Core Quality Control in Die Casting: Ensuring Consistent Reliability

Pre-casting Quality Measures: Material Assessment and Design Simulation

Quality control starts much earlier than most people realize at a good die casting plant. Before any hot metal goes into molds, they run all sorts of tests on materials to check if the alloys are right and how they handle heat. This helps catch problems that might cause things like air pockets or cracks down the road. The industry has gotten pretty smart about using simulation tools these days too. These programs look at mold designs and figure out where issues might happen during filling. According to some recent numbers from 2023, companies using this tech cut down their prototype costs by around 35%. And when manufacturers follow those ISO 9001 standards for materials? They tend to see about 40% fewer size differences in their products compared to places without certification. Makes sense really, since standardized processes just work better overall.

In-Process Monitoring and Statistical Process Control for Consistency

Real-time sensors track injection pressures (±1.5% accuracy) and die temperatures (±2°C variance), feeding data into statistical process control (SPC) systems. This enables immediate correction of deviations exceeding 4Ï control limits â a practice shown to reduce scrap rates by 28% in aluminum die casting applications.

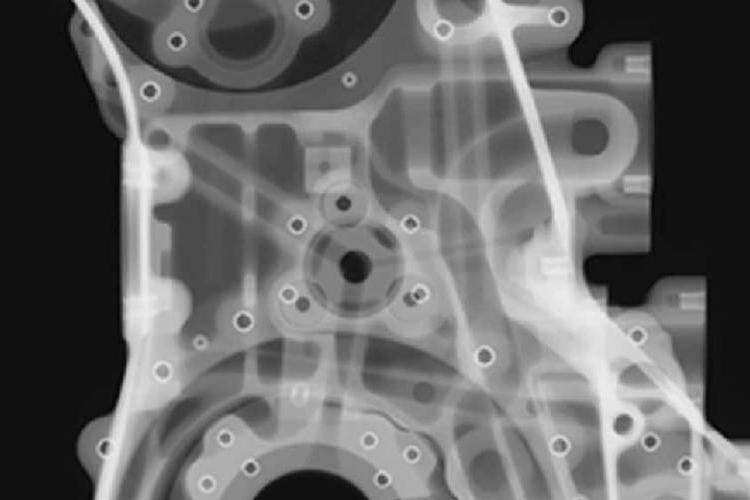

Post-Casting Inspection and Non-Destructive Testing Methods

Automated coordinate measuring machines (CMMs) validate part dimensions within 5µm tolerances, while X-ray inspection identifies sub-surface flaws undetectable to visual checks. Leading facilities employ phased-array ultrasonic testing to examine 100% of high-stress components, achieving defect escape rates below 0.02%.

Dimensional Accuracy and Mold Maintenance Best Practices

Preventive mold maintenance schedules every 50,000 cycles preserve critical clearances (±0.005mm). Plasma-nitrided mold surfaces maintain surface finish requirements (Ra â0.8µm) 3x longer than conventional coatings, directly impacting part consistency across production batches.

Role of Advanced Technologies in Modern Die Casting Quality Assurance

AI-powered vision systems now detect micro-defects (â0.1mm) 12x faster than human inspectors. Closed-loop real-time process monitoring systems automatically adjust 23 machine parameters simultaneously, maintaining optimal conditions despite alloy batch variations. These protocols collectively define the operational excellence of a modern die casting factory.

Common Defects in Die Casting and Prevention Strategies in a Professional Die Casting Factory

