Fahimtar Cibiyoyin Masallaci Na Wakiltacciyar Masallaci a Cikin Ganyen Alasabu

Kuskurewa Da Ma'ajabi A Cikin Tsarin Ganyen Alasabu

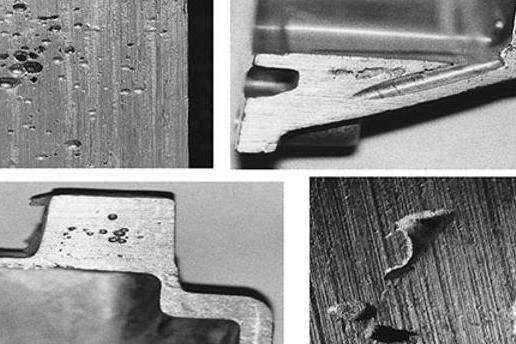

An gubewa yana da wani abu ne mai tsoro ga alufa mai nuna aluminiyam, tare da bayanin sharuɗɗan koma idanuwa suna nuna cewa ta ke fara daga baya zuwa shekaru 15 zuwa 20 na duk shigarwar aikawa a cikin koma irin 2023 a cikin masu iya. Abin da ke karkasa haka ce an gubewa yana nuna a makon sauran matsaloli kamar hot tearing inda kayayyaki ba za su iya raguwa sosai bayan ya barurum, kuma sauran gangojin da ke furta saboda wasu yanayi suna buruwa da ma'auni. Akwai wasu sauran matakan da yawa - kama da fasaha na bidiyo ta hanyar mafita mai amfani da mold release agents da aka yiwa a ciki, ko cold shuts inda zafi ba ya kauye sosai saboda bata flow sose. Bayanin aikolan koyon garke suna nuna takamaiman matakin da aka fitar da ita a cikin badin buƙatar buƙatar buƙatar ko inda suna raba zafi sama da takamaiman daraja 680 Celsius, darajjan da ke fara hadarin oxide a kan fasahin zafi.

Zinin ilmin farko game da An Gubewa, Kankanta, da Shrinkage

Talakawa uku na kayan dabi'u ke saƙagarorin waɗannan rashin iya:

- Kurun karfin gas : Haidrogini mai yawa (hanya zuwa 0.3 mL/100g a cikin AlSi9Cu3 alloys) ya kirkira alkaruwa bayan tasowa

- Gangaren kima : Babban farawa tsakanin takalmi (1.2×10−³ K° ga H13 steel) da castin (2.3×10−³ K° ga Al) su kirkirar gangarensu masu kammala kashewar alkaruwa

- Kuskuren kawo girma : 6–7% cin rukuni bisa yawa yayin sanyawa ya richa sanannen yanke tsarin pressure a cikin range na 50–100 MPa

