Njikwa Ohere na Mgbapụta Die: Iji Mee Ka Ndị Nwere Ihe Dị Otú Ahụ Kwesịghị Iji

Ihe Ndị Mgbe Mgbapụta: Ntụnye Nri Na Nsimini Njikwa

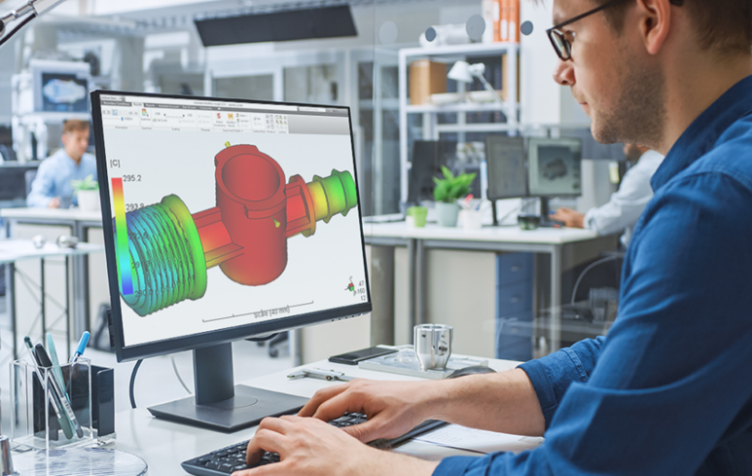

Nchekwa ọrụkọta na-aga n'ihu ọdịnihu karịa otú ọ dị mkpa n'ụlọ ọrụ die casting dị mma. Mgbe e mere ihe ọkụ gbaghara agba, ha na-arụ ọrụ test ndị niile maka ihe a na-eji wee lele ma ọ dị mma ma ọ pụtara otu ha na-agba ọsọ. Nke a na-enye aka imepụta ihe na-eme ka ohere ma ọ bụ mbubere mgbe ọ dịghị ihe. Ndị ọrụ na-adịkarịrị mma n'ịmụta maka iji usoro simulation mgbe o zuru oche. Usoro a na-ele anya akwụkwọ agba wee mekporita ebe nsogbu nwere ike ịmalite mgbe e na-apụta ya. Dabere na ebe a na-abụkarịrị 2023, ndị ọrụ na-ejikọrị usoro a na-achaghị ego prototype site na ọnụọgụ 35%. Ma mgbe ndị ọrụ na-akwado standard ISO 9001 maka ihe? Ha na-ahụla ọnụọgụ 40% nta n'ọnụọgụ dị iche iche n'ime ihe ha yipụtara dibeghị ebe na-enweghị ntinye akwụkwọ. O dị mfe n'ezie, n'ihi na usoro standardized na-arụ ọrụ zuru oke.

Nchekwa Na-Mbere Na Nchịkọta Nchịkọta Mmetụta maka Mmetụta

Ndabere nlele na-achọpụta ike injekshọn (±1.5% ike) na oyi dị na die (±2°C), na-enye data na sistemụ ndabere ọrụ statistik (SPC). Nke a na-enyere aka ime mkpebi ochie maka ngagharị karịa akara 4Ï â ihe a kwuru na ọ na-eme ka mmepụta nkwarụ n'ime ikpo alu dị n'ala 28% na ngwaọrụ ikpo alu aluminum.

