Igbanwe Ihe Ndị Dịka Ihe Ndị Na-Enyere Obi Uba N'Aluminum Die Casting

Ndị Njehie Na-Adabere Na Njehie N'Aluminum Die Casting Processes

Ihe nwere ike ịdị irè n'ime aladì na-achọghị ka ọ dịrị ya maka ndị na-ejikarị aladì, site n'ime data njikọ a na-ezighị ezi maka ịdị irè na-adịkarị n'etiti 15 ruo 20 percent nke ụfọdụ akụrụngwa ndị a na-enyere anya na mpaghara a na-abịa na afọ 2023 gara aga. Ihe na-enwekarị mmeri bụ na ịdị irè na-adịkarị n'akụkụ ihe ndị ọzọ dị ka inweta ọtụtụ mgbe akụrụngwa enweghị ike ịpụta n'oge ikpotogharị, ma ọ bụ mkpụkpụ irè nke na-eme bara uru n'ihi na ọnụ ọgụgụ dị iche iche na-erisaa n'ọnụ ọgụgụ dị iche iche. E nwere ihe ndị ọzọ dị ukwuu - lee ihe ndị dị ka irè nke oke ibu nke mere ya site n'ime ihe na-enye akụrụngwa nke a tụfuru n'ime, ma ọ bụ inweta oyi nke na-emegbu emegbu n'ime aladì na-anabata ekwenye ma obere oge sị na ha na-agbanwe. Akụkọ njikọ nke factory floor na-egosi na otu atọ nke onwe ụlọ nke ọdịda ahụ dabere na ngwaahịa ngwa ngwa ma ọ bụ mgbe ha na-echekwa aladì n'elu 680 degrees Celsius, temperature ndị a na-eme ka ihe ndị oxide dị n'ihu aladì.

N'ihuenyo Ndị Saisịntifik Nke Porosity, Cracking, na Shrinkage

Ndị oghọm mkpụrụ ọtụ three na-agba mbọ ọdịdị banyere:

- Nchekwa nke ihe mgbawa : Ihe mgbawa hydrogen (n'akụkụ 0.3 mL/100g dị n'ime AlSi9Cu3 alloys) na-eme bubụlụ mgbe eji eme ya akpụkpọ acha acha

- Ọgụga ọgụga : Njikọta dị iche iche n'etiti mkpịsị aka (1.2×10−³ K° maka H13 steel) na mkpịsị aka (2.3×10−³ K° maka Al) na-mepụta ọgụga ndị na-abịa n'ime mkpịsị aka

- Ihichapụ ikike ịbawanye : 6–7% nke ngbeghị obimba mgbe ọ na-acha achị achị chọrọ ikike ikike dị n'ime 50–100 MPa

Akwụkwọ Nzukọ: Mmepe Ọdịdị n'ime Ngwá Ọrụ Aluminum Na-Akwụkwọ Nzukọ

Mmiri 2024 nke 50,000 ngwá ọrụ transmission housings ekpugara akụkụ ndị dị mkpa:

| Ụdị Ọdịdị | Ọnụ nchekwa | Ihe omume mbụ |

|---|---|---|

| Microporosity | 62% | Ọkụlọ ụgbọ ala n'akụkụ (n'etiti ±15°C) |

| Hot tears | 28% | Mbelata ụgbọ mmiri (n'akụkụ ±15°C) |

| Ntaramahụhụ akụkụ | 10% | Igbe ntị n'ime na n'elu (n'akụkụ ±15°C) |

| Ịmepụta sensozụ nke ọkụlọ dị n'otu na inweta AI maka mbelata ọkụlọ kwadoro ogo mkpokọta site na 18% ruo 4.7% n'ime otu osisi ịghịrị. |

Gbalịa ịkwalite Porosity na Gas Entrapment site na Advanced Process Control

Mechanisms of Pore Formation na Gas Trapping During Solidification

Ndị pores nke sị na aluminum die castings dabere n'ụwa abụọ. Mbụ bụ iyi hydrogen nke na-adị n'elu melted aluminum. Nke abụọ bụ iyi nke na-akpọkarị mgbe metal na-inject n'ime molds. Mgbe metal na-aburu, oke hydrogen nke nwere ike ịdị n'elu ahụ dị ala karịa 90%, nke mere ka tiny bubbles si. Na mpụga ahụ, ma metal na-agba nso n'ime mold, ọ na-enweta pockets nke iyi, ebe dị ka n'ime nzukọta dị njikere. Ndị pockets nke iyi nwere ike ịdị iri, nke atụrụ ịkọta site na 5% nke otu nzukọta mgbe mmepụta na-esi na mmeri.

