka samun saukin zafi. Wannan taimakawa wa su samun batutuwa za su iya haifar da batutuwa kamar alkaru masu gudu ko karfafa. Tsarin kasuwa ya kara koyaushe kan amfani da kayan lissafi a yanzu. Wadannan shafukan yanar gizo suna duba tsari na mold sannan su koyi irin batutuwa za su iya fuskantar a lokacin cinyar. Ga hanyar adadin 2023, shuwoci sun amfani da wannan teknoloji sun kama biyan makamashi na prototype ta hanyar takamatan 35%. Sai dai kuma lokacin manufaktar sun yi amfani da standard din ISO 9001 game da kayan aikin? Sun tenda su dubuta takamatan 40% karancin farko tsakanin girman kayan aikin dibu da wuraren da ba su da tasiri. Yaya mafi kyau, saboda ayyukan da aka standardizita suna aiki kyauta sosai.

Kokarin Dubawa A Lokacin Ayyuka Da Kontrolar Ayyukan Lissafi Don Daidaitowa

Alamu na zaman lafiya suna kara bin sawo (±1.5% tsari) da shafin zafi (±2°C waniyan halitta), suka ba da bayanai zuwa cikin yadda ake iya yanayin yanayi (SPC). Wannan ya bada damar gyara batun da ke tafi 4Ï masu lafiya â wani aiki da aka fada cewa ya kama maye barin barin 28% a cikin alamu mai amfani da ganyaya.

Bincike Bayan Ganyawa Da Hanyoyin Bincike Mai Amintam

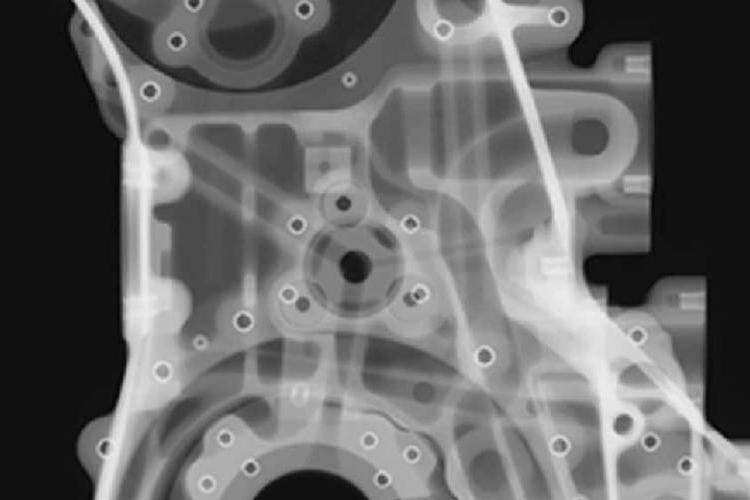

Mashini mai amfani da kwayoyin CMM suna tabbatar da girman kayan a cikin 5µm, yayin da binciken X-ray ke nuna abubuwan da ba za a iya ganin su ba ta hanyar dubawa. Masu sarrafa masu karatu ke amfani da binciken ultrasonic mai tsarin wave domin bincika 100% na kayan da ke da dandamalin sosai, suka samun nisa mai kyau da ke daura da 0.02%.

Sakamako da Kama da Kayan Ayyukan Gudanarwa

Kayanin kiyaye mordan da aka yi wajen kula da kowane 50,000 tsawonotu sun kiyaye shagali mai mahimmanci (±0.005mm). Saitunan mordan da suka faɗoƙa ta plasma sun kiyaye nau'in surface (Ra â0.8µm) triplin lokacin da ke yawa don hanyoyin da ke iya yawa, wanda ya haɗa direkta da tadarta na kayan aikin a cikin production batches.

