Understanding Product Performance Requirements for Optimal Alloy Choice

Selecting the right alloy starts with a clear analysis of your component’s functional demands. According to a 2024 MetalTek International manufacturing report, 84% of die casting defects arise from mismatched material choices. Establish key priorities early:

- Mechanical stress tolerance for load-bearing components

- Corrosion resistance in aggressive environments like marine or chemical settings

- Thermal conductivity for heat dissipation in sensitive assemblies

Manufacturers that engage in collaborative discovery processes—aligning alloy properties with operational needs—can reduce rework costs by up to 40%.

Suitable Materials for Die Casting: Aluminum, Zinc, Magnesium, and Their Properties

| Material | Tensile Strength (MPa) | Density (g/cm³) | Key Benefits |

|---|---|---|---|

| Aluminum | 220–310 | 2.7 | Lightweight, corrosion-resistant |

| Zinc | 280–440 | 6.6–7.1 | High ductility, excellent detail reproduction |

| Magnesium | 160–240 | 1.8 | Best strength-to-weight ratio |

Aluminum is used in 70% of die casting projects (PwC Manufacturing Report 2023), thanks to its versatility. Magnesium is gaining traction in aerospace and automotive applications where lightweighting is critical.

Aluminum vs. Zinc Die Casting: Matching Alloys to Application Demands

Aluminum alloys such as A380 and ADC12 are ideal for thin-walled parts requiring thermal management—examples include LED housings and engine brackets. In contrast, zinc alloys (ZA-8, ZAMAK) excel when:

- Dimensional stability within ±0.1mm is required

- Electroplating compatibility is essential

- High impact resistance is needed

A 2023 field study on automotive sensor housings showed zinc achieved a 92% first-pass yield, outperforming aluminum’s 84% due to lower porosity rates.

Matching Material Selection to Environmental and Mechanical Conditions

In coastal environments, alloys must exhibit <2% annual corrosion rates, making aluminum-silicon blends a preferred choice. For components exposed to repeated thermal cycling—such as EV battery trays—magnesium’s coefficient of thermal expansion (CTE) of 26 µm/m°C offers reduced warping compared to zinc’s 27.5 µm/m°C.

As outlined in comprehensive material selection guidelines, balancing ASTM/AISI standards with real-world conditions ensures long-term durability and performance over a decade of service.

Assess Die Design Capabilities and Tooling Quality

Die Design as the Foundation of Part Consistency and Durability

Top tier die casting operations rely on designs backed by science, taking into consideration how heat moves through materials, what happens when parts are ejected from molds, and how different alloys contract as they cool. Before cutting actual tool steel, engineers run simulations through parametric modeling software covering well over 1,200 potential production runs. This helps make sure finished components stay within tight tolerances of plus or minus 0.1 millimeter. When it comes to keeping dies working longer, proper stress management makes all the difference. High chromium content tool steels are particularly good at holding shape, staying accurate to within 0.05 mm even after half a million cycles in tough automotive manufacturing environments where precision matters most.

Tooling Lifespan, Maintenance, and Precision Engineering Standards

Proactive maintenance separates top-tier suppliers from average performers. Facilities following ASM International’s die maintenance guidelines achieve tooling lifespans of 18–24 months, nearly double those of non-compliant operations. Critical practices include:

- Preventive maintenance: 15-point laser alignment checks every 5,000 cycles

- Surface treatments: Titanium nitride coatings reduce wear by 63% (Battelle 2023)

- Repair standards: Maximum allowable crack propagation ≤0.02mm

Impact of Mold Complexity on Production Efficiency and Cost

Multi-slide molds with 15+ components increase per-part costs by 22–35% versus single-cavity designs. However, complex tooling becomes cost-effective at volumes above 250,000 units due to fewer secondary operations. Consider the trade-offs:

| Factor | High Complexity | Low Complexity |

|---|---|---|

| Initial Tool Cost | $120k–$450k | $30k–$90k |

| Cycle Time | 45–90 seconds | 18–30 seconds |

| Ideal Production Run | >1 million units | <100k units |

In-House vs. Outsourced Tooling: Evaluating Control and Quality Trade-Offs

While 68% of Tier 1 suppliers operate proprietary tool rooms, smaller foundries often outsource complex tooling. Key differences:

