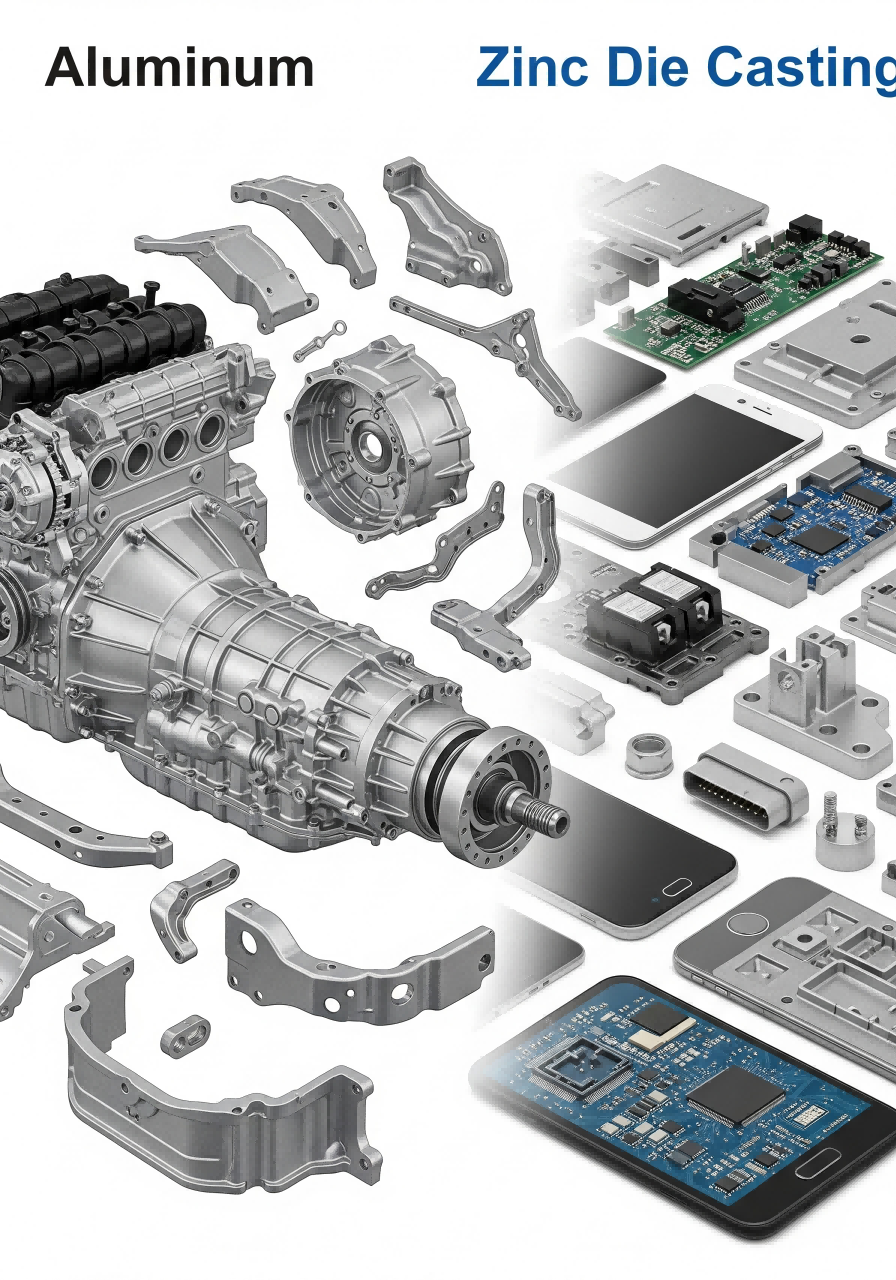

Aluminum ta amfani da Zinc Die Casting: Differensun Na Uku

Bayan Rubutu Kasa

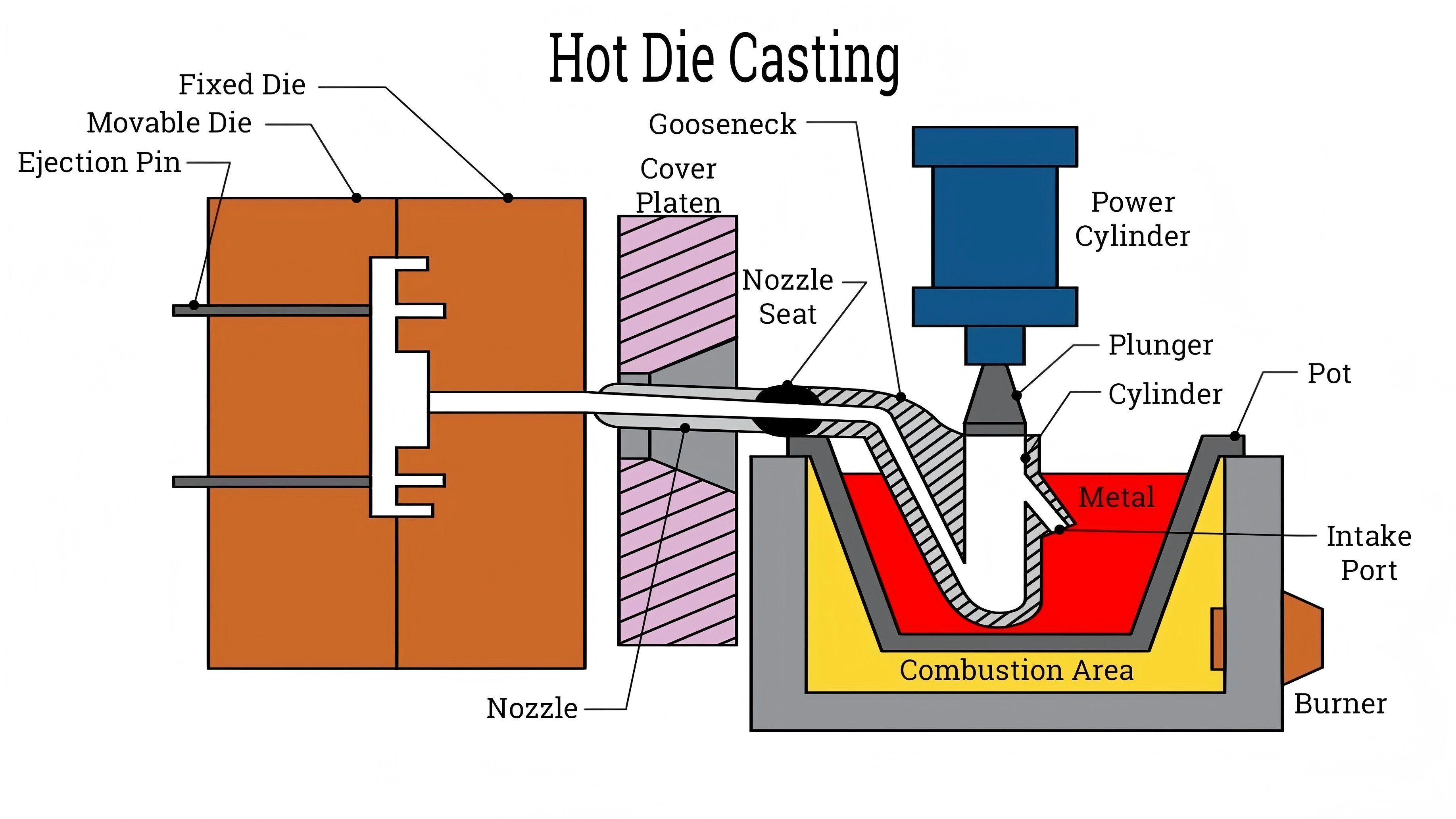

A karkashin, waqtan yin aluminum die-casting, zan yi injekci na aluminum mai rage a cikin mold babba da tsawon pressure. Wannan tsarin ya dace short cycle time kuma samar da iya yin abubuwan da suke da nisa yayin da aluminum ke flow a tsawon takamai. Zinc die casting pia ya amfani da abubuwan da suke da nisa ko abubuwa da za suka gudu da fuka mai tsoho wanda ke kama da rigidity mai utsa. Duk da wadansu abubuwa, zinc ya nuna maitakai a makala da formability kuma dimensional accuracy, musamman a intricate mold designs. A wasu lokaci, zan yi amfani da nitrogen purging a lokacin tsarin casting don taimakawa wajen yin cutar ginya kuma sauki oxidation a cikin mold cavity, don iyakokin kwaliti na casting. Maimakon farko na aluminum da kuma zinc die casting shine don samar da abubuwan da casting quality akwai, har ma mold type kuma setting times suke da farka. Gani wa suka differensun wancan zai taimakawa wajen masana company wacce abubuya kuma tsari do suke buƙata don tabatar da production needs-nsu.

