Understanding Mechanical and Environmental Stress on Automobile Parts

Mechanical Durability and Resistance to Load, Vibration, and Road Stress

Car parts deal with constant mechanical stress all day long. Suspension systems alone go through more than 50 thousand stress cycles just during regular testing procedures. Things like engine mounts and wheel bearings have to handle all those tiny road vibrations that build up over time, which costs the industry around $5.2 billion every year according to the latest durability report from 2024. Manufacturers run their components through special tests that mimic what happens on actual roads after many years of driving. These tests push parts beyond normal conditions by applying forces three and a half times higher than what they normally experience, helping engineers spot where things might eventually break down. Take transmission housings for example they're built nowadays to take at least 200 kilonewtons of force along their axis without cracking or failing structurally.

Environmental Challenges: UV Exposure, Thermal Cycling, and Chemical Degradation

The sun and those wild temperature swings really take a toll on materials over time. Take dashboard plastics for instance they tend to lose around 38% of their tensile strength after only about 1,000 hours exposed to UV light. When parts go through repeated heating and cooling cycles from as cold as minus 40 degrees Celsius all the way up to 120 degrees, sealants break down at least four times quicker than what laboratory tests originally predicted. Research into environmental stress cracking has shown something pretty surprising too about 25% of problems with automotive plastics actually come from chemicals reacting with road salts and various fuels. Manufacturers have responded by developing better underhood coatings that hold up during salt spray tests for over 500 hours now, which represents roughly a 70% boost compared to what was possible back in 2018.

Case Study: Suspension Components and Dashboard Materials Under Real-World Conditions

A 2023 field analysis revealed significant regional performance differences:

- Aluminum control arms corroded at 0.12 mm/year in Nordic climates compared to 0.8 mm/year in coastal regions

- UV-stabilized polypropylene dashboards retained 92% colorfastness after five years, outperforming standard materials at 67%

These insights have driven OEMs to adopt hybrid materials combining metals with glass-reinforced polymers, extending joint assembly service life by 82%.

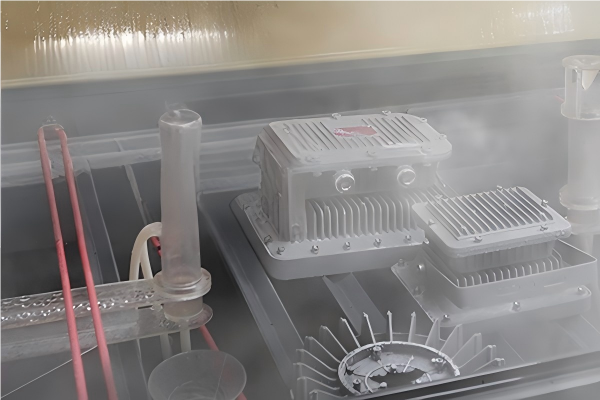

Integration of Real-Time Monitoring and Accelerated Stress Testing

Leading manufacturers now embed IoT strain gauges to monitor part performance across 12+ environmental variables, including humidity and harmonic vibrations. Accelerated aging protocols compress decade-long wear into six-month trials using high-fidelity simulations:

| Test Parameter | Simulation Accuracy | Industry Benchmark |

|---|---|---|

| Thermal Shock Cycling | 98% | 50 cycles/day |

| Multi-Axis Vibration | 95% | 0.7 Grms RMS |

| Corrosion Resistance | 89% | 1000+ salt spray hours |

This data-driven approach has reduced steering component warranty claims by 41% since 2021 and cut validation costs by $18k per vehicle platform.