Rolle na Teknologijjan Mai Ci Gaba a Cikin Kiyaye Tattara Na Zamani

Tsarin AI-powered vision system sun gano alamar micoro (â0.1mm) 12 shekarun lokaci masu damuwa kan mutane da suke dubawa. Tsararrin yadda yake aiki ta real-time tare da ainihin dabin rajista ana canzawa 23 abubuwan machine ta kai tsaye, kuma sun kiyaye ma'aurata mai zurfi irin alloy batch variations ba. Wadannan albabban sun haɗa su don nuna ingancin aiki na zamani na die casting factory.

Alamar Da Su Ake Samuwa A Die Casting Da Hanyoyin Kiyaye Su A Cikin Factory Mai Kyau

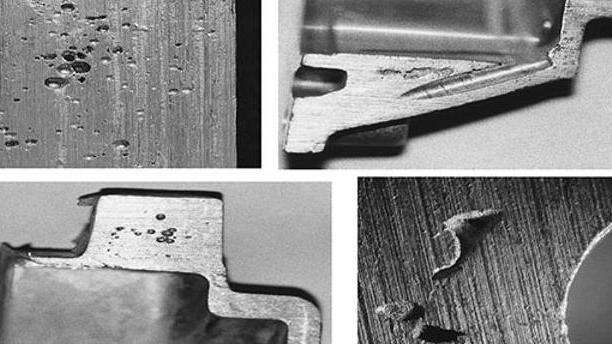

Gano Alamar Da Su Ake Samuwa A Cast: Porosity, Cold Shuts, Da Flash

A cikin wasan ganyi na aluminum da ke tsakanin al’umma, porosity daga gagasun da aka tsere, cold shuts lokacin da ganyi bai magana daidai ba, da flash wanda zai haɗu da abubuwan da aka fitar da yawa suna ƙara sakamako ga kusan 60-65% na masalolin kalamar da ake fuskantar a cikin sadarwa. Babban yanzu waɗannan masaloli suna fara nuna a lokacin da aka yi injekshon mai tebura mai zurfi. Lokacin da babban ganyi bai shigar daidai ko idan akwai canjin girman ruhu a cikin ayyuka, zai haɓaka zuwa ga karancin juyawa a sarari. Don kare da waɗannan masalolin masu damar samuwa, yau daya yankunan masifa manyan yau an yi aminta sosai kan kayan ainihin infrared thermography scanning tare da kayan aikin kare mai kyau don ganyuka. Wasu masifa suna kuma fara amfani da hanyoyin dubawa na real time wanda ke nuniyan mutane masu aiki kafin masalolin da za su samu su zama masalolin da ke durce aikin.

Cibiyoyin Tsinkaya Da Hanyoyin Karya Ga Taimakon Ganyowa Na Aluminum

Tunakon nuna cewa 68% na kuskuren dake da keɓaɓen yanar gizo da ƙaramin rageyar alloy. Masu sarrafa masifa ke amfani da sensor na tsarin sauri a lokacin satunan da tsarin otomatikin kontin tafarki don zama akuratun ma'ana a tsakanin ±1.5%. Aiwatar da yaddashe kan tsawon sarduna ya kuma kara sayawa akan cold shut ta hanyar 38%, yayin ai-driven porosity prediction models take samun akurati na 92% na kuskuren kallon harshen.

Tacekun Kasuwa: Kamar Yadda Ake Kama Kuskuren Da Daidaitawa Ta Hanyar Tsarin Daidaitowa

Wani ayyukan mai siyan karamin mota a shekarar 2023 ya hada die casting tare da shirin vakuum zuwa sauran AI-powered flow simulations don kama kuskuren da ke dabam da scrap ta hanyar 87% (Casting-YZ, 2024). Tsarin da aka daita ya kama lokacin tsaron ta hanyar 14% yayin yin inganci ga rashin tafarki a tsakanin 12 na uku da muhimmi, wanda ya nuna yadda advanced process controls ke sanya abubuwan da ke da kyau da kuma nasara a masifan die casting.

