The Shift to Automated Die Casting in Automotive Manufacturing

Traditional Stamping vs. Modern Die Casting

Stamping Parts The traditional mold is the foundation of automotive production, as it has been a stable method of forming vehicle parts for decades. Nevertheless, such a method is hampered by wastage of material as well as the complexity of complex patterns. Die casting is increasingly supplementing and, in some applications, replacing traditional stamping methods and shows better efficiency in manufacturing die casting shapes with less material waste. A single study has me asking if die casting can reduce production time by as much as 30% over traditional methods. In addition, the progress in techniques of aluminum die casting has achieved a remarkable reduction of defects and increased production capacity so that it is possible to provide a product of excellent quality without much defect. These advances highlight that the future of manufacturing is moving to more sustainable and efficient processes.

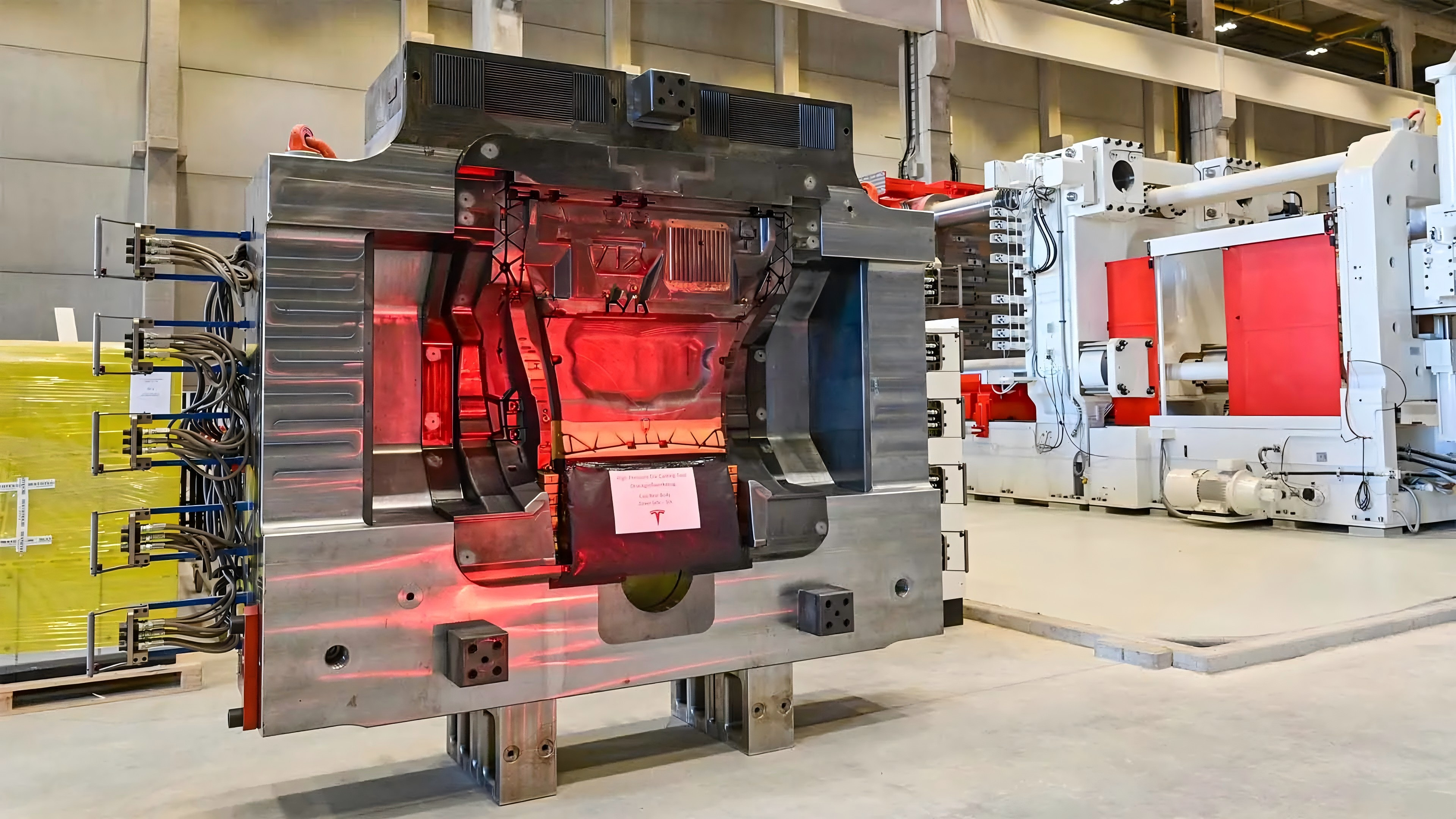

Tesla’s Integrated Die Casting Innovation

Tesla’s die casting innovation, especially with the Gigapress, upended auto production by significantly simplifying the production of parts. The novel approach has allowed Tesla to simplify parts significantly, with the number of parts in certain structures being reduced from 70 down to 2. These developments have resulted in large gains in deployment logistics and structural stiffness. Tesla has become a benchmark for competitive advantage with its innovative practices, which other manufacturers within the industry are now obliged to follow. Top performers in the automotive world are those that recognize how die casting can be strategically integrated into their business to optimize their operations—always reducing costs and increasing performance in the process.

