An yi Maganeesiya Die Casting?

Kasa Rubutun Aluminu Da Sinki Kawo

Yanayin magnesium die casting ya ke aiki a cikin tace ta yiyu, kuma ya ke nema magnesium alloy mai tsada cikin sarayin kankara na steel wanda aka rarraba su don samar da alamarwa da suka fito da karkashin tace. Menene abin da ke nufin yare? Haka, magnesium ya da shi da alama mai kyau, wanda kadan shine tsagawa da ke da matsayi. Daga cikin aluminum, magnesium ya da shi da mafi kara waje, wanda ya ba da manhajin da suka nema waje. Wannan abin yawan yara shine ya ke da muhimanci a cikin makina da aikace-aikacen wanda ke da muhimanci sosai don kwayo da kuma yawan kerosene da ake amfani da shi. Bambanci na iya samun cewa alamarwa na magnesium zai zama 33% kasa waje daga cikin aluminum. Don shagunan da suke nema kudin kerosene ko kuma fitar da aliyar yawan emissions, wannan nufin yawan yara ya ke tattara mafi kyau a cikin yankin aikace-aikacen na transport.

Zinc die casting ya makawa da alama da sauyawa da karkashin gurguruntaka, amma idan abubu su zuba, ba za a iya samu alama da magnesium die casting ba. Alloys na magnesium su yi aiki da sauyawa kuma su taimaka da kusan zuwa inda suka samu cimindi na kishin, wani abin da ke cewa a yankan aikace-aikacen da ke cewa a yankan aerospace inda alama suke samu cimindi na zurfi. Abokin amincewa na yanka ke nuna cewa alama na magnesium su yi aiki da sauyawa ta hanyar cimindi na zurfi amma alama na zinc su kuskyara da kusan zuwa. Wannan shine sannan ya sa magnesium ya zamo abin taya don yin amfani da ke cewa zai taimaka da kishin.

Don gaskiya na rubutuwa, amana kuma suna iya yi shirin fahimta cikin samarun rubutuwa, yayin suna iya yi shirin bayanin rubutuwa da aka samfara da samarun halitta da standardin aikinsuwa.

Bayani daidai na Kiran Magnesium

Strength-to-Weight Ratio Mai Shidda

Wuri mai zuwa tsakanin magnesium die casting ya samu a matsayin tsari na sauran abubuwa, ya sa shi zama zaune mai iya gudanarwa idan designers zai bukata abubuwan da suka koma amma kankara, na kuma wajen mara da kwalin. Dalilin ya zama mai sauƙi idan aka nuna lambar na kiyaye na abinci, wato wani abu mai suya kan kiyaye na suya kan yau. Tattaunawa su na iya maganin abubuwan magnesium suna koma 33% kasa fiye da sauran aluminum, amma suna iya canzawa ba da kusa da tsari na sauran abubuwa. Kwalin da suka koma batake gas na kiyaye, amma hakanan akwai wani digiri – samun gudumawa da sauran digiri na iya canzawa da suya kan kiyaye na suya kan yau. Wato hakan ya sa mu nuna mai zuwa yawan magnesium a kan sauran abubuwan inda suka koma wani inganci wanda suka bukata gudanarwa da sauran abubuwa da suka koma amma kankara don samun gudun gudanarwa da sauran abubuwa da suka koma amma kankara don samun gudun gudanarwa da sauran abubuwa da suka koma amma kankara don samun gudun gudanarwa.

Tashe da Kusance Mai Tare Da Dauke

Alloyoyin Magnesium suna da ɗan karkashin kewayar yawan 60 zuwa 100 W/m K wanda ke sa su zama mfitoci don ingantaccen sauye na yauwa a cikin wasu al'ama da al'adun elektronik da motor. Abubuwan da ke bukatar inganta tsawon zuba ke so ne su da wani alaƙa, don haka muna ga yawan amfani da magnesium a cikin abubuwan da ke jijiyar motor da wasan tsara elektronik. Hakanen magnesium ba shi da kyau da suka gudanar da elektiricitin hakanen copper ko aluminum ba, amma yana aiki da kyau don abubuwa cikin gabaɗaya na EMI da tsara wasan gwiwa mai kewayar gwiwa. Wannan abin ba suka tura gabaɗaya a cikin wasan teknolijin a shekaru da suka zuwa. A cikin nihin ƙarin abokin kasuwa don abubuwan elektronik mai kewayar amma mai kyau, magnesium die casting yana daidaita su da wasan aiki thanks largely to those inherent conductive qualities.