- In-house advantages: 38% shorter lead times, immediate process adjustments

- Outsourced benefits: 15–20% cost savings on exotic material tooling

- Hybrid approach: 53% of manufacturers now combine both models (NADCA 2023)

Always confirm ISO 9001:2015 certification and robotic polishing capabilities for surface finishes below Ra 0.8µm.

Analyze Process Control and Production Technology

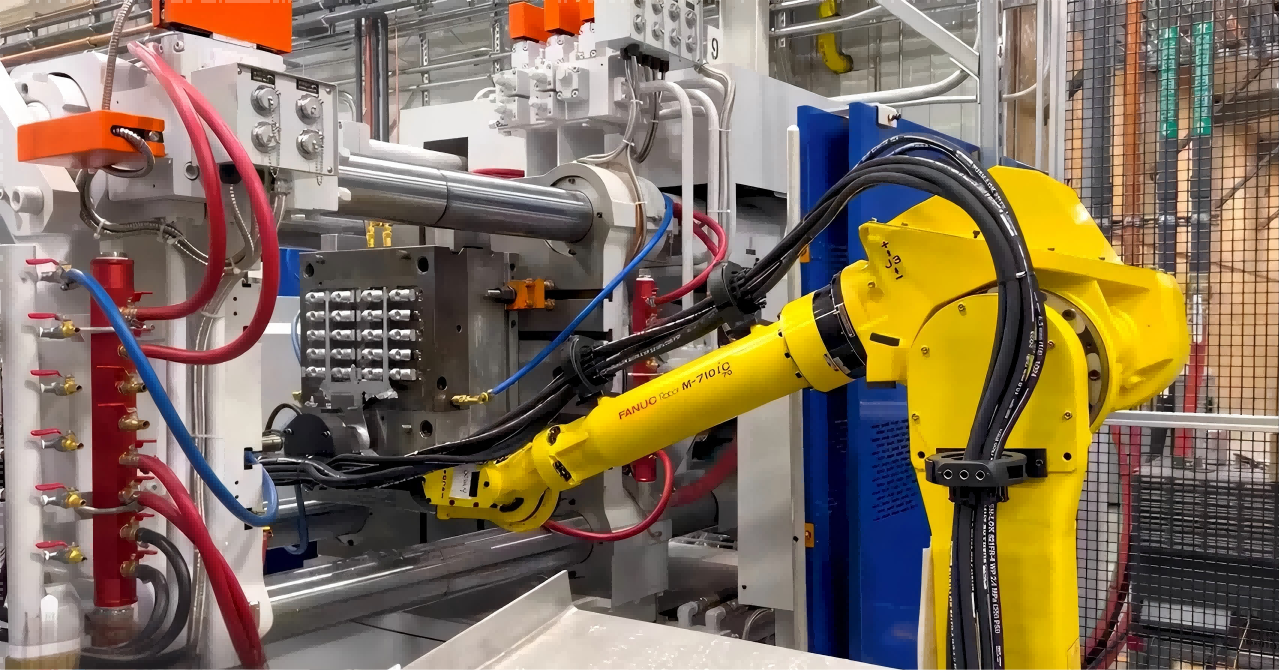

Process Control Systems Ensuring Repeatability in Die Casting

Advanced die casting facilities use closed-loop control systems that dynamically adjust injection speed, pressure, and cooling rates. These systems maintain dimensional consistency within ±0.05mm across large production runs, particularly vital in automotive manufacturing. Real-time monitoring via 15–20 sensors per machine enables instant correction of deviations, preventing non-conforming output.