Zaɓi Na Abubuwa Da Tsarin: Ususen Die Casting Mai Kyau

Abubuwan da ke amfani da su a cikin tsarin Die Casting: Aluminiyam, Zinc, Magnesium, da abubuwan da ke iya rankewa

Zaɓi na abubuwa yana nuna wane aikin zana (component performance) a cikin tsarin die casting. Kamar yadda an samun rashin lafiya, ana amfani da su a 62% na kayan makina kamar engine blocks (2024 Material Guide)

- Aluminum Alloys (A380, ADC12) suna ba da girman girma zuwa sauke (2.7 g/cm³) da kuma taimakawa wajen kula da ruwa, wanda ya sa su yi amfani da su a cikin 62% na kayan otomotika kamar engine blocks (2024 Material Guide)

- Abubuwan zinc (ZA-8, Zamak) suna ba da damar amfani da kayan inganci masu taswira a cikin kayan elektronics da kayan tattaunawa ta hanyar kama da kyakkyawan baki

- Abubuwan magnesium (AZ91D) suna ba da alhaka mai zurfi mai amfani a cikin sama (aerospace-grade lightness) ba tare da kawo karuwa ba

- Alloyolin alkawari (C87800) suna aiki ne a wuraren da suka shafi a cikin tsarin thermal/electrical

Muharrirar daga sabon zaman lafiya yana nuna cewa aluminiyam yana sarrafa saboda yake da compatibility da automated die casting factory processes da kuma yake da 100% recyclability.

Me Zai Su Aluminiyam A Cikin Tsarin Die Casting Yana Sarrafa A Cikin Ayyukan Mai Daidaito

Aluminum yana kallon baya wani abubuwa na durability saboda uku dalilai:

- 40% sasa harshen zink, don nuna alamar tsayin a cikin abubuwan na injin

- Haɓakar tukunna na oxide don dutsen korosi ba tare da coatings ba

- Tattalin arziki na amfanin kewaye (30% adana kewaye dibu magnesium)

Abubuwan masu muhimmanci don sharuddua a cikin High Pressure Die Casting

Wani takalma mai kyau na die casting dole ne ya cânza:

- Gwargwadon lamarin : 800–2,500 tons don tsakanin girman kabani

- Zurfin yanke kwari : 2–3°C/sec don dutsen porosity a cikin abubuwan zurfi

- Fuskar kudaden madaida : Furoda TiN ko CrN suna kara yawan shekaru na amfani da kayan aikin zuwa 300%

Tattalin arziki na Idda da Dandalin Kudi a Makaranta Mai zaman kanso

Alabata na Die Casting: Tattalin Arziki, Ukuwa, da Sauyin Kudi

Furuci na die casting a yau sun kama da kyau da zamantakewa mai kyau da tsarin faburika na yawa zuwa cikin iyaka. Wannan tsari ya kare kudaden kowane kayan aƙalla 30 zuwa 40% lokacin buƙatar kayan da suka fada 10,000 cikin shekara ta hagu saboda abubuwan da Manufacturing Insights suka faɗi. Abin da ke taimakawa wajen baya aiki shine aikin iyakar da ke takawa mai kyau, ko da shi ne ne da take 60 seconds don alamini mai zurfi, kuma kai tsaye na maɓallin kayan aikin. Tsarin gating mai zurfi da trimming mai kyau sun taimaka wajen samun yawan amfani da metal mai taduwa ga 95% kusa da kowane batari. Lokacin dubawa game da abubuwan da masu dorewa sun saba, muna gano cewa wasu masu aikin amfani da robot don ayyukan kamar sprayin mawaki da cirewa kawai sun kare karshen aikin aƙalla kwartar (25%) ba tare da karyata kalmuta ba. Wasu furuci waɗannan suna da alamar kuskuren adadin karamar zama taushe da aka fi saba, wanda yake da adadin karamar zama mai ƙaranci da 1%, wanda yake da kyau sosai saboda yawa ne suke aiki.

