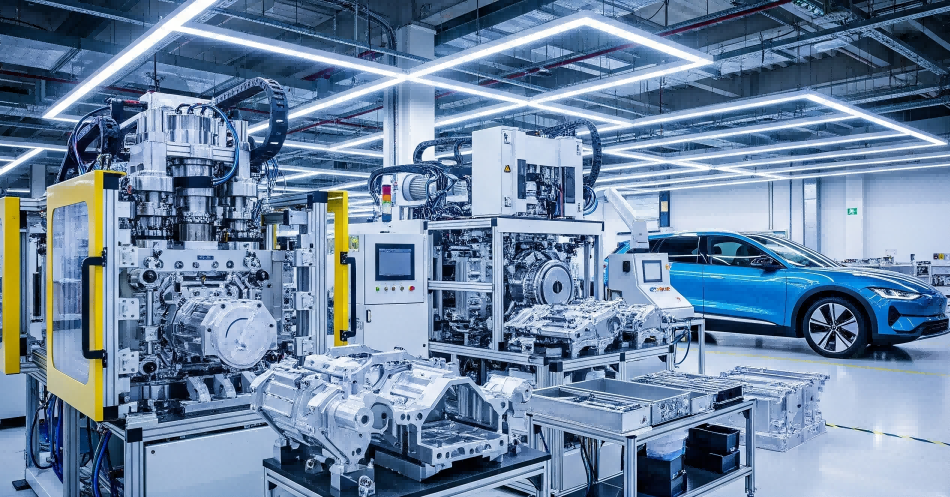

The Critical Role of Die Casting in New Energy Vehicles

Lightweighting Strategies for EV Efficiency

The use of lightweight materials makes a big difference in how efficient electric vehicles actually are, and die casting helps cut down on weight quite a bit too. When car makers switch to lighter stuff for their EVs, they get better mileage out of the battery power, which means people can drive farther between charges without guzzling so much electricity. Aluminum works really well for this kind of thing through die casting processes. Many modern cars now feature aluminum parts made via die casting techniques, including things like suspension components and structural pieces that would traditionally be heavier metals. This shift toward lighter construction isn't just about saving energy either it also affects handling characteristics and overall performance metrics that matter to consumers looking at these vehicles.

The numbers don't lie when it comes to lighter car parts making cars better on gas and performing stronger overall. Take away 10% of a car's weight and drivers typically see around 6-8% better mileage, which many automotive reports have confirmed over time. With electric vehicles becoming everywhere these days, this becomes even more critical. Manufacturers are finding themselves stuck between battery weight and range expectations. So what do they do? They turn to die casting techniques for lighter components. It's no longer just some fancy new tech experiment either. For companies trying to build cars for tomorrow, going light with smart materials has become practically essential if they want to stay competitive in the market while meeting those tough emission standards everyone keeps talking about.

Structural Integrity in High-Voltage Components

Structural integrity matters a lot when it comes to high voltage parts in new energy vehicles. After all, these cars depend so much on their electrical systems that any weakness could lead to problems or even endanger passengers. That's where die casting becomes really important. This manufacturing process makes components like battery enclosures and housing for power electronics much stronger and more reliable over time. What sets die casting apart is how consistently it produces parts with tight tolerances, something critical for keeping those high voltage systems intact under various conditions. Manufacturers have found through experience that properly cast components just hold up better in the long run compared to other methods.

Industry insiders keep pointing out why die casting remains so important for structural parts. Research published in the International Journal of Advanced Manufacturing Technology showed that when manufacturers use die casting methods, their components become much tougher. These parts actually hold up better against all sorts of stressors both electrical and mechanical that come their way during normal operation. What makes die casting really stand out is how long lasting it proves to be. For companies working on new energy vehicles (NEVs), this matters a lot. The automotive sector needs materials that won't fail over time, especially as we push toward greener transportation solutions. So while some might see die casting as old school tech, it's still playing a critical part in making sure our cars of tomorrow are both durable and environmentally friendly.

Advanced Materials Revolutionizing NEV Die Casting

Aluminum Die Casting Parts for Sustainable Mobility

Aluminum die casting has become a game changer for New Energy Vehicles (NEVs), mainly because it supports both sustainability efforts and recycling initiatives. The metal's light weight helps boost energy efficiency in electric cars, something automakers care about a lot these days. Plus, since aluminum can be recycled multiple times without losing quality, manufacturers cut down on waste during production cycles. We see aluminum castings all over modern EVs - think motor housings, transmission cases, even structural supports that hold everything together. These components strike a balance between being light enough to save battery power while still strong enough to handle daily driving stresses. Looking at numbers from the industry, aluminum usage keeps climbing as carmakers push harder toward greener manufacturing. Some reports suggest demand could jump dramatically over the next few years, showing just how important this material has become for making electric vehicles both efficient and environmentally responsible.

