Fahimtar Buƙatar Aiki na Nau'in Samfurin don Zaftan Da Yake Iyaka

Zaunin zaftan daidai ya fara tare da fahimci mai zurfi game da buƙatar aikin samfurin ku. Ga addimin ilmin sayarwa na MetalTek International zuwa 2024, 84% na kuskuren kashi suka fito ne daga zaftan da ba su dace ba. Sanya mahimmancin buƙatar fara:

- Gwagwamega har zuwa ga abubuwan da ke kasa kansu don abubuwan da ke kasa kansu

- Juriya na Lalata a cikin alamomin da ke da harshen kamar yadda a rumin saman ko kimika

- Tsiba na Zafi don rage yawan harshen a cikin abubuwan da ke da mahimmanci

Masu mamita da yawa wanda ke amfani da proses na taka rawa—wanda yana karkatar da cin zarar alloy zuwa tsarin aiki—zai iya reduce biyanin sake amfani ta hanyar 40%.

Abubuwan da ke kama don Die Casting: Aluminiyam, Zinc, Magnesium, da Gabaɗayan Sune

| Abu | Tensile Strength (MPa) | Tasawwar (g/cm³) | Abubuwan da Suka Sa Ya Yi Amfani |

|---|---|---|---|

| Ƙarfe na ƙarfe | 220–310 | 2.7 | Kadance, babbar karo na korosion |

| Zinc | 280–440 | 6.6–7.1 | Takaitaccen ductility, kyau mai ban shaƙaƙe |

| Magnesium | 160–240 | 1.8 | Mafi kyau nisbi na uku zuwa tsauki |

An amfani da Aluminiyam a 70% na mafara die casting (Rewayar PwC na 2023), thanks to its versatility. Magnesium is gaining traction in aerospace and automotive applications where lightweighting is critical.

Aluminum vs. Zinc Die Casting: Haɗawa Alloys zuwa Kayan Aiki

Alloy na aluminum kamar A380 da ADC12 suna iya amfani da kayan abubuwan da ke bukatar tafiyyar hankumi—misalai shine LED housings da engine brackets. Bayan haka, alloy na zinc (ZA-8, ZAMAK) suka nuna inganci lokacin:

- Daidaiton girman zuwa ±0.1mm yana bukata

- Zai shiga da electroplating yana muhimci

- Takaitaccen tasowa ta dum chiye

Aƙwai rashin bincike na 2023 a fagen sensor na otomatikai ya nuna cewa zinc ta sami 92% first-pass yield , wanda ya fara dari aluminum na 84% saboda ko'ina mai kyau.

Haɗawa Zabunta Harshe zuwa Dandalin Gudunwaye da Kimaicin Halayen

A yankunan littattafai, alloys dole ne su nuna <2% matsarin kankanta na annabawa , saita tsaron alaminiyum-silikon sun zama zaune mai godiya. Ga abubuwan da suka hada da tafiye-tafiyen hankali-mafafa—kamar alhurari na batiri na EV—mafuco na magnesium na thermal expansion (CTE) na 26 µm/m°C yana ba da ruwa mai karanci karaga zuwa CTE na zinc na 27.5 µm/m°C.

Kamar yadda lura da shi ne a cikin gwaji mai zurfi na tallafin abubuwa, hadawa kanunon ASTM/AISI da halayyen na yanayi ya sa durability da aiki mai tsada shekara goma.

Gwadawa Ilimi na Tsarar Hanyar Tsara da Nau'in Na'ura

Tsarar Hanyar Tsara Sabilin Muhimmancin Tattara da Durability na Abubuwa

Ayyukan kashi na uku na farko suna taimakawa da shawararran da ke da ilimi, sanya bayani game da yadda yankin ruwa ke tsayawa akan aljarumi, irin abubuwan da suke faruwa yayin an nika abubuwan kan dutsen, da yadda alkarabuɓi guda biyu ke karkata lokacin yake sanyawa. Kafin an kashi gargadi mai kyau, masu iya ilimi suna amfani da samar da hoton labarin akan software na modelin parametric wanda ya gabata da 1,200 run production potenshin. Wannan taimaka yana sa abubuwan da aka kama suwa a cikin ma'auni mai zurfi na plus ko minus 0.1 millimeter. Lokacin yake taimakawa da kashi suyi aikata a tsakiyar shekara, ingancin stress mai kyau ita ce babban abubu. Aljarumin gargadi mai kyaututu na chromium suna da kyau a cikin kama wurin wurin, karatuwa a cikin 0.05 mm kamar yadda ya kasance har zuwa halitta na mita biyu da ashirin koma biyu a cikin wasan manufacturing na otomatikin waɗanda precision yake mahimmanci sosai.