High-Pressure vs. Cold-Chamber Die Casting: Selecting the Right Method by Alloy

Aluminum alloys with more than 10% silicon content require cold-chamber machines operating at 40–200 MPa to avoid premature solidification during injection. Zinc, with its lower melting point, uses high-pressure systems exceeding 500 MPa to produce walls under 1mm thick. The optimal method by alloy is summarized below:

| Alloy Type | Melting Point | Recommended Method | Pressure Range |

|---|---|---|---|

| Aluminum | 660°C | Cold-Chamber | 40–200 MPa |

| Zinc | 419°C | High-Pressure | 500–1400 MPa |

Automation and Real-Time Monitoring in Modern Die Casting Operations

Top-tier factories integrate automated process controls that cut human intervention by 80% while sustaining 99.7% equipment uptime. Vision systems combined with infrared thermography detect internal defects like porosity in under two seconds—significantly faster than traditional 15-minute manual inspections. This technological shift allows identical energy inputs to generate 12–15% higher annual output.

Verify Quality Assurance and Inspection Protocols

Ensuring structural integrity through systematic quality control

Tiered quality assurance protocols are essential to prevent common defects such as porosity and cold shuts. Leading manufacturers apply statistical process control (SPC), with 78% of ISO 9001-certified plants reporting 30% fewer defects than non-certified peers, according to a 2023 foundry management study.

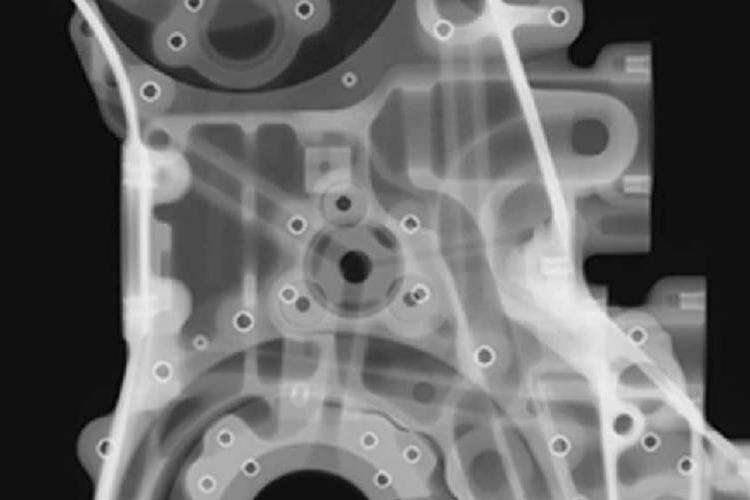

Non-destructive testing (NDT), X-ray, and CMM inspection methods

Modern inspection combines multiple advanced techniques:

- Ultrasonic NDT detects internal voids down to 0.5mm resolution

- X-ray tomography visualizes density variations in intricate geometries

- CMM arms verify ±0.02mm accuracy across 95% of surfaces

Plants using automated CMM systems achieve 40% faster first-article approvals, as shown in a 2024 manufacturing quality report.

Factors affecting dimensional accuracy and how to minimize variation

Precise thermal management is crucial—maintaining die temperatures within ±5°C reduces warpage by 62% in aluminum castings. Automated lubrication systems applying 0.8–1.2µm release coatings help prevent sticking and associated dimensional shifts.

Adherence to geometric dimensioning and tolerancing (GD&T) standards

Compliance with ASME Y14.5-2018 is achieved through strict control of key variables:

| Factor | Target | Impact |

|---|---|---|

| Mold surface finish | Ra ≤ 0.4µm | Reduces flashing by 55% |

| Clamping force variance | ≤2% cycle-to-cycle | Improves part consistency by 37% |

| Cooling rate control | ±3°C/sec | Lowers residual stress by 29% |

Balancing high-volume production with tight tolerance requirements

Automated vision inspection enables 100% screening at speeds of 450 parts per hour while holding ±0.05mm positional tolerances—a capability now standard in 68% of automotive-grade die casting operations.