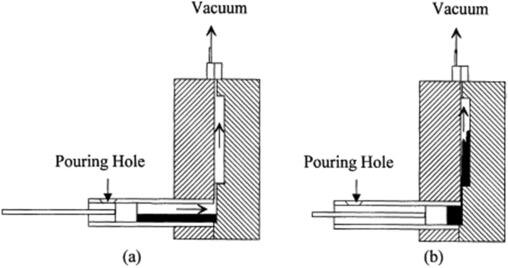

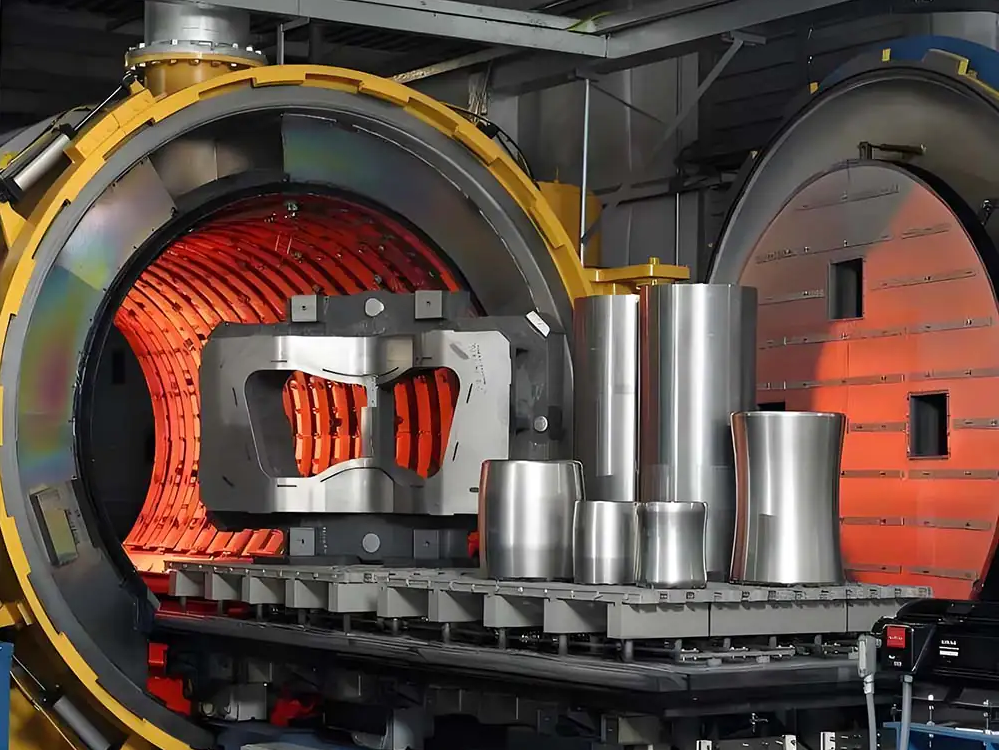

Ọrụ nke Vacuum Die Casting (HVDC) na iduza internal defects

High Vacuum Die Casting ma ọ bụ HVDC dị ka a maara ya karịa nwere ike inwe gas bubbles n'ime ngwaọrụ eji eme ya n'ihi na oche ahụ adịghị 50 ruo 80 millibar mgbe a na-egbu egbu metal eji eme ya. Ebe ọcha ahụ dị adị 95 peresentị karịa ọnọdụ dị mkpa nke ngosipụta traditional. Nchekwa ahụ nwere ike ịkpagba ụgbụa nke zuru oke, nke dị ka 60 ruo 75 peresentị enweghị. Na eziokwu a, ezigbo isi ihe bụla, nke a na-enyere aka imebebe nke omume maka njikwa isi ihe site n'imebebe oke omume n'agbanyeghị isi ihe. Ngosi ndị ugbu a gara n'ihu iji mee ka olee nke a na-arụsi ọrụ maka ngwakọta auto transmission cases. Mgbe e si eji HVDC, ngalaba ndị a na-ejikọta 12 n'ime 100 ngwaọrụ mgbe a machitela ha. Mgbe e mere ntinye akwụkwọ ọhụrụ ahụ, mmepụta a pụrụ ọnụ dịka 3.8%. Ndị a na-achọpụta afọ gara aga n'Journal of Materials Processing Technology.

Nlele Njikwa na Iwu Mmekọrịta Mmekọrịta

Sistemu modren enweela ike mgbanwe atọ imepe ihe onwunwere:

| Oke | Ebe nchekwa | Ọkacha ịgbadụ |

|---|---|---|

| Ogologo oyi mmiri ahụ | Pyrometers infrared | stabilization ±5°C |

| Ogologo oyi injection | Pumps servo-controlled | modulation 0.5-8 m/s |

| Igbe vacuum | Onyonyo mmiri ikuku | 20-100 mbar imekọrịta |

Algorithim closed-loop na-agbanwe ihe na-adịghị 30ms n'ime mgbe ha na-elekọrịta njikọ ma ọbụ gas pockets, na-arụ ọrụ maka 99.2% njikọta n'ụzọ dị ka ọ dịrị n'ịme ka oke ihe dị elu.