Ma'auni na Zaman Lahira, Gudummawa, da Ma'auni na Ingancin Na'illahi

Gwagwarmayar ayyukan dabin da ke saƙa suka farko daga cikin waɗanda ba su. Alaluben da ke biyansu shawarar ASM International game da gwagwarmayar dabi, sun sami zaman lafiya na 18 zuwa 24 wata, kusan duble lambobin waɗanda ba su biyo. Hanyoyin halartawa masu mahimmanci sun haɗa da:

- Gwagwarmayar ayyuka tambayon gyara laser na 15 kowace 5,000 tsarin

- Tsun Fasalin Gida: Kofinar titanium nitride tadaba tushen kan 63% (Battelle 2023)

- Shawararran gyara: Ƙima mai karfin kuskuren kariƙi ≤0.02mm

Tafarka ta Takaingin Motali akan Kwatanta Kwatantar da Kudaden

Motalolin da ke da 15 ko fiye da kayayyaki sun kara kudaden kowane kayan duka ne 22–35% dibdibin motalolin da ke da kayan guda. Amma, motalolin masu takaici sun zama masu amfani a kudaden da suka fada 250,000 saboda kashewar ayyukan gabaɗaya. Duba farakinyar hakan:

| Faktar | Takaici Mai Yawa | Takaici Karanci |

|---|---|---|

| Kusar Naƙuduwar Aikace-Aikace | $120k–$450k | $30k–$90k |

| Lokacin Tsawon Zane-Zane | 45–90 seconds | 18–30 seconds |

| Zana Zane Mai Daidaito | >1 million units | <100k units |

Aiki a Kasa vs. Aiki da Yawa: Hinawa tsarin Kontin da Tattalin Arzikin Alhali

Wajen hagu 68% na abokan kariya na gwaji ke amfani da wasan koyarwa, duk da haka wasan kariya masu fiye da yawa ke sarda wasan tsere. Babban bedi:

- Alamar juri: tsawon lokaci yaƙe 38%, canje-canje na iya-duniya

- Alamar sardawa: sauye 15–20% akan murya wasan kayan aiki mai zurfi

- Hanyar fasaha: 53% na masu amfani yanzu sun kama biyu (NADCA 2023)

Daidaito tabbata dala tarin ISO 9001:2015 da alamar robotiko don nisafofin saufin sama ko daya da Ra 0.8µm

