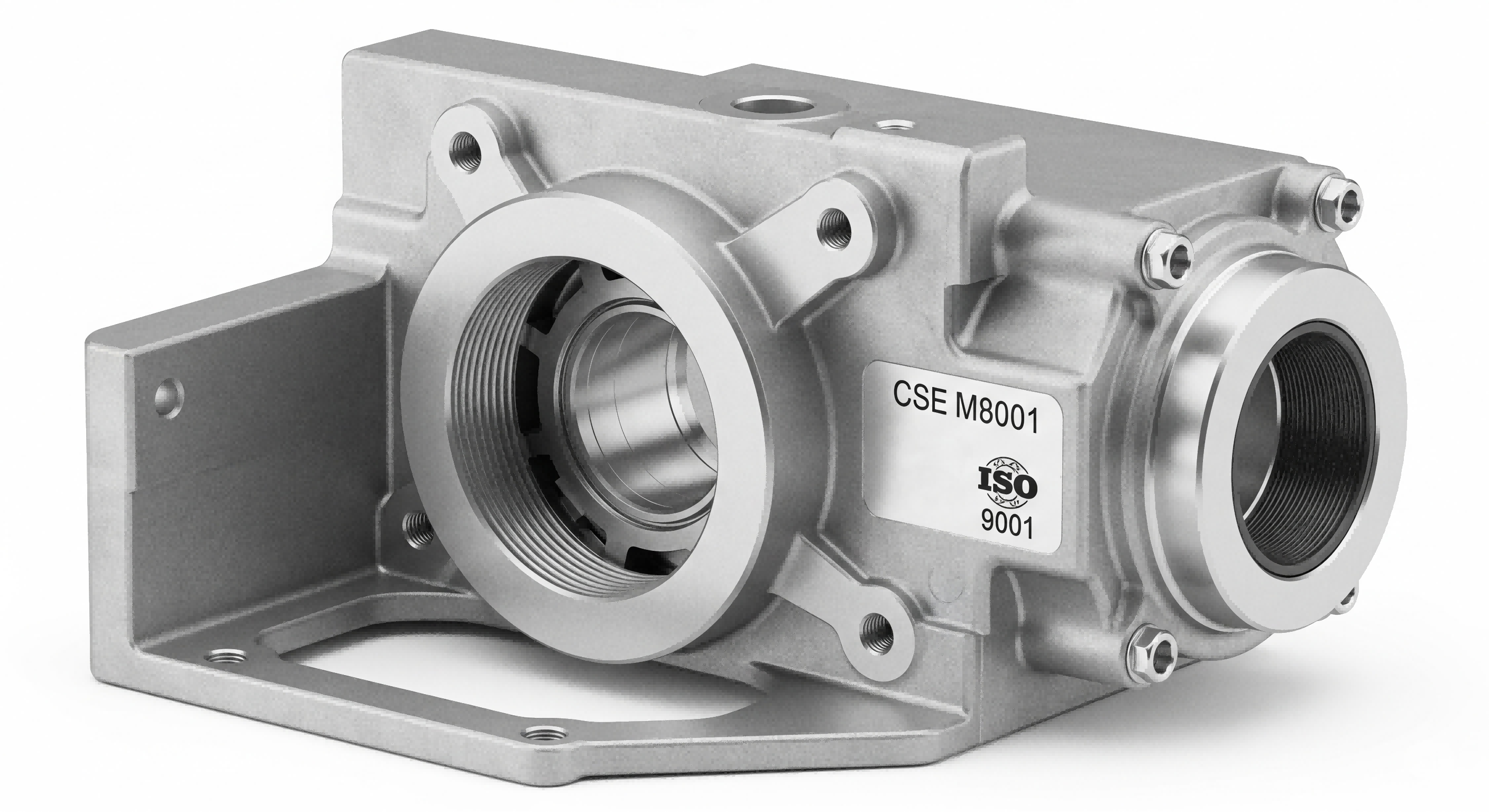

Sino Die Casting, an ISO 9001 supplier, has carved a niche for itself in the global manufacturing landscape. Since our establishment in 2008 in Shenzhen, China, we have been dedicated to providing high - quality products and services to our clients worldwide. Our ISO 9001 certification is a testament to our unwavering commitment to quality management.As an ISO 9001 supplier, we understand the importance of meeting customer requirements. We start by engaging in in - depth communication with our clients to gain a clear understanding of their needs. Whether it's a custom - designed part or a standard component, we ensure that every detail is captured accurately.Our design team uses the latest software tools to create detailed product specifications. These specifications serve as the blueprint for our manufacturing processes, ensuring that the final product matches the client's expectations. In the mould manufacturing stage, we follow strict quality control procedures. Our mould makers are highly trained and experienced, and they use precision equipment to create moulds that are durable and capable of producing consistent parts.When it comes to die casting and CNC machining, we adhere to ISO 9001 standards at every step. We monitor the production process closely, checking for any deviations from the set parameters. This helps us detect and correct issues early on, preventing the production of defective parts. Our quality inspection team conducts thorough checks on each product before it leaves our facility. They use advanced testing equipment to measure dimensions, check surface finishes, and verify mechanical properties.As an ISO 9001 supplier, we also focus on building long - term relationships with our clients. We provide excellent after - sales service, addressing any concerns or issues that may arise promptly. We are constantly looking for ways to improve our products and services, based on feedback from our clients. Our goal is to be more than just a supplier; we want to be a strategic partner for our clients, helping them achieve their business objectives through high - quality manufacturing solutions.