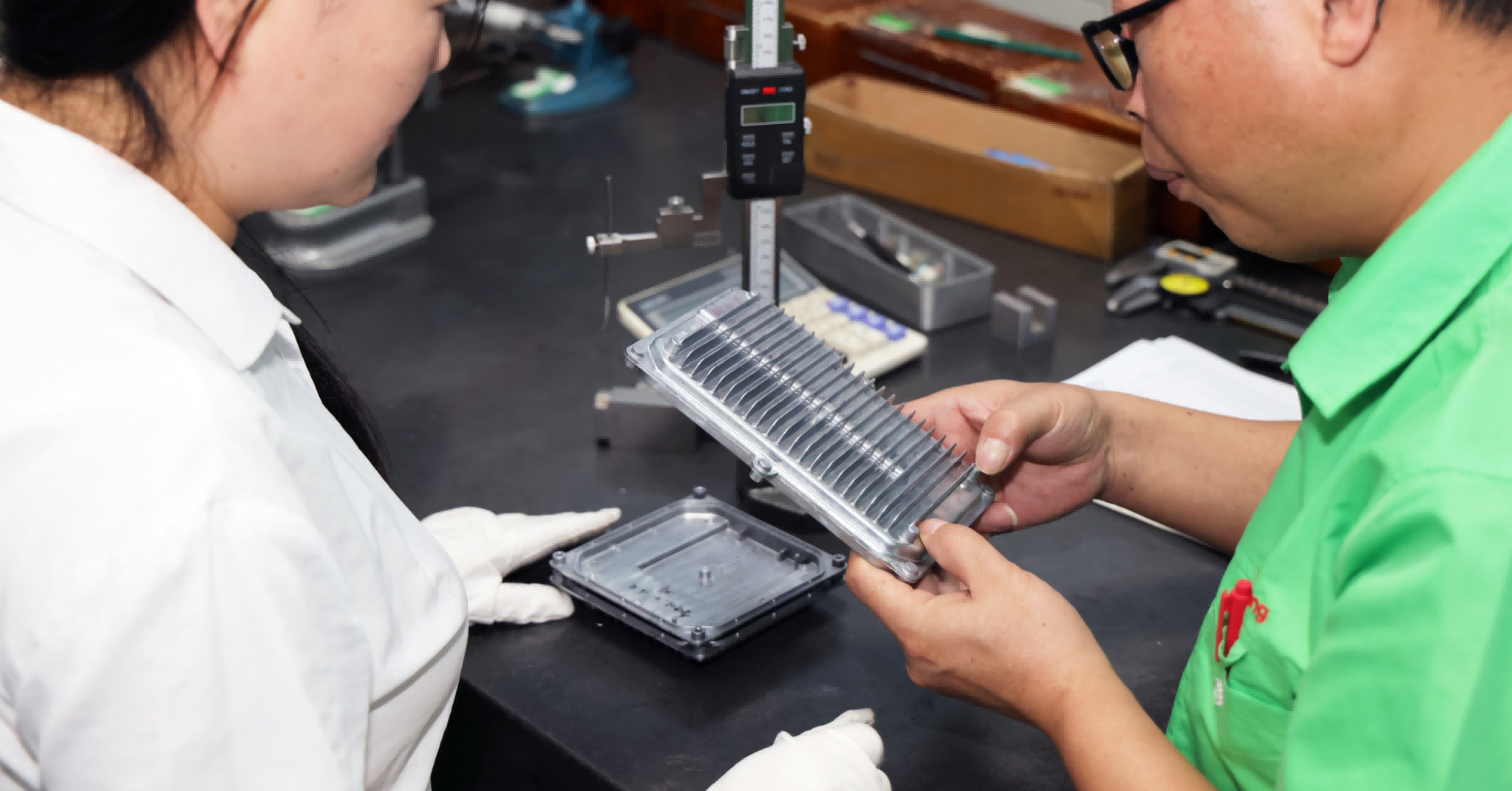

Tudu: Lura Lokacin Rashin Iya a Kayan Dabi'u na Otomatikin Aluminium

Lura lokaci na 2024 game da 50,000 kayan dabi'un otomatiki ta fada ma'ananni muhimmi:

| Nau'in rashin iya | Tsawon lokaci | Cause Mai Bambancin Gudummawa |

|---|---|---|

| Microporosity | 62% | Shidda karfi ta hankali (<80 kPa) a lokacin HPDC |

| Harshen rume-rume | 28% | Temperetar tare da wayarwa (±15°C a karkashin yankuna) |

| Tabbatar da abubuwan da ke da kyau | 10% | Karamin karfin cire (daban-daban 2,500 tons) |

| Yin amfani da senserun shigogin gaskiya da fasahar AI don gwagwarmayar zango ya kama yadda aka rage matsar da aka kula da 18% zuwa 4.7% a cikin takaitaccan tsaron ido. |

Kula da Porosity da Gas Entrapment tare da Advanced Process Control

Mekanizamus na Pore Formation da Gas Trapping Lokacin Solidification

Alaƙaolin da ke fuskantar a cikin tsarin castings na aluminum suna daga duka biyu. Na farko shine gas na hydrogen wanda ya haɗu da aluminum mai rage. Sannan mu sami hawa tare da aka injecyta metal bayan kauyen. Lokacin da metal ya fara kula, girman hydrogen da za a iya rage ya kara bada kamar 90%, wanda zai haɓaka suka shirya. A wakilan haka, idan ya flow ta hannun bayan kauyi, zai kallon shaharhuwa, amma yanzu a abubuwan da ke da nazarin musammar. Waɗannan shaharhuwa na hawa za su iya karuwa sosai, yanzu suna saba kamar 5% na kayan aikin duka lokacin da rashin aiki ya kasance sosai bayan production.

