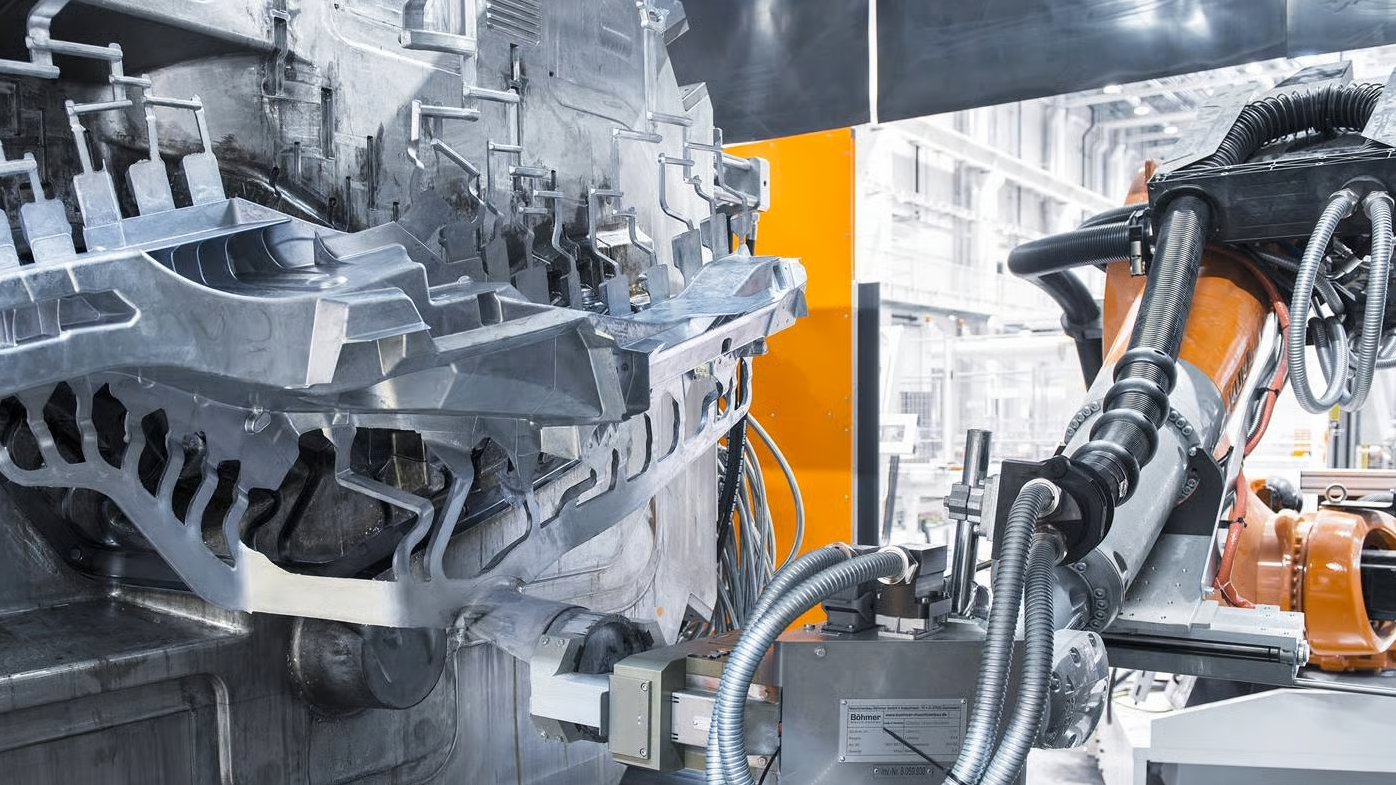

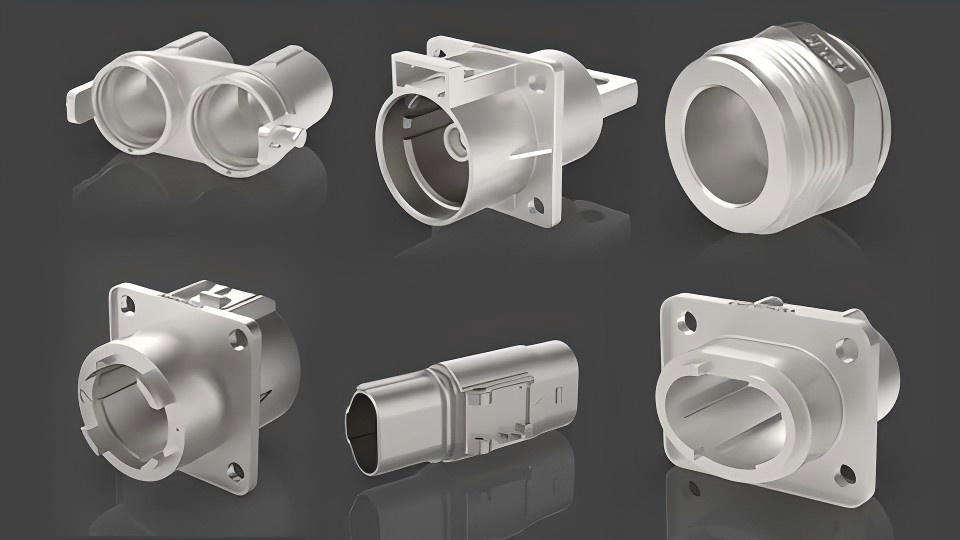

Sino Die Casting, founded in 2008 in Shenzhen, China, is a high - tech enterprise dedicated to providing high - quality components with precise surface roughness. Surface roughness is a critical factor that affects the performance, durability, and appearance of metal parts in various industries, including automotive, new energy, robotics, and telecommunications. With ISO 9001 certification, we ensure that our surface roughness control meets the highest industry standards. Our manufacturing processes are carefully designed and executed to achieve the desired surface roughness. From mould design and manufacturing to die casting and CNC machining, every step is optimized to control the surface texture. We use advanced testing equipment, such as coordinate measuring instruments and roughness instruments, to measure and verify the surface roughness of each part. This allows us to provide our global clients, whose products are exported to more than 50 countries and regions, with components that have the exact surface roughness required for their applications. Whether it's for parts that need a smooth surface for low - friction operations or those that require a rough surface for better mechanical interlocking, we can deliver components with the optimal surface roughness, making us a flexible and reliable partner in the manufacturing industry.