Igosi Ndịdozi Mmadụ maka Mkpebi Alloy Dị Mma

Ịhọrọ alloy dị mma na-abịa site na njikwa zuru oke nke ihe ndekọ gị. Gbasara rapọt nke MetalTek International manufacturing afọ 2024, 84% nke nzaghachi die casting dabere na mkpebi nke ihe aghaala. Gbanwee isi ngosipụta ezigbo mgbe:

- Njikota nke mechanical stress dịka ihe na-enweghị ego

- Corrosion Resistance n'ime oke mkpụrụ osimiri ma ọ bụ ebe na-eji kemịkal

- Mmezi ume maka nweta ụtụ n'ime ihe na-enweghị ike

Ndinaya nke na-agba ọsọ na ọgụgụ mmekọrịta—na-enye ike ihe na-anwetaghị ahụ—nwere ike ịghapụ ọnụ ego nke merebita site na 40%.

Ihe Karia Kwesịrị Eme Ka Otu: Aluminium, Zinc, Magnesium, Na Ihe Nkwesịrị Ya

| Materila | Ike ọgwụ (Mpa) | Mkpilo (g/cm³) | Ihe Obodo |

|---|---|---|---|

| Aluminium | 220–310 | 2.7 | Obara elu, na-egbu egbu |

| Zink | 280–440 | 6.6–7.1 | Obara elu dị elu, mkpuchi mkpuchi pere mpe |

| Magnesium | 160–240 | 1.8 | Mkpanaka obi na obara |

Ezigbo emechara nke ahụrụ 70% nke ihe ngagọ die casting (Nkọwa PwC maka 2023), dabere na mmetụta ya. Magnesium na-acha ohere na aerospace na njikwa auto ebe njikwa nta bụ ihe pụrụ icheta.

Ezigbo vs. Zinc Die Casting: Ikwado Alloys na Azịza Ndị Achọrọ

Alloys ezigbo dị ka A380 na ADC12 dị mma maka ihe ndị atụ dị elu nke chọrọ ikpuchi obibi — ụtọ dị ka LED housings na engine brackets. N'otu oge ahụ, alloys zinc (ZA-8, ZAMAK) dị mma mgbe:

- Njikọta ogo na ±0.1mm pụrụ ịdị

- Ikwesịrị ikwesị maka electroplating

- Ọ dị mkpa ịdị nke ọkụkọ

A 2023 nkà akụrụngwa banyere sensor housings maka auto ekpela zinc nyere 92% isi na-adịgboro , na-eme mgbe e mere ya karịa 84% nke aluminum n'akụkụ iwu porosity dị ala.

Ịdị ndị na-amalite na Mmekọrịta ahụ na Mmekọrịta Otu

Na mpaghara oru, ndị alloy kwesịghị ime <2% nkeji corrosion na afọ , na-enye usoro nke aluminum-silicon aka ikpebi. maka ngwaọrụ e mesịpụtara na thermal cycling mgbe niile—dị ka EV battery trays—mgbe e mere ya Coefficient nke Thermal Expansion (CTE) nke magnesium bụ 26 µm/m°C nwere ike ịgbakwunye warping dibu ya karịa zinc 27.5 µm/m°C.

Dị ka akwadotara na ndekọ zuru oke maka ịhọrọ ihe, na-ebuchee ASTM/AISI standards na mmekọrịta ezi umunna, n'akaọcha mkpali duru na mmetụta na afọ iri.

Gbalịarị Die Design Capabilities na Tooling Quality

Die Design dị ka Akụkụ Ndụ nke Part Consistency na Durability

Ndị na-arụ ọrụ die casting n'ọkè ọkè na-eji ihe ndekọ ekekọrịtara n'ime ihe sayensị, na-ahụ maka otú ụgbụa pụta gbasaa materials, ihe ga eme mgbe parts apụghị molds, na otú alloys dị iche dị iche gasị mgbe ha malite. Mbụ ịbubata tool steel, ndị inyenyi na-agbakwunye simulations site na parametric modeling software nke na-akpọkarị 1,200 mmalite nhazi. Nke a na-enyere aka ịmepụta components nwere ike ịdọrọ ọnọdụ dị ka +0.1 millimeter. Mgbe ị na-achọ ịkpachara dies n'ọrụ, mgbanwe stress dị mma bụ ihe kachasị mkpa. Tool steels nwere chromium dị elu bụla dị mma maka ịkpachara akara, ịdọrọ ọnọdụ dị ka 0.05 mm ebe ọ bụla mgbe ị na-acha n'ime ihe nhata karịrị n'ime ngwaọrụ automotive nke precision dị mma.