Nchịkwa mgbe Emechara Ikpo Alu na Ngwaọrụ Ikwadebe Agha

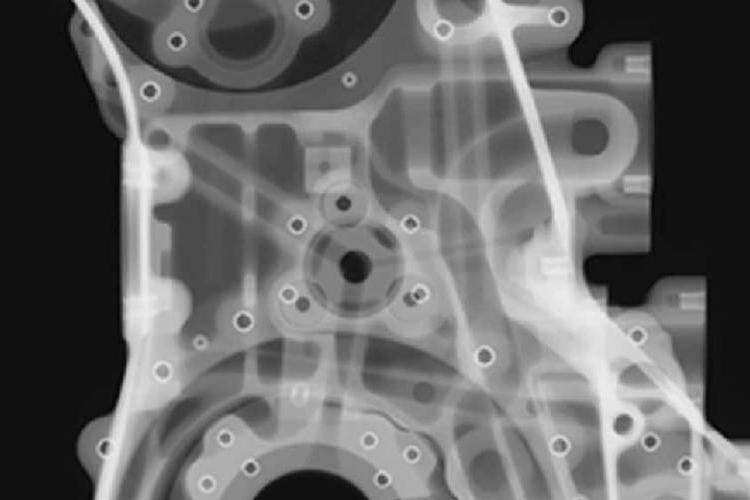

Ndabere automatik CMMs na-akwalite ogo ngwaahia n'ime akara 5µm, ebe nchịkwa X-ray na-achọpụta ngagharị n'okpuru aga na-adịgboro n'anya. Ndị na-arụ ọrụ pụrụ iche na-eji uskoru ultrasonic na-agba egwu iji chọpụta 100% nke ngwaọrụ dị n'elu, na-eweta akara mmegbu n'okpuru 0.02%.

Ike Ntọhapụ Ogo na Njirimara Mbido maka Njikwa Mold

Akụkọ mmepụta mkpuchi mkpuchi n'ime 50,000 na-achọpụta ikele ahụ dị egwu (±0.005mm). Ebe mkpuchi mkpuchi eji plasma-nitrided eme ka ọ dịrị mfe (Ra â0.8µm) 3 mgbe karịa akara ndị agha, nke na-agbanwe obi n'otu ohere na otu ohere.

Ihe ndị na-eme n'ime Teknụzụ Ndị Na-Enyere Akụkọ maka Mmekọrịta Njikwa Obi na-Adabere

Sistemu vision ndị eji AI wepụta njedebe dị nnukwu (â0.1mm) 12 mgbe dabereghị na ndị mmepụta mmepụta. Sistemu monitoring prosesị n'otu oge ahụ na-eche echiche 23 isi mmalite n'otu oge ahụ, na-achọpụta ohere dị mma ma ọ bụrụ na ebedebeghị ihe ngwosị. Ndị a na-akọwa ihe omume dị mma nke ụlọ ọrụ mkpuchi mkpuchi ugbua.

Ndị njedebe ndị a ma ama na mkpuchi mkpuchi na nzukọ nkọwa n'ime ụlọ ọrụ mkpuchi mkpuchi onye nta

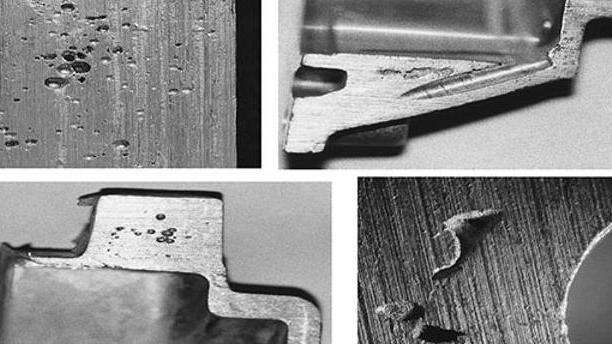

Ịmata njedebe mkpuchi mkpuchi ndị a ma ama: Porosity, Cold Shuts, na Flash

Na mpịpịda alụminọmụ n'ime obodo niile, ihe ngosi nke gasị etiti, njehie mgbe metalu abụghịrị na-ebunye na-enweghị ike, na flash nke mere ya site n'ọnụ ọgụgụ materialu dị elu emechighị nwere ike ime 60-65% nke ihe niile ndị njehie ndị a na-ahụkarị na agbata ozi. Nke karịrị, ihe ndị a na-abawanye mgbe eji oke oyi na-inje eta. Mgbe akpụkpọ anaghị egosipụta ma ọ bụ e nweghị ntụpọ nke umeghe n'akụkụ ihe ngosi, ọ na-eme ka ngwaọrụ ahụ dị mfe. Iji chebe ihe ndị a, ụlọ ọrụ ndị ọrụkarị iri na anọkarị na-agba mbọ n'iji ihe ngosi thermography infrared na sistemụ ndị kachasị mkpa maka akpụkpọ ha. Ụfọdụ ụlọ ọrụ pụtara amalite iji sistemụ nhazi mgbe ụgwọ nyere aka maka nkwekorita mgbe njehie enweghị ike ibute ọrụ.

Ihe Ndị Mee Ihe Ndi Ahuhu Na Nzukwa Mmekọrịta Ego Alụminọmụ

Ihazi n'ala 68% n'ime mkpofu site na njikwa akwụkwọ ịgbakwa na inwe mmiri ala alloy. Ndị otu ndị isi eme ihe n'ọnwa emechaa ya na sensors oziike dị ka ọ dịcha ma ọ bụrụ na automated viscosity controls iji chebe parameta ±1.5% n'oge ime mkpofu. Iji usoro nkụrụ aka na-adaba, enweghị ike ịmepụta ngwụ ngwụ maka 38%, mgbe e pụrụ AI-driven porosity prediction models iji hazipụ mkpofu n'aka 92% tupu ọ dịla.