Review Supplier Experience, Certifications, and Cost Efficiency

Evaluating die casting factory experience in your industry segment

Assess potential partners based on documented success in your specific sector. Automotive suppliers should demonstrate mastery of tight tolerances (±0.05mm) for engine components, while electronics manufacturers need proven experience with EMI-shielding magnesium enclosures. Validate claims of 95%+ on-time delivery using third-party audit records and production volume benchmarks.

Case study: Long-term defect reduction in automotive die casting

One transmission housing supplier reduced porosity by 37% over three years by upgrading to real-time pressure monitoring and optimizing vacuum systems. This improvement highlights how experienced manufacturers use closed-loop controls to consistently meet automotive surface finish standards (≤12 RA µin) across half a million units annually.

Production scalability and volume capacity for future demand

Tier-1 qualified facilities typically offer monthly capacities exceeding 80,000 units, supported by 2500-ton die casting machines. Scalable partners maintain redundant production cells, enabling 30% output increases within 60 days—an essential capability given projected surges in EV battery housing demand through 2030 (PwC Automotive Outlook).

Certifications matter: ISO, IATF, and ASTM compliance verification

Prioritize suppliers with active IATF 16949 certification for automotive work and AS9100 Rev D for aerospace. These frameworks mandate traceable quality systems covering over 120 process parameters—from verifying aluminum ADC12 purity (≤0.15% Fe) to maintaining die temperature stability (±3°C).

Product quality as a non-negotiable standard in manufacturing

Demand access to SPC data showing wall thickness consistency (Cpk ≥1.67) and tensile strength compliance (≥310 MPa for AZ91D magnesium). Leading producers also use 3D scanning for full dimensional validation on safety-critical components such as steering knuckles and brake caliper brackets.

Cost transparency, customization options, and long-term value

Request total cost analysis models comparing aluminum and zinc over a 10-year lifecycle. Suppliers achieving 92%+ material yield rates often provide better long-term value despite higher initial part costs, especially at scale—making waste reduction a decisive factor for productions runs exceeding one million units.

Frequently Asked Questions

What are the primary considerations for selecting alloys for die casting?

Primary considerations include mechanical stress tolerance, corrosion resistance, and thermal conductivity depending on the component's functional demands.

Which materials are commonly used in die casting, and why?

Materials commonly used include aluminum for its lightweight and corrosion-resistant properties, zinc for high ductility and excellent detail reproduction, and magnesium for the best strength-to-weight ratio.

How do environmental conditions affect material selection?

In environments with high corrosion potential, such as coastal areas, materials with low annual corrosion rates, like aluminum-silicon blends, are preferred. In applications with frequent thermal cycling, magnesium is favored for its lower warping tendencies.

Table of Contents

- Understanding Product Performance Requirements for Optimal Alloy Choice

- Suitable Materials for Die Casting: Aluminum, Zinc, Magnesium, and Their Properties

- Aluminum vs. Zinc Die Casting: Matching Alloys to Application Demands

- Matching Material Selection to Environmental and Mechanical Conditions

- Assess Die Design Capabilities and Tooling Quality

- Analyze Process Control and Production Technology

-

Verify Quality Assurance and Inspection Protocols

- Ensuring structural integrity through systematic quality control

- Non-destructive testing (NDT), X-ray, and CMM inspection methods

- Factors affecting dimensional accuracy and how to minimize variation

- Adherence to geometric dimensioning and tolerancing (GD&T) standards

- Balancing high-volume production with tight tolerance requirements

-

Review Supplier Experience, Certifications, and Cost Efficiency

- Evaluating die casting factory experience in your industry segment

- Case study: Long-term defect reduction in automotive die casting

- Production scalability and volume capacity for future demand

- Certifications matter: ISO, IATF, and ASTM compliance verification

- Product quality as a non-negotiable standard in manufacturing

- Cost transparency, customization options, and long-term value

- Frequently Asked Questions