Ọrụ Njikwa, Mmekọrịta, na Ndụmọta Engineering Njikwara

Nkwado ọzọ na-eme ka ndị onye nchịsị dị mma sịrị ndị ọrụ. Ndị na-agba ọsọ na-arịọta akụrụngwa ASM International zuru oke iji chekwaa ngwaọrụ site na 18 ruo 24 mbụ, karịa otu n'ime ndị na-ejikọtakarị. Nke a bụ ihe kachasị mkpa:

- Nkwado ọzọ: nche 15-point laser alignment gara n'ihu na-enyekarị maka 5,000 cycles

- Ihuenyo usoro: Coatings titanium nitride na-eme ka ọ nwụrụ 63% (Battelle 2023)

- Usoro mmepụta: Oke oma karịa crack propagation ≤0.02mm

Mkpa nke Mold Complexity na Production Efficiency na Cost

Multi-slide molds nwere 15 ma ọ bụ karịa ngwaahia na-enwe ezigbo ọnụ egosipụta ya site na 22–35% dibu design single-cavity. Mana, ngwaahia dị obere pụtara ọnụ egosipụta ya n'obi abụọ mgbe ọ dị elu karịa 250,000 units n'ihi na-enweghị njedebe ndị ọzọ. Gbalịa ịmata ihe ndị a:

| Factor | Obere pụta | Mmetụta Nta |

|---|---|---|

| Ngozi Ngwugwu Mbido | $120k–$450k | $30k–$90k |

| Oge Ikebe | 45–90 seconds | 18–30 seconds |

| Igwe Ogu Ogugu Dika Mma | >1 million units | <100k units |

In-House vs. Outsourced Tooling: Mmekọrịta Nnukwu Na Nkata Mmetụta

Dị ka 68% n'ime ndị isi mmekọrịta na-eji ngwaọrụ dị n'ụlọ, ụlọ ọmụrụ pụrụ ichebe na-enweghị ike ịnabata ngwaọrụ dị mkpa. Ihe dị iche iche:

- Ihe omume n'ime ụlọ: oge kacha obere site na 38%, mgbanwe omenala n'oge o mere

- Ihe omume n'ime ụlọ ọmụrụ: njide ozi site na 15–20% maka ngwaọrụ nwere ihe dị iche

- Onye nchikota: 53% n'ime ndị ọrụ ihe ọmụrụ bụ ebe a na-ejikọta usoro abụọ a (NADCA 2023)

Maa mee mma na ISO 9001:2015 na ike mesomgbakwunye robotịk maka njide akwara n'okpuru Ra 0.8µm.