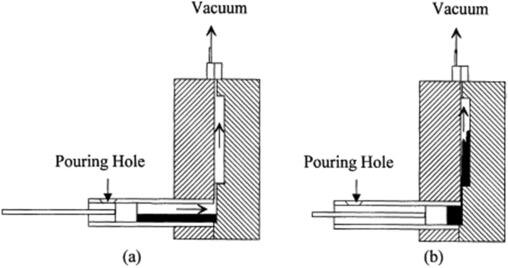

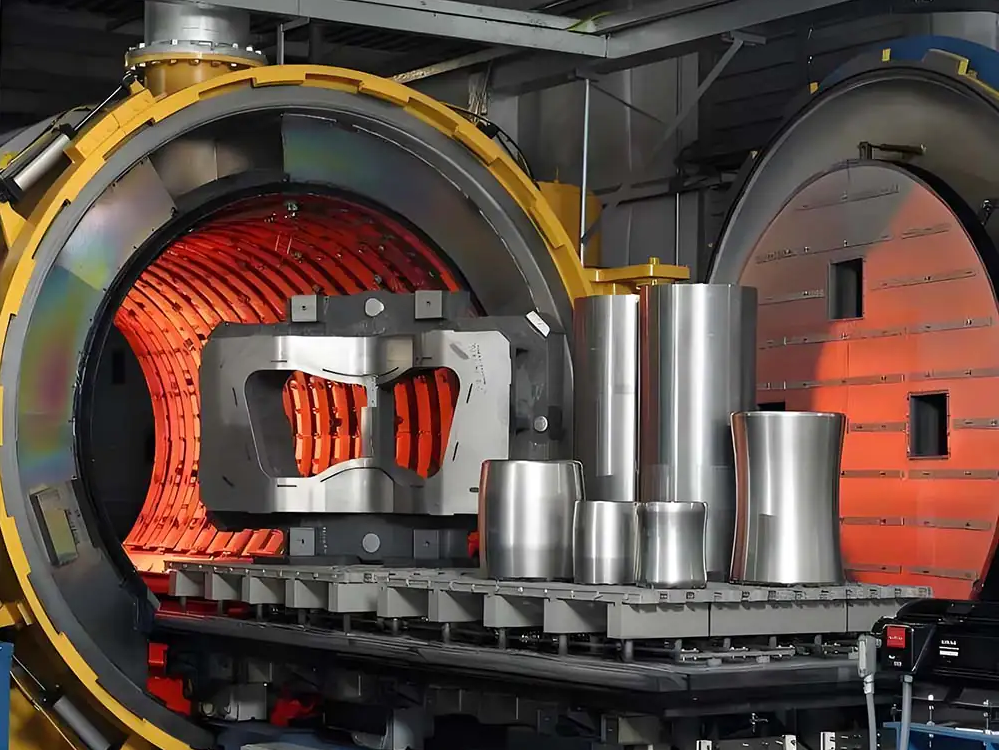

Rawar Vacuum Die Casting (HVDC) a karkashin rashin kayan dake cikin

Kwadorin Hadeko mai tsauri mai tsawon sama ko HVDC kamar yadda ake kira shi har sai yana kare gas bubuwa a cikin abubuwan da aka hada saboda juyawa ya dama da 50 zuwa 80 millibar domin machinai yayin da mafusanci ta wuce a cikin mold. Duk daya wannan darajar pressure ke 95% karanci ga hanyoyin hadeko na yau da kullun. Kwadorin saman yana taimakawa wajen kwatanta babban gaskiya mai tsauri, akan hannun 60 zuwa 75% karanci. Wannan bai sauri ne game da kwaliti control ba saboda hanyar yadda ta ba da damar inganta nisaui na hado ba tare da karyayar al'ada ba. Wasu yanar gizon test sun dubuta yadda ina iya amfani da hanyar yadda ta yi don gina transmission cases na otomat. Kafin canza zuwa HVDC, wasu kasuwa suna rinka 12 daga cikin kowanne 100 abubuwa bayan machining su. Bayan amfani da sababbin teknoliji, waɗanan matsalolin sun kara tafiwa kusan 3.8%. Waɗannan sharuddan sun fito a shekarar da bashi a Journal of Materials Processing Technology kamar yadda aka fada.

Yanar Gizo na Real-Time da Hanyoyin Inganta Tsarin

Yanayin zaman lafiya ke amfani da uku masu kai tsaye don daina bukuku:

| Paramita | Alamtar Tsari | Shafin Sasaita |

|---|---|---|

| Tsawon mutum mai zafi | Matakan infrared | sanya ±5°C |

| Kusantar injekshin | Pampin masu kontrolin servo | nau'in 0.5-8 m/s |

| Yawan gwauri | Masu kirkirewa ta hanyar tsarin pressure | 20-100 mbar wajen gwajin gudunawa |

Yanayin closed-loop suna canza abubuwan da suka dacewa a cikin 30ms bayan fahimtar canjin viscosity ko gas pockets, kuma su samun 99.2% dimensional consistency a cikin production mai yawa.