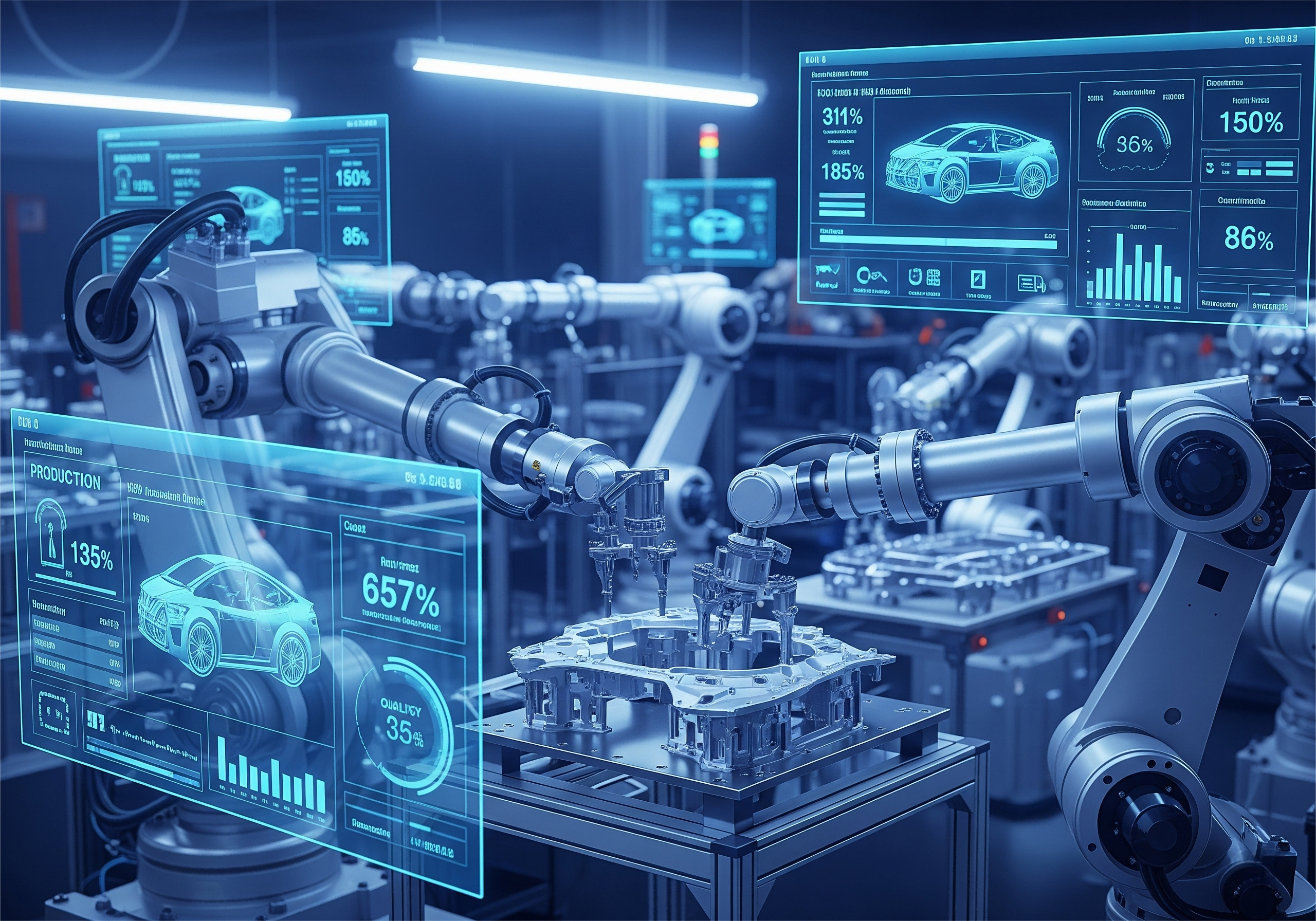

Role of Automation in Streamlining Production

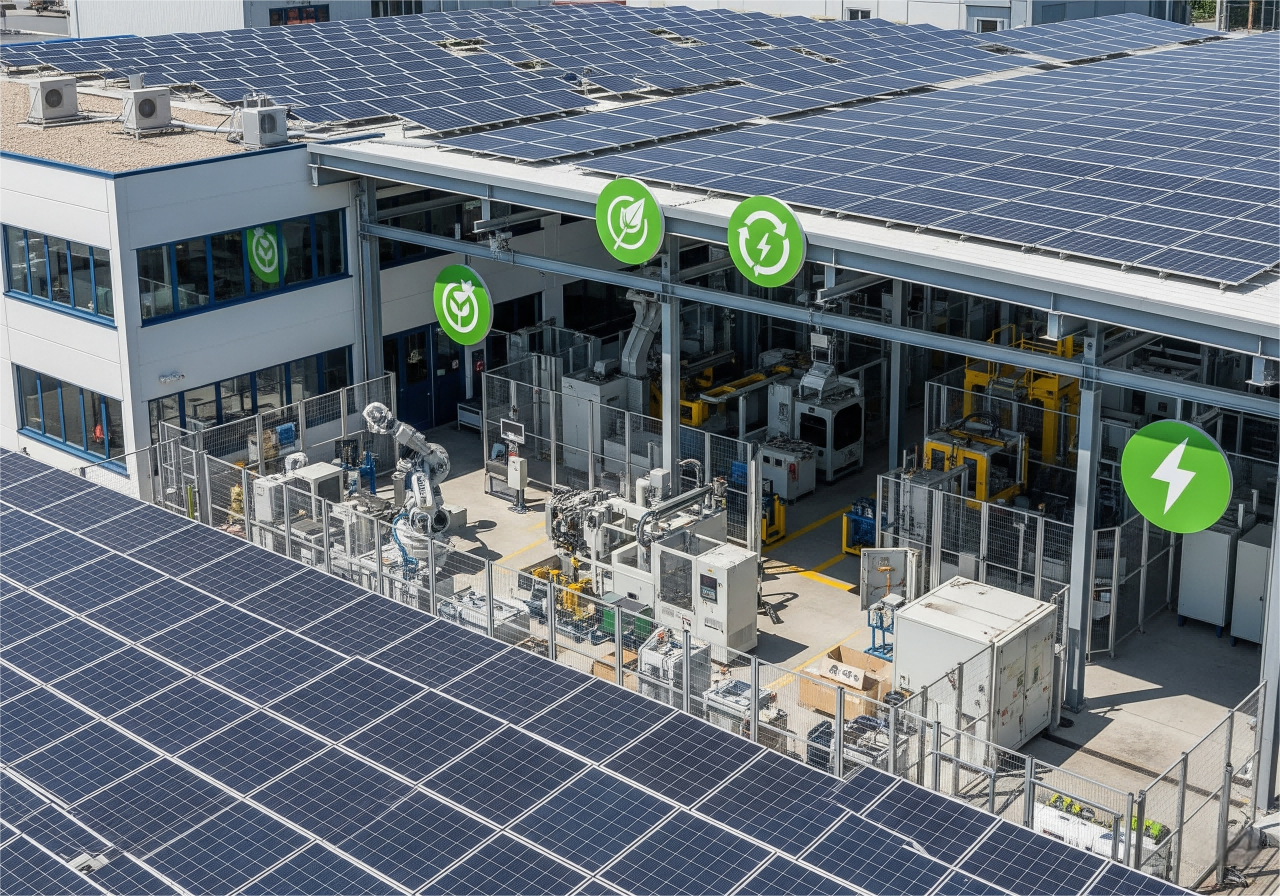

Robotic systems and AI-driven equipment are used extensively to improve die casting process precision and consistency and reduce labor costs. These techniques enable companies to reach an even greater level of precision while preserving the quality of the product, which is critical for the smooth running of production chains. Real-time monitoring and data analytics also further enhance production by minimizing downtime by 20 percent and delivering high-quality output. Looking ahead, future developments in automation will likely yield additional efficiencies; however, there are some challenges, such as integration difficulty and staff training. These are the kinds of trends that are likely to transform the manufacturing industry over the next decade, and any players within it will need to adjust themselves in order to stay competitive.