Gbalịarị Mmetụta Mmetụta Na Teknụzụ Ọrụ

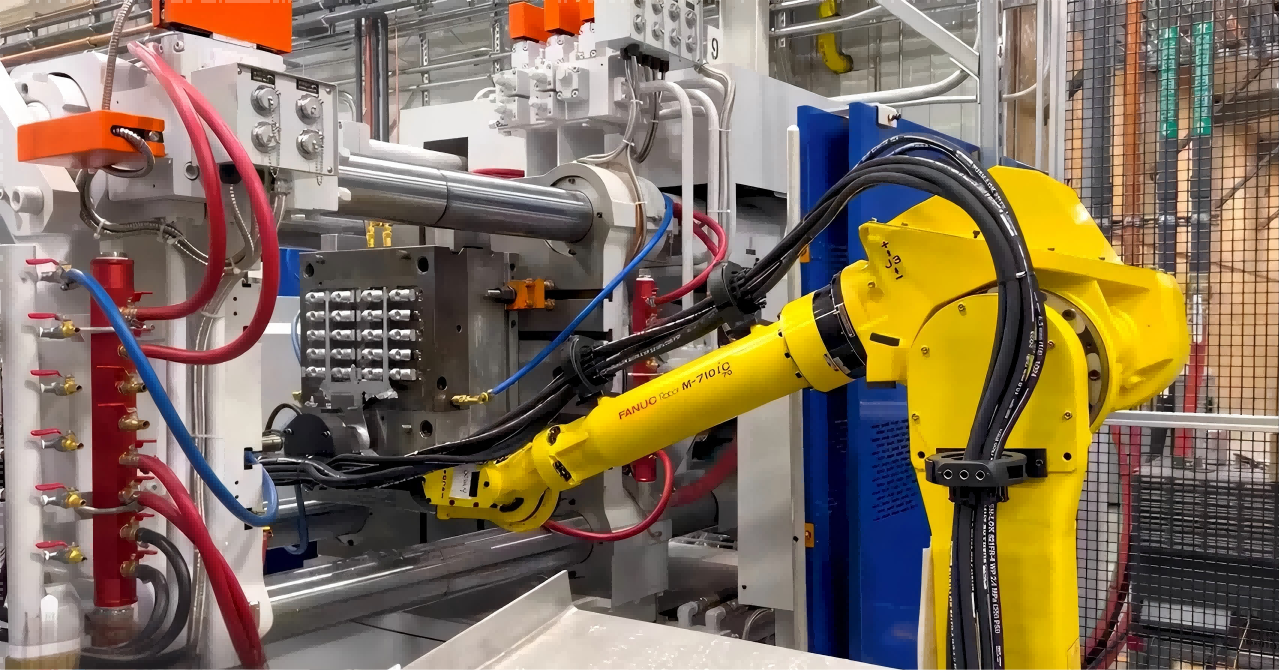

Sistemu Ikpebi Njikwa Ikwado Na Die Casting

Ebe obibi die casting dị elu enye sistemu ikpebi n'ime obere obere iji gbanwee otu oge injekshọn, obobo, na oke ịgbachara. Sistemu a na-akpali akpali ngwaọrụ dị ka ±0.05mm n'ime njikwa ngwa ngwa, nke dị mkpa na mmepụta ngwaọrụ ebe amụrụ. Njikwa n'oge ugbua site na 15–20 sensor na ngwaọrụ kewaa mpaghara, imecha ọ bụghị ihe dị mkpa.

Igbo Iji Obobo Oke vs. Cold-Chamber Die Casting: Hụrụ Usoro Kwesịrị Ebenye Site na Alloy

Alloy aluminum nwere karịa 10% silicon chọrọ mesin cold-chamber imefu 40–200 MPa iji chebe ịdị irè n'oge injekshọn. Zinc, nwere oke mmetụta nta, enyere usoro obobo karịa 500 MPa iji mee akpaka nwere oke nta karịa 1mm. Usoro kwesịrị ịbanye site na alloy anwụsịla dịdị mma ebe a:

| Ụdị Alloy | Oke Mmetụta | Usoro Kwesịrị | Ọkwa Obobo |

|---|---|---|---|

| Aluminium | 660°C | Cold-Chamber | 40–200 MPa |

| Zink | 419°C | Ọkụkọ Oke Oyi | 500–1400 MPa |

Ikwakọ na Njikwa Akụkụ Ugbu Na Mbipụta Mmiri Die Casting

Ụlọ ọrụ ndị pere mpe na-agbanwe njikwa ihe nchekwa automatized maka ịdịghị aka mmadụ site na 80% mgbe ebele ọgụgụ ihe ọkụkọ dị irè 99.7%. Sistemu ozi na-adaba n'ime infrared thermography na-achọpụta ihe ngochi dị n'ime, dị ka porosity n'ime sekọndụ abụọ - nke dị ukwuu ọsịa karịa njikwa onye ọrụ ndị a na-ejikarị ya n'akụkụ 15 minit. Njedebe nke techenology nyere aka ike ịdị otú ahụ iji mere 12–15% ihe ndị a na-enweghị afọ.

Lee Ndịm Ndịm na Ndịm Ndịm

Ịhazi ike ihe nchekwa site na njikwa ihe nchekwa

Ndịm ndịm ndịm dị mkpa iji cheba ihe ngochi ndị a ma ama dị ka porosity na cold shuts. Ndị ọrụ mbipụta ndị pere mpe na-eji statistical process control (SPC), nke 78% nke ụlọ ọrụ ISO 9001-certified na-azaghachi 30% ihe ngochi dị ala karịa ndị na-adịghị akara, dịka e kọrọ na nsonaazụ foundry management 2023.

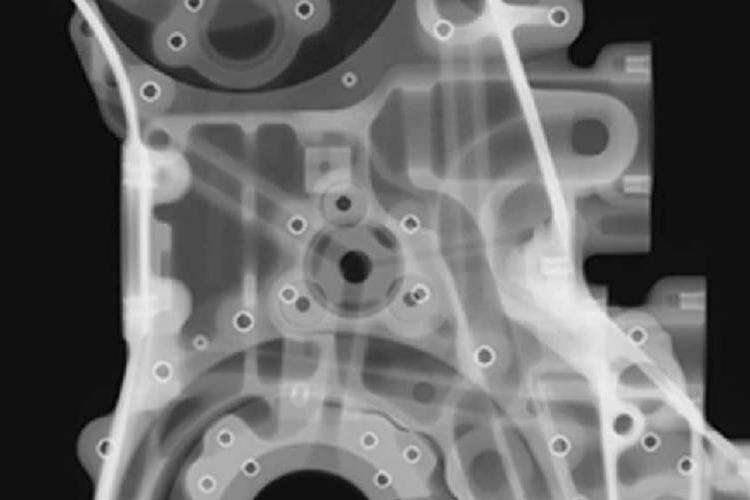

Ntụgharị n'ọghị ike (NDT), X-ray, na ọnọdụ mmemme CMM

Ịmeme mmemme ọhụrụ na-enwetaghị otu ụdị njikọ ozi:

- Ultrasonic NDT na-achọ mkpụmkpụ mmiri dị ka 0.5mm resolution

- X-ray tomography nwere ike ime ya aka gbasaa usoro dị iche iche n'ime obodo

- CMM arms nchọpụta akụkụ ±0.02mm dịka e kwadoro ya n'akụkụ 95%

Ndụ mmiri eji sistemụ CMM mechaa ọrụ, enweghị ọtụtụ 40% zuru oke maka nkwenye mbụ, dịka a kwadoro na ulo ọrụ 2024 maka ozi ome

Ihe ndị na-ezọ aka na akụkụ akpa na otu esi wepụ ya

Ikwesị maka njikọ nke omume na-achụ n'aka—imepụta oyi dị ka ±5°C napụghị warpage site na 62% na aluminum castings. Sistemu ikpochapụ automatized nyerebe 0.8–1.2µm ndepụta nrụpụta kwalite kwesị maka inwe ike imejụrụ ya ma wepụ mgbanwe akwụkwọ obere.

Igosi maka ngalaba akwụkwọ na mkpanaka (GD&T) usòrò

Igosi maka ASME Y14.5-2018 enweghị site na ntanye aka nke ihe dị mkpa:

| Factor | Ntanye | Mmetụ |

|---|---|---|

| Mold surface finish | Ra ≤ 0.4µm | Napụghị flashing site na 55% |

| Clamping force variance | ≤2% cycle-to-cycle | Mee ka ihe pụtara ịdị irè site na 37% |

| Njikọrịta ikwesu ụtụ | ±3°C/sec | Na-agbanwe ego ebele n'ime 29% |

Ibawanye njikota dị elu na iwu mmalite dịkịtịkịtị

Ịkpachara anya na-akpaghị aka enye ohere maka ịgbasa 100% n'ọnụọgụ 450 ngwaahịa per awa ma ọ bụrụ na ọ dabere na mmalite ±0.05mm—a mkpa a bụ isi okpukpe n'ime 68% nke ndị na-enweghị akwụkwọ na-aracha ngwaahịa ala.

Lee Nnukwu Onye Mee, Ndọrọ Ndọrọ Ochịchị, na Ikekwe Ọsọ

Ịmata nnukwu onye mechie nke ụlọ ọrụ aracha ngwaahịa ala n'ime obodo gị

Gbalịa ndị onye otu nwere ike basaa n'aka n'usoro gị pụrụ iche. Ndị na-enego ngwaahịa ala kwesịghị ịdị ndụ n'ịkpali mmalite dịkịtịkịtị (±0.05mm) maka ngwa ngwa ụlọ ọrụ, mgbe ndị na-enyere ngwaahịa elekereekọ ghaghị ịdị ndụ n'ịkpali magnesium maka inweta EMI. Kwalifikata ihe ndị a na-ekwu maka 95% ma ọ bụ karịa n'oge nyere site na edemede ndị akụziri ya na ngalaba njikota ngwaahịa.

Akwụkwọ ọrụ: Ngbanwe n'obi agbanwe agbanwe n'aracha ngwaahịa ala

Onye isi nchịkọta transmission housing nyere ike na porosity site 37% gafee afọ atọ site na ikpuchi na-adịgboro maka mmalite na ikperesosoro vacuum. Nke akwụkwọ mmasị otu esi onye nnwale ndị dị ichekarị iji ihe ngwọta mgbanwe aka iji mee mkpanaka ozi mbupu (≤12 RA µin) n'ime ugboro narị iri ise na agụ na afọ.

Ike ịgwakọ ọrụ na ike ịgbakọ maka akụkọ mbipute

Ụlọ ọrụ Tier-1 dị ọcha ziri ezi ike ịgbakọ karịa ugboro iri anọ na ogu abuo na otu afọ, nke ekekere ya site na mesịn dị 2500-ton die casting. Ndị onye nlekọta dị ike nweta elu igwe ọrụ nwere ike ịdịgbe site na 30% n'ime ụbọchị isii - ike dị mkpa nke a dabere na akụkọ mbipute nke ọnụ ahịa EV battery housing ruo 2030 (PwC Automotive Outlook).