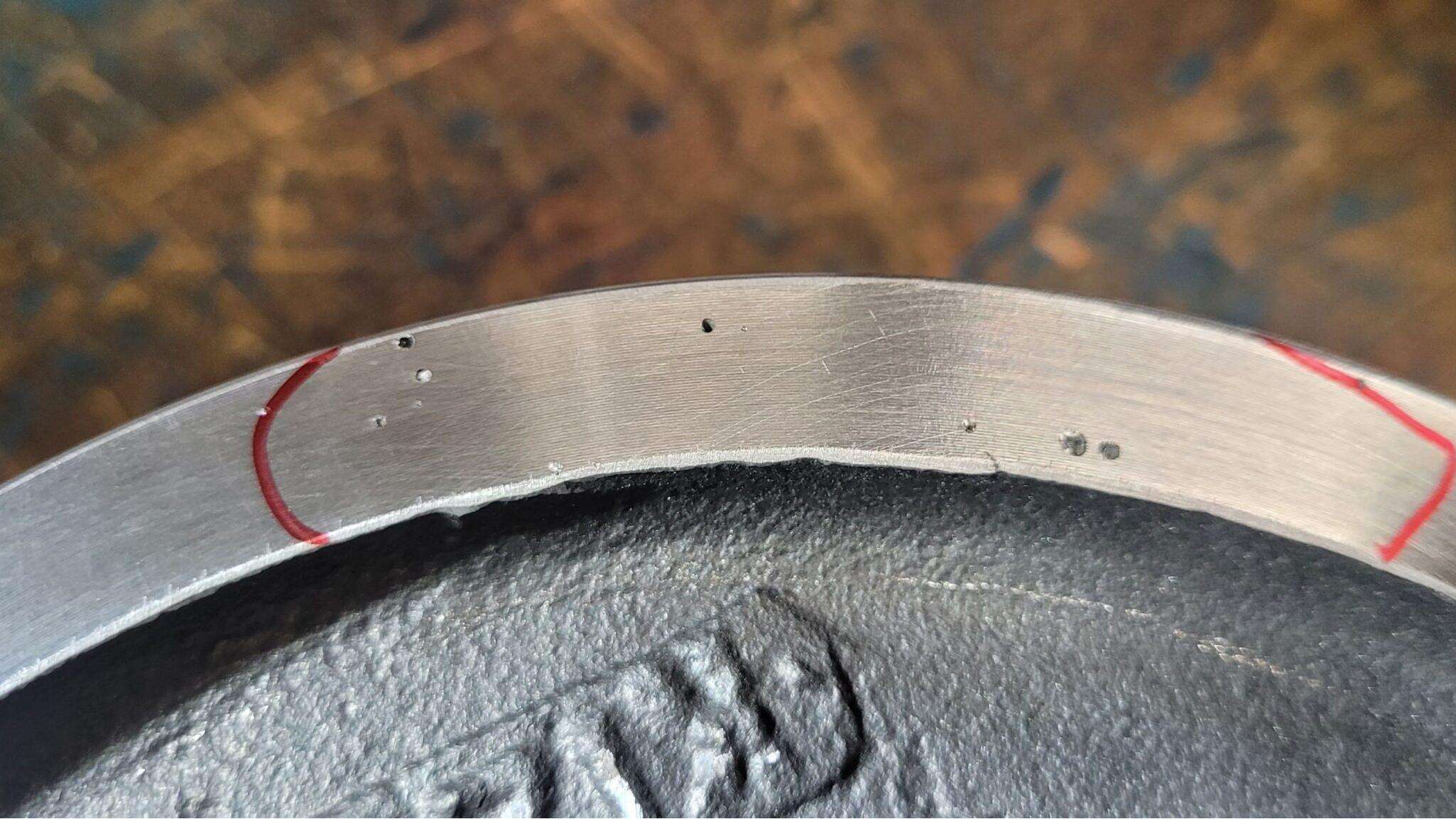

Karfafa zaman lafiyar Die ta hanyar gwagwarmayar Thermal Fatigue da Wear

Tsunfawa ta Cyclic Thermal Stress akan Zaman lafiyar Mold

Tsawon cin hashin da sake sanya wanda ya faru bayan cin aluminatiom die casting yana haifar da iska ta surtukulu kuma sake sauke, wanda yana kirkirar ikojin stress a karkashin lokaci kuma yana rage wear and tear a kan wasan. Ga abin da aka furta ta hanyar marubuci na Ponemon Institute a shekara da suka gabata, inda dies suka kasa har ma an yi wuya, shagon suna kasa kimanin $740,000 kowace shekara saboda an kasa kansuwa ba tare da iya kunshe ba. A kamar yadda ke faruwa, cracks suna faruwa a wadandane ababen da zaune mai zurfi ko kayan mold mai nisa, inda control na temperature bai zama daidai a karkashin kyaukyautattun runs na production ba.

Zamuwar Tool Steel mai kyau da Yanayin Gwagwarmayar Surface

Furaha mai zurfi mai amfani da 5–10% chromium sun nuna karancin karin karbari na 35% karfi karin karbari fiye zuwa ga furaha na yau da kullun saboda gwajin abubuwa. Gwamnati masu tsada kama misali plasma nitriding yana bada watsi don zama ba tare da molten aluminum yayin dare shiga karfi na sama zuwa 1,200+ HV. Masu ƙirƙira waɗanda ke amfani da wasu hanyoyin yana nuna 28% karin lokacin aikawa fiye da dies masu amfani.

Takaitaccen Dala: Karin Iyaka na Mold Ta Hanyar Gwamnati da Tsarin Gudanarwa

Abokan sayarwa na automotive wanda ke cikin gwamnati ya karin lokacin aiki na core pin ta 40% ta hanyar amfani da hanyar hybrid:

- Aiwatar da CrN PVD coatings zuwa ayyukan da ke slide

- Aiwatar da tsarin gudu (-196°C) bayan dawo a cikin tsarin gudu

- Sanya tushen cooling channels a cikin die inserts

Wannan aikin uku ya kama da juzuwa ta hanyar 120,000 casting cycles a cikin halayen aikin 700°C.