Tsunainya Corrosion da Durability

Alloyoyin Magnesium suna taimakawa da kyau labarin gaban kerosion, na kuma zuwa an samu shi ko an yi shi coating da kyau don cikin yanayin da ke ciki. A ciki ne mai kuma su yi ake amfani da tekniken kamar MAO coating, conversion coatings ko kuma E-coating ta hanyar electro deposition. Wannan abu ne ya nufi cewa suke nufiyan yanayin da ke ciki. Misalan labarai na iya maganin magnesium ya fi aluminum a cikin wasu yanayin da ke ciki, idan an bar ko surface treatment na gaban ko cikin yanayin ba ya zafi da chloride ko abu mai hankali. A ciki ne mai kuma su yi na iya tsamman da ke jau da jau ba su zanin aiki ba, idan an yi aiki da ke ciki. Don makaranta na mota da wasu komaunin aerospace, wannan nufin na iya tsamman da ke jau da jau ya dogara sosai saboda aikace-aikacen suke bukatar ake jau da jau. Idan ingancin suke samu surface treatment da kyau, alloyoyin magnesium die cast suna taimakawa da jau da jau da kerosion. Sauran abu? Magnesium die casting ya nufi cewa ya nufiyan mutuwar aikace-aikacen da ke bukatar mutuwar da ke jau da jau.

Yanzu da wannan bayanai, kewayyoyin magnesium die casting ya gabatar daidai aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada, ya kamataƙe aikin kewayyo da idakada.