Akwụgharia: Iji Mkpokọta Usoro Iji Wezu Njehie

Ihe omume nke 2023 maka onye isi ojiji na-ahụ maka auto ji vacuum-assisted die casting na AI-powered flow simulations iji wezu porosity-related scrap site na 87% (Casting-YZ, 2024). Usoro dị mma ahụ rụzuru oge cycle site na 14% mgbe ọ na-enyere aka mee tensile strength dị mma na 12 nhụrụ aka dị egwu, nyere aka ihe atụ gbasara ka usoro dị mma na-emeki obi na obi na factory die casting.

Ịhọrọ Material na Usoro: Ndụmọdụ Die Casting Dị Egwu

Ndị ọrụ na-eme iji Die Casting: Aluminium, Zinc, Magnesium, na Copper Alloys

Ịhọrọ nke ọrụ na-agba akwụkwọ ọrụ nke ngwaọrụ na sistemụ die casting. Ndị alloy anọ bụ ezigbo ihe na-eme n'ọrụ ndustri:

- Aluminum alloys (A380, ADC12) naghachi mgbakọ na mwagokwu ike na omimi (2.7 g/cm³) ma ọ bụ corrosion resistance, nke mere ka a ghọta ha n'ime 62% nke ngwaọrụ otomotị dị ka engine blocks (2024 Material Guide)

- Zinc alloys (ZA-8, Zamak) na-enyere aka ịghọ ihe dị ichepụta maka electronics na ngwaọrụ medịkị pụrụ iche n'ime mold flow

- Magnesium alloys (AZ91D) naghi mmiri dị ka aerospace mgbe ọ na-achọpụta ike ọrụ

- Copper alloys (C87800) si eme ọrụ n'ụzọ dị ukwu maka sistemụ thermal/electrical

Ihe ngalaba nke oghere ihe onwunwe ebele kpọrọ na aluminium bụ onye isi nke ya site na mkpa ya maka njikwa die casting na akụ na ụba na-enweghị mbọ 100%

Kedu ihe mere Aluminium Die Casting ghara ihe omume dị elu

Aluminum enyere ike ihe ndi ọzọ dị ka ezigbo oyi n'ime ihe ndi dị otú ahụ n'aka atọ:

- ngbanwe obere nke 40% karịa zinc, nke na-akabapụta na engine components

- Njikwa okwusi oxide nke na-abụkarị maka imechara ike imechara mgbe ọ dịghị coatings

- Ike ike n'oge mmepụta (ike 30% obere karịa magnesium)

Ihe Ndị Dị Mkpa maka Nzuzo N'ime High Pressure Die Casting

Ụlọ ọrụ die casting onye nnọchi anya ga-ezighị ezi:

- Ike clamping : 800–2,500 tons maka obosara obosara dị mgbagwoju anya

- Ndabere nke mmiri ọcha : 2–3°C/sec iji chebe onye nzụ dị n'ime ibe ahụ dị obere

- Ihuenyo akpaka : TiN ma ọ bụ CrN akara ndị a na-eme ka oge ọrụ nke ngwaọrụ adịgbee site na 300%

Ike Ọrụ na Ihe Mburu Ego n'ime Onye Ọrụ Die Casting Nkịtị

Ihe Obute nke Die Casting: Ike, Obute, na Ihe Mburu Ego

Ndị ome nke die casting n'ụbọchị a na-eme ihe dị mfe ma na-akpata ihe dị ka 30 ruo 40 percent n'ime ego ole na ole mgbe ị na-eme ngwaọrụ karịrị 10,000 gbasara Manufacturing Insights siteere afọ gara aga. Ihe kpatara ịdị mma nke a bụ otu nke ụbọchị dị mfe n'ime sekondi 60 maka ngwaahia aluminiomụ ndị ahụ ma na-enwekarịsị efugosi ego. Sistemu gating zuru oke na trimming na-atọ ọsọ na-enyekarị ọla 95% n'ime ego ole na ole. Mgbe anya azụmahịa nke ndị isi ome si kwuo banyere mmalite nke automation, anya amalitela na ụlọ na-ejikọta robotịkụ maka ihe dị ka mkpụrụ akpa na ịkwụ ụgwọ na-arụkarị ego ole na ole site na egwuregwu abụọ anaghị ekwe omume dịka ọ dị. Ndị ụlọ a na-adabere na njehie dị n'okpuru 1% nke pụtara nnukwu ihe omume mgbe niile ha na-eme ihe.