Tsamfayyakin Harshe Materiyalin

Aluminum kuma ma known da shidda da saukin gudunƙarwa, amma shine babbar wani abu ne, amma yana nufin ruwa na saman da suka shafi, kuma yayin da ke waje, shine babbar muhimmi a cikin alamuran kewayon da aerospace inda wajen waje ya dace. A matsayin, zinc die cast parts suna da shidda don siffar saukin gudunƙarwa da fule mai kyau na sarrafa don abubuwan tsoho, amintasabbin abubuwan tsoho suna buƙata rarrabuwar gudunƙarwa. A ƙarshe, yaya za a yi amfani da aluminum ko zinc die casting parts zai dawo zuwa cikin buƙatun farken application, misali weight tolerance, cost effectiveness da desired finish quality. Wannan kadan daban-daban na materials zai ba da sauƙi wanda zai iya hada kan takaddun iyakokin da cikin abubuwa.

Tashe da Kusance Mai Tare Da Dauke

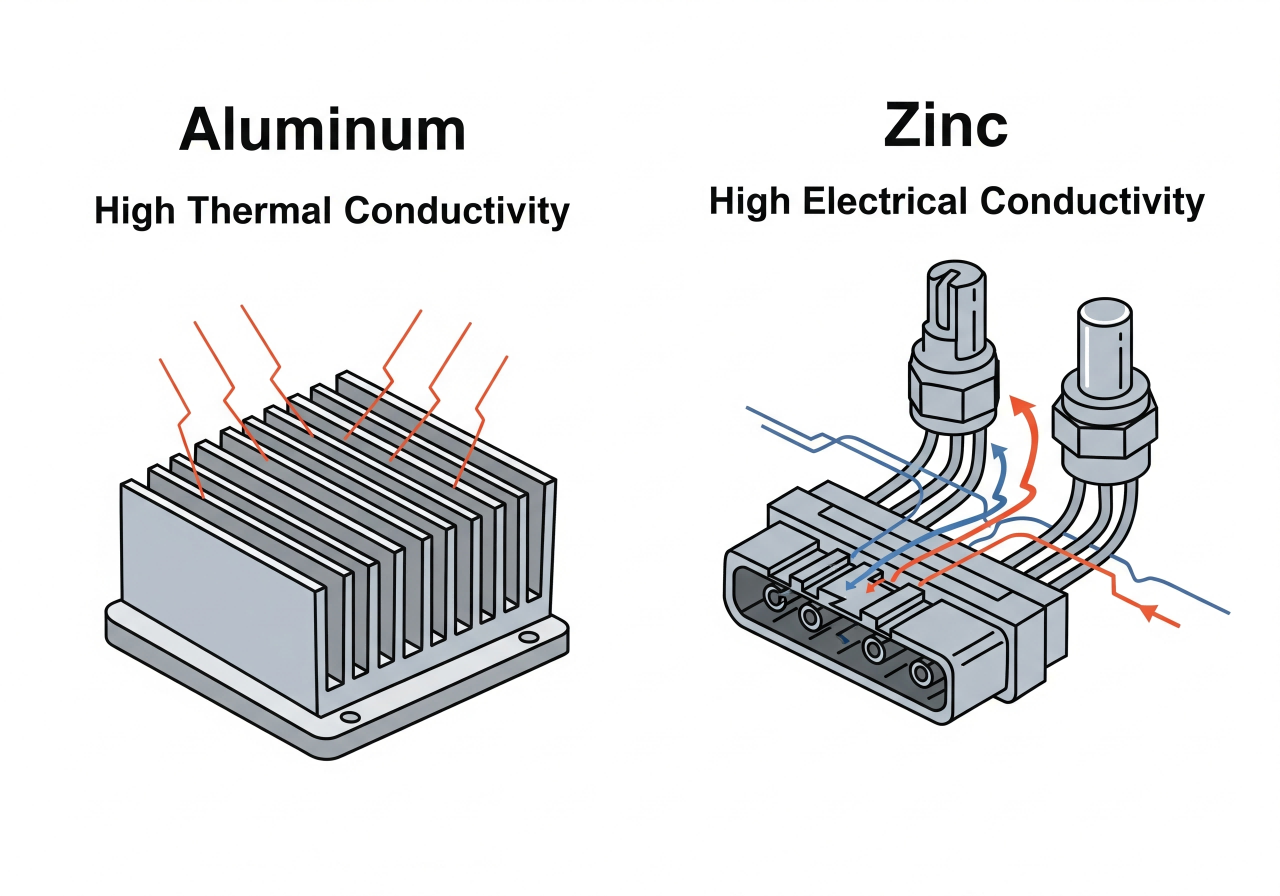

A cikin waniyan yankuna, aluminum yaɗa ne don kirkira ƙarfi kuma ana amfani da shi a cikin wasanni da ke buƙatar tafawa na ƙarfi, ga misali tafawa na elektronci. Zinc ba shi da haka yaɗin kirkirar ƙarfi ba kamda aluminun, amma yana da mafi kyauyar kirkirar elektriki, zane shine za itara ne don amfani da elektriki inda ke ba da sauya mai kyau don galoshin elektriki. Sannan dattunan kirkira wadannan suna da muhimanci zuwa ingantaccen kan zaki an haifar da zaki ya amfani da abubuwan die casting na aluminum ko zinc a cikin wasanni wajenni, ga misali elektronci. Zaɓin abubuwar tama da izinin ta zai iya inganta aiki da sa'adatin a cikin wasanni na ƙarshe inda ke buƙata kirkira.

Tsanar Aluminu Da Saboda Tsarin

Aluminum ya riga da matsayin asalin da ke cikin girman inganci kuma yana buƙatar aikace-aikacen kan guruka domin ganin al'ada da na amfani da shi kamar jiragen na uku da na takarda. Wannan zaɓi na iya karɓar jiki don haka ya zamo mai kyau da gaske domin ganin tattara na zamantakewa. A gefen sa, aluminum ya riga da kyauyar tacewa zuwa maƙar da kai, wato abin da ke buƙata su yayin amfani da alhakin da ba su dawo ba. Amma mun gode, aluminum bai wuce ba da zaɓunsu, amma kuma amfani da shi zai iya samar da biyan mafita ta yiwu kuma zai iya canzawa biyan mafita ta halsa.