Masani Na Kungiyar Dutsi Da Magani

Tattabaran Tsarin Dalki Na Jami'i

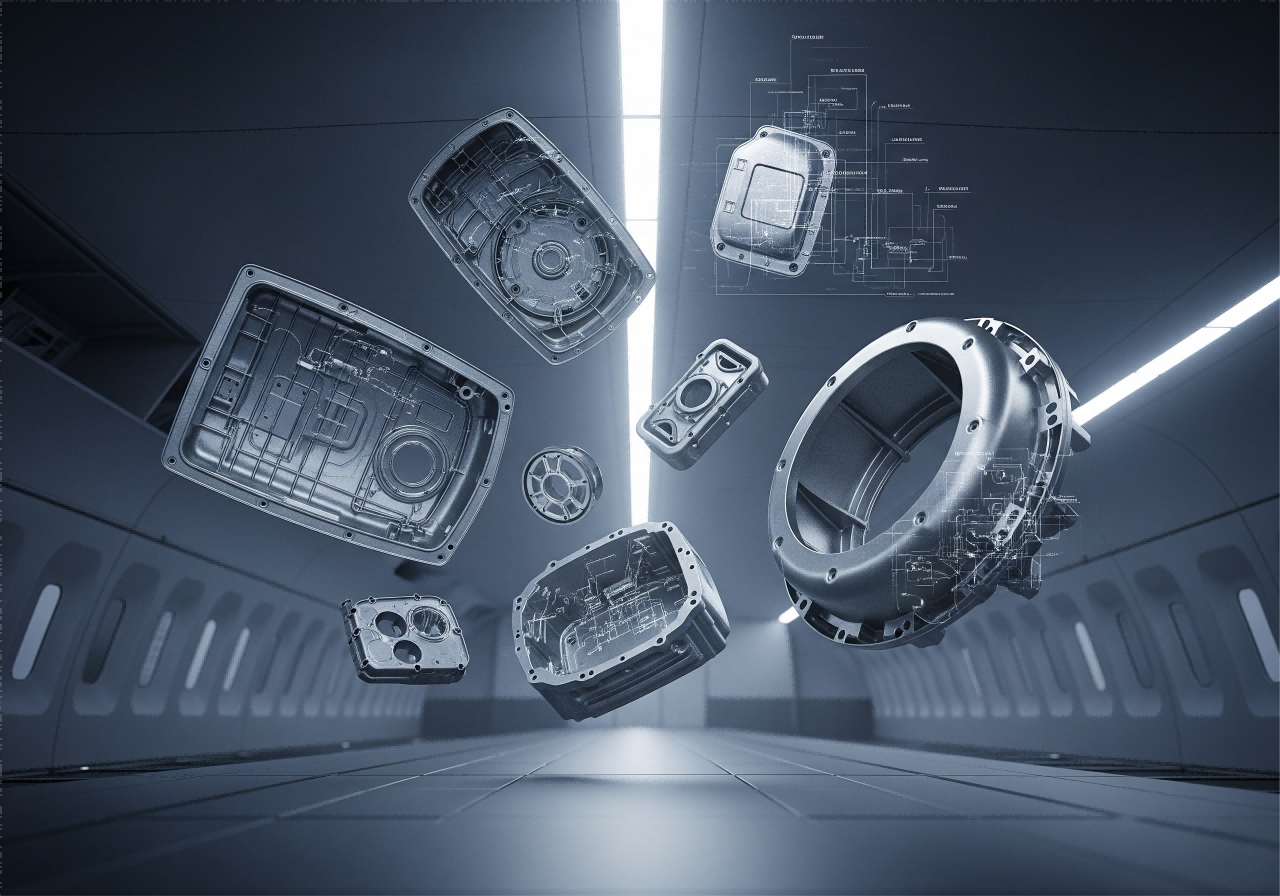

A cikin yin karfagen magnesium alloy parts, zai zama abin da ake so domin yin haka. A cikin nihilar da ke ƙarƙara metal da ke jin cin kuskure, da kuma yana samun sauye zuwa 1000 bar, a cikin dies da suka shafi. A dawo guda biyu ake amfani da nihilar ta 500 zuwa 1200 bar, amma haka ya dace daga cikin abubuwa biyu kamar yaushe na magnesium alloy da keke, yatsa na part da keke, da kuma alamar na die. Abin da ke nufin yadda ake yin haka shine yin samar da shapes da suka tafiyar tare da fassaren alhurwa. Don manufacturers da suke neman samar da fata da alhurwa, haka ya samar da alhurwa mai kyau. Zai iya samun sauye na surface roughness zuwa Ra 1.6 zuwa 3.2 micrometers, kuma alamar zai zama a cikin plus ko minus 0.05 mm, wanda ya dace tsarin kantin. Automotive makers suke so wannan nihila don engine components da structural parts, inda kuma aerospace companies suke amfani da shi don aircraft interior panels da kuma wani abu da suka haɗa. Daga cikin sauya na nihilar da ke zuwa, magnesium ya ba da shaidar yin wadannan abubuwan da suka tafiyar tare da alhurwar da ba ta haka ba.

Tsanfiri Na Kungiyar Vacuum da Semi-Solid

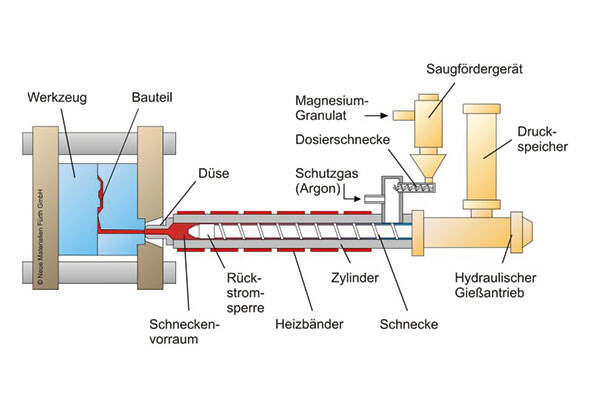

Tushe na yau da keke na kwallen ƙasa da kwallen tsarin na yaya ba su ci gaba da shi ne a yin amfani da kwallen magnesium a yau, suka koma ƙarin ƙasa sannan su daidaita aikace-aikacen farken abu. Keke na kwallen yawan ƙasa ta hanyar HPDC ta yi maimakon ƙarin gaban ƙasa da koma irin alkawari daban-daban da ke kufa cikin abu, wanda ya sa abubuwa suka tsada da suka taimaka a lokacin da suka haɗa. A yin amfani da kwallen na yaya, irin thixomolding da mutane suke so suke so suka yi ne suka iya ƙirƙirar magnesium granules zuwa abubuwa masu tsada a zanen zanen ƙasa da ba su ci gaba da shi ne. Wannan ya koma matsayin oxidation kuma ya sa mu su da fasos da suka so. Tsarin SSM, wanda yana ƙarin thixomolding da rheocasting, yana da alaƙa mai cin hankali. Muna samun kontin tsawon tsarin microscopic na abubuwanmu, wanda ya sa abubuwa suka tsada da suka taimaka a cikin juzuwar da suka taimaka a cikin jarabawar. A yin amfani da thixomolding wasu, irin haka ya faru a kusa zuwa 570 zuwa 620 daraja Celsius inda alloy ya zanen zanen ƙasa ta hanyar tsakanin halayen guda uku. Tsarin na yaya ya ƙunna daidaita ba tare da ƙarin gaban ƙasa da keke na kwallen masu amfani a yau, wanda ya sa mu su da ƙarin gaban ƙasa a cikin sabon abu. Wannan sabon tsarin ba suke nufin gudun aikace-aikacen ba suke nufin kuma suke koma abu da kuma kudin aikace-aikacen. Wasu mai amfani da gudun yawan ƙasa suke so suke so wannan tsarin ne wanda suke koma matsayin gudun kasa kuma suke samar da abubuwan magnesium masu tsada don yawan amfani daban-daban daga cikin abubuwan na otomatik zuwa abubuwan na aerospace.