Aluminum Die Casting Components in Electrical Systems

Aluminum die casting brings some pretty special characteristics to the table, especially when it comes to resisting corrosion and maintaining strength over time. That makes it a go-to material for various parts in NEV electrical systems. The aluminum parts used in these vehicles are essential for keeping things running smoothly and reliably. They offer durable, precisely made components for complicated parts such as connectors and terminal bodies that just wouldn't work as well with other materials. What really stands out is how these cast aluminum pieces maintain steady electrical performance, which protects vehicle systems from both wear and corrosion issues down the road. Another big plus is the near-net shape feature that cuts down on production time for intricate components. This means fewer steps in manufacturing and better control over those tight dimensional requirements needed for today's EV electrical systems. Looking at what's happening in the market right now, there's definitely a shift toward using more aluminum in car manufacturing because of all these benefits. Automakers are increasingly turning to aluminum components as they look for ways to build vehicles that last longer and perform better under real world conditions.

Cutting-Edge Technologies Shaping Die Casting's Future

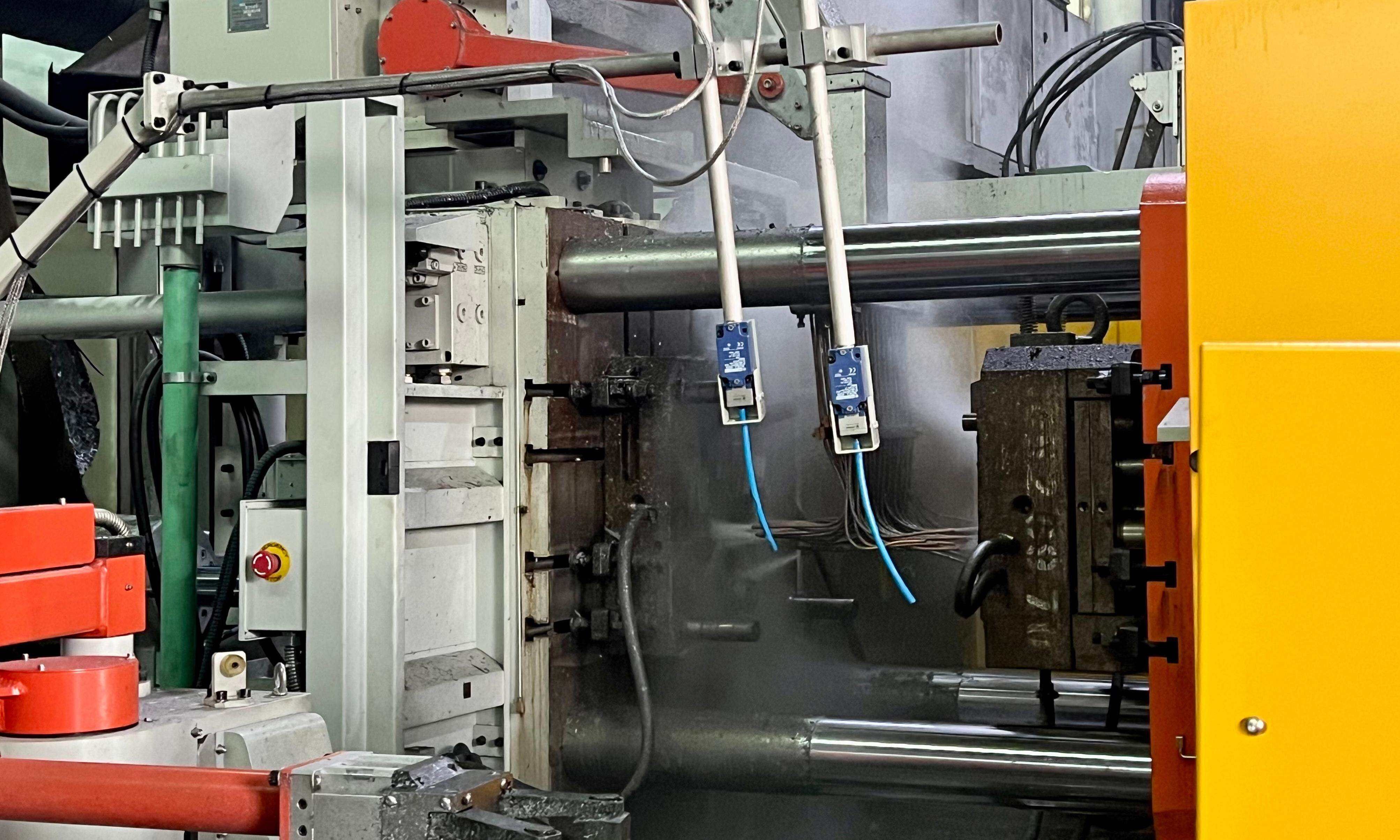

High-Pressure Die Casting Machines for Large Components

High pressure die casting machines have come a long way in recent years, making it possible to create bigger parts while still maintaining top notch efficiency and accuracy. Newer models can apply much greater force during the casting process, which means manufacturers can now produce complicated, large scale components that maintain consistent quality throughout. What makes this so valuable is how these machines cut down on defects and enable the creation of those tricky shapes needed for things like new energy vehicles (NEVs) and other big automotive parts. Looking at where the industry is heading, most analysts believe these improvements in die casting tech will really ramp up productivity numbers. Some estimates even point to a possible 20% boost in NEV manufacturing efficiency within the next ten years as companies adopt these advanced systems.

Smart Manufacturing in Aluminum Die Casting Production

Smart manufacturing tech is changing how aluminum die casting works across the board when it comes to making things faster, better quality products, and being able to adapt on the fly. When factories start bringing in automated systems along with IoT devices, they get to watch what's happening during casting right as it happens and tweak things accordingly. What this means for the bottom line? Less scrap material going to waste and much tighter control over dimensions. Take Nemak or Ryobi Group for instance - these big players have already jumped on board with advanced monitoring systems that track everything from temperature fluctuations to mold wear rates. The whole die casting sector is slowly but surely moving towards these kinds of intelligent operations. For smaller shops trying to keep up, now might be the time to look into some basic automation solutions before getting left behind completely.

Sustainability and Cost Efficiency in Modern Foundries

Eco-Friendly Processes in Zinc Die Casting Operations