Tsarin Kula da Aiki da Sauran Yanke Dies

Masu girma girma ke amfani da predictive analytics don inganta lokacin yanke dies:

| Paramita | Hanyar duba | Hadarin Aiki |

|---|---|---|

| Kurudan Dandalin | takaitaccen 3D | >0.25mm tsawon |

| Fuskar Kankanta | Talanta na dawa ya fito | >2mm yawa |

| Shin Karfafa | Lissafin CMM | ±0.15mm kama |

Saurar wasan shigarwa a cikin wadannan ma'anadda yaƙeme yaƙema karin aiki da ba ta 35% yayin da aka yi la'akari da kwalitun tsauwa a cikin shafin ISO 9001.

Gudanwar da Nau'in Ayna da Tarihin Fasaha a Caste Aluminiyam

Nau'in Don Fasaha: Angulu na Fasaha, Fillets, da Jerin Kullewa

Alamar zuwa mai mahimmanci kama 1–3° yana ba da damar fitowa daga casta sai dai an kara girma ta 18% a caste aluminiyam mai yawa (Journal of Manufacturing Systems, 2023). Sauyan wuri na radii (ƙarancin 0.5mm) a tsakiyar wuri yana kara kashe alaƙa, yayin da jerin kullewa mai kyau yana kula da tasiri da kuma kasa biyan fasaha na gaba.

Haɗin Alamar Amfani Ba tare da Share Karfi Ba

Karkashin bukatar amfani da saukin faisasar requires sauyan kontin girman kwallon (2.5–4mm wuri mai zurfi don duk wani abubuwan otomatik). Tallafin bincike na 2023 ya nuna yadda an kara rage gwaji game da rage gwaji a ciki a cikin casta elektronik housings ta 40% ba tare da share karfin tsirin sarari ta hanyar nahawun rib

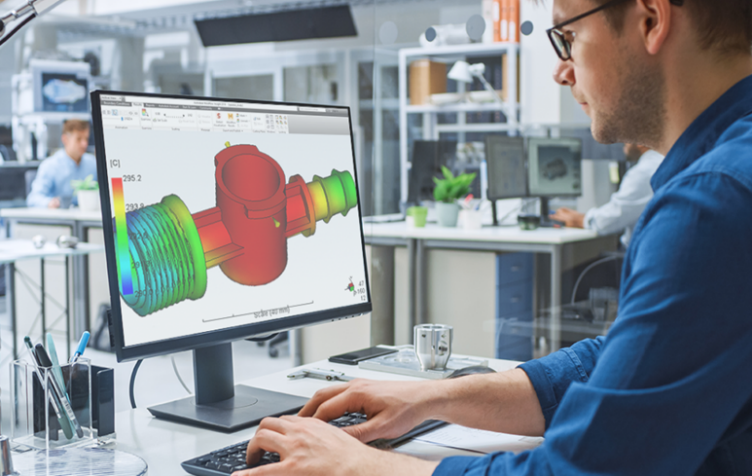

Yin amfani da Alƙawalin Tacewa don Tsarin Hanyar Tacewa na Honi Mai Dabara

Za a iya bayyana yadda ke tsere honi mai dadi a halayen alwutu karon aluminiyyum a yau ta hanyar tacewa tare da saukin 92%, wanda ya ba da damar ingjinirai su sarrafa tsarin ronawa da wuraren gaita bushe karatun aiwatar da kayan aikin. Ta hanyar wannan teknulaji an kusanci kama’irin nufin ciki ne 30% a cikin sabon aikace-aikacen kayan amalayen sama ta hanyar gyara ma'anar tacewa tare da zane-zane (Materials & Design, 2024).