Key Benefits of Die Casting for Automotive Efficiency

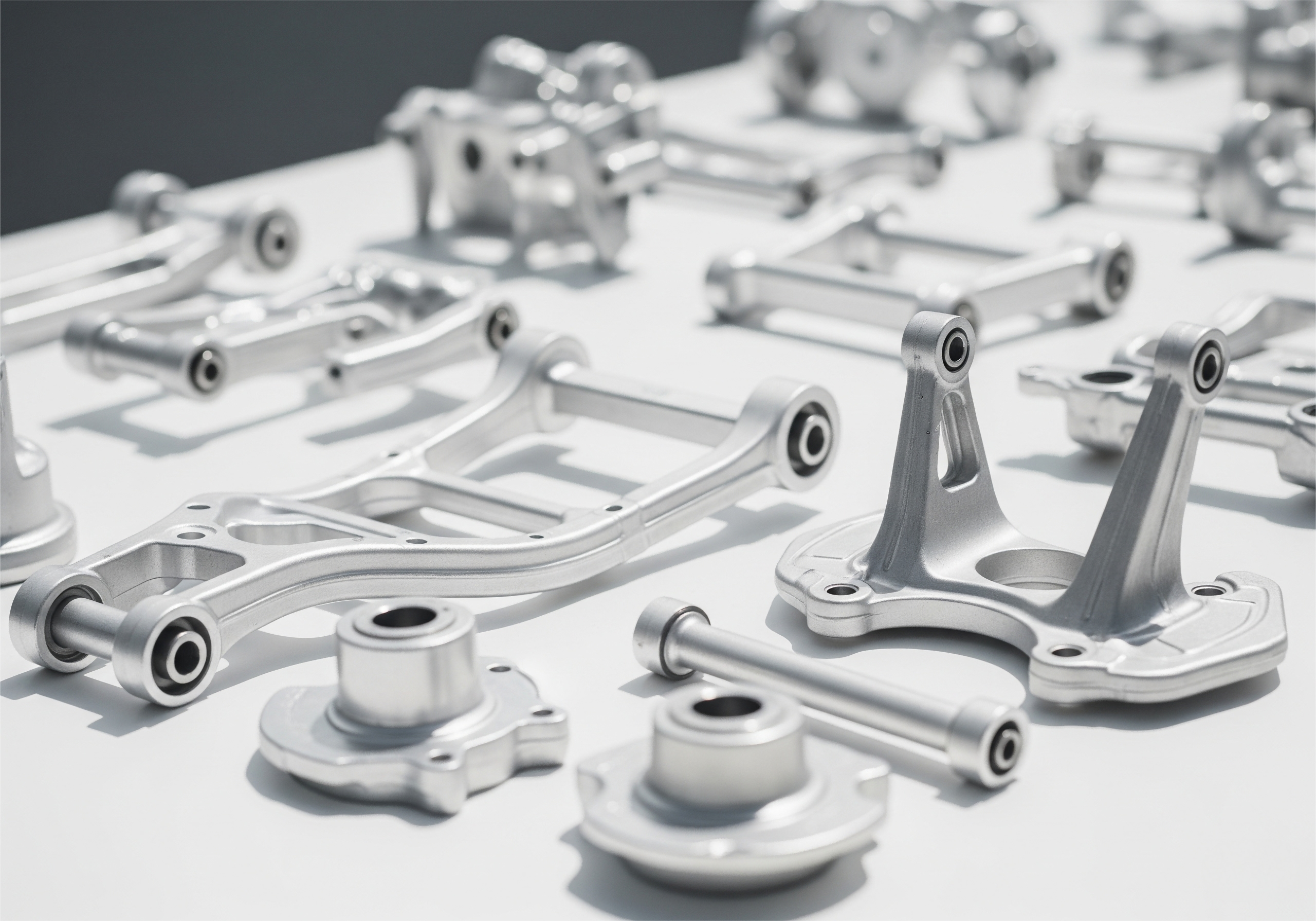

Reducing Component Count and Weight

Die casting has a clear advantage over conventional manufacturing techniques by producing complicated components, which are replacing many parts of a vehicle. The leaner component count simplifies manufacturing and reduces potential points of failure. Second, lighter components help cut the pounds, which is particularly helpful when trying to improve the fuel efficiency and performance of a car. Research indicates that reducing a vehicle's weight by 10% can lead to a fuel efficiency improvement of approximately 6-8%. Major automotive companies, such as Tesla, have reaped the rewards of integrating die casting techniques by achieving greater efficiencies with lighter vehicle models that meet strict environmental requirements.