The aluminum die casting sector is seeing a real shift toward greener approaches because these methods actually help the environment while also cutting costs for businesses. Foundries across the country are finding ways to generate less waste and get more bang for their buck when it comes to energy usage. Take a look at what's happening with closed loop systems that keep recycling those die casting alloys right back into production lines, slashing material waste dramatically. Plus, newer technologies in this field mean plants can run on far less power than before, so companies save money on electricity bills while emitting fewer greenhouse gases. Look at XYZ Die Casting as proof point they rolled out several green initiatives last year and saw around 25 percent less energy going through their facilities plus about 30 percent less trash ending up in landfills. Makes sense really, since saving resources translates directly to bottom line improvements without compromising quality standards.

Global Market Dynamics and Industry Projections

Regional Manufacturing Hubs for Die Cast NEV Parts

As the automotive world keeps changing fast, some parts of the globe are becoming really important centers for making die cast components used in new energy vehicles. Look at Asia right now, especially places like China and India where we see lots of new die casting plants popping up because governments there are giving them good support and investors are pouring money into these operations. Why? Well, people want more NEVs on the road and countries are trying hard to build up their own manufacturing capacity instead of relying so much on imports. Take China for example it has this huge existing industrial infrastructure already in place plus they're throwing serious resources into upgrading their casting tech. Production numbers there are expected to jump pretty dramatically in coming years according to most analysts, probably doubling or even tripling within ten years. What all this means is that these Asian manufacturing zones will likely become essential suppliers for die cast parts worldwide, which makes sense given how critical those components are throughout the entire car making process.

Emerging Standards in Automotive Die Casting Quality

The auto industry keeps moving forward fast, especially when it comes to die casting quality standards that now play a big role in making new energy vehicles. What drives these changes? Mostly regulations and certification programs that set the rules for how things should be done. Take ISO 9001 for instance. This one covers basic quality management across industries. Then there's IATF 16949, specifically tailored for automotive manufacturing. It takes everything from ISO 9001 and adds extra layers for controlling processes better, stopping defects before they happen, and constantly improving across all parts of the supply chain. Car makers who want to stay competitive have no choice but to follow strict rules laid down by organizations like ISO and groups within the automotive sector such as IATF. These standards aren't just paperwork either they directly affect how products get made and what customers end up driving.

Following these standards brings about better precision, repeatable processes, and trackable results in die casting work all important aspects for making sure NEV parts hold up structurally and perform well over time. The rules keep getting tighter every year, pushing manufacturers to deliver top notch quality while also being environmentally responsible. What we're seeing from people who know this industry inside out is that these certification standards aren't just box ticking exercises anymore. They're actually changing how cars get made across the board. Companies want to produce stuff that works great for customers but also ticks all those regulatory boxes without breaking the bank on compliance costs.