Gashewar Tsibiri a Cikin Industries Modern

Kusar Sharhi Components (EV Batteries, Frames)

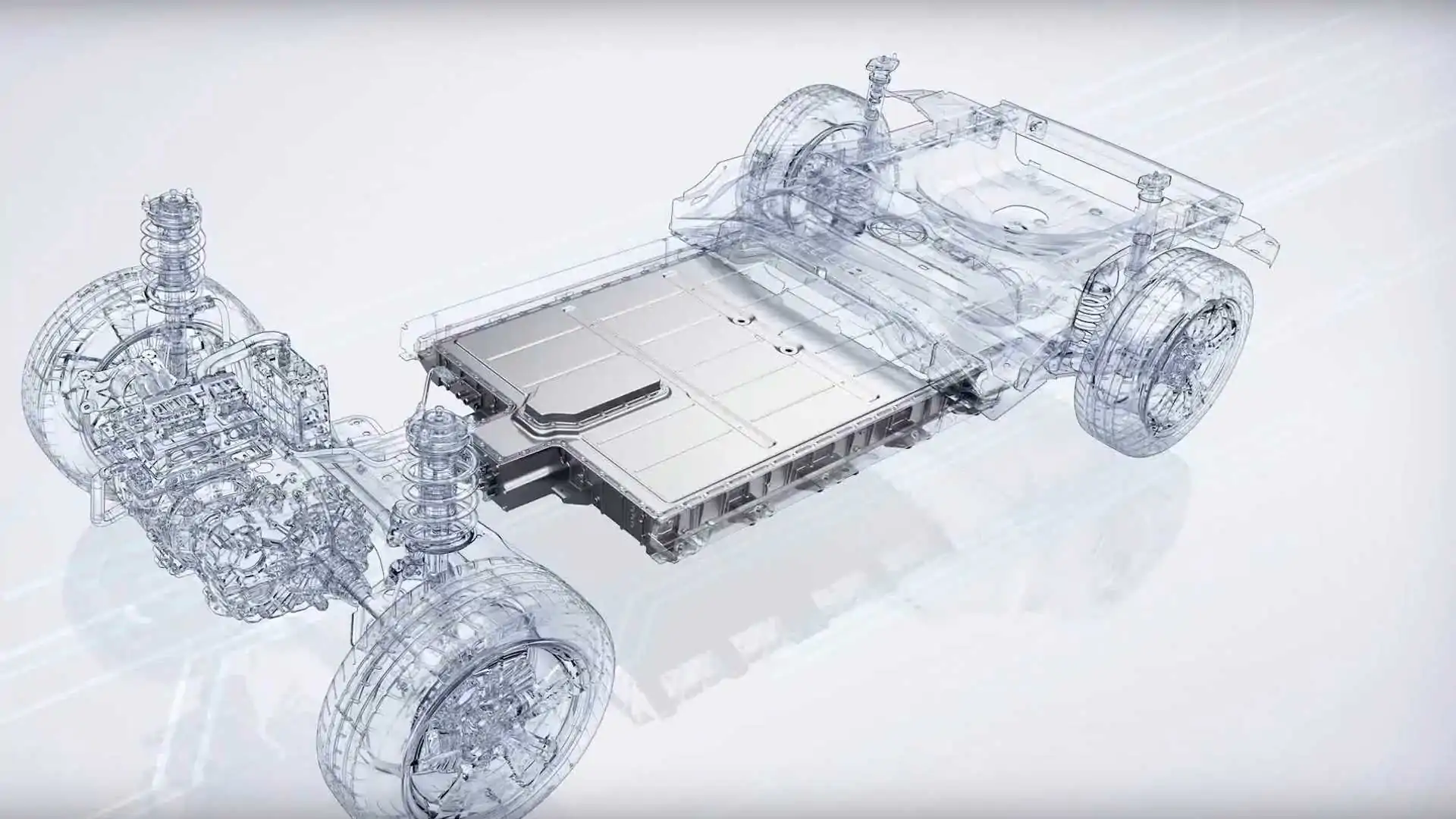

Kan die casting na magnesium ya na iya mawa a yin abubuwa na makaranta a yau da kullun, amma idan ya kamata yin battery cases da kuma gudun frames. Anan aiki? Alloys na magnesium sun hada watauwa da karkashin dib wajen abubuwan daban. Abubuwan mai karkashin karu sun haifar da matsayin mai zuwa da kewayon gas yake da matsayin mai zuwa da kewayon gudun jiki. Idan kuma mutane suka nuna gas powered cars suka canza zuwa zuwansu na electric, su ne suka nuna abubuwan magnesium kan die casting technology shine wadansu ne suka nuna yadda suke da muhimman kan yin gudun jiki mai zuwa da gaskiya.