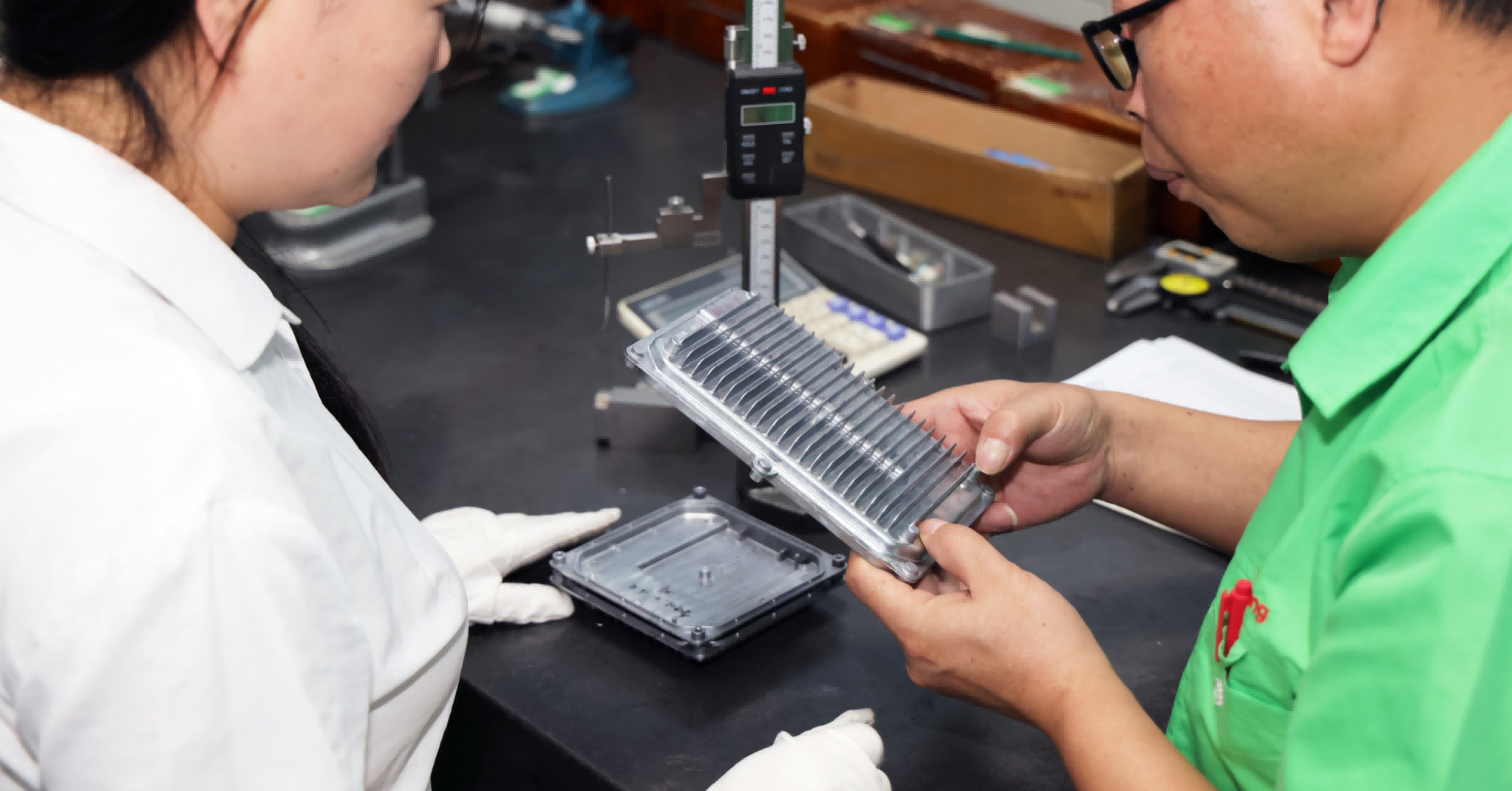

Igbanwe Oge Ndị Ndị Na-eme Ka Ndị Ndị Nwere Obobo Maara Ma Ewepụwa Ihe Nwere Obobo