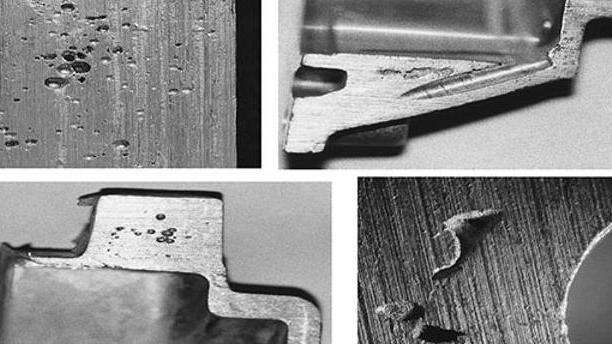

Identifying Common Casting Defects: Porosity, Cold Shuts, and Flash

In aluminum die casting shops across the country, porosity from trapped gases, cold shuts when metal doesn't fully fuse together, and flash caused by excess material getting pushed out make up around 60-65% of all quality problems encountered on production lines. Most often these issues start showing up during those intense high pressure injection stages. When molds aren't properly vented or there are temperature fluctuations throughout the process, it leads to structural weaknesses in the final product. To fight back against these common defects, many modern manufacturing facilities now rely heavily on infrared thermography scanning equipment along with sophisticated predictive maintenance systems for their molds. Some plants have even started implementing real time monitoring solutions that alert operators before potential issues become actual production stoppages.

Root Causes and Prevention Strategies for Aluminum Casting Reliability

Analysis shows 68% of defects stem from improper gating design and insufficient alloy degassing. Leading factories employ real-time pressure sensors and automated viscosity controls to maintain ±1.5% parameter accuracy during casting. Implementing stratified cooling regimes reduces cold shut occurrences by 38%, while AI-driven porosity prediction models achieve 92% defect detection accuracy pre-production.

Case Study: Reducing Defect Rates Through Process Optimization

A 2023 automotive supplier initiative combined vacuum-assisted die casting with AI-powered flow simulations to reduce porosity-related scrap by 87% (Casting-YZ, 2024). The optimized process decreased cycle times by 14% while improving tensile strength consistency across 12 critical components, demonstrating how advanced process controls elevate both quality and efficiency in die casting factories.

Material and Process Selection: Foundations of High-Performance Die Casting

Materials Used in Die Casting: Aluminum, Zinc, Magnesium, and Copper Alloys

Material selection directly determines component performance in die casting systems. Four alloys dominate industrial applications:

- Aluminum alloys (A380, ADC12) provide optimal strength-to-weight ratios (2.7 g/cm³) and corrosion resistance, driving their use in 62% of automotive components like engine blocks (2024 Material Guide)

- Zinc alloys (ZA-8, Zamak) enable complex geometries for electronics and medical devices through superior mold flow

- Magnesium alloys (AZ91D) deliver aerospace-grade lightness without sacrificing structural integrity

- Copper alloys (C87800) serve niche roles in thermal/electrical systems

Recent manufacturing analyses reveal aluminum’s dominance stems from its compatibility with automated die casting factory processes and 100% recyclability.

Why Aluminum Die Casting Dominates High-Performance Applications

Aluminum outperforms alternatives in durability-critical scenarios due to three factors:

- 40% lower thermal expansion than zinc, ensuring stability in engine components

- Natural oxide layer formation for corrosion resistance without coatings

- Energy efficiency during production (30% less power vs. magnesium)

Key Considerations for Success in High Pressure Die Casting

A professional die casting factory must balance:

- Clamping forces: 800â2,500 tons for consistent wall thickness

- Cooling rates: 2â3°C/sec to prevent porosity in thin sections

- Mold coatings: TiN or CrN layers extending tool life by 300%

Production Efficiency and Economic Performance in a Modern Die Casting Factory

Advantages of Die Casting: Efficiency, Strength, and Cost-Effectiveness

Today's die casting plants have really ramped up their game with fast production cycles and near net shape manufacturing techniques. This approach cuts down per unit costs by around 30 to 40 percent when making batches over 10,000 units according to Manufacturing Insights from last year. What makes this work so well is the combination of super quick cycle times under 60 seconds for those little aluminum parts plus amazing material efficiency. Advanced gating systems and automatic trimming help get up to 95% metal usage out of each batch. Looking at what the industry reports show about automation improvements, we find that shops employing robots for tasks like mold spraying and part removal actually cut labor expenses by about a quarter without compromising quality much at all. These facilities typically maintain defect rates below 1% which is pretty impressive considering how much faster they operate now.

