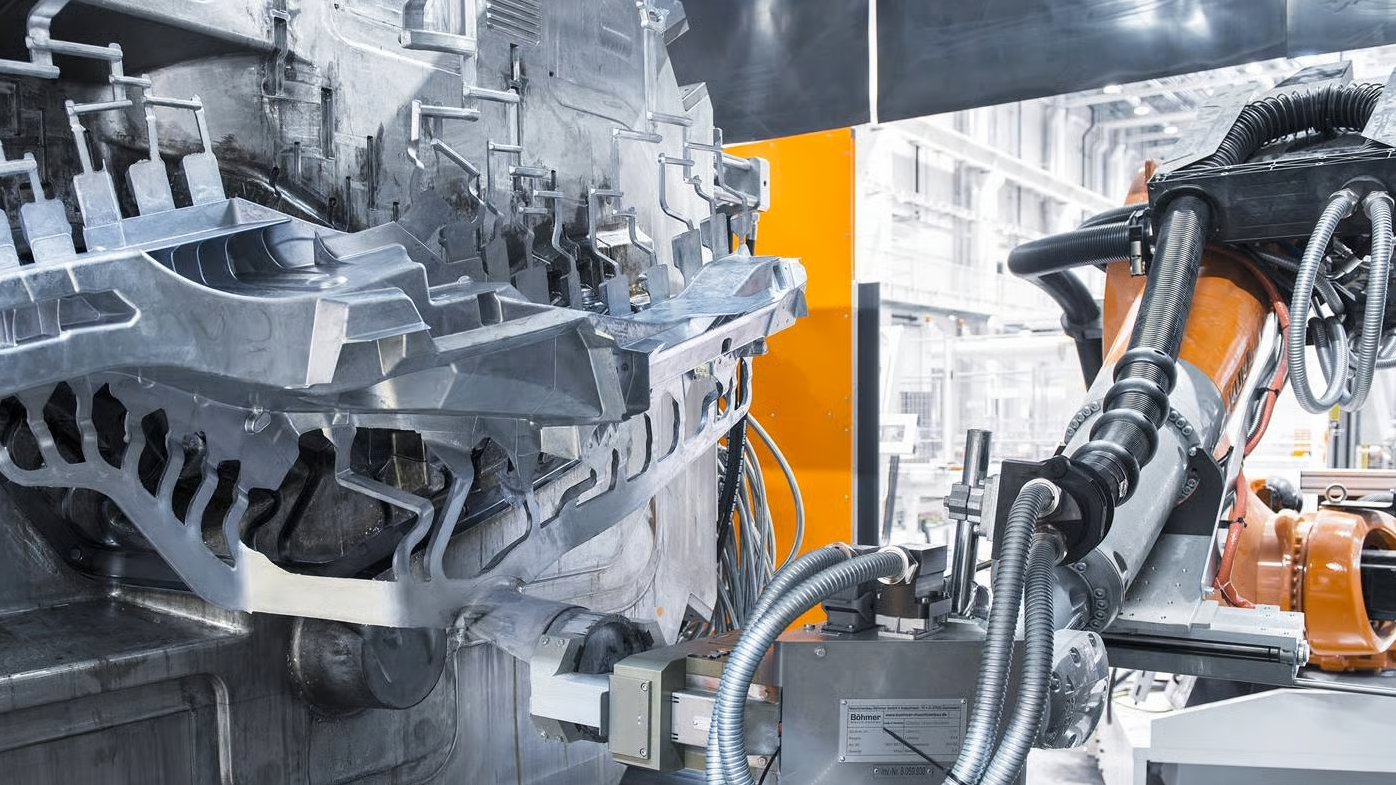

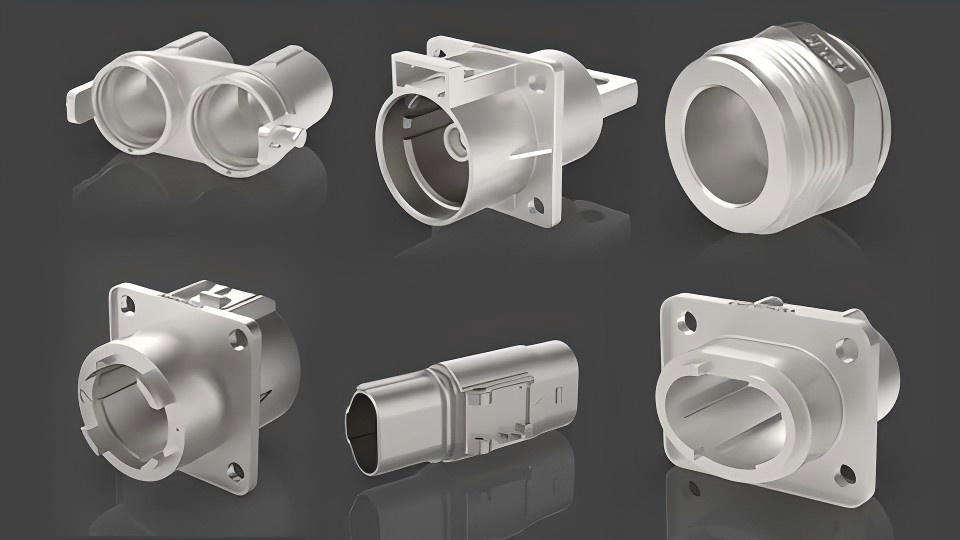

Sino Die Casting, a high - tech enterprise founded in 2008 in Shenzhen, China, places great emphasis on the quality of the casting surface. The casting surface is a critical aspect that determines the overall performance and appearance of the final product. Our expertise in high - precision mould manufacturing, die casting, and CNC machining allows us to have full control over the casting surface. In the die casting process, we use advanced equipment and optimized parameters to ensure a smooth and defect - free casting surface. A high - quality casting surface is essential in industries such as automotive, where components need to fit precisely and have a good aesthetic appearance. For example, engine blocks and transmission cases with a smooth casting surface can reduce friction and improve the overall efficiency of the vehicle. In the new energy sector, components like battery housings with a well - finished casting surface can enhance heat dissipation and prevent corrosion. In robotics, parts with a good casting surface can ensure smooth movement and reduce wear and tear. We employ various post - casting surface treatment methods to further improve the quality. These include grinding, polishing, and shot blasting, depending on the specific requirements of the part. Our team of experienced engineers carefully inspects each casting surface to ensure it meets the strict ISO 9001 quality standards. With our ability to provide solutions from rapid prototyping to mass production, we can cater to the needs of clients worldwide, whose products are exported to more than 50 countries and regions, making us a reliable partner for achieving high - quality casting surfaces.