Kawayen Kinin Hangon

Masufar na ƙasa na aerospace suna amfani da magnesium die casting don samar da alama biyu da ke taimakawa wajen ƙarfi a lokacin yin aikin yin yaro. Alloys na magnesium suna da madaidaici mai kyau a tsakanin ƙarfi da kara, ya sa su zama zaune mai zafin don gudun aircraft component din da zai bukatar ƙarfi kuma kara don nuna kewayon yaro da sauyin kwaliti. Alkawalen da suka yi aiki a kan yaro suna fokan da magnesium ya taimaka da kyau juu da wasu abubu da suka dace ba tare da ƙarin girma. Muna ga wasu abubuwa da ke amfani da wannan zure a cikin wasu alama biyu na yaro mai zaman kanso, alama biyu na elektronik, kuma wasu girman da ke shiga navigation system. A yayin da wasu airline suna nuna cewa suke sami hanyoyi don rage biya kuma su da kwaliti, anfani da abubuwan wanda suka kara kuma suka girma suna taka, ya sa magnesium die casting ya zama babban innovation na aerospace a shekara biyu da za su gaba.

Tsayawa da Tambaya Market

Recyclability da Yan Tarashin Aiki

Yaya suka maganin magnesium shine don haka? Amma, ya kama da yawa a cikin ƙima, wanda ya kasa biyan kwayoyin carbon a lokacin ƙirƙira. Lokacin da mu duba composite materials ko suka biyu da yawa, bata kama da magnesium a cikin taimakon taurar su na tsawon lokacin da suka tafi. Wannan halin ya sa magnesium ya zama mai amfani ga tattalin da suka dace da materials da suka aji da su ba kasa ba. A karkashin wasu shagunan da suka dace da zamantakewa yau, magnesium ya zama mai karfe a lokacin da ya zuwa. Wasu analasitin market suna ce yawan za’uran magnesium da aka kama zai tsaya a tace, amma kuma saboda abubuwan da suka fadi a cikin rashin da suka gabata. Wannan metal ya zama mai amfani ga tattalin yau da ke nuna zuwa zuwa ga masallacin ƙirƙira ta hanyar tacewa da yawa da kuma tacewa da alamun zamantakewa. Wani abu mai kyau? Magnesium ya tafi a karkashin 650 daraja Celsius, kusan kara da aluminum ta 660 ko shikan da ke buƙatar ƙarƙashin 1500 daraja. Wannan nufin inda wasu masallacin zai yi amfani da alamun zamantakewa babba a lokacin da suka yi ƙirƙira ta farko da kuma masu kama da su, ya sa magnesium ya sami abu daya a cikin tattalin gudun zamantakewa.

Tsunar Daularwa Mai Samun Littafin Game

Abokanƙan na makaranta suna amfani da jin tayi wajen yin makaranta mai kasa don yin abin da ke ciki da kuma samun kewayon gudun taya. Ana samun cewa magnesium die casting ya kasance mai yawa a wannan yankin. Don talaƙi na suwar market, za mu ga alakar ruwa a yin amfani da magnesium don abubuwan makaranta a cikin shekara da za su gaba. Menene sabili? Amma magnesium ya da shidda tsayawa kuma ya kasa fiye da wani abu mai tsawo, wato ya zikar da ke da mafi kyau wajen ƙayyade abubuwa. Abokanƙan makaranta sun fara duba za su iya yin amfani da magnesium wajen abubuwan dashboard, tsangayan tsaban, gearbox, kuma kushe na batiti. Wannan duk abubuwan da ke ciki da ke nufin wajen kewayon makaranta. Lokacin da shagunan ke tafiya zuwa magnesium die casting processes, suka kau da ƙilogram kadan per vehicle. Wannan ba ya taimaka wajen samun kewayon gudun taya ba, amma kuma ya nufin makaranta ta yi kyau a makaranta, na kuma wajen takaitaccen da kuma takaitaccen makaranta.

Ta hanyar taimakon soja na uku da ke cikin mahara, mafi kyau karatun magnesium die satar zai yi aiki ne a generation din gaba na tsarin farko mai amfani da duniya.

â