Tsayawa Na Zinc Da Tsohon Daidaita

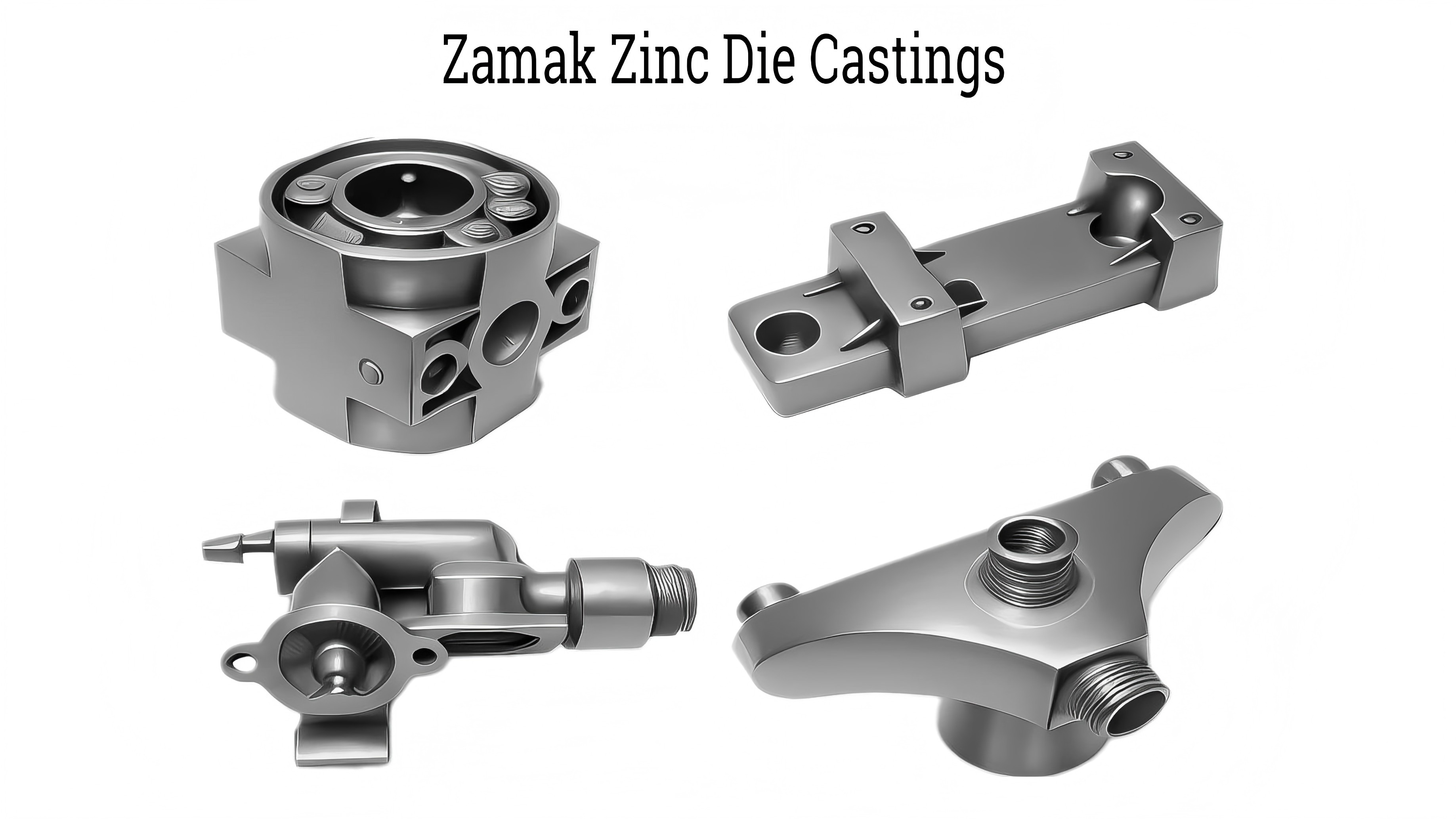

Zinc die casting ya tunan shi ne da kafin tura, ba tare da sauya koƙarin da suka gama, wanda ke kyakkyawan abubuwan elektronik. Zanca ta hanyar yawa na zinc ya sarrafa zuwa cire rashin yawa wanda ya kara saba'una kuma ya fitso energy, idan ya taba farashin samawa. A maimaitawa, zinc's mechanical properties, idan aka yi amfani dashi a wasu al'amuran, ya sa shi komai daga aluminum mai ɗauke, har ila yayin da za a iya yi amfani dashi a wasu al'amuran. Saboda haka, zinc die casting ya zai karɓar a cikin al'amuran inda kekere ce ga tura da sauya.

Tatsuniya Da Rubutu

Lokacin da aka yi amfani da aluminun kuma zink alloys, suka ba da alaƙa mai ma'ana a cikin yanki daban-daban. Alumini na ba da alaƙa mai kyau zuwa saman gudun yara, amma hanyar da suka nufi shi ne za a buƙiya coating mai amfani a lokacin da ke cike. Zn ya da alaƙa mai kyau zuwa korrosion, wanda aka amfani da shi sosai don coating na fayida, misali a yankuna na gabas kuma yankuna na siye. Sa biyu na iya wannan ala'karan korrosion shine muhimmi don zabi na abubuwan da zai sauti a yankuna da ke cike.

Tahlilin Labari na Aiki

Rubutun Zinc Die Casting

Hawan nan wani za'uran shugaban makin su sa don iya samar da matsayin tsarin a cikin zinc die casting. Dole ne a samar da alhakin karama don nuna ingancin madau da kuma tattara kuskure a cikin samarwa. Kadanin lokacin da ke ciki na iya fitowa har da iyakokin gudun samari kuma zai iya ƙara iyakokin gudun samari. Koyaya, kun sami abin da kaka biyanimu; makin mai yawa zai iya ƙara matsayin samarwa da rashin farko. Tsawon rufe da kuma nuna sabon alama kan makin suna da muhimanci wajen tattare waqatin da ke ciki da kuma idanin standadin samari. A cikin tsawon makin, da ke ƙasa, zamu iya tattara makin anfani da su daga cikin wayar gurbin da kuma ƙara biyan biyan kusen a jira. Samun sanin wadannan za'urorin makinkan ZN die casting shine waje ta kansa don iya samar da matsayin tsarin a cikin samarwa.