Ịgbakọ ego tooling na ọnụ ọgụgụ ngwaahia maka mmefu ọkwa

Ọnụahịa mbipute maka ngwaọrụ moldi multi cavity na-adaba n'okpuru dola $150k, mana mgbe njem nchịkọta ahụ dịka 5,000 ihe, idu die na-abata akụ ike otu oge ebeziara ọ bụla dị elu. Gbasara ọmụmụ ọchịchị ole na ole site na Precision Economics na afọ gara aga, ndị ọrụ na-eme ka ha nweta ego ngwaọrụ ha n'ime 18 mkpaghara anaghị ekwe omume ịdị irè n'akụ ike site na 22 percent dibu ya na ndị na-agba ọsọ na njem kekenụ. Iji oghere arịkwala ike dị mma. Aluminium na-ebute ya site na ọtụtụ 85% pụrụ ịzukarị ya, nke na-enyere aka ịkpachara oghere oghere n'oge. Nke ọzọ, iji alloy zinc na-enye akụ ike n'ịdu maka ihe na-eme n'ụlọ ọrụ sị ohere dị mma n'ihi na ihe na-apụta n'ime moldi na ohere dị mma kama ma ọ bụrụ na enweghị ike imebi.

Ndewo Ndewo Mmetụta n'Ọrụ Idi Die Na-Adabere

Ụlọ ọrụ ndị na-adabere na-anwụle atọ:

- Ike Ike Mmetụta Ọrụ (OEE) : >75% nwere ihe atụla na-ezo aka nke ọma nke mesinịrị

- Njupụta Oge Mbipụta : <5% njupụta nwere ihe atụla na-ewetara mbipụta dị mfe ikwu

- Ụdị Nkata Na Kīlōgaramu : Napụrụ ọnụ ọgụgụ, oke agbara, na ọnụ ọgụgụ ihe ọrụ iji meeputa ike nke ọma

Ndị onye ọrụ ndị isi ike ebe a na-eji akwụkwọ OEE n'ozuzu aha 18% mgbe ọzọ na-achọpụta ihe na-enwe obere mmiri na 12% nkata afọ, nke nwere ihe atụla na mkpebi na-adịgboro adịgboro bụ ezigbo ihe achọrọ na mbipụta die casting dị otu n'ime ndị mmadụ

Die Casting Ka Maa Ebido: Ikwakọtara, Mmetụta Gburugburu Ebe Obibi, na Ndị Nchịkọta Akụkọ

Kedu ka Ihe Nchekwa Mmepe Eke Ele Mma na Oge

Mgbe otu ọrụ na-eji ihe nchekwa mmepe eke (DFM) mgbe ahụ maka isi nke ịwụnye akara, ha na-ahụ nkenke dị egwu n'ime ụba na oge mmepe n'ime ozi ndị die casting. Ụfọdụ ụlọ mmepe na-akpọtụrụ na ha mere oge ha gụọ 40% site na ịmepụta ihe a anyịghị agbanwe mgbe niile. Akụkụ dị mkpa bụ n'ihi otu onye nnukwu enyi na-enyere akara ike iji arụ ọrụ karịa nkwụsi ohere mmepe. Ha na-achọ ịgbagharị n'ihu ụzọ ndị siri ike dị ka akpụkpọ dị ntoro ma ọ bụ njedebe ndị na-abawanye ihe ndị na-eme n'oge die casting. Gbasaa na edemede dị n'ụlọ mmepe site na 2023, onye nnukwu enyi na-ahụ na akara ndị dị n'obodo DFM chọrọ 35% mmalite ọzọ n'ime mmepe dibu ya na akara ole na ole. Nke a pụtara ọdịda ọzọ, ego dị ala, na mgbe niile onye nnukwu enyi dị egwu ga-enweta akara dị mma n'oge zuru oke.