Mmiri Mmiri Njikọta Mmiri Na Ndị Ndị Nwere Obobo

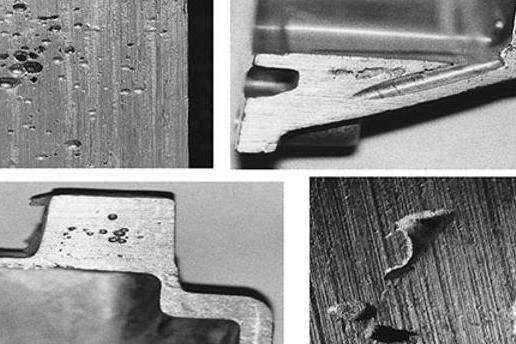

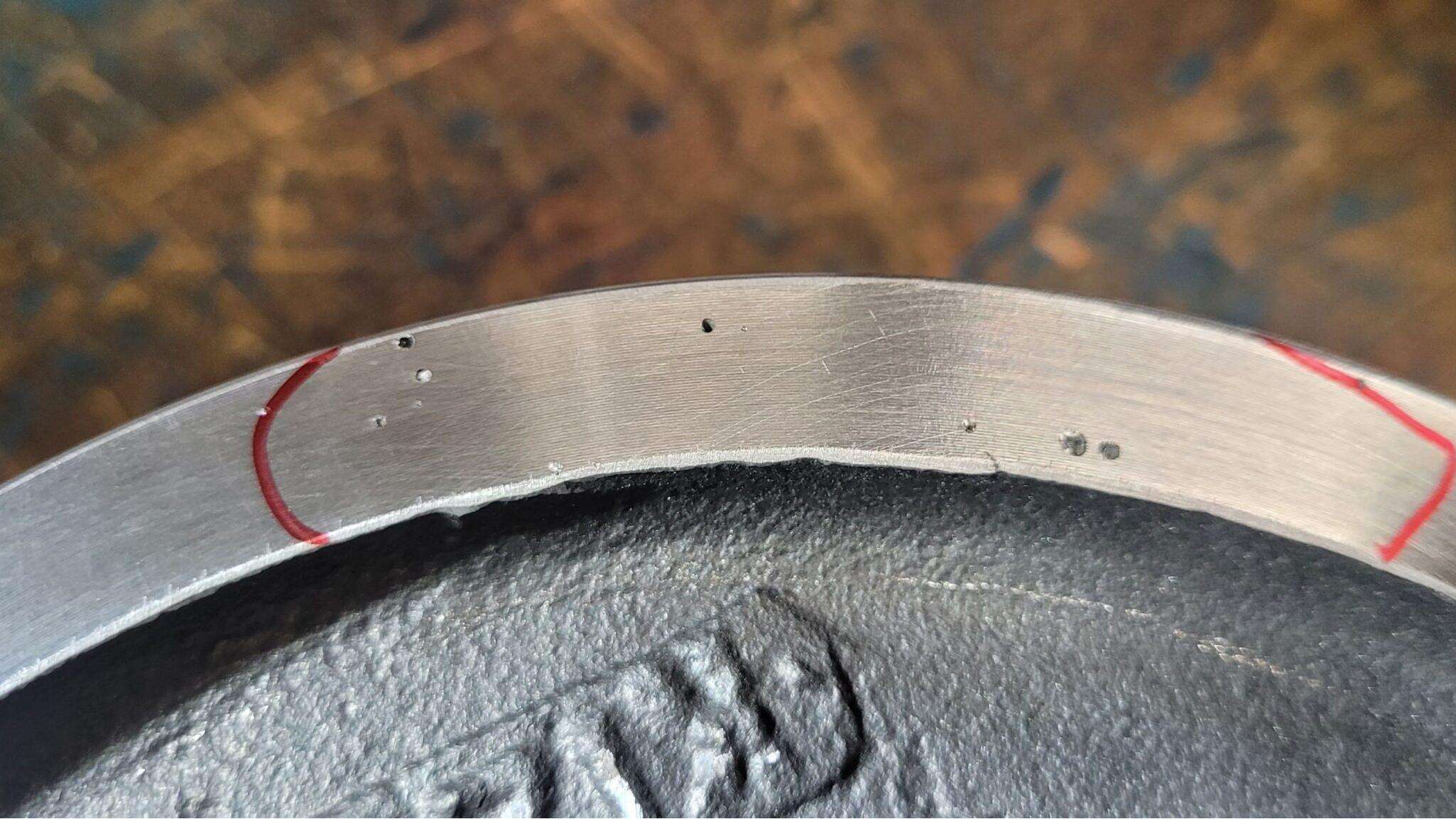

Njikọta mmiri na mmiri nke dị na aluminum die casting na-emekarị tool steel ịdị ya obere ma ọ bụ ọdịda ya, nke na-enweta ike na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na-adịghị ọcha na......

Ihe Kacha Mma Nke Onyonyo Steel Na Ihe Ndị Na-eme Ka Obodo

Steelụ nke dị ọla na-enwe chromium nwere ike 5–10% nwere ike ịdị irè maka ngwaọrụ nke ọkụ 35% karịa steelụ ndị siri ike gbasara njikọ akụrụngwa. Ndị na-ejikarị usoro ọhụụ dị elu, dị ka plasma nitriding, imejụta ike mbepụ nke aluminum mmiri ebe ọ bụla ọ na-enyere nkwarahụ mmiri ọkụ 1,200+ HV. Ndị ọrụ na-ejikarị usoro a nwere ike ịdị irè 28% mgbe ụbaa anya dibu ibu ahụ.

Akwụkwọ Nchịkọta: Iji Coatings na Heat Treatment mee ka Okirika Mould dịrị

Omenala nke abụọ na-ese okirika: Ime ka Ebe Core Pin dịrị site na 40% n'iji usoro nke ọtụtụ:

- Jikarị CrN PVD coatings na ngwaọrụ sliding

- Mee cryogenic treatment (-196°C) tupu emechaa tempering ikpeazụ

- Gosipụta cooling channels conformal n'ime die inserts

Usoro atọ a napụta nkebi nwere ike ịkpachara usoro dị otú ahụ ruo 120,000 casting cycles n'okpuru 700°C operating conditions.