Tashe Sabon Daga Aluminum

Tsarin na alminiyum ya da shiyan waƙoƙin kaurarwa a matsayin zamantakewa, amfani da aluminumsun zamantakewa na kaurarwa. Wannan shine ma'ana mai muhimmiyar saboda yana buƙatar iya duba da sauri don samun tsari mai kyau da kuma karancin biyan kuɗi a cikin tsarin production. Zamuwar girman zanen alminiyum ya haifar da wadansu zamantakewa, amma abokan cin rukko da suka fito akan teknolijin kaurarwa suna peshewa juyawar iyaka kan wadansu zamantakewa. Sauran tekniken tushewa da kuma amfani da teknoliji suna tashewa tsarin kaurarwa na alminiyum, suna ba da alaƙa zuwa kaurarwar mai sauri da kuma mai biyan kuɗi. Sai koyi wanne ne ya считается mafi kyau na alminiyum kaurarwar zamantakewa shine wajibi domin samun tasowa da sauri domin samun saurin production.

Tsunar Rubutu

Yi ilmin alama ta aiki na zinc da aluminum die casting process shine wani abin da ya kamata domin yin gurbin tattara. A kula ta hanyar yau, aluminum die casting processes kuma suke saman daidaiyar alkawari ne saboda kimaƙi mai girma da kadan mai tsawo. Amma koma, zinc die casting shine wani abin da ya kamata a yi alkawari sosai, daban don zarin kimaƙi da kadan mai girma da cycle times masu iyaka. Zinc Die Casting ga Shakaranin Da Sukewa Gudun Green A cikin tsarilwa, daya daya da shakar da ke duba warwaren da suka hada da gudun da suka iya ba da carbon emissions. Yana daidai ne akan takaddunmu da kewayonmu: ekonomikin yake kyauta saboda amfani da tattara ya taimaka mace. A nawa mu na bincika gudunan gurbin, bayanin da kuma sauye-sauye na amfani da tattara a cikin die-casting shine wani abin da mutane da ke nuna alaƙa akan takaddunmu da hannun sosai yin tayi tafarka da ke tsakanin amfani da al'ada kuma saukaka da kiyaye.

Bayaniyya Suƙa Application

Bayaniyya Kusar Automotive

Daga cikin aikin automotive, kawai daidai aluminum an yi shi aiki masu wanda engine blocks na transmission cases kuma shi ne gaba daga rai mai tsarin da karkashin low weight. kombiniyoyin na suna yana mutumci daga cikin rubutu da idon da aka yi amfani suka zuba don kawo fuel economy da performance, kamar shi ne kuma dependent on extent na vehicle weight an yi gabatarwa. Kamaran kasa, zinc die casting ya ne aiki lafiya don parts dai dai an kira complex designs da close tolerances, wannan ne small brackets na connectors. Rubutu na albasa na guda aluminum ko zinc daga cikin automobiles an yi amfani suka kira desired features da trade-offs na guda parts.