Ndepụta dị mkpa: ISO, IATF, na ASTM compliance verification

Tinye ndị onye ntụaka nke nwere iwe omeziwara IATF 16949 maka ọrụ na-ala ugbo ala na AS9100 Rev D maka mmepụta egwuregwu. Ndị a na-akatamkpokwu sistemụ omeziwara nke pụtara parameta prosesị karịa 120—site na ikwenye purutii aluminium ADC12 (≤0.15% Fe) ruo imepụta obere obere obere obere (±3°C).

Obi ike ngwaahịa dị ka akụkọ ọzọ adịghị ekwe omume na mmepụta

Jiri azụmahịa SPC kọwaa njikọ njide (Cpk ≥1.67) na ikike ikike (≥310 MPa maka AZ91D magnesium). Ndị mmepụta pụrụ iche na-eji 3D scanning maka ikpebi ogologo niile na ngwaọrụ ezigbo ezigbo, dị ka steering knuckles na brake caliper brackets.

Ihe ọbara, ihe mgbakwansi, na ihe ọbara n'ụbọchị iri

Jụọ ụdị mmefu akwụkwọ nke na-enye ihe ọjọlụ maka alụmịnịmụ na zink dịka ebeere n'akụkụ iri afọ. Ndị ọrụ na-enyere aka nke ọ bụla ọzụzụ 92% ma ọ bụ karịa nke na-enye ohere elu karịa n'ọnwa mbụ, site na ngbanwe ihe ọjọlụ, naanị n'ọnwa mbụ—na-eme ka mkpuchi mmezi bụ ihe kachasị mkpa maka ihe ọjọlụ ndị na-adaba karịa otu megatọn.

Ndị Mmeri Ndebi

Kedu ihe ndị dị mkpa maka ịhọrọ alloy maka die casting?

Ihe ndị dị mkpa pụtara nsogbu mekaniikịl, ike ịgbadụ, na ike ime obere nha, na-agbanyeghị na azịza nke ngwaahịa.

Kedu ihe ndị a na-eji karịsịa na die casting, ma gbasaa?

Ihe ndị a na-eji karịsịa pụtara alụmịnium maka ihe ọbara ya na ike ịgbadụ, zink maka ihe ọbara zuru oke na njikọta ihe dị mfe, na magnesium maka ike zuru oke na ihe ọbara.

Kedu ka ose ahụ mmụọ na-egosipụta ịhọrọ ihe?

Na obodo ndị dị ka obodo ọchịchịrị, n'ime obodo ndị ezipụta obodo na-eme ike, otu n'ime ihe ngosi dị ala dị ka aluminum-silicon blends bụ isi okwu. Na njikọtara nke dị n'akụkụ maka magnesium nke dị ala n'ime mkpụrụ mmiri, magnesium bụ onye ocha nke dị ala n'ime mkpụrụ mmiri.

Ndepụta nke ọdịnaya

- Igosi Ndịdozi Mmadụ maka Mkpebi Alloy Dị Mma

- Ihe Karia Kwesịrị Eme Ka Otu: Aluminium, Zinc, Magnesium, Na Ihe Nkwesịrị Ya

- Ezigbo vs. Zinc Die Casting: Ikwado Alloys na Azịza Ndị Achọrọ

- Ịdị ndị na-amalite na Mmekọrịta ahụ na Mmekọrịta Otu

- Gbalịarị Die Design Capabilities na Tooling Quality

- Gbalịarị Mmetụta Mmetụta Na Teknụzụ Ọrụ

- Lee Ndịm Ndịm na Ndịm Ndịm

-

Lee Nnukwu Onye Mee, Ndọrọ Ndọrọ Ochịchị, na Ikekwe Ọsọ

- Ịmata nnukwu onye mechie nke ụlọ ọrụ aracha ngwaahịa ala n'ime obodo gị

- Akwụkwọ ọrụ: Ngbanwe n'obi agbanwe agbanwe n'aracha ngwaahịa ala

- Ike ịgwakọ ọrụ na ike ịgbakọ maka akụkọ mbipute

- Ndepụta dị mkpa: ISO, IATF, na ASTM compliance verification

- Obi ike ngwaahịa dị ka akụkọ ọzọ adịghị ekwe omume na mmepụta

- Ihe ọbara, ihe mgbakwansi, na ihe ọbara n'ụbọchị iri

- Ndị Mmeri Ndebi