Koyi Tsarin Kontrol da Teknolojin Faburika

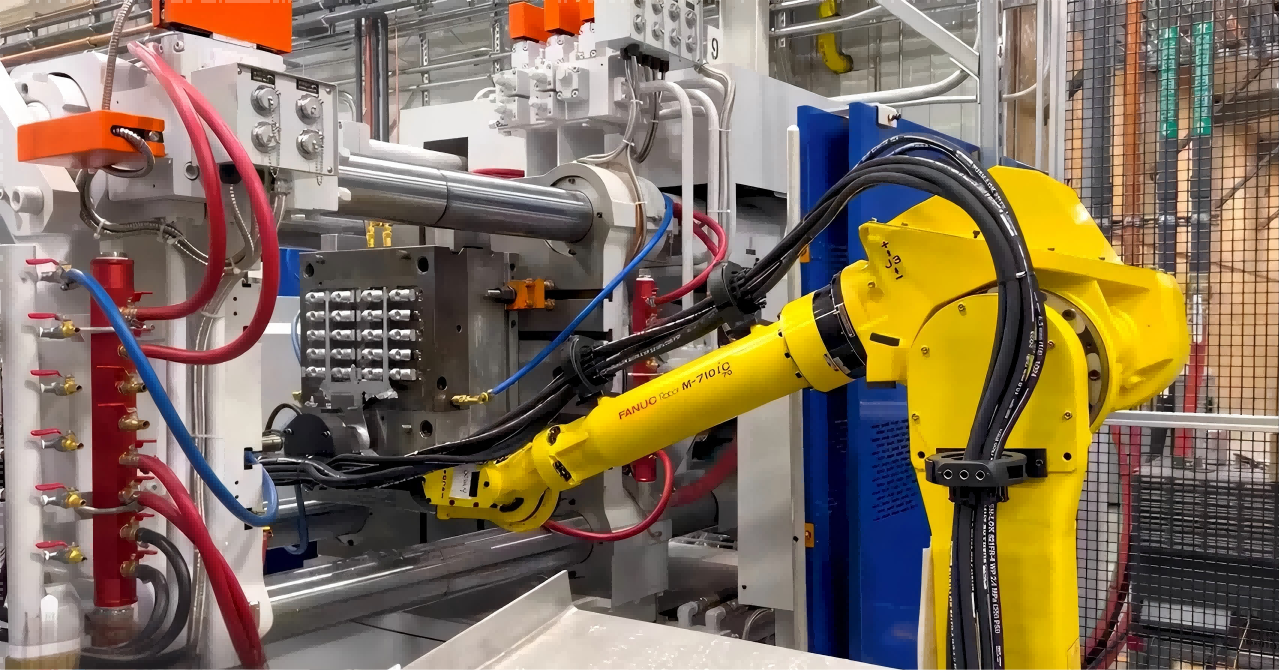

Zuwa Zuwa zuwa Kontrol don Tabbatar da Iyakar Aikin Kashi

Tasirin kafaɗan die casting na yau da kullun suna amfani da tsarin kontin closed-loop wanda ke neman canje canje zama'in injection, pressure, da yankin cooling. Wadannan tsarin ke kiyaye tsarin girman zuwa ±0.05mm a karkashin production mai yawa, wanda ke mahimmanci a tsara abubuwan otomatik. Tsarin yanke lokaci akan 15–20 sensors per machine yana ba da damar gyara kuskuren lokaci, kuma yana kula da output mai adali.

Tsarin High-Pressure vs. Cold-Chamber Die Casting: Zayin Hanyar Da Ake So Ta Hanyar Alloy

Alloy na aluminum wanda yana da yawa da 10% silicon dole ne ya amfani da mesin cold-chamber wanda ke aiki a 40–200 MPa don kula da kaiwa a lokacin injection. Zinc, tare da wannan yankin melting mai ƙasa, ke amfani da tsarin high-pressure wanda yana tafiya 500 MPa don produce walls under 1mm thick. An koyon hanyar mafi kyau ta alloy a karkashin:

| Nau'in Alloy | Tsakiyal marubuta | Hanyar da aka kira | Range na Pressure |

|---|---|---|---|

| Ƙarfe na ƙarfe | 660°C | Cold-Chamber | 40–200 MPa |

| Zinc | 419°C | High-Pressure | 500–1400 MPa |

Kwakwalwa da Kallon Lokaci a Cikin Masu Daidaitowa a Yau Da Fuskani

Masu dadi mai amfani da kwakwalwa suna hadawa da abubuwan da ke kara yawan gwajin mutum ta hanyar 80% yayin da suka tsaya cikin 99.7% lokacin amfani da wasan kasa. Nuna kayan aiki masu amfani da girma na infrared suna nuna abubuwan da ba su dace ba kamar yadda suka porosity a cikin gaba daya biyu—yawan lokaci babu shi karshen lokacin gwaji na iyaka 15. Wannan canjin teknoloji yana ba da damar yadda zasu iya samun tafiye-tafiyen 12–15% a kowace shekara.

Tabbatar da Tarihin Kwamitatin Kwamitati da Gwajin Matakanin

Tabbatar da ingancin tsirri ta hanyar gwajin kwamitati ta hanyar tsarin gwaji

Matakanin kwamitatin kwamitati na rarrabuwa suna bukatar tabbatar da abubuwan da ba su dace ba kamar yadda suka porosity da cold shuts. Masu haɓakawa masu gabatarwa ke amfani da statistical process control (SPC), tare da 78% na masu dadi da ISO 9001 masaƙi suna iko 30% abubuwan da ba su dace ba karanci ga wadanda ba su da shi, saboda ra'ayin bincike na 2023 game da sarrafa masu dadi.

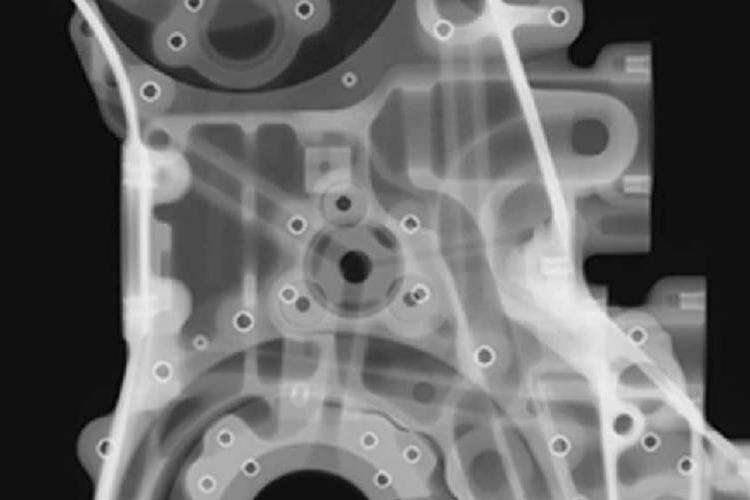

Gwajin abubuwan da ba su dace ba (NDT), X-ray, da matakin CMM

Yanayin kula da yawa sun haɗa da teknikun da aka yiƙura:

- Ultrasonic NDT yana nuna abubuwan da suka wuya zuwa tsakanin 0.5mm

- X-ray tomography yana nuna yanayin zama borbori a cikin kayan ajiyar da suke iya canzawa

- CMM arms yana tabbatarwa tsawon ±0.02mm a 95% na kayan sifa

Albishiyoyin da ke amfani da CMM masira suwurin yanzu sun sami tasiri mai kyau a 40%, kamar yadda aka fassara a risharsharin 2024 game da kwaliti na abincin abubuwa.

Abubuwan da suka haifar da canjin girman kayan ajiyar da kuma yadda za a kashe waɗannan canje-canjeni

Gudummawar umfar tushen yaɗuwa ta atomatik—kare tsawon tsakar kayan ajiyar a tsakanin ±5°C yana rage warpage ta 62% a cikin aluminum castings. Yanayin atomatikin lube da ke amfani da 0.8–1.2µm yana taimakawa wajen kasa matsala ta stuck da sauran canje-canjenin girman kayan ajiyar.

Ayyukan kiyasta da kuma kuskuren kiyasta (GD&T) masu alaƙa

Iƙatarwa zuwa ASME Y14.5-2018 a dacewa tare da mamaye ayyukan masu mahimmanci:

| Faktar | Matsala | IMPACT |

|---|---|---|

| Fuskar na'ura | Ra ≤ 0.4µm | Yana gudanar da rashin nashama ne 55% |

| Ƙarfin ƙarfin ƙuƙwalwa | ≤ 2% daga sake zagayowar zuwa sake zagayowar | Yana inganta daidaito na kashi 37% |

| Ƙarfin sanyaya | ƙarƙashin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙarancin ƙaran | Yana bada stress na residual ta 29% |

Tambayoyin tasowa da yawa zuwa da bukukuwar hanyoyin da ke tsari

Tsarin ikojin nuna yana ba da damar dubawa a kowace mataki ta hanyar 450 kayan duka per sa’a yayin ke tsaddawa tsakanin ±0.05mm, wanda yanzu shine abin da aka fi amfani da shi a 68% na fasaha mai amfani da die casting a otomotika

Duba Zubin Mai siyasa, Ijazah, da Kama da biyan kuɗi

Gamaƙe duba zubin masu siyarwa na die casting a alamun ku

Gamaƙe duba masu haɓakawa base ga sharuddan da suka fasahe a alamun ku. Masu siyarwa na otomotika suna dole don iskar tsaddamar (±0.05mm) na kayan injin, yayin da masu amfani da elektronituna suna buƙatar zubin iskar magnesium mai daki zuwa EMI. Tabbata da rashin kuskuren bayarwa na 95% ko fiye ne ta hanyar tallafin masu audita na wasu kuma maƙalar fasahar production

Takaitaccen bayani: Raguwar cin zarar sababoda lokacin cikin die casting na otomotika

Mai sayarwa mai gwiwa transmission ya kara porosity ta 37% bayan shekara uku sai dai ya yi yabo zuwa ga ma'aikatan yanar gizo da kuma nuna tsarin vacuum. Wannan tarbiyya tana nuna yadda masu amfani da alhakin yin aikin yana amfani da controls na closed-loop domin dacewa da standard na automotive surface finish (≤12 RA µin) akan mitin biliyan kayan aiki kowace shekara.

Iyaka na production da alamar abubuwan da za’a iya amfani da su don richiyar buhari

Albarkatun masu ingantawa masu ingantawa zafi suka iya ikojin kariya mai yiwuwar 80,000 wata, masu karfin mesinai na die casting na 2500-ton. Masu amfani da iyaka suna da production cells da suka dace, sannan su iya kara 30% a cikin 60 rana—wannan yiwuwar yake da muhimmanci saboda an yi takaitaccen buhari na EV battery housing a makon 2030 (PwC Automotive Outlook).