Balancing Tooling Costs and Volume Output for Economic Efficiency

The upfront cost for multi cavity mold tooling often goes beyond $150k, but once production hits around 5,000 units, die casting starts making financial sense because each additional unit costs significantly less to produce. According to some industry research from Precision Economics last year, manufacturers who manage to recover their tooling investment within just 18 months see about a 22 percent boost in return on investment when compared to those stuck with smaller batch sizes. Choosing materials wisely makes all the difference too. Aluminum stands out since roughly 85% of it gets recycled eventually, which helps keep material costs down over time. Meanwhile, working with zinc alloys saves money on machining work because parts come out of the mold with such good surface quality already that there's less need for extra finishing touches.

Productivity Evaluation Metrics in High-Output Die Casting Operations

Top-performing factories monitor three key metrics:

- Overall Equipment Effectiveness (OEE): >75% indicates optimal machine utilization

- Cycle Time Variability: <5% deviation ensures predictable output

- Cost-Per-Kilogram: Combines energy, labor, and material costs for holistic efficiency tracking

Leading manufacturers using real-time OEE dashboards report 18% faster bottleneck identification and 12% annual throughput gains, proving data-driven decision-making is no longer optional in competitive die casting operations.

Future-Ready Die Casting: Automation, Sustainability, and Design Collaboration

How Design for Manufacturability Improves Quality and Speed

When companies apply design for manufacturability (DFM) right from the start of product development, they see significant reductions in both material waste and production time across major die casting operations. Some factories report cutting their cycle times by around 40% just by incorporating these principles early on. The key lies in how engineers shape parts to work better with manufacturing limitations. They tend to avoid those tricky areas like thin walls and complicated undercuts that often lead to casting problems down the line. Looking at actual shop floor data from 2023, manufacturers found that parts designed with DFM in mind needed about 35% less fixing after casting than older designs did. This means less rework, lower costs, and ultimately happier customers who get quality products faster.

Collaborative Prototyping and Simulation in Reliable Die Casting Factories

Advanced simulation platforms enable real-time collaboration between design teams and production engineers. Cloud-based systems allow simultaneous evaluation of filling patterns and thermal stresses, cutting prototype iterations by 50%. This digital twin approach validates mold designs in virtual environments before commissioning physical tooling, ensuring faster time-to-market.

Emerging Trends: AI-Driven Quality Control, Automation, and Sustainability

Facilities today are hitting almost zero defects thanks to those smart vision systems powered by artificial intelligence. These advanced eyes check over 500 different factors during each casting cycle. The results? A massive drop in scrap caused by porosity issues down by around 62%, all without slowing down production speeds according to the Advanced Casting Journal from last year. At the same time, companies have started implementing automated lubrication systems alongside closed loop cooling circuits. This combo has slashed energy usage by nearly 28% when compared with older methods. Industry reports on sustainability show these improvements aren't just theoretical but actually happening across manufacturing floors nationwide.

Future-Proofing Die Casting Operations with Smart Manufacturing

Leading factories integrate IoT sensors across production lines, enabling predictive maintenance that reduces unplanned downtime by 73%. This shift toward smart facilities combines real-time process data with enterprise resource planning systems, creating agile ecosystems ready for Industry 4.0 demands.

FAQ

What are common defects in die casting?

Common defects in die casting include porosity due to trapped gases, cold shuts where the metal doesn't fully fuse, and flash caused by excess material seepage. These issues typically arise during high-pressure injection stages.

How does simulation improve die casting quality?

Simulation tools predict where issues might occur during the filling process, allowing manufacturers to standardize procedures and optimize molds, which can reduce prototype costs by about 35%.

Why is aluminum preferred in high-performance die casting?

Aluminum is favored for its optimal strength-to-weight ratio, corrosion resistance, lower thermal expansion, and energy efficiency during production, making it ideal for durability-critical applications.

What benefits does real-time monitoring bring to die casting?

Real-time monitoring with sensors provides accurate tracking of injection pressures and die temperatures, enabling immediate deviation corrections, reducing scrap rates, and enhancing overall quality.

Table of Contents

- Core Quality Control in Die Casting: Ensuring Consistent Reliability

- Common Defects in Die Casting and Prevention Strategies in a Professional Die Casting Factory

- Material and Process Selection: Foundations of High-Performance Die Casting

- Production Efficiency and Economic Performance in a Modern Die Casting Factory

- Future-Ready Die Casting: Automation, Sustainability, and Design Collaboration

- FAQ