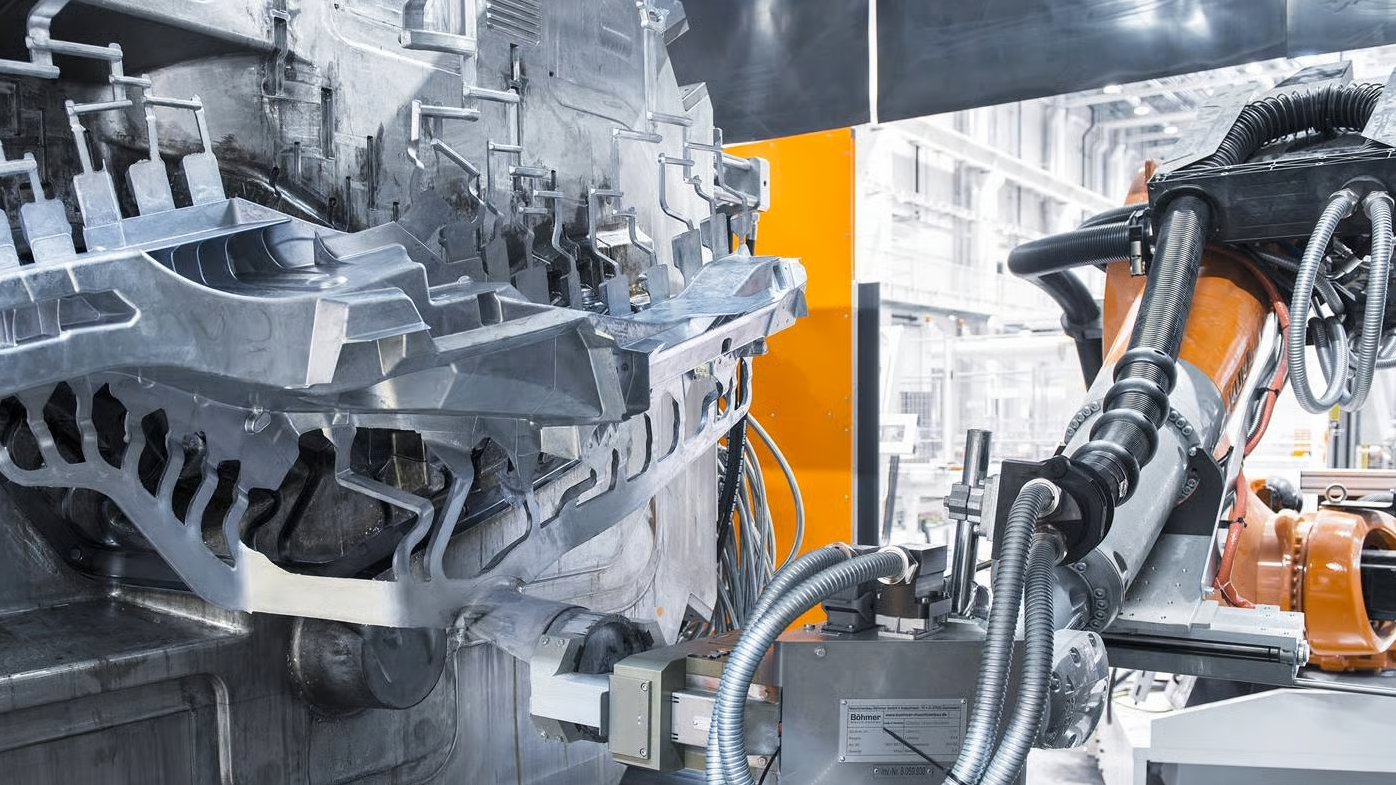

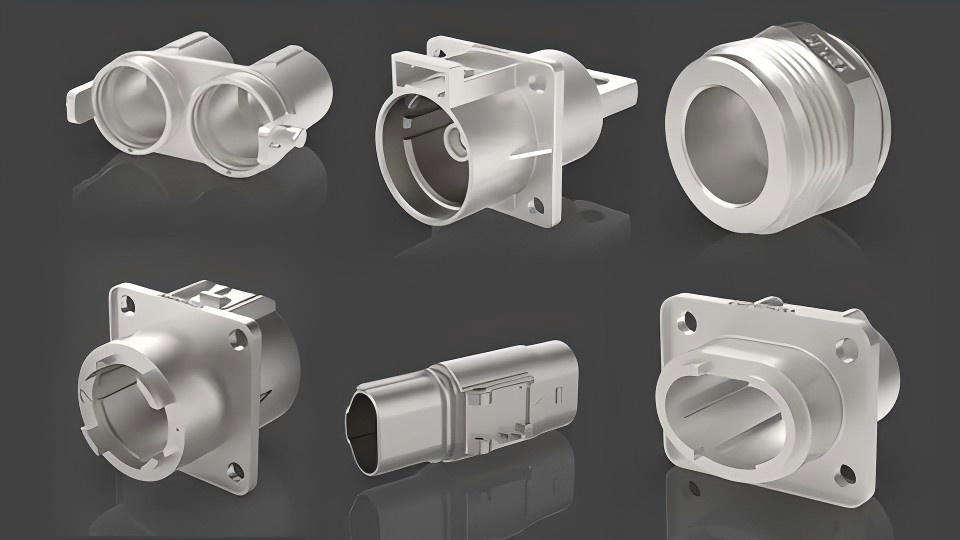

At Sino Die Casting, a high - tech enterprise based in Shenzhen, China since 2008, anodising is one of our core specialties. Anodising is an electrochemical process that transforms the surface of metals, especially aluminum, into a durable, corrosion - resistant, and aesthetically pleasing layer. We offer anodising services that are widely applicable in industries such as automotive, new energy, robotics, and telecommunications. In the automotive industry, anodised parts can withstand the harsh conditions of the road, including exposure to salt, moisture, and extreme temperatures. This makes them ideal for components like wheel rims, engine parts, and exterior trim. In the new energy sector, anodising helps protect solar panel frames and wind turbine components from corrosion caused by the elements, ensuring long - term performance. For robotics, anodised parts have improved wear resistance, which is crucial for the moving parts of robots that are subject to constant friction. Our anodising process starts with thorough pre - treatment of the metal surface, including cleaning and etching to remove any impurities and create a uniform surface. Then, the metal is immersed in an electrolyte bath, and an electric current is passed through it, causing the formation of the anodic oxide layer. After anodising, we can also apply various coloring techniques to give the parts a unique and attractive appearance. With ISO 9001 certification, we ensure that every step of the anodising process is carried out with precision and quality control. Our products are exported to more than 50 countries and regions, and we can provide solutions from rapid prototyping to mass production, making us a reliable partner for all your anodising needs.