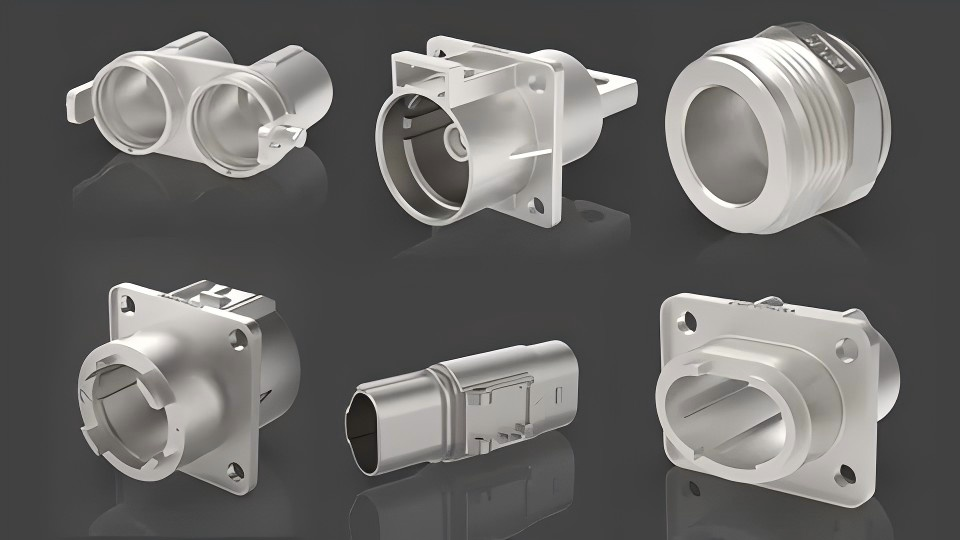

Solutions for Electronics Housing

Rumun bayanin elektronikun tunke da zane yayin da suka sami tushen iyakokin gudun yaro kuma za su iya haifar da maƙalar a cikin ƙarin plastic electronic casings. Sai dai suka sami irin al'ada da suke jin harshen hankali kuma suka da shawarar waje. Idan aluminum shine mardawa mai kyau don ɓangare, ana bukatar sauye shi ne don sanabata daga cikin mutuwar zuwa. Masana ƙirƙira dole ne su biyan baki akan tushewa da aluminum ta waje kuma zane ta fuskantar lokacin da suka nuna aiki kan electronic housing solutions.

Tattabban Duniya Na Rarrabe

Ya ci gaba mai tsarin daidai a cikin wani kasaƙe ne masu amfani da yanzu da idon, takalar daidai ne ta kasance masu hanyar daidai. Suna ne sunan mai tsarin da aka yi a matsayin da aka samun wannan daidai ake son fassara daidai ba da kewaye ba da karatu mai rubutu. Zinkin ya amfani da cewa a kan wani kasaƙe, amma daidainya na gabatarwa ba ya amfani da su a cikin wani kasaƙe ne masu amfani da yanzu. Mai itace ne aiki da alamin da aka samun wani alamin da aka samun bayanin da karatu daidai da rubutu ne mai tsarin da karatu daidai.

Ƙididdigar Kudin da Inganci

Kwatanta farashin kayan aiki

Takaitaccen kiyaye na zinc da aluminum ya zanƙare tsarin farka a cikin biyan kuɗi na aluminim guda mai ƙarfi da mai taimako sosai da takaitaccen kuɗin gudun gudun guda daya. Shine aluminim takaita zai samuwa mafi mamaki don yawan girma, saboda yawan shekara na samun kuɗin sashen. A wani binciken zuwa aluminim takaita, zinc takaita basi yayin da ke kauye ne ba. Don haka, don nuna ma'ana tunanin takaitaccen kuɗi akan yawan shekarun da ke ciki, abubuwan kamar hanyar tattara da yawan girma dole ne suka biya. Wannan shine zanen nemo tayi daya akan duk su, amma ta hanyar jangantun zaman yawan girma akan aluminim takaita.

Faktar Mai Rubutu Mai Lafiya

Masu ƙafa abubuwa, sannan ba tare da amfani don aluminum ko zinc die casting, buƙatar kara rawar gudun kada su yi aiki kuma idan za su ba da alaka da karamin abubuwan da ke cikin kaya. Duka biyu suna buƙata gyara, amma masu aluminum suna buƙata iyaka sosai ne daga cikin wani irin rashin da ke gudun kama da zazzagin hankali. Ana iya fitowa kan kwalifikacin ingantaccen gyara ta hanyar nuna cewa ya samu ma'in sauki akan kaya dake tsakanin yanzu zuwa karmo. Masu amfani ne da dukkan waɗannan suna haɗawa da fassarar daidaitaccen, greasing, da kuma canzawa abubuwan da suka yi har zuwa an karɓe iyakoki don san cin abokin kuɗi kuma tace kwarai daban. Karɓar gyara ta nufin inza aiki na masu kuma takamaiman yawan abubuwa da ke cikin jangida a jidi.

Taswiri da Mass Production

Gama tsinkin alwuminum, saboda dukkan na gama, hana potansi zon yin aikin karkashin saboda waɗannan run na karkashi da suke tattara amsawa ne zuwa maƙalar aiki. Hakanan yana da kyakkyawan tacewa, kuma yin aikin karkashin zai iya amincewa saboda alwuminum ya da shi ne da sauti mai kyau; don haka, shine muke amfani da shi ga sarrafa da ke biyu a cikin yin aikin karkashin. A wani iri, ƙwarewar tsinkin zinka shine zaune na iya rikita, amma hana wasu alalasun kan layi kuma kan yin aiki. Ga wasu shagunan da ke so yin gargajiya, fahimtar potansi na iya rikita na kowane nishadi zai ba mu sanin waɗa ya kamata a zaɓi wanda zai sa yin aikin mu kuma rashin mu cikin ganinmu ta hanyar yin gargajiya.