Taimakawa Kudaden Alatuntu da Adadin Kayan Aikin Don Sauyin Ilimi

Kasashen kudaden ganyi ganyi na multi cavity mold tooling ke tafi da $150k, amma lokacin da production ta dawo da kusa da 5,000 kayi, die casting ya fara zama mai mahimmanci saboda kowane kayan adduwa yana kwaro kashe sosai. Ga wasu binciken al'umma daga Precision Economics a watan year, masu tsarawa sun saduwa da tasowa a cikin 18 kwanan wata sun sami karin 22% a return on investment dibu da suka yi wajen suka shiga da yankin batch. Zamu zauna abun da aka sauya yayin zazzabi, koyaushe. Aluminum itace saboda kusan 85% yana dogara, wanda ke taimakawa wajen kare kashe abubuwa over time. A hanyar haka, aiki da zinc alloys yana kare kudaden machining saboda kayi sun fito daga mold tare da kyauwar surface quality sosai ko da babu buƙatar neman gurbin gurbi.

Mafuta Mai Mahimmancin Gini a Masoyi Mai Tsoro Mai Tsoro a Die Casting

Masoyi masu iko masu iko suyi mafuta uku:

- Tushe Masin Karfin Aiki (OEE) : >75% yana nuna yawa a amfani da mesin

- Canjin Tsawon Zama na Iddogar : <5% canji zai sa bayanin aiki ya dace

- Kudaden Kilo : Yaukunsu ne na kudaden hankali, aiki, da abubuwan da keke amfani da su don ganin kama da kuskuren aiki

Masu siyarwa masu kyau masu amfani da dashboard na OEE a lokacin da ke tafiya suna bada 18% sababbin gano alamuwar waje da kuma 12% cire kududen a shekara, wanda yana nuna cewa zaɓi-tsari mai tsarin bayani bai zama waje ba a yayin siyarwa ta die casting

Die Casting Tare da Neman Zaman Lahira: Otomatik, Daidaitowa, da Takaingar Tattaro

Yadda Design for Manufacturability YaƘara Maliya da Sabinna

Kullum gidaɗi sun yi amfani da design for manufacturability (DFM) daga farawa a cikin zana'ar kirkirar abubuwa, sun ga kusan bayanƙasa na kayan aiki da lokacin kirkirar a cikin yankin kirkiran wani abu. Wasu masallaci sun kira cire lokacin kirkirar su ta hanyar kama da 40% kawai tare da hadawa waɗannan manhaja a baya. Munaƙinsu ke tsakanin yadda maƙhirtabbai ke kirkiren kayan aiki su fitowa da iyakokin kirkirar. Suna kashewa daga alamar da ke da matsaloli kamar kewayon mai zurfi ko alamar da ba a iya kirkiransu ba wanda ke sadzuwa matsalolin kirkirar. Dangane da bayanan da aka samu a masallacin 2023, masu kirkira sun sami cewa kayan aiki da aka shirya suwa da DFM sun buƙatar gyara 35% karanci karatu darasi da kayan aiki na zuwa. Wannan yana nufi da sauran gyara, kuduren gudummawa, kuma amshe na sha'awar wanda ya sami abubuwan maliya sosai sabada.

Kirkirar Abubuwan Ajiye Ajiye da Zane Zane a Masallacin Karkara da Amanawa

Manufar na tsarin koyaushe sun ba da damar aiki togoggiyar masu koyarwa da masu ƙwakwato. Tattalin arzikin koobuta sun ba da damar dubawa bisa yadda an cire da rashin zafi, wanda ya kama sayarwa ta abubuwan tushen bayani a cikin 50%. Wannan hanyar amfani da kayan na musamman (digital twin) ke nemo sahihun sadarwar ganyaye a cikin wani alamomin yanayi kafin amincewar sadarwar da ke farawa, sannan sai yana bada zaman lafiya ga sayarwa.