Enhancing Structural Integrity and Safety

Advantages of die-cast parts Die-cast parts are stronger than plastic parts and have more rigid material characteristics, which are most important in maintaining tolerances and structure in the auto industry. Die cast parts stand up to demanding safety tests—as required to meet automotive crash safety standards. Higher reliability of these parts is indispensable in ensuring a long service life and safety of the consumer's vehicle. Die casting parts are often tested under restrictive automotive standards to ensure durability and safety under the harshest conditions to which the modern vehicle is subject, further supporting the safety application of die casting in modern vehicles.

Cost-Effective Mass Production Solutions

Die casting is more convenient for mass production and provides a better per-unit cost as compared to other methods of casting, based on production time and material wastage. This effectiveness also means that it's very cost-efficient for manufacturers, as the process of die casting eliminates the need for post-production machining, which means fewer resources used. Industrial reports note that businesses that spend on these die casting methods save money, offsetting the cost of investment. With the decreasing cycle time of the production automation process, die-casting proves itself a low-cost, automotive-manufacture-friendly process for gaining high-quality output.

Innovations in Die Casting Technology

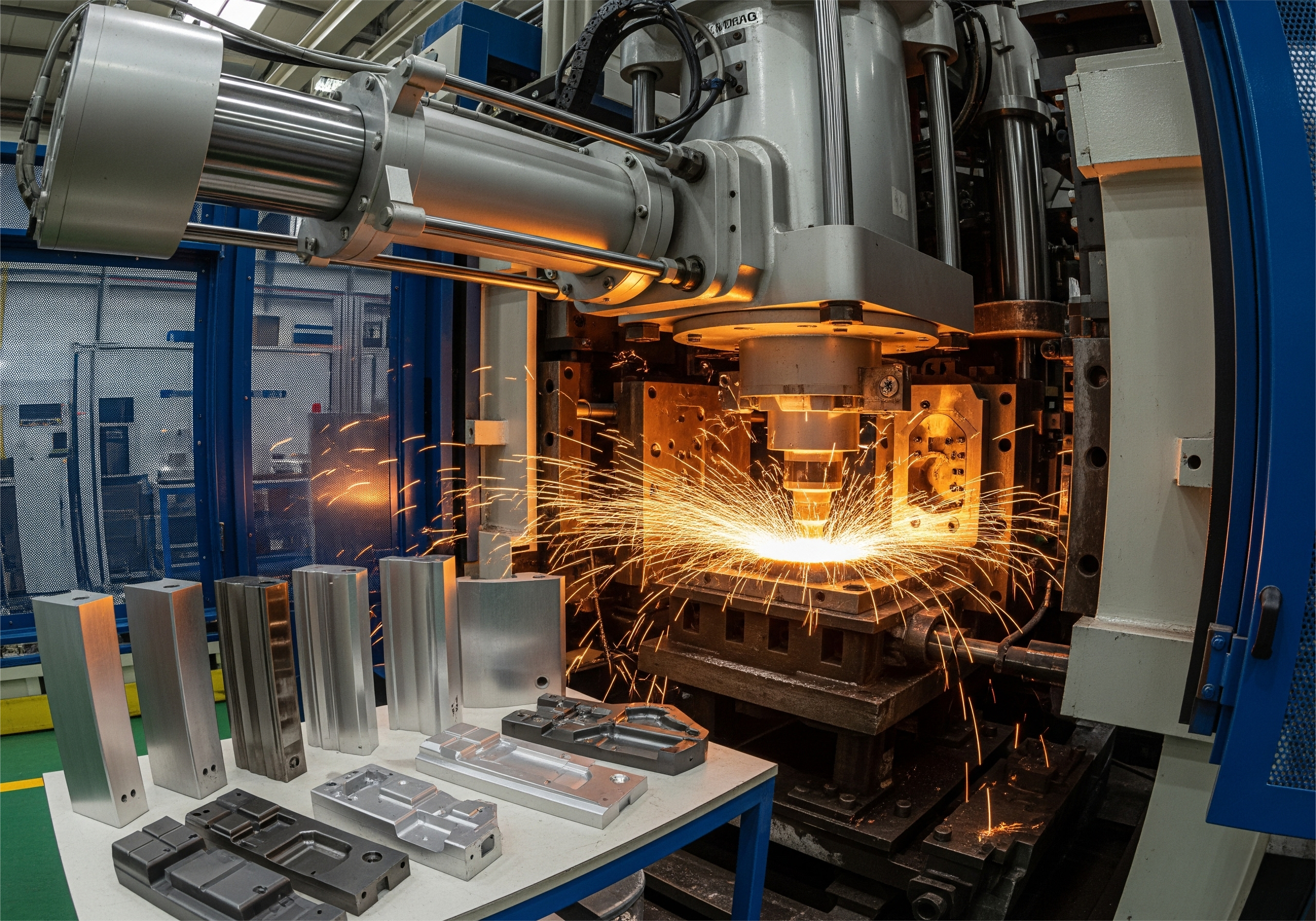

High-Pressure Aluminum Die Casting Machines

High-pressure aluminium die casting machines have rewritten the rules regarding the flexibility of production. These machines introduce state-of-the-art new features that will decrease cycle time, allowing higher production output and more competitive part pricing. Critically for the car brands, recent developments make it possible that, in the future, output of new vehicles could be raised by as much as half again, a big step forward for manufacturers trying to stay competitive in a fast-moving automotive market. As the number of performance and material requirements for automotive parts increases, keeping pace with these developments is paramount for any manufacturer hoping to stake a claim in the market.

Zinc Die Casting Processes for Complex Parts

Zinc die casting methods have gained much attention for their ability to cast complex parts more accurately in dimension than other processes can. Such processes are most beneficial for the automotive industry, where smaller and more complex parts are in demand. For example, zinc die cast has been effectively utilized as a substitute for conventional steel parts with weight reduction and material cost benefits. In addition, zinc is one of the most recyclable metals, and it consumes less energy compared to other metals such as aluminum and is an eco-friendly option for manufacturers who want to reduce their environmental footprint.

Material Advancements and Alloy Development