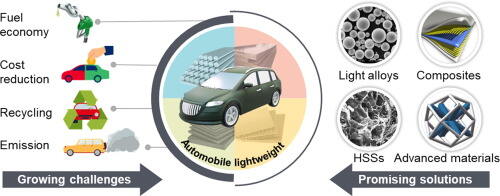

Comparing Metals and High-Performance Polymers for Durability

Car manufacturers really care about finding materials that can last for years under constant mechanical stress without putting anyone at risk. Steel is still king when it comes to building car frames because it has this amazing tensile strength ranging from around 380 to 550 MPa plus it doesn't break the bank too much. But lately there's been some serious competition from advanced plastics such as PA6-GF30 material. Take turbochargers for instance these new composite materials cut down on weight by about 40 percent compared to traditional options yet they can handle temperatures all the way up to 220 degrees Celsius according to recent findings published last year in automotive material studies. What we're seeing here is basically how the whole auto industry is trying hard to find that sweet spot between making cars tough enough but also light enough to meet those ever stricter fuel efficiency standards.

Corrosion-Resistant Materials: Galvanized Steel, Aluminum, and Advanced Coatings

Modern vehicles use layered strategies to resist corrosion:

- Galvanized steel with a 10–25 µm zinc layer provides over 15 years of rust protection for door panels

- 6000-series aluminum alloys reduce brake caliper weight by 35% versus cast iron while resisting road salt degradation

- Plasma-electrolytic oxidation coatings extend aluminum engine block service life by 300% (ESD-SAT 2023 testing)

These innovations address the $740,000 lifetime corrosion repair cost per vehicle reported in the Transportation Materials Analysis.

Balancing Weight, Cost, and Longevity in Automotive Material Choices

Material engineers navigate a trilemma:

- Weight reduction – every 10% reduction improves fuel efficiency by 6–8%

- Cost containment – aluminum costs 2.5x more than mild steel per kilogram

- Durability requirements – 25-year corrosion warranties are increasingly standard

Advanced high-strength steels (AHSS) currently offer the best compromise, delivering components that are 30% lighter than conventional steel at only a 15–20% higher cost. Ongoing research into nano-coatings and self-healing polymers holds promise for future gains in sustainable durability.

Durability Testing Standards and Validation Methods for Automobile Parts

Overview of industry-standard durability and environmental testing protocols

Car components need to pass pretty strict tests before they can be considered reliable enough for actual vehicles. There are specific guidelines out there like ISO 16750-3 which looks at how well electrical systems handle vibrations, and then there's SAE J2380 dealing with things like sunlight damage over time. Meeting requirements set by groups such as NHTSA and EPA isn't just about following rules it actually keeps people safe while making sure cars don't pollute too much. The automotive sector is placing more attention these days on creating test environments that mimic what happens on the road. Salt spray tests according to ASTM B117 standard and checking materials under extreme temperatures ranging from minus 40 degrees Celsius all the way up to plus 85 have become increasingly important aspects of quality control.

Lifecycle testing: Car doors, interior trim, and wear-prone components

Manufacturers perform detailed life cycle assessments on key vehicle components to ensure they stand up to real world conditions. Take door hinges for example these parts need to survive at least 100 thousand open and close operations before being approved, which basically checks if the latch still works after all that wear and tear. Interior trim gets rubbed against by passengers constantly so we run abrasion tests following ASTM D4060 guidelines this helps us predict how the material will hold up after years of use in actual cars. For powertrain mounts, our standard is over a million load cycles to mimic what happens during extended driving on rough roads. Brake calipers go through rigorous testing too about 500 hours of humidity exposure makes sure water cant get inside where it might cause problems later on down the road.

Accelerated aging tests and their correlation with real-world performance

Testing techniques that speed up aging processes can pack what would normally take years into just a few weeks. Take dashboard materials as one instance they're exposed to about 1500 hours worth of xenon arc UV light, which mimics roughly five full years under actual sun conditions. Meanwhile suspension bushings get put through their paces with around 50 thousand compression cycles on those specialized multi axis testing rigs. Some recent research has found pretty impressive results too there's about a 92 percent match between materials tested in labs after accelerated aging and real world samples taken from vehicles that have been retired after extended service. This happens especially when we combine extreme temperature changes from minus 30 degrees Celsius all the way up to plus 120 with different frequency vibrations during testing.