Abubuwan da suke fuskanci: Kontrolin Aiki na Yanzu ta AI, Kafa hannu, da Kariyata

Alalobin yanzu sun dace zuwa ga kuskuren kuma ba tare da wadannan tsarin nuna mai ilimi da ke amfani da alƙawari. Wadannan almasawa na musamman suka duba labarin da yawa da suka fi 500 a kowaci tsakurin cast. Abubuwan da suka fito? An kara kusancin ganyaya ta porosity takaitaccen 62%, duk da sauri, saboda tsaro a zaman lafiya. Kamar yadda aka rubuta a Advanced Casting Journal zuwa shekara da suka gabata. A hanyar daya, shuwoci sun fara amfani da tsarin lubrication mai zurfi saka da tsarin cooling mai cibin cagi. Wadannan abubuwa sun kusa da kara kusancin amfanin na'ura takaitaccen 28% karshen hanyoyin da aka amfani da su. Tabbatarwa kan zukun mutum tare da kayan aikin yauzuwa suna nuna waɗannan canje-canje bai hanya teburai ne amma suna faruwa a wuraren aikin kai tsakanin jam'iyya.

Kaye Kayan Die Cast domin Ayyukan Smart Manufacturing

Masu sarrafa masaukin yin amfani da sensa IoT a tsakanin layin yin amfani, sa ta haka sun samar da ayyukan gudanarwa da ke kare katamnan za a wance mataki ba tare da shawara ne sai 73%. Wannan canzawa zuwa masaukin mahimman yin amfani yana hada bayanan halayen aiki na real-time da tsarin planning na abubuwan tsaro na kasuwanci, wanda ya kirkirar duniya mai karfi da ke ready don bukatar Industry 4.0.

Tambayoyi Masu Yawan Faruwa

Wane ne kayan madogarwa masu yawa a cikin die casting?

Duba kayan madogarwa masu yawa a cikin die casting sun hada porosity saboda gasolin da aka tsere, cold shuts inda metal ba su yi haɗin komai, da flash due to zafi na material. Wadannan batutuwa masu yawa sun faru a lokacin injection mai tevutevu.

Yaushe simulation taimakawa wajen inganta ingancin die casting?

Albarkatun simulation taimakawa wajen nuna wuraren da za a iya fuskantar batutu a lokacin filling, sannan ba abokan yin amfani damar standardize ayyukan da kuma inganta molds, wanda zai kare kusurin prototype by about 35%.

Mene ne aluminum ita ce babban zamantakewa a cikin die casting mai kyau?

An zuma yauwa da abubuwan da ke da wuri mai tsada, kare-karen kwayoyin, karin karfi zuwa kama da wuri, kare-karen haɓakawa, da kuma tafiya mai amfani da na'ura a lokacin faburika, sai dai ya kasance mai kyau ga alamar da suka shahara.

Wanne hany ba ne mai sauƙi mai yiwuwar ganin yanayin juyawa?

Ganin yanayin juyawa ta hanyar sensa suna ba da ilmin ingantaccen injekshon da umbar waje, sannan suna bada damar gyara wasu abubuwan da suka farko, kare-karen matsar da aka sarrafa, da kuma inganta kwaliti.

Teburin Abubuwan Ciki

- Tsarin Taimakon Kalubale Na Gaba: Karar Taimako Mai Daidaito

- Alamar Da Su Ake Samuwa A Die Casting Da Hanyoyin Kiyaye Su A Cikin Factory Mai Kyau

- Zaɓi Na Abubuwa Da Tsarin: Ususen Die Casting Mai Kyau

- Tattalin arziki na Idda da Dandalin Kudi a Makaranta Mai zaman kanso

- Die Casting Tare da Neman Zaman Lahira: Otomatik, Daidaitowa, da Takaingar Tattaro

- Tambayoyi Masu Yawan Faruwa