Ịkpachasị Udo na Njehie Njehie maka Dies

Ndị isi foundries na-eji predictive analytics iji wepụ ya ma wezute ohere maka ijupụta dies:

| Oke | Onye na-ahụ maka Usoro | Igbe Njikwa |

|---|---|---|

| Njizi Nke Onuoru | igukọ 3D | >0.25mm obere |

| Mgbagwoju Anya Ikwaa | Ịnụ ụlọ nke ahụ dị ya na njide | >2mm ogologo |

| Mgbanwe Obara | Igukọ CMM | ±0.15mm njikwa |

Ịbata nke aghaala na-adabere na atụmatụ a na-eme ka oge ọ bụghị na-ezí 35% mgbe e kepela isi ihe nchinda dịka nke ISO 9001.

Ịmụta Ndị Ọrịa Na Ikwanso Mmepe N'ime Ọrụ Mmiri Aluminium

Ihe Mmepe maka Ọrụ: Ebe Ndị Daghara, Fillets, na Parting Lines

Ndị ọrịa geometric dị mkpa dị ka ebe ndị daghara 1–3° nwere ike inye ohere ọkụ mma, na-eme ka ohere nkwarụ ahụ anwụsị site na 18% n'ime ọrụ aluminium die casting dị elu (Journal of Manufacturing Systems, 2023). Imeputa radii (nkenụma 0.5mm) n'akụkụ nchikota na-adaba stress, ma parting lines edepụtara ya eme ka enweghị flash formation na onwe onwe ọnụ egwuregwu.

Incorporating Functional Features Without Sacrificing Integrity

Ịgbakwa ike ngwaọrụ na ike ọrụ mere ka ịkpachara obere obere (2.5–4mm optimal range for most automotive components). A 2023 thermal analysis study demonstrated how integrated cooling channels in cast electronics housings improved heat dissipation by 40% without compromising structural rigidity through topology-optimized rib patterns.

Iji Njikọba Njirimara maka Mbido Ndị Na-Adịkarị

E kọwara nke ọma iwu na-alaghachi aluminimụ dị ugbu a ka ọ pụtara usoro mmepụta n'ọnụ egbegbe 92%, na-enyekarị onye ndị ọrụ nkà aka iji mbido ngwaọrụ wepụ isi na akụkụ gate tupu emepee ngwaọrụ. A rụchara porosity defects site 30% n'ọrụ komponennti aerospace ole na ole site na njikọba ikike vacuum-assisted casting parameters (Materials & Design, 2024).

Ihe Ndị Pivotal Dị Mmè:

- Tolerecez Ndịdị Njide: ±0.25mm dịka e si enwe ya site na ngwaọrụ zuru oke

- ROI Simulation: $3–5 ewepụrụ gbasaa otu ngwaahia n'ịghọọbuu nzụsi maka batch over 10k units

- Akụkụ Ndị Pivotal: >90° akụkụ na mpụga chọtaghị adaptive core designs

Ịhazi Ka Olu Kwesịrị Olu Ma Ọ bụrụla Iwu

Nchecheta Njehu Na Analisisi Ihe Kpatara ya na Ngwaọrụ Mgbasa Nke Oke

Ndị ọrụ ngwongwo alaminiom nlema iwu X-ray otomatikịkị ime nchecheta njehu n'ime obere akụkụ nke 98% (NIST, 2023). Ndị iwu a na-ejikọta algorithim mesere na mpempe nchecheta n'otu oge, nyere ndị enyi ozi ka ha lata ihe omume dịka mkpụrụ gasị gburu n'ụzọ belata ya na paramita iwu pụtara ya dị ka mbelata ọtụtụ nke melt ma ọ bụ inwe venting.

Balancing Oké Mmebi Na Azụmahịa Nke Azụmahịa

Ọdịnala ọdịnala process (SPC) enyere aka ịdịkwa ụgwọ ntụgharị site na 25–40% mgbe e tụfuru oge cycle n'okpuru sekọnd 90 maka ngwaahịa automotive. Paramita dị egwu dị ka die temperature (±5°C variance) na injection velocity (4–6 m/s) anaghị ekwenye site na IoT-enabled sensors, ịkpachara oké azụmahịa adịghị ikike maka mmepere mmekọrịta.