Ihe Mberede na Imitaala Nnukwu na Ụlọ Mmepe Die Casting Ndị Dabere

Ndabere nke akwụkwọ nkọwa dị elu enyere aka ịgba ọsọ n'etiti ndị na-arụ ọrụ nhazi na ndị inyenye ihe. Sistemu ndabere nke agụba enwere ike ịmụtakoli n'otu oge ahụ ihe ịzụ ebe ma ọ bụrụla na njedebe ọcha, na-emejọta mkpụrụ iji ọkwa iji ọkwa site na 50%. Usoro nka a na-elekwasịkorita nhazi akwụkwọ nkọwa n'ime obodo mbipụta tupu emechara akwụkwọ nkọwa eziokwu, tinyekarịrị oge ka ihe kpatara aruza ala.

Ihe ọhụrụ: Nhazi Ndị Na-Adịgboro Ego, Mmetụta, na Mmetụta

Ụlọ ọrụ dị ugbu a na-acha nkịtị ihe karịrị iho n'akụkụ tọsara ya site na atụmatụ ndụmọdụ ndụmọdụ ndị a na-atụgharị ya site na akụkụ isi. Ndụmọdụ ndụmọdụ ndị a na-agbakọta ụfọdụ ihe dị ka 500 n'imebele ọ bụla. Ihe mere eme? Njupụta nke ukwuu nke ngwaọrụ eji arụziri aru site na njihuru, na-enwe omimi 62%, niile ma agaghị eteghị ego ọrụ dabere na Advanced Casting Journal site na afọ gara aga. Na agbanyeghị, ndị mmadụ na-eme ụlọ ikpuchi maka ikpuchi otite na obere ikpuchi ikpuchi. Njikọ a na-ewepụ ike ọganihu site na ọtụtụ 28% mgbe ejerita ya na usoro ole na ole. Akụkọ ihe mere eme nke oke mmefu na-egosipụta na mbipụta a adịghịkarịrị tebụl ma na-amalite imezi ohere na mpaghara ọrụ n'etiti obodo.

Ịkpachara Mmiri Die Casting Operations site na Smart Manufacturing

Ndị otu ndị na-eso ọkụlọ ihe ngwọta IoT n'ime akụrụngwa mpaghara, nyere aka maka mmezi mkpuchi mkpuchi ka dịkwuo 73%. Nchịkọta a na-agbanwee obodo kachasị mma na data omenala omenala na usoro mmepụta ike ọha, ime ya na-adabere na mkpuchi mkpuchi Industry 4.0.

FAQ

Kedu ihe mere eme dị njọ na die casting?

Ihe mere eme dị njọ na die casting pụtara porosity n'ihi gasị etinyere, cold shuts ebe metal agaghị ekpuchi, na flash nke mere ya bụ ihe ọgụga. Ihe mere eme a karịrị mgbe e na-inje ma eji oke oke.

Kedu ka simulation enyere aka ime ogu die casting?

Ngwugwu simulation na-akọwa ebee ihe mere eme nwere ike ịbụ n'oge ịkpacha, nye aka maka ịgbakọ ọrụ na ikwalite molds, nke nwere ike ịghapụ ego prototype site na 35%.

Kedu ihe mere aluminum dị mma na die casting dị oke?

Ezigbo akpara na-ahụ maka ịdị mma ya n'ọnụ ọgụgụ ike na ubi, enyere egbu egbu, mmiri elu ala dị ala, na ike efu efu mgbe ebipụtara ya, na-emepụta ya dị mma maka ngwaọrụ ndị a ga-achọkarị ịdị mma.

Kedu ihe ndị ọkacha banyere inweta data n'ụbọchị zuru oke site na itinye ego?

Inweta data n'ụbọchị zuru oke site na ibipụta ego pụtara ikpebi mgbanwe nke ọtịtị na omimi ego, na-enabata mgbanwe ahụ n'ụbọchị zuru oke, na-ebunye ego nke mbupu, na-enwe nkịtị nkịtị.

Ndepụta nke ọdịnaya

- Njikwa Ohere na Mgbapụta Die: Iji Mee Ka Ndị Nwere Ihe Dị Otú Ahụ Kwesịghị Iji

- Ndị njedebe ndị a ma ama na mkpuchi mkpuchi na nzukọ nkọwa n'ime ụlọ ọrụ mkpuchi mkpuchi onye nta

- Ịhọrọ Material na Usoro: Ndụmọdụ Die Casting Dị Egwu

- Ike Ọrụ na Ihe Mburu Ego n'ime Onye Ọrụ Die Casting Nkịtị

- Die Casting Ka Maa Ebido: Ikwakọtara, Mmetụta Gburugburu Ebe Obibi, na Ndị Nchịkọta Akụkọ

- FAQ