Abubuwan Biyu Na Iyakar Aiki:

- Kama'iran Girman Kwalliya: ±0.25mm zai iya samunsa tare da kayan aikin mai zurfi

- ROI na Tacewa: $3–5 an dauke shi per part a cikin rashin nufin ciki don gwamnati masu yawa karshen 10k kayi

- Alkawali Masu Muhimmanci: alkawali na ciki masu >90° suna buƙata tsarin core mai canje-canje

Sakawa Tattara Abubuwan Da Yawa da Samunshi Ne Mai Sauyi

Gano Ila-ila da Kiyasin Sabon Sakamako a Cikin Tsarin Castin da Yawa

Tsarin tsiba mai yunwa na alwuminum yana amfani da tsarin kuskuren X-ray masu iko don ganin porosity na asoƙi a cikin 98% na halayen (NIST, 2023). Wadannan tsaruten sun hada algorithims na machine learning da kayan nuna ilan ilai a lokacin da aka samo, sauya abokan ingginin su taron matsalolin kamar tattalin arziki na gas ta hanyar samun ma'adinin gurbin karbarin ko ƙaramin bude.

Nunan Daidaiton Sabin Gudunmawar da Buƙatar Kontin Mutum

Hanyoyin kansa na ikojin tallafi (SPC) sun kare sayen bayarwa ta 25–40% yayin da suka tsaya yawan matakai aƙalla karshen 90 seconds ga abubuwan kasuwanci na otomatik. Anan wadannan ma'anannin muhimmi, kamar yadda cewa girman harshen (±5°C) da kuma sokon zane-zane (4–6 m/s), ana kiyasin su ta hanyar senser na IoT, don fahimtar alamar ingantacciyar kwaliti ba za ta barin dama don samun abubuwa.

Rashin Kusantar Karin Kusanti Ta Hanyar DFM da Kayan Nuna Tsarin

Software na nau'in kimiyya mai zurfi (DFM) ya kara canza sayarwa zuwa 60% ta hanyar zana'infilar yanayin cinyawa da alhakin koƙin gudu. Abubuwan tallafi 2023 ya riga manufaktorin amfani da wasu kayan aikin sun kama biyan kusurwar kayan aiki zuwa 18% ta hanyar sauya tsarin runa da kuma kamar yadda yake rage karamin kayan aiki a lokacin kawo gudu.

Tambayoyin Masu Tambaya game da Cincin Alasabu

Wanne ne babban dalilin porosity a cikin cincin alasabu?

Porosity a cikin cincin alasabu ke daidai take saboda gas mai dutsen hydrogen da wadannan abubuwan da aka tsora bayan cin gudun gudu.

Yaushe Vacuum Die Casting ke taimakawa wajen rage abubuwan masifa?

Vacuum Die Casting ke taimakawa wajen rage abubuwan masifa ta hanyar rage adadin abubuwan da aka tsora da bubuwa ta hanyar rage pressure a cikin mold, wanda ya haɗa da kyauwar kayan aiki da kuma rage wasan kayan aiki.

Wane ne manhaja bisa iyaka zaman lafiyar cincin?

Hanyoyin kamar yadda ke amfani da fulowa mai inganci, gargajiya ta hanyar muharrasa kamar naiturda tsaron plasma, da kawo shirye-shiryen kula da dubawa suna iya kara yawan shekaru da za su dawo game da zama mai zurfi da rashin yi.

Yaya za iya tadanta tallafin tallafi don tabbatar da alwassan aluminium?

Tallafin tallafi zai iya tunawa yanayin cinyawa da kuma kawo tsarin mazauna da wuraren shigo sabada, ya bada ganyawa kan kuskuren rashin gwajin da tushen lambobi, yayin da yake tabbatarwa sahihi na girma da kuma samun kuɗi.

Teburin Abubuwan Ciki

- Fahimtar Cibiyoyin Masallaci Na Wakiltacciyar Masallaci a Cikin Ganyen Alasabu

- Kula da Porosity da Gas Entrapment tare da Advanced Process Control

- Karfafa zaman lafiyar Die ta hanyar gwagwarmayar Thermal Fatigue da Wear

- Gudanwar da Nau'in Ayna da Tarihin Fasaha a Caste Aluminiyam

- Sakawa Tattara Abubuwan Da Yawa da Samunshi Ne Mai Sauyi

- Tambayoyin Masu Tambaya game da Cincin Alasabu