Addressing the gap: Over-testing vs. practical durability outcomes

Although 78% of manufacturers use ASTM G154 for accelerated weathering, 40% report over-testing beyond typical 15-year vehicle lifespans. More balanced approaches include:

- Aligning test durations with regional usage patterns (e.g., 200,000-mile North American benchmarks vs. 150,000-km European thresholds)

- Integrating field failure data to refine lab conditions

- Adopting AI-driven predictive models to reduce redundant testing by 18% (2023 Automotive Materials Symposium)

This strategy maintains critical system failure rates below 0.5%–including sealing components and electrical connectors–while minimizing development costs.

Quality Control and Manufacturing Practices to Enhance Part Longevity

Integrating durability testing into manufacturing quality assurance

Car manufacturers are starting to include real time checks for component durability right in their production lines these days. They mix things up with tests that look at how parts vibrate and respond to temperature changes over time. The Six Sigma approach has helped cut down on warranty problems related to transmissions by around 18 percent lately because they catch issues with clutch plates much earlier in the process. Meanwhile, those fancy camera inspection systems spot about 9 out of 10 tiny cracks in brake calipers before anything gets put together, which means companies aren't just fixing problems after they happen anymore but actually predicting them ahead of time. Putting all these technologies together makes cars last longer under normal wear and tear as well as harsh conditions we see on roads covered with salt during winter months.

Statistical process control and continuous improvement in production

SPC software keeps things within a tight ±0.005mm range for around 1.2 million suspension bushings each month by looking at all that CNC machining data. Combine this with regular Kaizen workshops and manufacturers see about 40% fewer issues with cylinder head casting shapes, all while holding down costs so they don't go up more than 2% per year. Starting from 2022 onwards, companies have been able to monitor those bearing surfaces as they happen on the production floor. This means instead of waiting for weekly reports, operators can spot problems right away and fix them before whole batches get messed up.

FAQ

What is the significance of mechanical stress testing for automobile parts?

Mechanical stress testing helps manufacturers identify potential weaknesses in car parts by simulating extreme conditions, ensuring long-term reliability and durability.

How do environmental factors like UV exposure affect car materials?

UV exposure can significantly degrade the tensile strength and colorfastness of car materials, necessitating improvements in material formulations and coatings.

What role do IoT strain gauges play in automobile manufacturing?

IoT strain gauges allow real-time monitoring of part performance under various environmental conditions, optimizing the durability and reliability of components.

Why are corrosion-resistant materials important in car manufacturing?

Corrosion-resistant materials are crucial for extending the service life of vehicle components, reducing long-term maintenance costs, and ensuring vehicle integrity.

What are the benefits of accelerated aging tests?

Accelerated aging tests help predict the long-term durability of materials in a compressed time frame, allowing manufacturers to validate performance without lengthy field testing.

Table of Contents

-

Understanding Mechanical and Environmental Stress on Automobile Parts

- Mechanical Durability and Resistance to Load, Vibration, and Road Stress

- Environmental Challenges: UV Exposure, Thermal Cycling, and Chemical Degradation

- Case Study: Suspension Components and Dashboard Materials Under Real-World Conditions

- Integration of Real-Time Monitoring and Accelerated Stress Testing

- Comparing Metals and High-Performance Polymers for Durability

- Corrosion-Resistant Materials: Galvanized Steel, Aluminum, and Advanced Coatings

- Balancing Weight, Cost, and Longevity in Automotive Material Choices

-

Durability Testing Standards and Validation Methods for Automobile Parts

- Overview of industry-standard durability and environmental testing protocols

- Lifecycle testing: Car doors, interior trim, and wear-prone components

- Accelerated aging tests and their correlation with real-world performance

- Addressing the gap: Over-testing vs. practical durability outcomes

- Quality Control and Manufacturing Practices to Enhance Part Longevity

-

FAQ

- What is the significance of mechanical stress testing for automobile parts?

- How do environmental factors like UV exposure affect car materials?

- What role do IoT strain gauges play in automobile manufacturing?

- Why are corrosion-resistant materials important in car manufacturing?

- What are the benefits of accelerated aging tests?