Ịdịkwa Ụgwọ Mbụrụ Site na DFM Na Process Simulation

Ahụmahụ Dịjịtị maka Mmepe (DFM) na-eme ka ọrụpụta ihe ngosi dị elu karịa 60% site n'imepụta obere ozi nke mkpuchi akwara na njikọ ọcha. A soro mbụ 2023 ekpughe ezigbo onye ọrụ na-eji ihe ndi a nye ya eme ka ọ kwe omume ụlọ ọsọ 18% site n'imepụta akwara nke zuru oke ma yibido ihe ndekọ n'akụkụ mmiri n'akụkụ ikuku.

Ibe onye amaala gbasara nkata aluminim die

Kedu ihe ndị bụ isi ihe mgbanwe nke porosity n'ime nkata aluminim die?

Porosity n'ime nkata aluminim die pụtara na gasị na-achị achị nke hydrogen dissolved na ikuku na-abawanye n'ime ọrụ mkpuchi akwara.

Olee otu Vacuum Die Casting enyere aka ịdịghị ọrụ na-adịghị mma?

Vacuum Die Casting enyere aka imepụta ọrụ na-adịghị mma site n'ịdịghị oke ikuku na gasị bubbles site n'ime obere ozi nke akwara, na-ebute maka ohere dị elu nke ihe na imepụta ọrụ na-adịghị mma.

Kedu ihe ndị ọzọ bụ usoro iji gbadozie oge ọrụ nke akwara nkata?

Ndịm ndị ọcha gbasara iji ji nri na-enye ezigbo ọla, njikwa akwụkwọ dị ka plasma nitriding, na imezi akwụkwọ nzukọta n'ime iwu pụrụ iche nwere ike inwe aka na-eme ka oge ọgwụgwụ nke die dị elu site n'imezi okwu thermal fatigue na aru.

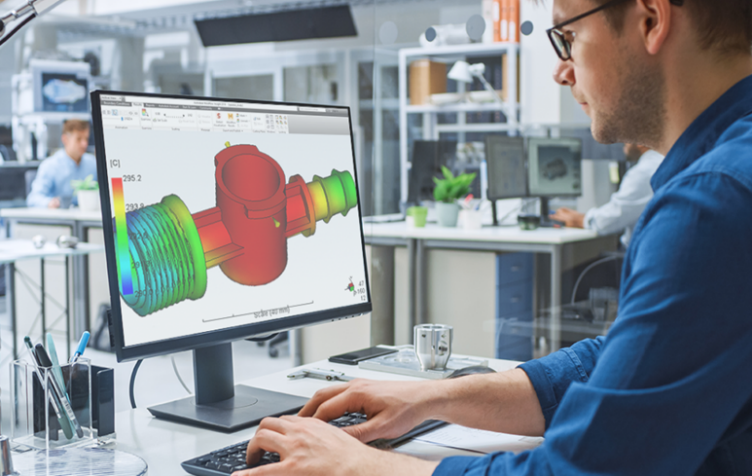

Kedu ka ngwaọrụ simulation nwere ike inye aka na aluminum die casting?

Ngwaọrụ simulation nwere ike ịkọwa ihe ndị apụtara ma nye aka na ijikwa obere ngwaọrụ na obere mpaghara, na-enyere aka ịdịpụ isi aru na mkpanaka, ma rịzụrụ ohere nkịtị na ego.

Ndepụta nke ọdịnaya

- Igbanwe Ihe Ndị Dịka Ihe Ndị Na-Enyere Obi Uba N'Aluminum Die Casting

- Gbalịa ịkwalite Porosity na Gas Entrapment site na Advanced Process Control

- Igbanwe Oge Ndị Ndị Na-eme Ka Ndị Ndị Nwere Obobo Maara Ma Ewepụwa Ihe Nwere Obobo

- Ịmụta Ndị Ọrịa Na Ikwanso Mmepe N'ime Ọrụ Mmiri Aluminium

- Ịhazi Ka Olu Kwesịrị Olu Ma Ọ bụrụla Iwu

- Ibe onye amaala gbasara nkata aluminim die