Tasiri suna da muhimmanci: ISO, IATF, da ASTM compliance verification

Sanya abokin sayarwa da ke da ijin karbar IATF 16949 don aikin otomatikai da AS9100 Rev D don samun sama. Wadannan tsarinke suna nuna bukatar tsarin kwaliti na iya budewa wanda ke kovera akan fota 120 na prosayi—daga tabbatar da safin alwuminum ADC12 (≤0.15% Fe) zuwa kare tsawon temperature na die (±3°C).

Kwalitin bayanƙi azaman standa mai tsada lafiya a cikin masu girma

Budé damar samun data na SPC wadda tushen tsankan idodi (Cpk ≥1.67) da kamar yadda aka yi amfani da quwat tensile (≥310 MPa ga magnesium AZ91D). Masu sarrafa masu koyaushe yake amfani da scan 3D don tabbatar da duka girman bayanƙi akan kayan aikin muhimmiyar lafiya kamar knuckles na steering da maganganin brake caliper.

Tsawon biyan kuɗi, zuta bisa buƙatar zamantakewa, da darajar dugon shekara

Nemage juyin kayan ayyukan kiyasi wato aluminum da zinc a ƙarni 10. Masu sayarwa da ke samun nisbi na yawa na abubuwan da ke 92% ko fiye, masu kyau cikin iyaka mai tsawo irin da suke da abokin biyan kari mai zurfi, musamman a takaitaccen girma—wanda ke sa rukunin rage wasan abubuwa ya zama mai mahimmanci ga alhakin bukata da ke goyan milion 1 ko fiye.

Masu Sabon Gaskiya

Wane ne dabi'un bayani masu mahimmanci don zaɓi na alloys don amfani da die casting?

Dabi'un bayani masu mahimmanci sun hada da karfin tafiya, karfin takauna, da kewayon haliyar ruwa, wato ma'anin abubuwan da ke chafe gurbin aiki.

Wane ne kayan abubuwan da ake amfani da su a die casting, kuma meye?

Kayan abubuwan da ake amfani da su sun hada da aluminum saboda mafi sauƙi da kusan takauna, zinc saboda mafi kwayoyin halayya da kewayon nuna alamar, da magnesium saboda mafi kyau a nisbi na strength-to-weight.

Yaya shafukan zamani suna magana da zaɓin kayan abubuwa?

A cikin alamun da ke iya ruwa sosai, kamar yaukidan kasa, an preferred materials da ke da ruwa kusa da karami, kamar rabin aluminum-silicon. A cikin abubuwan da ake amfani da su ta hanyar cututtuka, magnesium ita ce preferred saboda ba ke yanke sosai.

Teburin Abubuwan Ciki

- Fahimtar Buƙatar Aiki na Nau'in Samfurin don Zaftan Da Yake Iyaka

- Abubuwan da ke kama don Die Casting: Aluminiyam, Zinc, Magnesium, da Gabaɗayan Sune

- Aluminum vs. Zinc Die Casting: Haɗawa Alloys zuwa Kayan Aiki

- Haɗawa Zabunta Harshe zuwa Dandalin Gudunwaye da Kimaicin Halayen

- Gwadawa Ilimi na Tsarar Hanyar Tsara da Nau'in Na'ura

- Koyi Tsarin Kontrol da Teknolojin Faburika

-

Tabbatar da Tarihin Kwamitatin Kwamitati da Gwajin Matakanin

- Tabbatar da ingancin tsirri ta hanyar gwajin kwamitati ta hanyar tsarin gwaji

- Gwajin abubuwan da ba su dace ba (NDT), X-ray, da matakin CMM

- Abubuwan da suka haifar da canjin girman kayan ajiyar da kuma yadda za a kashe waɗannan canje-canjeni

- Ayyukan kiyasta da kuma kuskuren kiyasta (GD&T) masu alaƙa

- Tambayoyin tasowa da yawa zuwa da bukukuwar hanyoyin da ke tsari

-

Duba Zubin Mai siyasa, Ijazah, da Kama da biyan kuɗi

- Gamaƙe duba zubin masu siyarwa na die casting a alamun ku

- Takaitaccen bayani: Raguwar cin zarar sababoda lokacin cikin die casting na otomotika

- Iyaka na production da alamar abubuwan da za’a iya amfani da su don richiyar buhari

- Tasiri suna da muhimmanci: ISO, IATF, da ASTM compliance verification

- Kwalitin bayanƙi azaman standa mai tsada lafiya a cikin masu girma

- Tsawon biyan kuɗi, zuta bisa buƙatar zamantakewa, da darajar dugon shekara

- Masu Sabon Gaskiya