The progressive improvement of new die-casting alloys has been a determining factor in the general improvement of the performance of car parts. New lightweight and high-strength alloys contribute to the efficiency of vehicles and are in line with industry needs for sustainability. Through concerted efforts of automotive OEMs and material suppliers, highly engineered alloys for the purpose of die casting have been developed. The research has repeatedly pointed out to the positive results obtained related to the improved mechanical properties and the competitiveness of such new compounds, rendering them a precious tool for manufacturers committed to the perceived higher quality and level of efficiency that the automotive parts demand.

Impact on Electric Vehicles and Market Growth

Die Casting in EV Battery Housings and Frames

Die casting is essential to the production of battery housings and frames in electric vehicles (EVs), improving their performance and safety. All of these will help shave excess weight, which is really important when it comes to maximizing range and the performance that’s on tap from an EV. Your die-cast construction enhances durability and safety and provides encasement for the battery against impact and the environment. For example, manufacturers like Tesla have introduced die casting technology into their product range, resulting in significant benefits for safety and efficiency.

Regional Manufacturing Hubs and Industry Trends

Automotive is experiencing remarkable growth of die casting in the North America and Europe. These sites are forerunners when it comes to developments in die casting, investing in technology as well as infrastructure in anticipation of the growing electric vehicle (EV) market. Europe as an example - the industry is a significant contributor to the economy and to EV batteries, it’s a strategic growth trend. According to the industry's prospects, the pace of die casting will be accelerated, and it will be highly in line with the increasing EV production demand in the future, which will change the industrial pattern in the future and promote the regional economic development.

Sustainability and Future Automation Trends

There is a significant trend in die casting towards achieving the requirements of the automotive market in terms of sustainability, driving the industry to adopt more environmentally friendly production techniques. As part of a transitional arrangement, DEKRA has in place a sustainability program aimed at waste and energy savings, consistent with corporate environmental goals for automotive manufacturing. Further, automation innovations represent significant efficiency gains in die casting, cut labor costs, and real-time monitoring and adjustments to improve quality control. Environmental standards and concerns are of paramount importance for the industry, which is leading the industry towards environmentally friendly practices while producing positive environmental results.

Conclusion: Embracing the Future of Automotive Die Casting

As automotive manufacturers strive to meet the demands of electric mobility, lightweighting, and sustainability, die casting—especially in its automated and high-pressure forms—is becoming a cornerstone of innovation. Companies that invest in these advancements will be better positioned to achieve operational efficiency, environmental compliance, and long-term competitiveness in the global market.